Aqueous binder for positive electrode of lithium ion battery and preparation method of aqueous binder

A water-based binder, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electronic conductivity and ionic conductivity, low compaction density of pole pieces, and easy cracking of pole pieces. To achieve the effect of good dispersion characteristics, good suspension stability and excellent adhesion

Active Publication Date: 2022-05-31

SHENZHEN YANYI NEW MATERIALS CO LTD

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, PVDF itself has some disadvantages, such as poor electronic and ionic conductivity, poor cohesion, high swelling degree in electrolyte, and poor compatibility with metal lithium, LixC

6

An exothermic reaction occurs at a higher temperature, and there is a greater safety hazard

In addition, the positive electrode slurry prepared by PVDF is sensitive to environmental humidity, and it is easy to cause poor fluidity due to water absorption, difficulty in sieving, and abnormal conditions such as sedimentation

At the same time, the organic solvent N-methylpyrrolidone (NMP) used in conjunction with PVDF is volatile, flammable, and explosive, with high toxicity and high recycling costs

[0003]

From the viewpoint of environmental protection and performance, it is an inevitable trend to replace oily binders with water-based binders. Currently, various types of binders such as carboxymethyl cellulose salt, alginate, polyacrylate, and acrylonitrile multi-polymer are being studied. However, there are still some problems in the actual application of water-based positive electrode binders, such as difficult slurry adjustment, low compaction of pole pieces, easy cracking of pole pieces, poor cycle performance, etc., resulting in the failure of water-based positive electrode binders. application becomes difficult

[0004]

Therefore, there is an urgent need to develop a water-based binder for the positive electrode of lithium-ion batteries, which can solve the problem of easy gelation of the positive electrode slurry, low compaction density of the pole piece, and easy cracking of the pole piece when the water-based binder is applied. , poor cycle performance and other technical problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0062] The initiator can generate free radicals with initiating activity to initiate polymerization in the emulsion to achieve chain growth.

[0067] The present invention also provides the lithium ion battery anode aqueous binder obtained by the above preparation method.

