Intermittent vacuum pyrolysis reactor with built-in heat conducting pipe

A pyrolysis reactor and heat pipe technology, applied in the chemical industry, can solve problems such as the sealing effect of the connection sealing surface of easily polluted equipment, the difficulty in controlling the pyrolysis process, and the difficulty in opening the equipment, so as to solve the problem of incomplete pyrolysis reaction and easy disassembly Cleaning and solving the effect of many by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

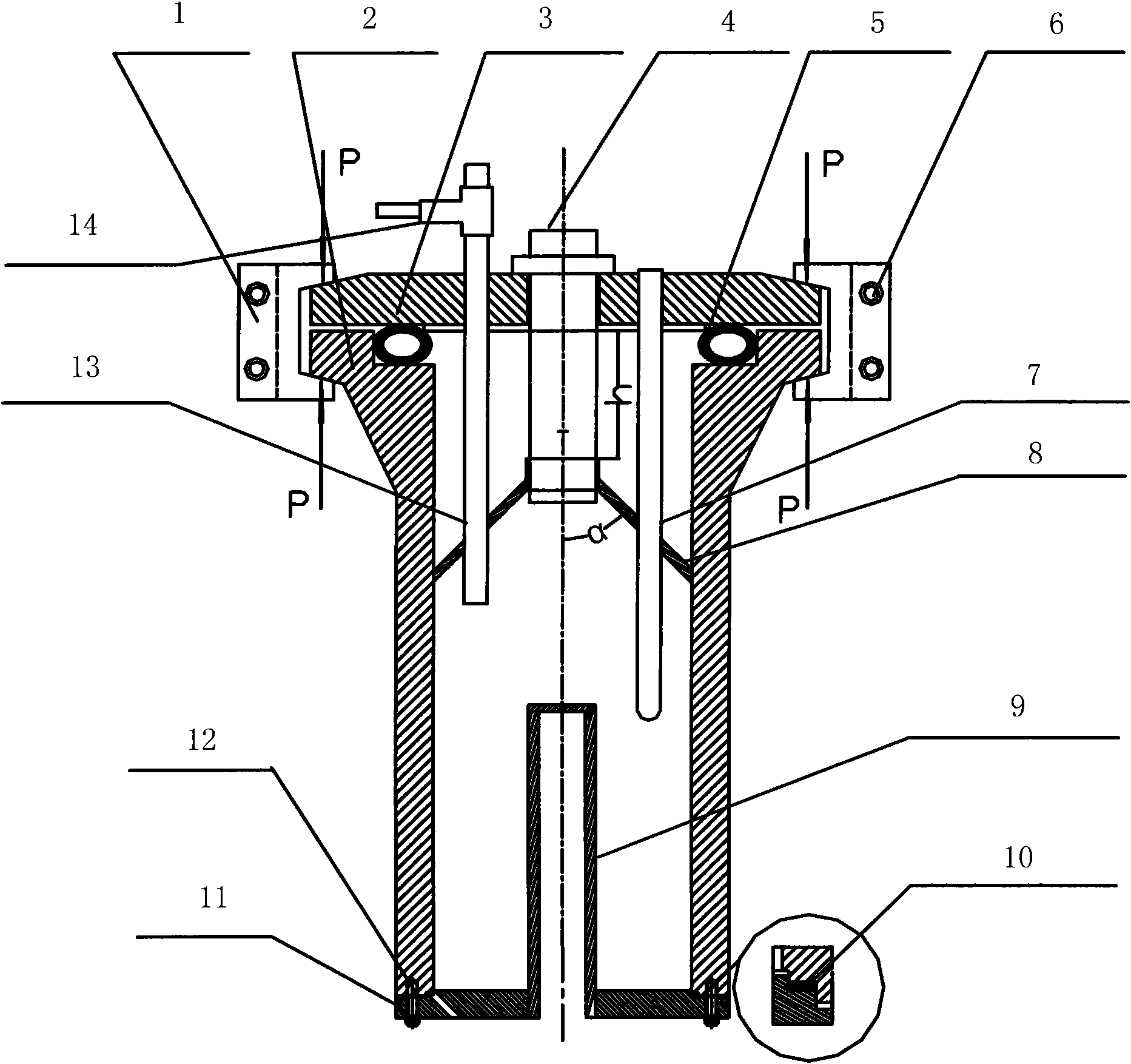

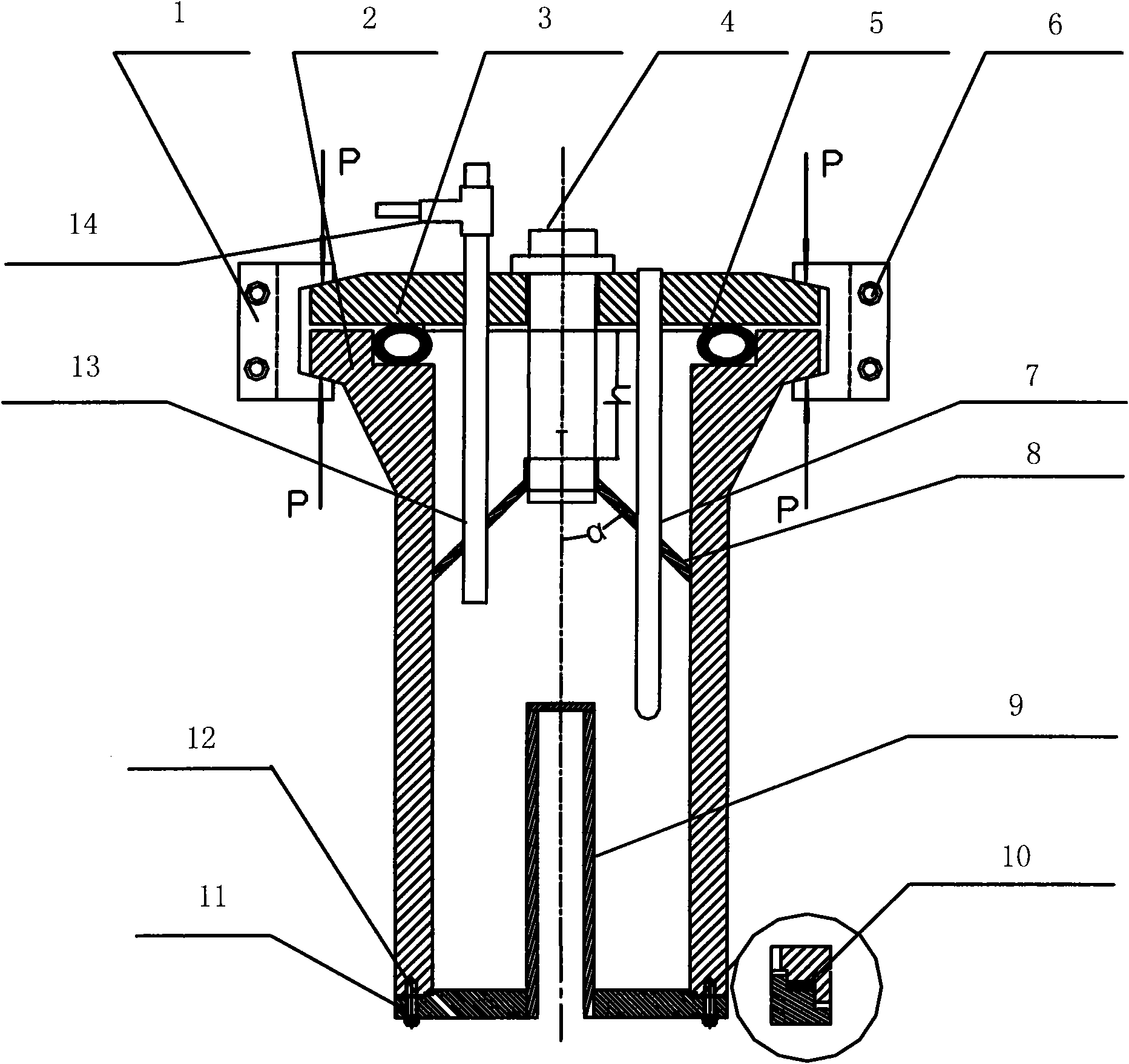

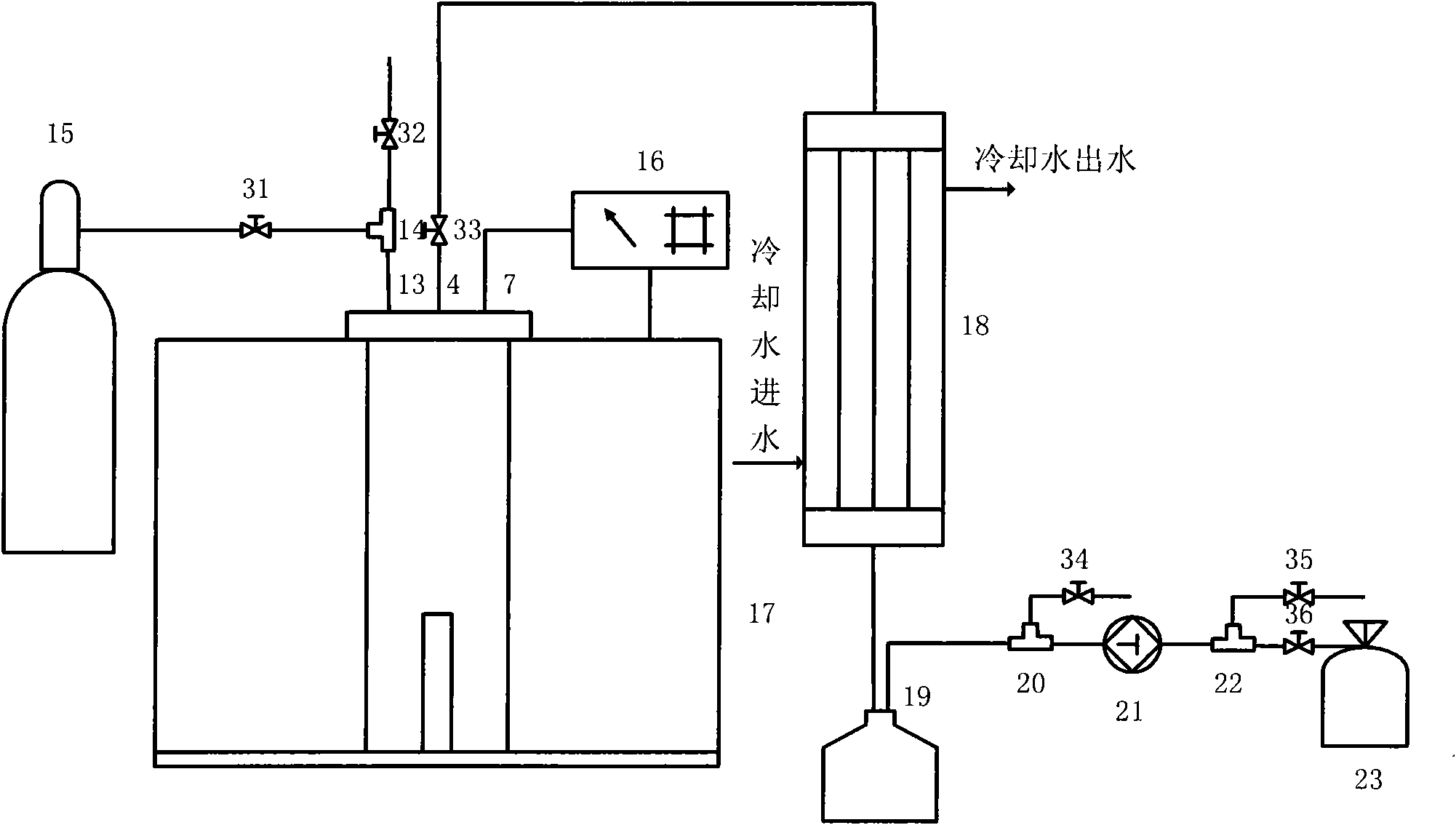

[0033] Example 1: It is used in the pyrolysis resource recovery reaction of waste tires. The reaction device and the pyrolysis process flow shown in Fig. 2 are adopted. Taking into account the heat