Universal template for floor heat guiding flexible pipe

A hose and floor heating technology, which is applied in the field of universal formwork for floor heating guiding hoses, can solve the problems of inability to freely adjust the distance between hoses for hot water supply, increased construction costs, and long construction periods, achieving unique flexibility and The effect of adaptability, construction cost reduction, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

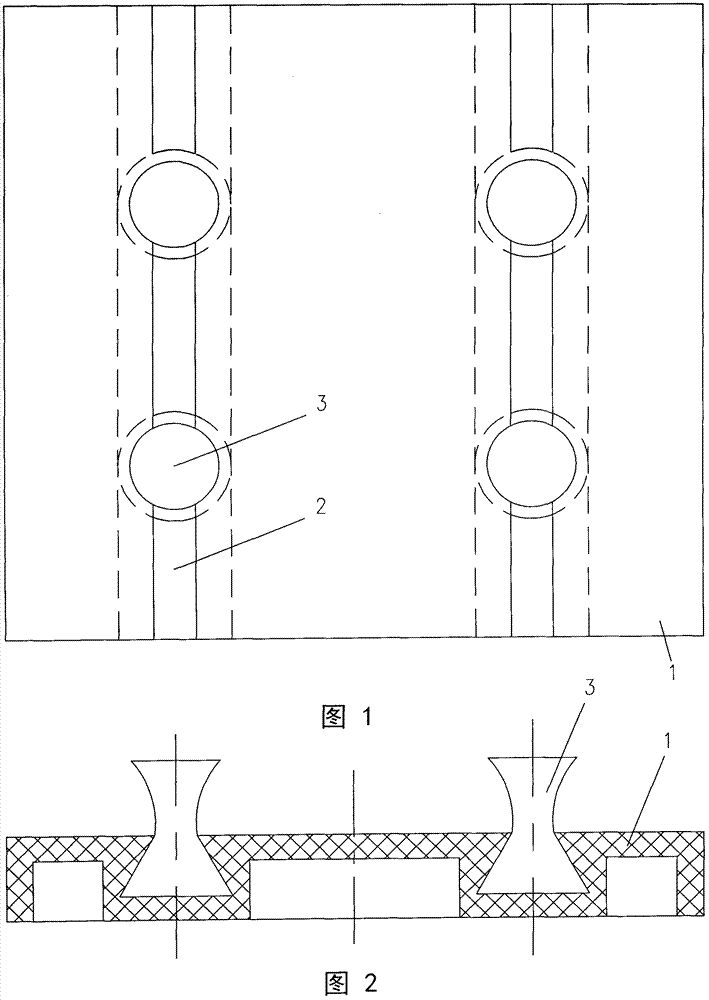

[0014] Such as figure 1 with figure 2 As shown, the universal template for floor heating guiding hose of the present invention includes a rectangular plate body 1 and a plurality of pipe-around pillars 3 (only four are shown schematically in the figure). The upper surface of the plate body 1 is provided with two There are two card column slots 2, the number of card column slots 2 can also be 3 or 4 or 5 or 6 or 7 or 8 or 9 or 10, and the lower part of each pipe winding column 3 adopts clearance fit insertion Installed in the card column slot 2, the bottom end of each pipe-around column 3 is attached to the bottom of the card column slot 2, and the column part of each pipe-around column 3 above the upper surface of the plate 1 is thick at the top and thin at the bottom The cylindrical part of each winding pillar 3 inserted in the clamping column slot 2 is a round table with a large bottom diameter. The cross section of each clamping column slot 2 is compatible with the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com