Water-fire tube gas-steam boiler with built-in condenser

A technology of gas steam and condenser, which is applied in the direction of air heater, fluid heater, lighting and heating equipment, etc., which can solve the problems of large structure area, safety hazard and high steel consumption, and achieve small space occupation and area, safety Guaranteed performance and large heating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

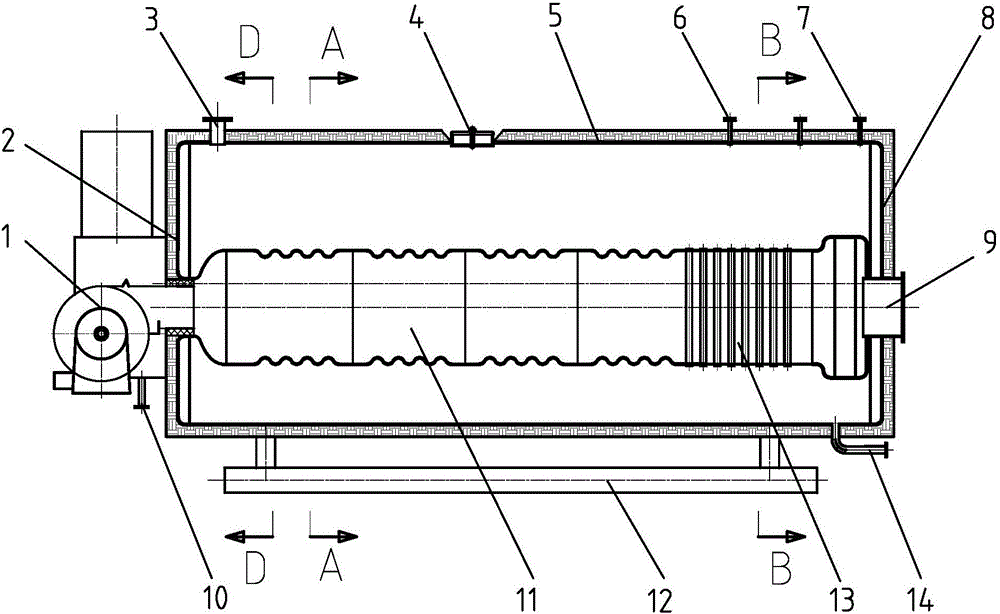

[0026] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Describe this embodiment, this embodiment includes burner 1, steam pipe seat 3, shell 5, furnace 11, smoke pipe assembly 20, backfire chamber 26, condensing chamber 18 and smoke box 15, described furnace 11, smoke The pipe assembly 20, the backfire chamber 26 and the condensation chamber 18 are all arranged in the casing 5, the burner 1 is arranged outside the casing 5 and communicates with the inlet of the furnace 11, and the outlet of the furnace 11 is connected to the backfire The inlet of the chamber 26 is connected, the outlet of the reburning chamber 26 is connected with the inlet of the smoke pipe assembly 20, the outlet of the smoke pipe assembly 20 is connected with the inlet of the condensation chamber 18, and the smoke box 15 is arranged on the casing 5 and it communicates with the outlet of the condensation chamber 18, the smoke box 15 is processed with a ...