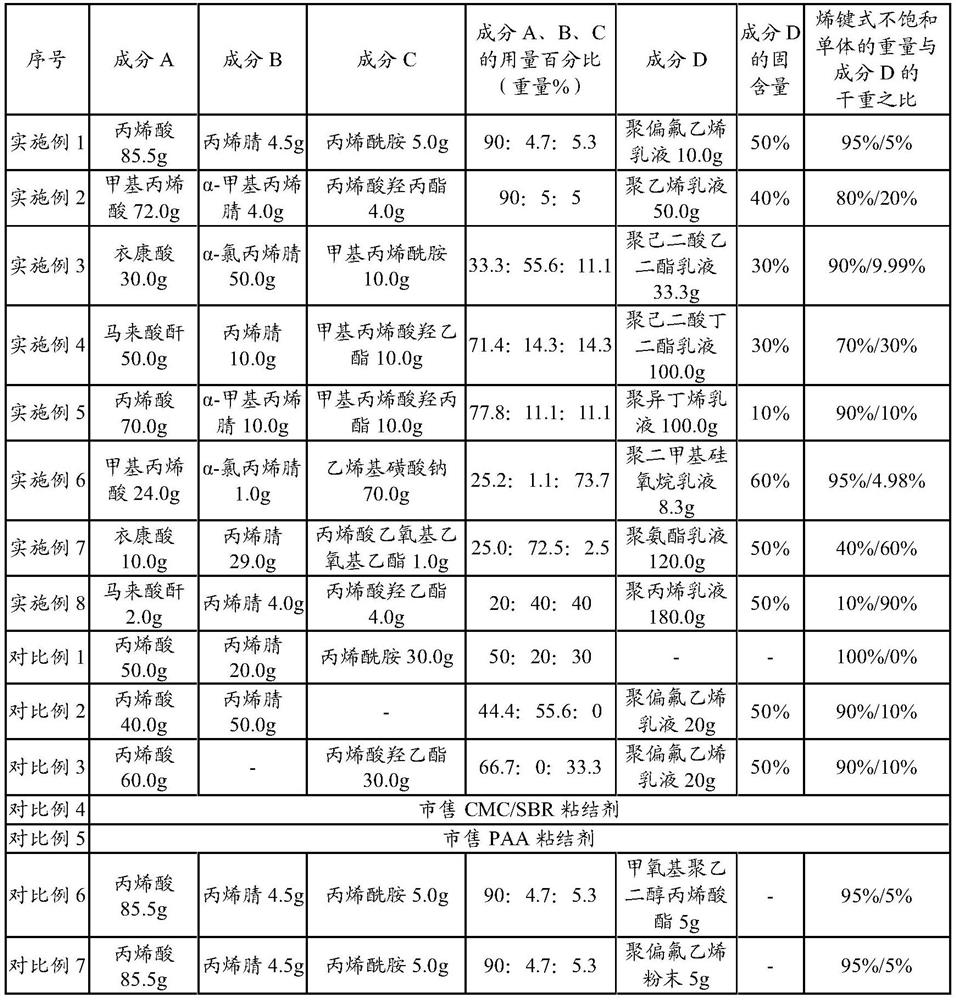

Embodiment 1

Embodiment 2~8

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

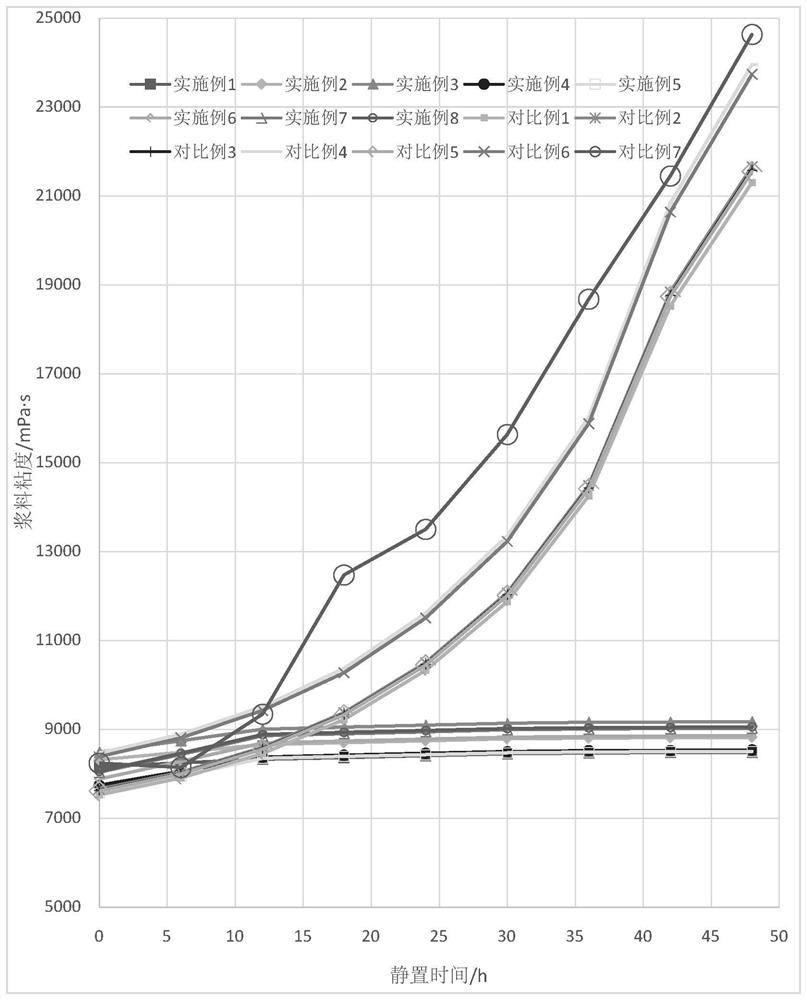

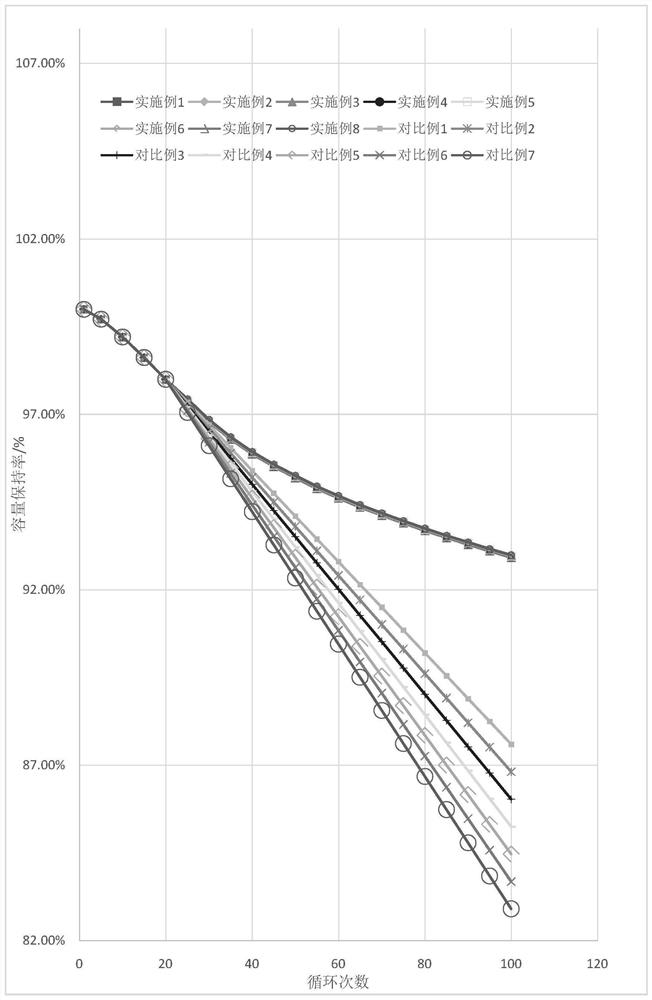

The invention relates to a lithium ion battery positive electrode aqueous binder, which is characterized by being formed by copolymerizing an ethylenic bond type unsaturated monomer and a flexible aqueous emulsion, wherein the ethylenically unsaturated monomer comprises an ethylenically unsaturated carboxylic acid or an ethylenically unsaturated carboxylic acid anhydride, an ethylenically unsaturated nitrile monomer and an ethylenically unsaturated hydrophilic monomer which does not contain a nitrile group and a carboxyl group; and wherein the flexible aqueous emulsion comprises water and flexible polymer latex particles. The invention also relates to a preparation method of the aqueous binder for the positive electrode of the lithium ion battery. The positive electrode slurry prepared from the binder is good in viscosity stability, and the positive electrode plate prepared from the positive electrode slurry is high in peel strength and good in flexibility under high compaction density. In addition, the lithium ion battery prepared from the binder provided by the invention has high cycle capacity retention rate, namely high cycle performance.

Description

