Liquid cargo tank arrangement form capable of effectively reducing 20000-30000 m<3> liquefied gas carrier cost

A technology for liquefied gas carriers and cargo tanks, which is applied in the field of ships, can solve the problems of increasing the number of tank materials, insulating materials, cargo pumps, and the cost of cargo maintenance systems, and increasing the complexity of crew operations for liquid cargo loss of liquefied gas carriers. Investment costs, improved operational safety, reduced evaporation rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

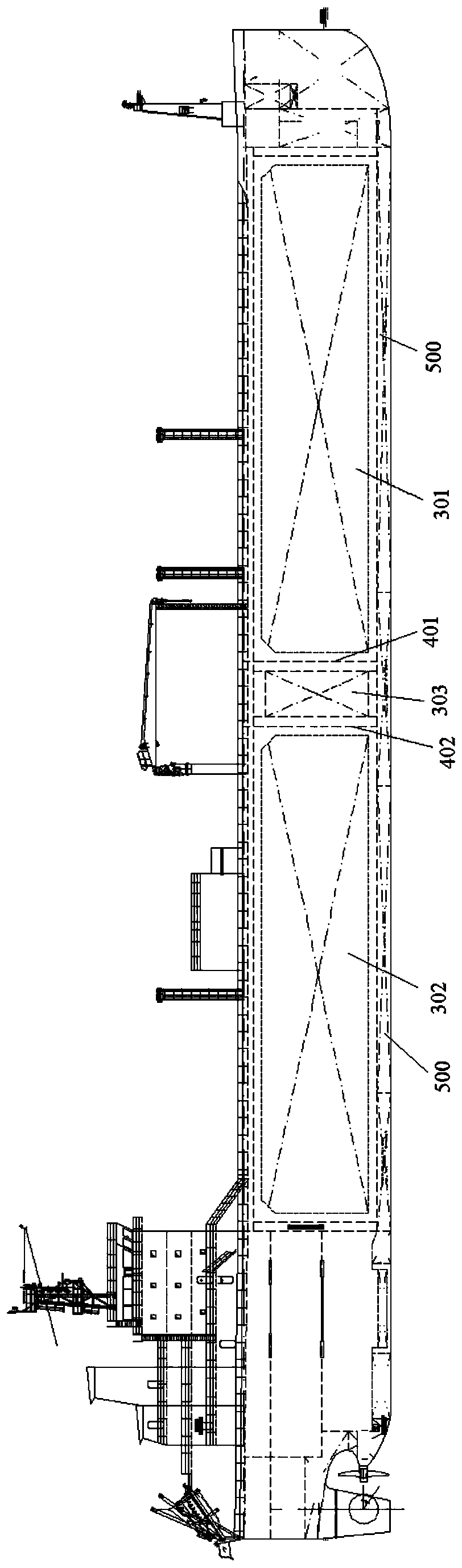

[0026] Such as image 3 and Figure 4 As shown, a liquid cargo tank arrangement form that can effectively reduce the cost of 20,000 to 30,000 cubic meters of liquefied gas ships, the number of liquid cargo tanks is only two, namely the first liquid cargo tank 301 near the bow and the second liquid cargo tank near the stern 302, a first transverse bulkhead 401 and a second transverse bulkhead 402 are provided between the first cargo tank 301 and the second cargo tank 302, the first transverse bulkhead 401 is close to the first cargo tank 301, and the second transverse bulkhead 402 Close to the second cargo tank 302; a non-cargo tank 303 is formed between the first transverse bulkhead 401 and the second transverse bulkhead 402, and the distance between the first transverse bulkhead 401 and the second transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com