Sludge drying system of combined solar energy and multi-coupled heat pump

A sludge drying and solar energy technology, which is applied in dehydration/drying/concentrated sludge treatment, energy wastewater treatment, etc., can solve the problems of not giving full play to the advantages of heat pump technology, increasing the difficulty of large-scale application of solar energy, and large energy loss of the system. , to achieve the effect of improving energy utilization, shortening heating time, and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

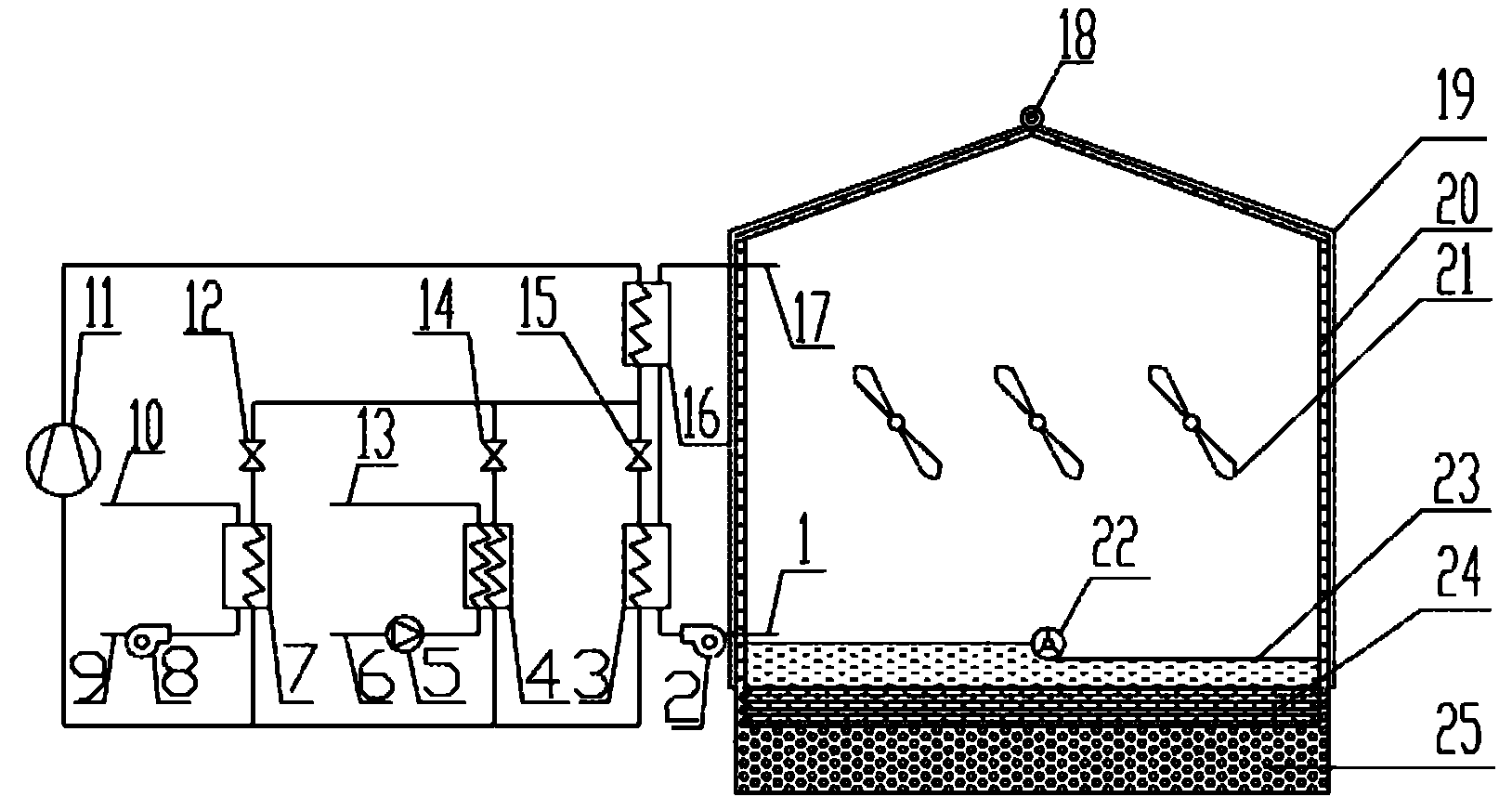

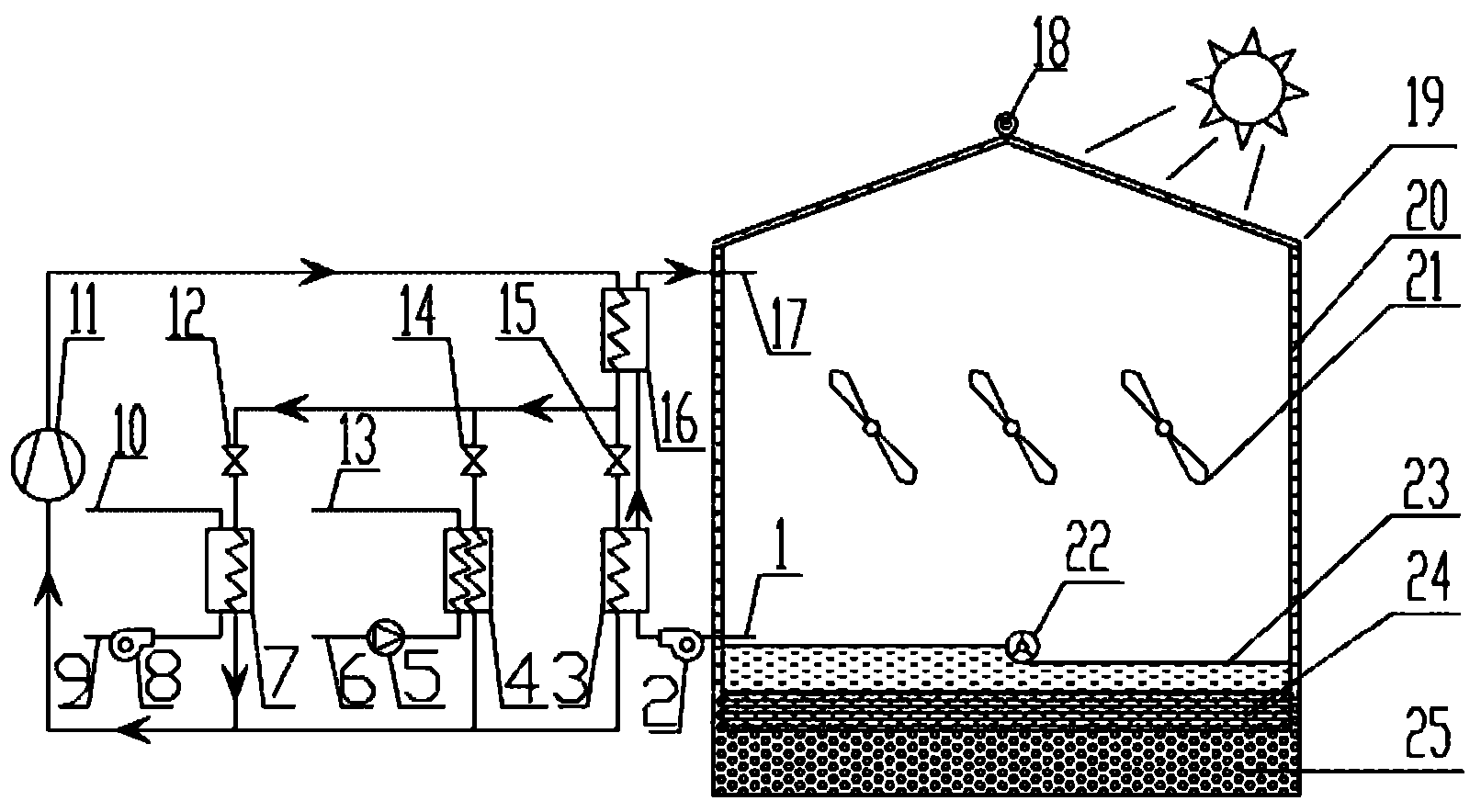

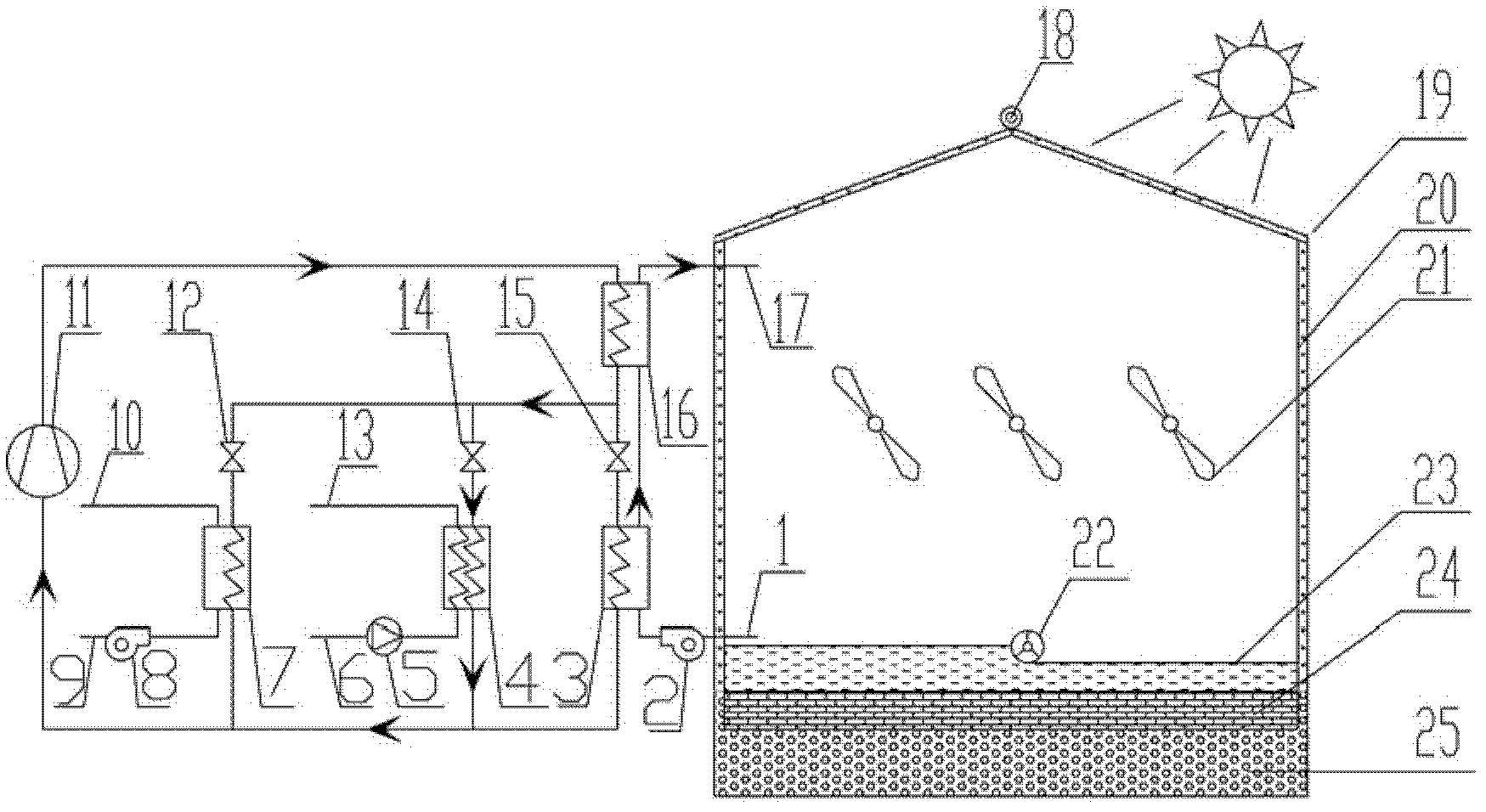

[0041] In order to improve the energy utilization rate of solar sludge drying technology, the present invention provides a sludge drying system combined with solar energy and multi-connected heat pumps, such as figure 1 As shown, the system includes: a solar house warming system and a heat pump subsystem; wherein,

[0042] The solar house warming system includes a house warming enclosure module, a bottom plate module, a gas diversion module, a thermal insulation film layer 19 and a mud turning module 22 .

[0043] The house-warming enclosure module constitutes the outer frame of the solar house-warming system, which includes an enclosure structure 20 composed of a thermal insulation material that is selectively transpar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com