Cylindrical iron core, stationary induction apparatus and induction heat-generating roller device

A cylindrical iron core technology, applied in the field of circular iron cores, can solve the problems of enlarged outer diameter, inability to prevent eddy current, and limited usefulness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] (best form for carrying out the invention)

[0054]

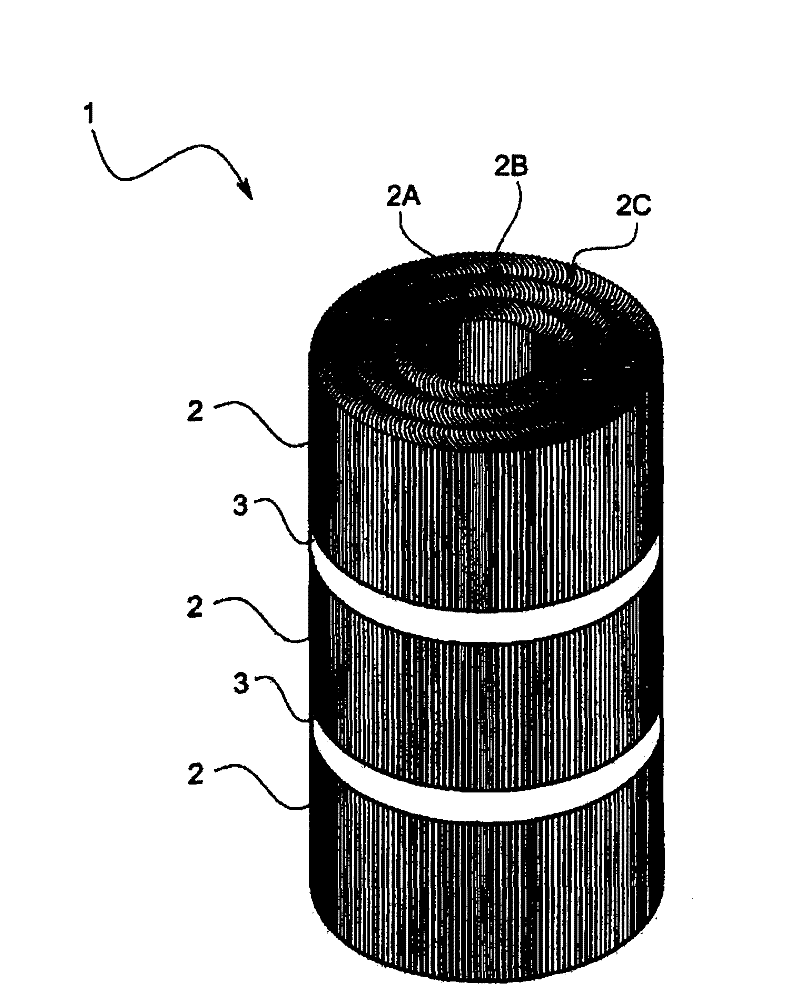

[0055] Next, an embodiment of the iron core 1 for static induction equipment according to the present invention will be described with reference to the drawings. Other, figure 1 It is a perspective view showing the outline of the structure of the static induction device core 1 of the present embodiment, figure 2 It is a top view of the iron core 1 of the static induction equipment.

[0056] The iron core 1 for static induction equipment related to this embodiment is, for example, a circular iron core used for a reactor or a transformer, such as figure 1 As shown, a plurality of core blocks 2X and a magnetic gap G provided between these core blocks 2X are included.

