Plastic formwork used for paving floor heating thermostat

A technology of plastic formwork and floor heating, which can be used in applications, household heating, household appliances, etc., and can solve problems such as unreasonable layout, long construction period, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

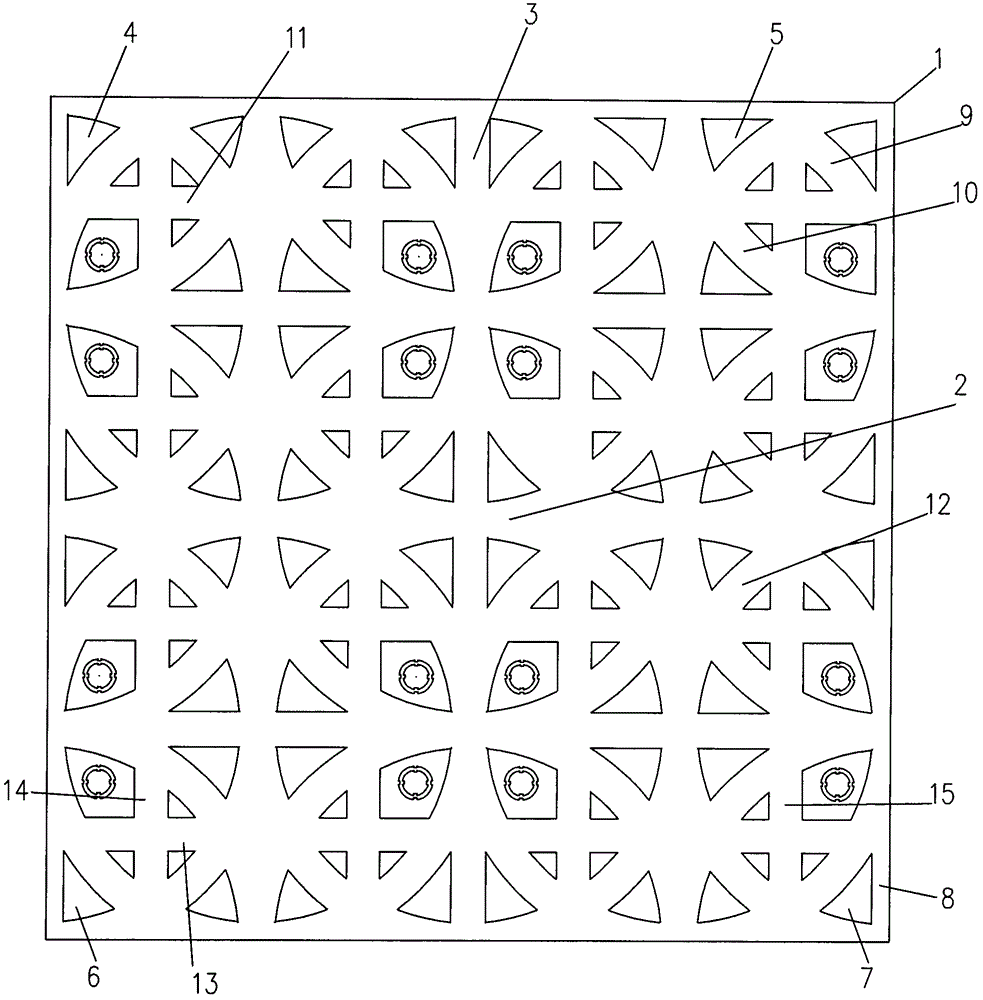

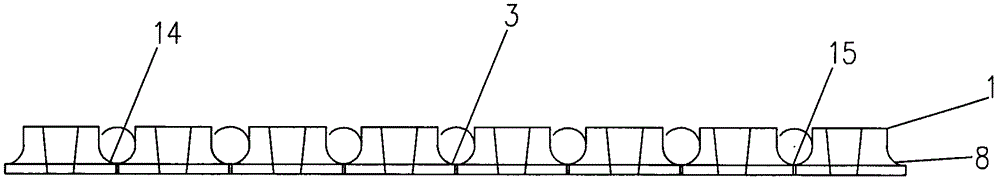

[0012] Such as figure 1 and figure 2 As shown, the plastic formwork for floor heating laying of the present invention includes a square plate body 1 made of plastic, the length of each side of the plate body 1 is 4R, and the upper surface of the plate body 1 is along the left and right sides of the plate body 1. The center line of the right side is provided with a pipe-laying groove 2, and the upper surface of the plate body 1 is provided with a B pipe-laying groove 3, A pipe-laying groove 2 and a B pipe-laying groove along the centerline of the front and rear sides of the plate body 1 3. Divide the upper surface of the plate body 1 into four equal-area square left front plates 4, right front plates 5, left rear plates 6 and right rear plates 7. The center of the plate 5, the left rear plate 6 and the right rear plate 7 is the center of the circle, and a circular C pipe-laying groove 9 with a central axis radius of R is provided. The central axis of each C pipe-laying groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com