specific Embodiment approach 2

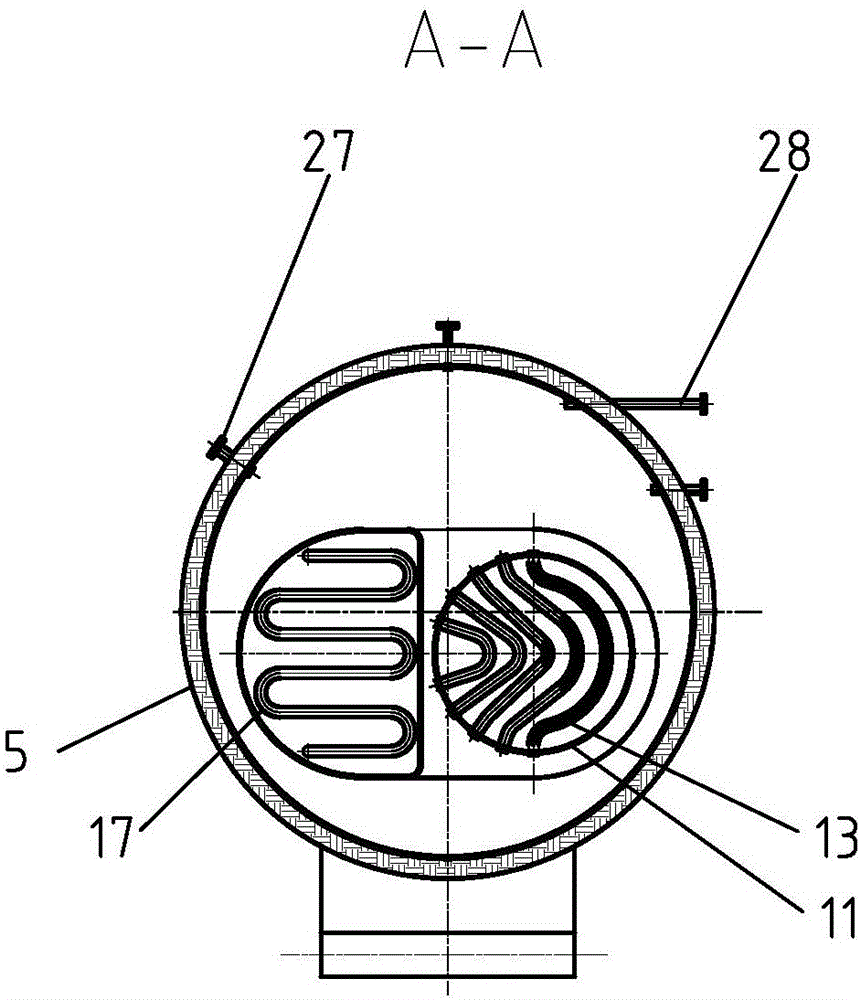

[0030] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment, the shape of the furnace 11 in the present embodiment is cylindrical and its outer wall is corrugated, multiple groups of convection tube bundles 13 are arranged near the outlet end of the furnace 11, and each group of convection tube bundles 13 includes a plurality of arc-shaped tube bundles, Both ends of each arc-shaped tube bundle are fixedly connected to the inner wall of the furnace 11, and two adjacent groups of convective tube bundles 13 are arranged in opposite directions.

[0031] In this embodiment, the shape of the furnace 11 is cylindrical and its outer wall is corrugated, that is, the furnace 11 has a corrugated cylindrical structure. Each group of convection tube bundles 13 is a plurality of arc-shaped tube bundles with different lengths. The multiple arc-shaped tube bundles are arranged in ascending order of length, and each arc-shaped tube bundle is bent. The ...

specific Embodiment approach 3

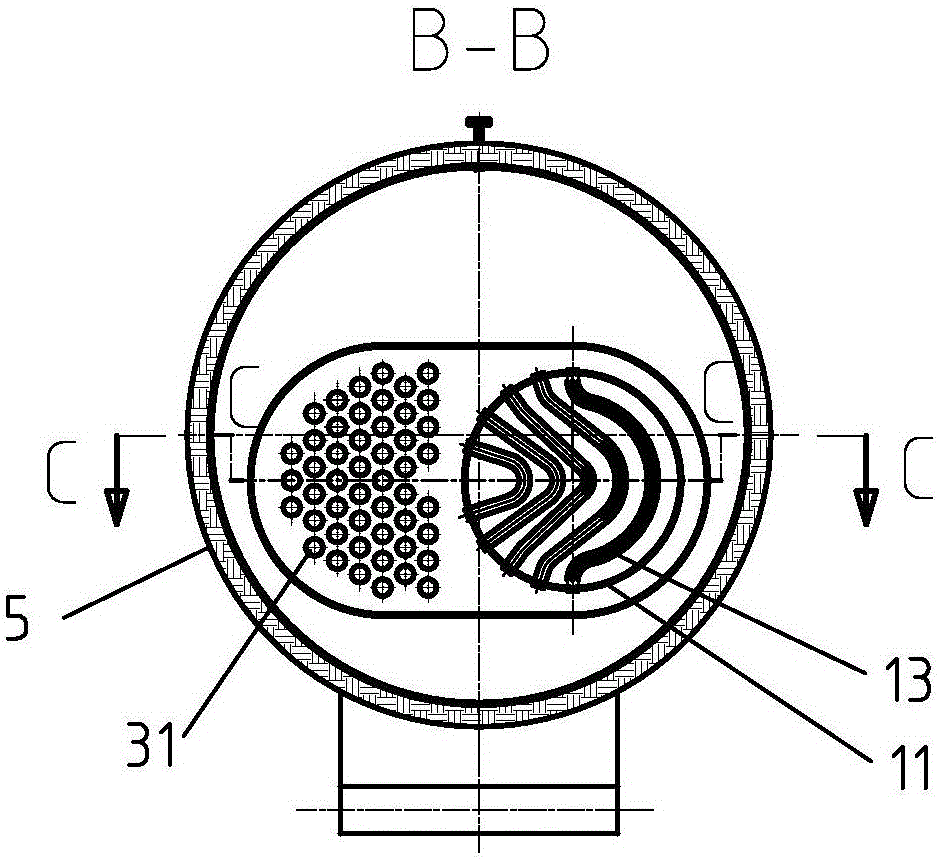

[0033] Specific implementation mode three: combination image 3 and Figure 4 Describe this embodiment, in this embodiment, the smoke pipe assembly 20 includes a plurality of single pipes 31, which are arranged side by side between the multiple single pipes 31, and one end of each single pipe 31 communicates with the front tube plate 22 for the combustion chamber. The other end of the single pipe 31 communicates with the condensation chamber 18 .

[0034] The arrangement of the smoke pipe assembly 20 in this embodiment is to provide a flow channel for the smoke. The single pipe 31 is a threaded pipe, a light pipe or a built-in spoiler. The single pipe 31 communicates with the condensation chamber 18 through the rear plate pipe 19 for the smoke pipe. Other unmentioned structures and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com