Novel circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, which is applied in the directions of fluidized bed combustion equipment, combustion type, and fuel burned in a molten state, can solve the problems of high ash content, low utilization rate of coal gangue, low calorific value, etc. Conducive to burnout and good heat and mass exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

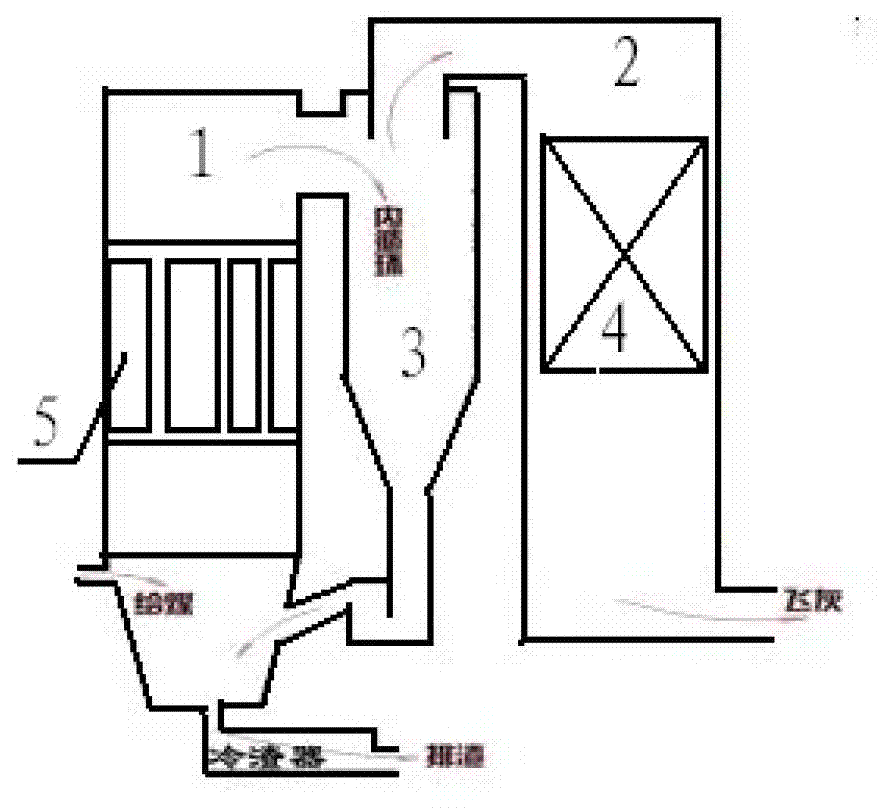

[0014] Example 1: A circulating fluidized bed boiler for the transformation of a XF-SI type circulating fluidized bed boiler purely burning coal gangue such as figure 2 As shown, it includes a furnace 1, a tail shaft 2, a circulation channel 3, a steaming heating surface 4, a water wall 5 and an air distribution plate.

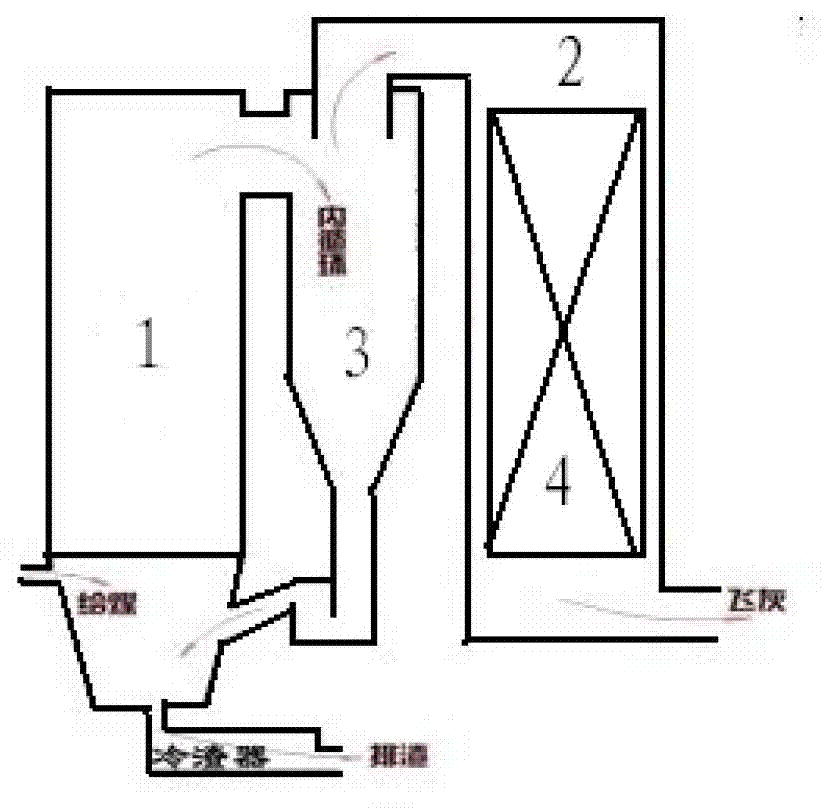

[0015] Remove the water wall in furnace 1, such as figure 1 As shown, other structures remain unchanged.

[0016] The furnace does not arrange a water-cooled wall 5 heating surface in the furnace 1 . After the coal gangue is sent into the furnace 1, charcoal is used to ignite. Since there is no water-cooled wall 5 to absorb heat, the heat released by the coal gangue combustion is used to raise the temperature of the furnace body, flue gas and ash, and continuously heats the coal gangue that is subsequently put into the furnace. The temperature of the furnace 1 can be raised to 950-1000°C, so that the coal gangue with high ash content, high moisture content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com