Blade server oriented box-sleeving type heat preservation/heat dissipation device

A blade server and cooling device technology, used in cooling/ventilation/heating renovation, instruments, electrical digital data processing, etc. And the fastening is simple and reliable, the structure is simple and compact, and the effect of improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings:

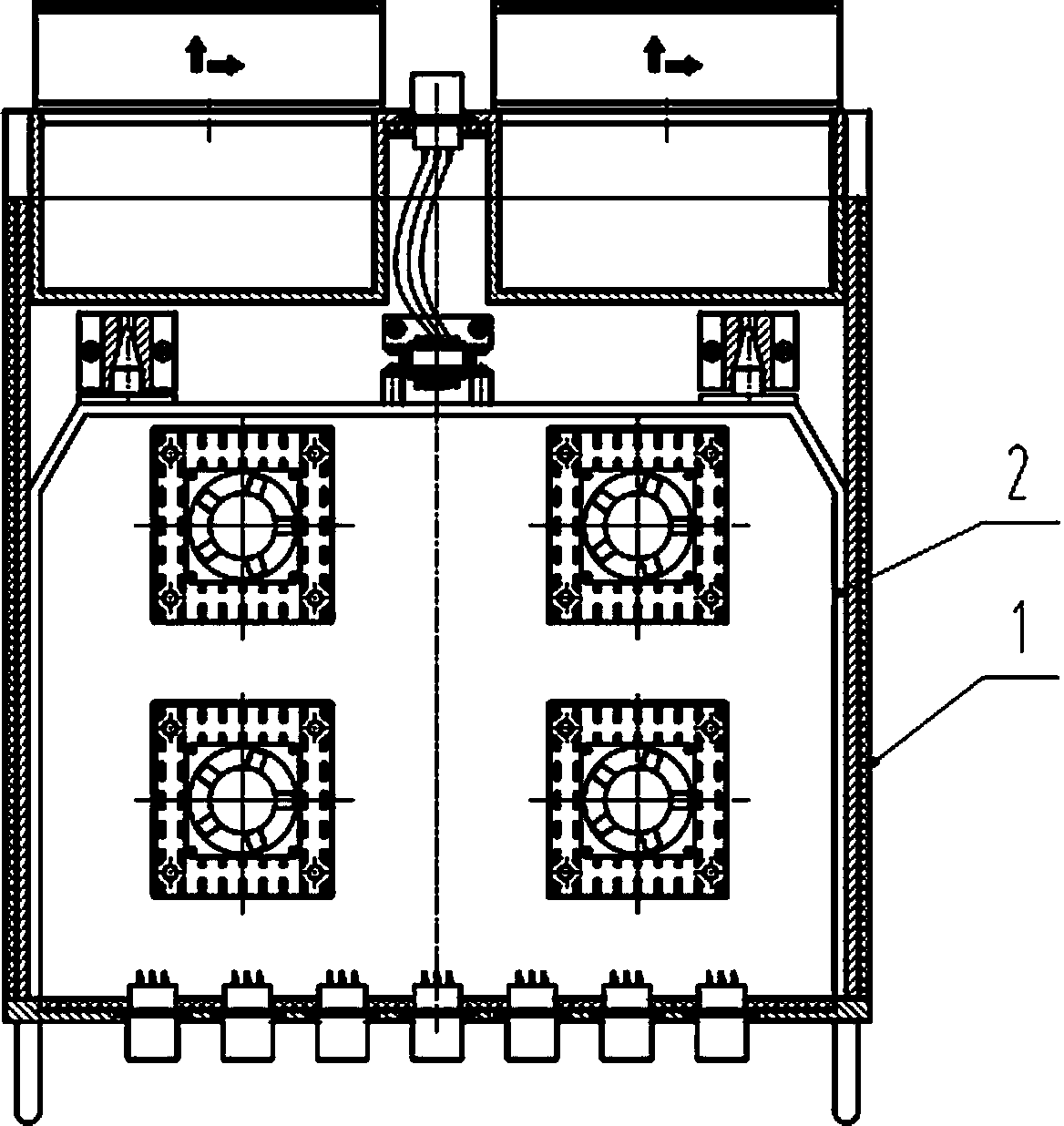

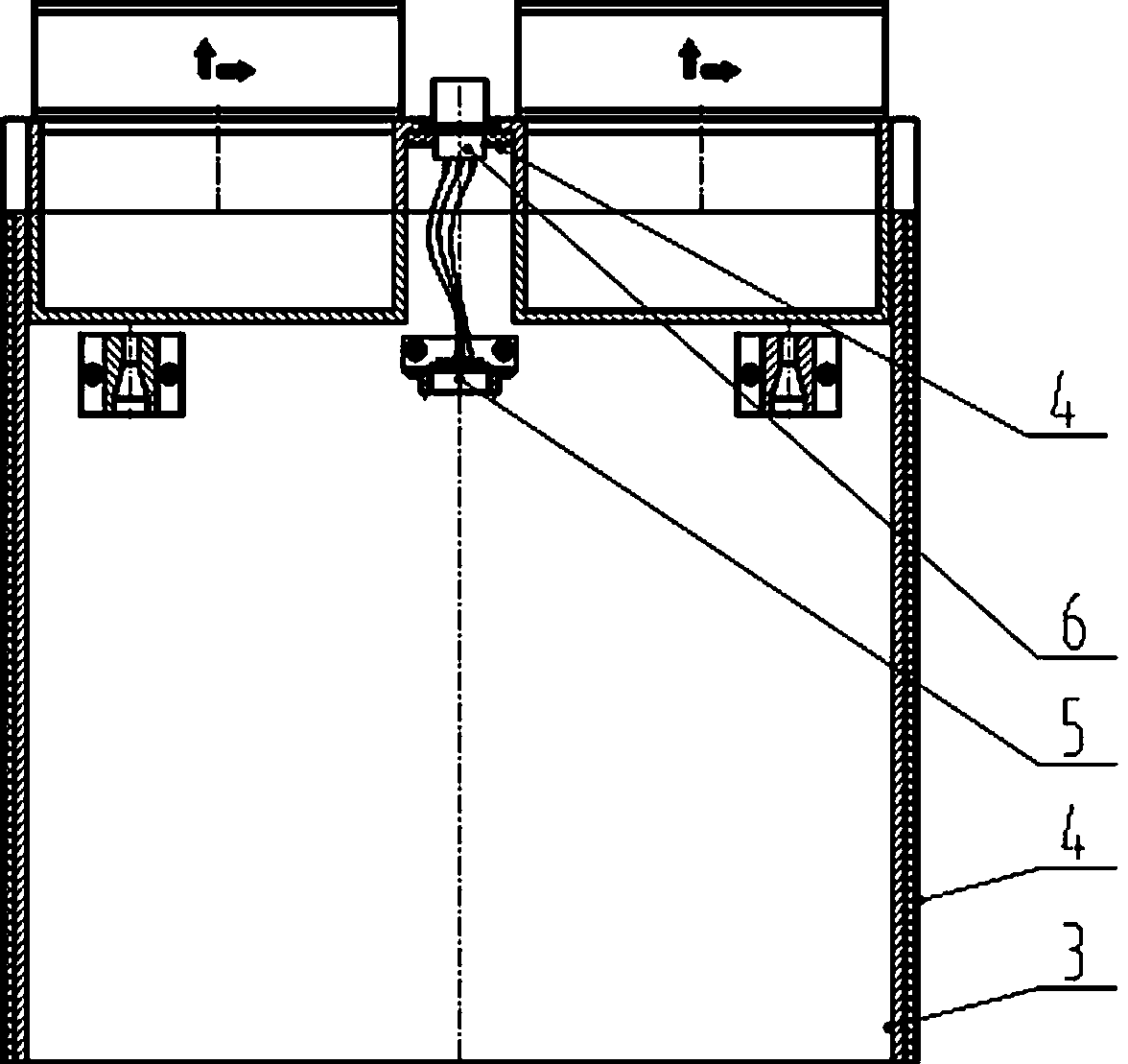

[0023] Such as Figure 1 ~ Figure 6 As shown, a box-type heat preservation / heat dissipation device for blade servers of the present invention is composed of an outer box 1 and an inner box 2. The inner box 2 and the outer box 1 pass through the conical