transfer effect of the built-in heat pipe and the filling capacity of the material in the cylinder, the ratio of the outer diameter of the built-in heat pipe 9 to the inner diameter of the cylinder is between 0.3-0.7, and the height should be greater than 1 / 3 of the height of the cylinder. The pipe material should be selected High-temperature-resistant low-alloy steel material; the angle α between the horn-shaped baffle 8 and the pyrolysis product discharge pipe 4 (as shown in Figure 1) should be controlled between 30° and 60°, and the angle α between the horn-shaped baffle 8 and the cylinder body 2 The inner wall gap should be less than 0.5mm. Cut waste tires into 8cm 3 For particles of about size, weigh 50g, 70g, and 100g of sample material respectively, place them in the reacto...

Embodiment 2

[0034]Example 2: It is used for the pyrolysis and recycling reaction of waste printed circuit boards. Use crushing equipment to crush the dismantled waste printed circuit boards into granular materials with a particle size of 0.4-0.6mm, and inject samples with 50g, 70g, and 100g materials respectively, using the equipment of the present invention and the process flow shown in Figure 2 and Example 1 The setting of the built-in heat pipe 9 and the trumpet-shaped baffle 8 described in , can convert the organic polymer substances such as epoxy resin in the non-metallic substances in the pulverized particles into pyrolysis oil, and the temperature is programmed to rise 10°C / min. Controlled at 450-600°C, the oil yield is about 7.4%, achieving high value; and the metal and non-metallic inorganic substances in the pyrolysis solid slag can be completely separated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com