Aqueous binder for lithium ion battery positive electrode and preparation method thereof technical field The invention belongs to lithium ion battery field, be specifically related to a kind of lithium ion battery positive electrode aqueous binder and preparation thereof method. Background technique In mobile electronics, electric vehicles and other cycle energy systems, lithium-ion batteries are the most promising mobile Dynamic energy storage products. Currently, the commonly used cathode binder in lithium-ion batteries is polyvinylidene fluoride (PVDF). However, PVDF itself has some disadvantages, for example, poor electronic and ionic conductivity, poor adhesion, degree of swelling in electrolyte higher, and with lithium metal, LixC 6 Exothermic reactions occur at higher temperatures, and there is a greater safety hazard. Furthermore, using The positive electrode slurry prepared by PVDF is sensitive to environmental humidity, and it is easy to cause poor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F259/08C08F220/06C08F220/44C08F220/56C08F255/02C08F220/42C08F220/20C08F283/02C08F222/02C08F222/06C08F255/10C08F283/12C08F228/02C08F283/00C08F220/28H01M4/62H01M10/0525

CPCC08F259/08C08F255/02C08F283/02C08F255/10C08F283/12C08F283/006H01M4/622H01M4/623H01M10/0525C08F220/06C08F220/44C08F220/56C08F220/42C08F220/20C08F222/02C08F222/06C08F228/02C08F220/282C08F220/28C08F283/00H01M4/62C08F261/00C08F255/00C08F289/00C08F271/00Y02E60/10

Inventor 王伟华刘俊岳敏

Owner SHENZHEN YANYI NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com