Heating kettle

A technology for heating pots and pots, which is applied to heating devices, cooking utensils, household utensils, etc. It can solve the problems of uneven heating of the pot body, sticky pot life, and difficult temperature control, so as to achieve easy control of the heating temperature and improve Service life and effect of heat loss prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

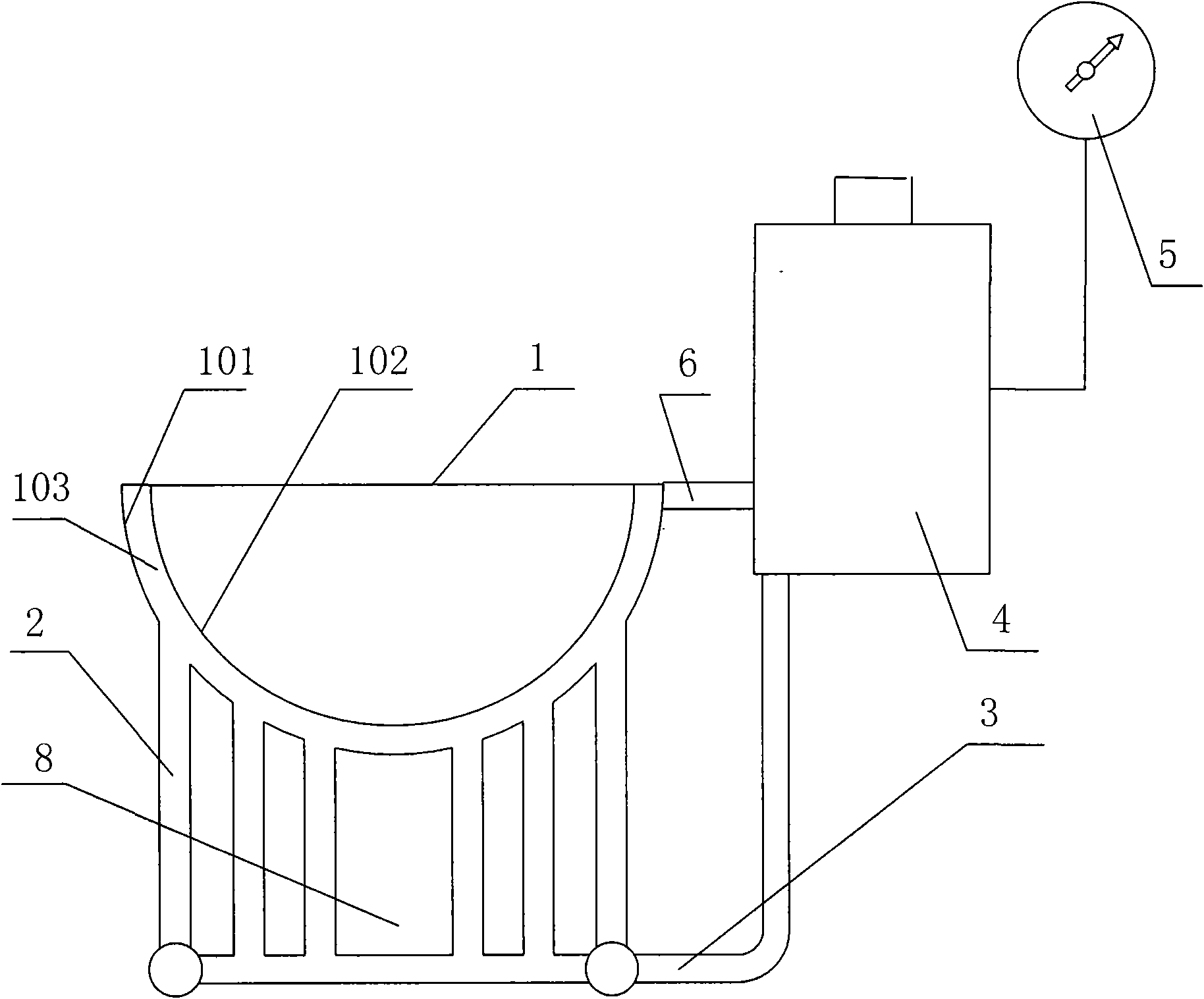

[0013] exist figure 1 Among them, a heating pot includes a pot body 1. The pot body 1 is composed of an inner pot body 101 and an outer pot body 102. The inner pot body 101 and the outer pot body 102 are made of high-quality stainless steel plates, which have good corrosion resistance and pressure resistance. . A closed interlayer cavity 103 is formed between the outer pot body 101 and the inner pot body 102 .

