Spherical jacketed kettle for drying or mixing powdery materials

A technology of spherical jacketed pot and powdery materials, which is applied in the direction of making medicines into special physical or taking form devices, non-progressive dryers, drying, etc. problems such as low efficiency, to achieve the effect of improving heat transfer efficiency, shortening time and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

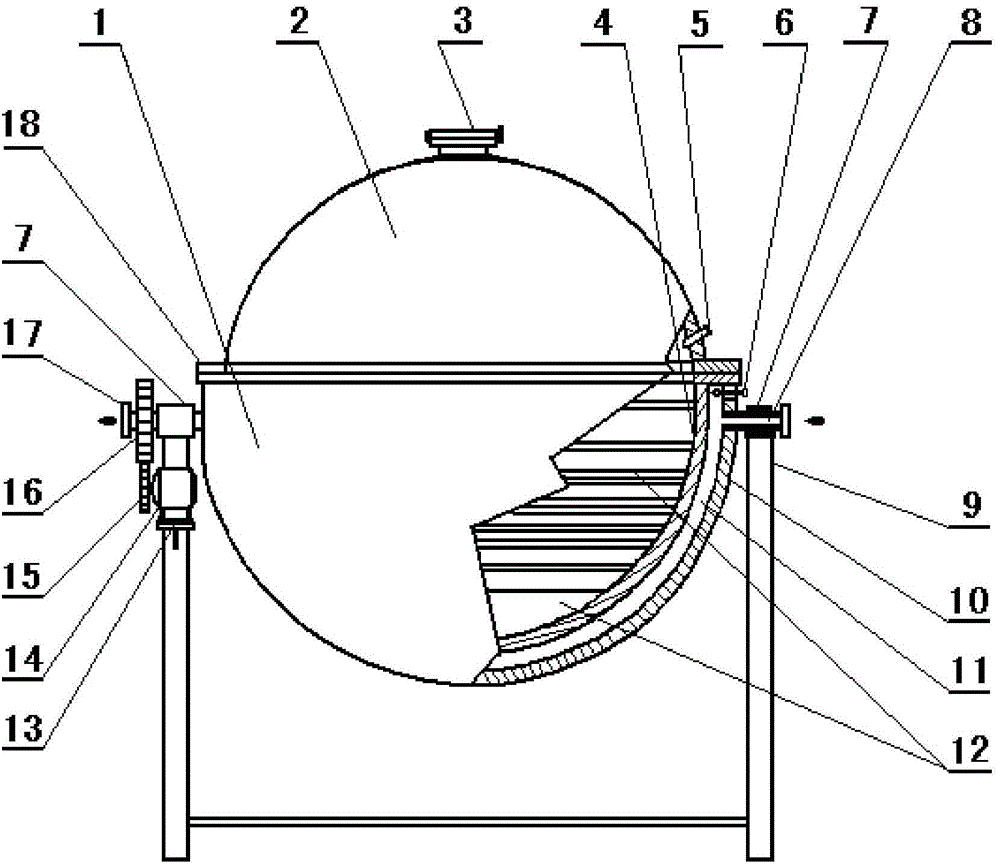

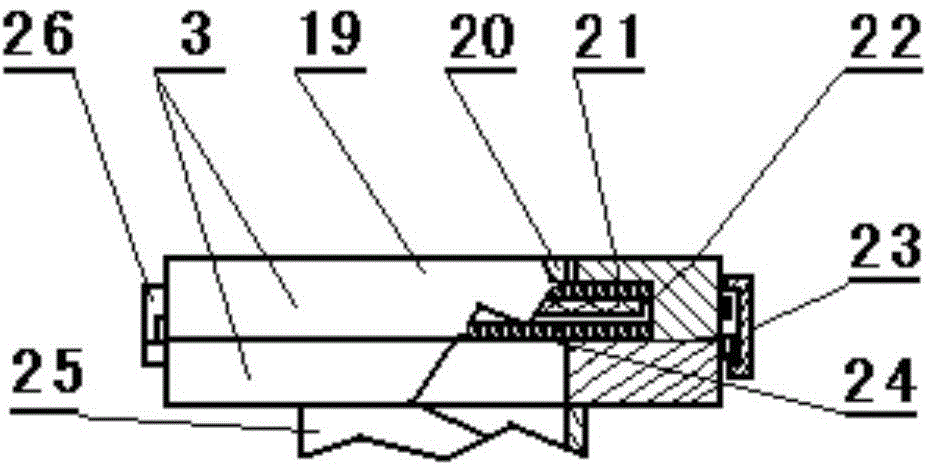

[0024] Such as figure 1 with figure 2 As shown, the spherical sandwich pot for drying or mixing powdery materials is provided with a lower pot body 1, an upper pot body 2, a support pipe 8, a support frame 9 and a motor 14, and the lower pot body 1 is provided with supports on the left and right sides of the upper section. Pipe 8, support pipe 8 is arranged on the bearing seat 7 on support frame 9, and the other end of support pipe 8 is provided with driven wheel 15, and driven wheel 15 is connected with the driving wheel 16 that is arranged on motor 14, and lower pot body 1 and lower pot body 1 and the upper pot body 2 are provided with a flange 18 to connect.

[0025] The top of the above-mentioned upper pot body 2 is provided with a material mouth cover 3 , the lower port of the upper pot body 2 is provided with a flange 18 , and the upper pot body 2 is provided with a material thermometer 5 .

[0026] The above-mentioned lower pot body 1 is provided with an outer lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com