guide at the tail of the inner box 2 The positioning pin 16 is fixed with the screws on the front panel 13 of the inner box.

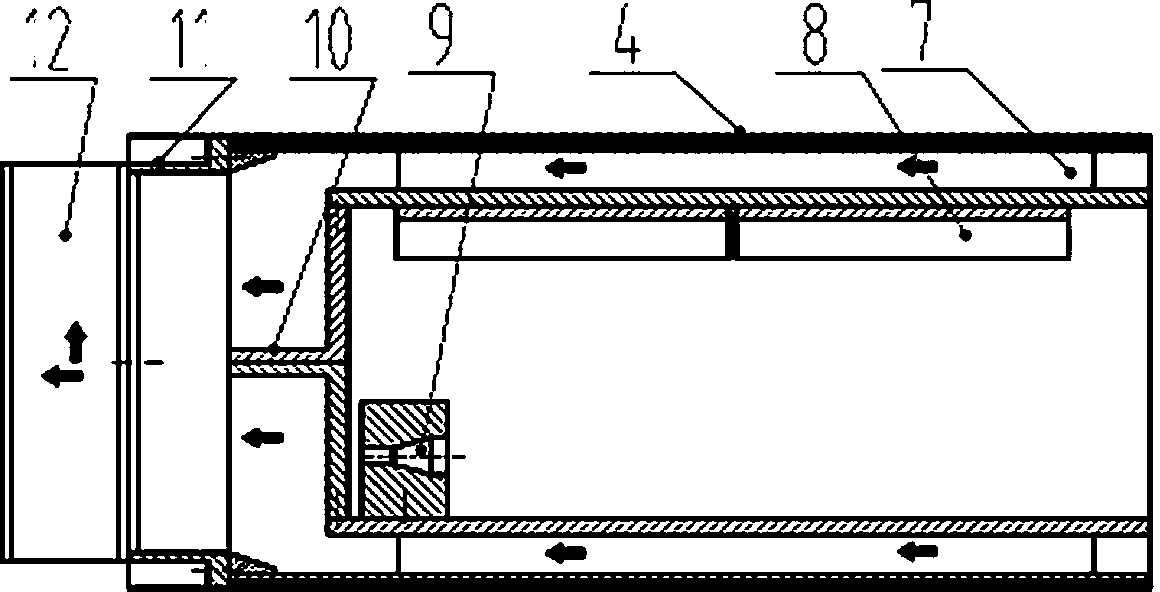

[0024] The outer box 1 is a heat-preserving / heat-dissipating box body, including: side plates 3, heat-insulating plates 4, collision-type adapter sockets 5, external connectors 6, air duct plates 7, finned radiators 8, and conical shapes Positioning pin seat 9, air box 10, confluence wind box 11, external fan 12; the upper and lower sides of outer box 1 are composed of air duct plate 7 and heat insulation plate 4, air duct plate 7 is on the inside, and heat insulation plate 4 is on the outside ; The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com