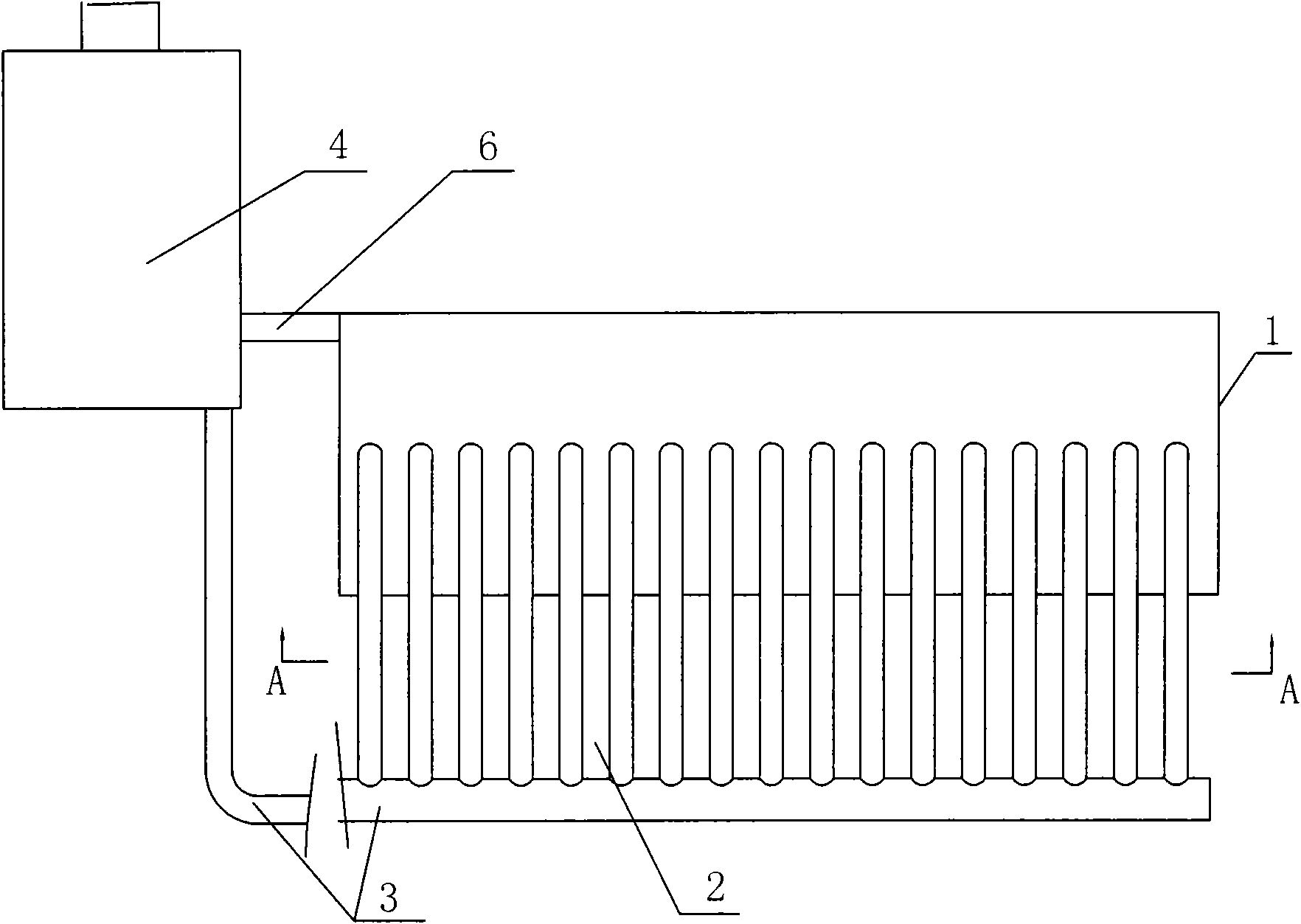

[0014] In order to increase the amount of once-cooked seafood materials and facilitate the cooking of materials, such as figure 1 , figure 2 , image 3 As shown, the pot body 1 adopts a long groove type pot body, and its cross section is semicircular.