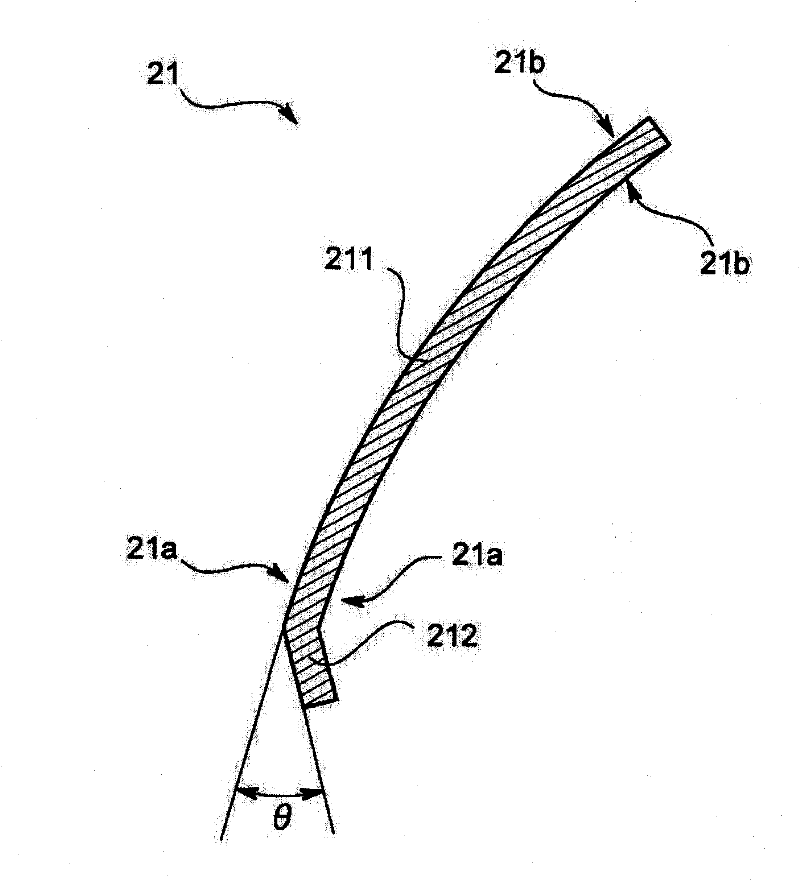

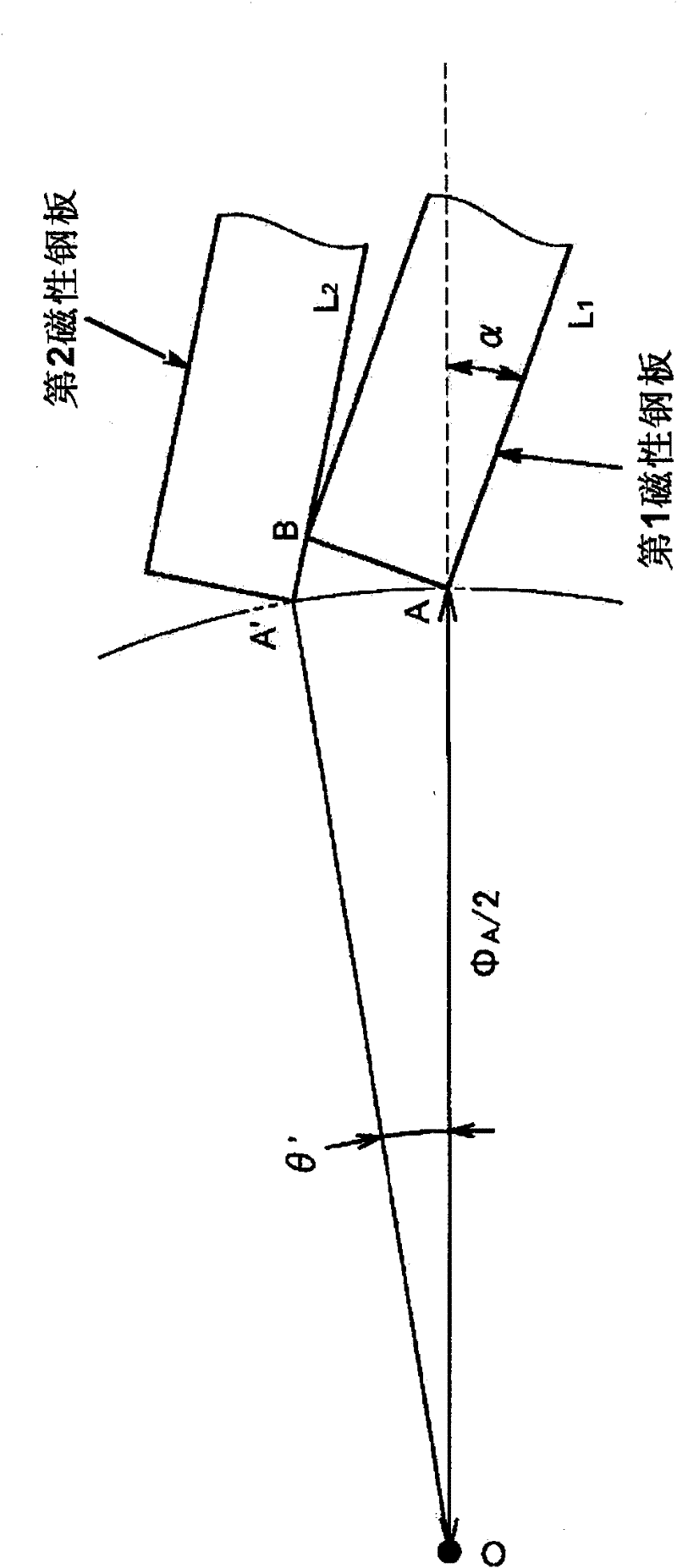

[0057] Core block 2X, such as figure 2 As shown, a plurality (three in this embodiment) of cylindrical core elements 2A, 2B, and 2C are stacked in a radial direction to form concentric circles. In the radial direction, adjacent cylindrical core e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com