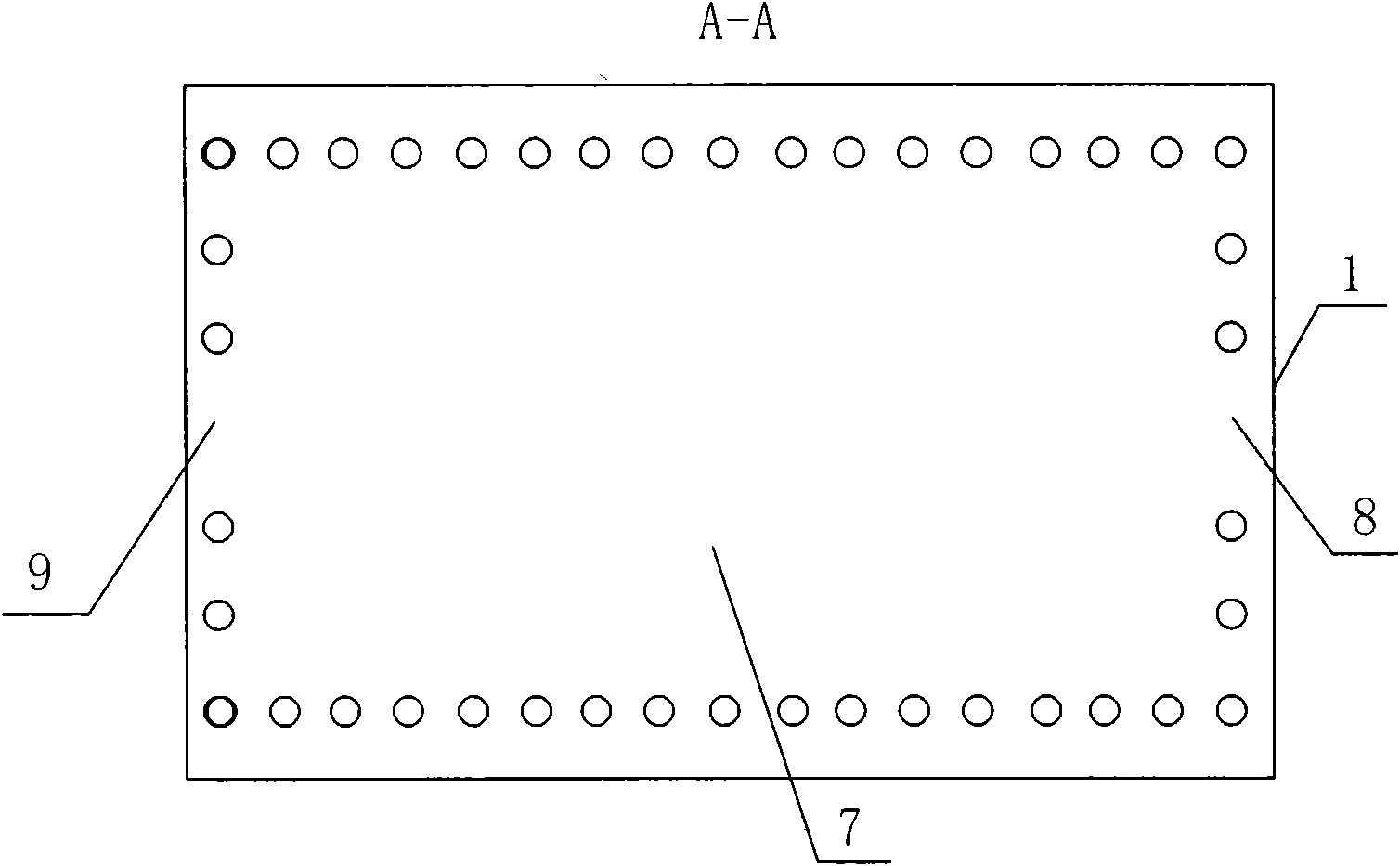

[0015] exist figure 1 , figure 2 , image 3 Among them, 42 heat pipes 2 connected to the interlayer cavity 103 are sealed and welded around the bottom of the outer pot body 102 . The heat pipe 2 adopts seamless stainless steel pipes, which are arranged in a frame and distributed around the bottom of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com