Circulating fluidized bed combustion device with internal double-inlet cyclone separator

A technology of cyclone separator and circulating fluidized bed, which is applied in the directions of fluidized bed combustion equipment, fuel burned in a molten state, and combustion method, etc. Problems such as large start-stop inertia, to achieve the effect of simple and reliable return material structure, shorten start-up time, and avoid high temperature coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] specific implementation plan

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

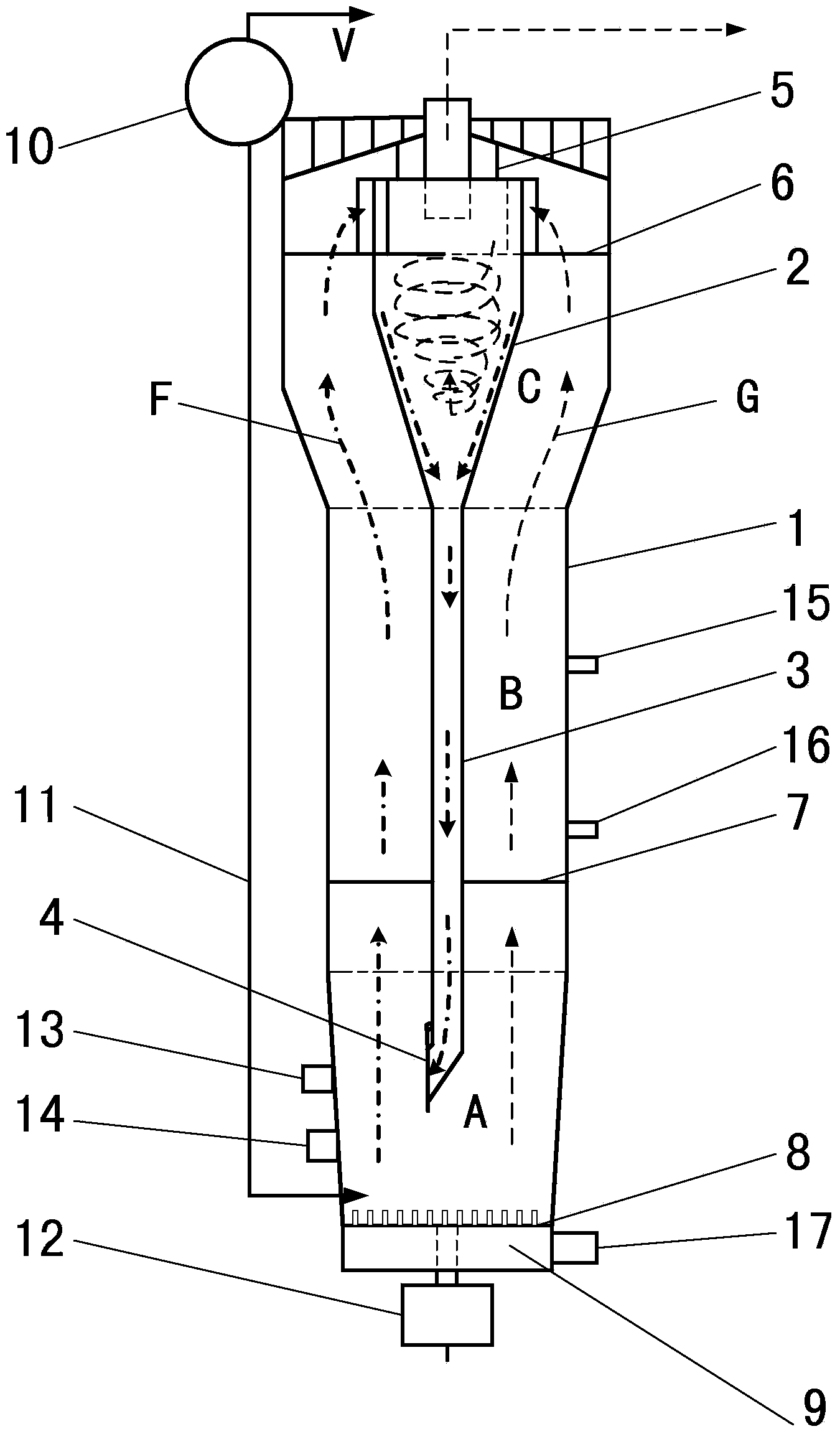

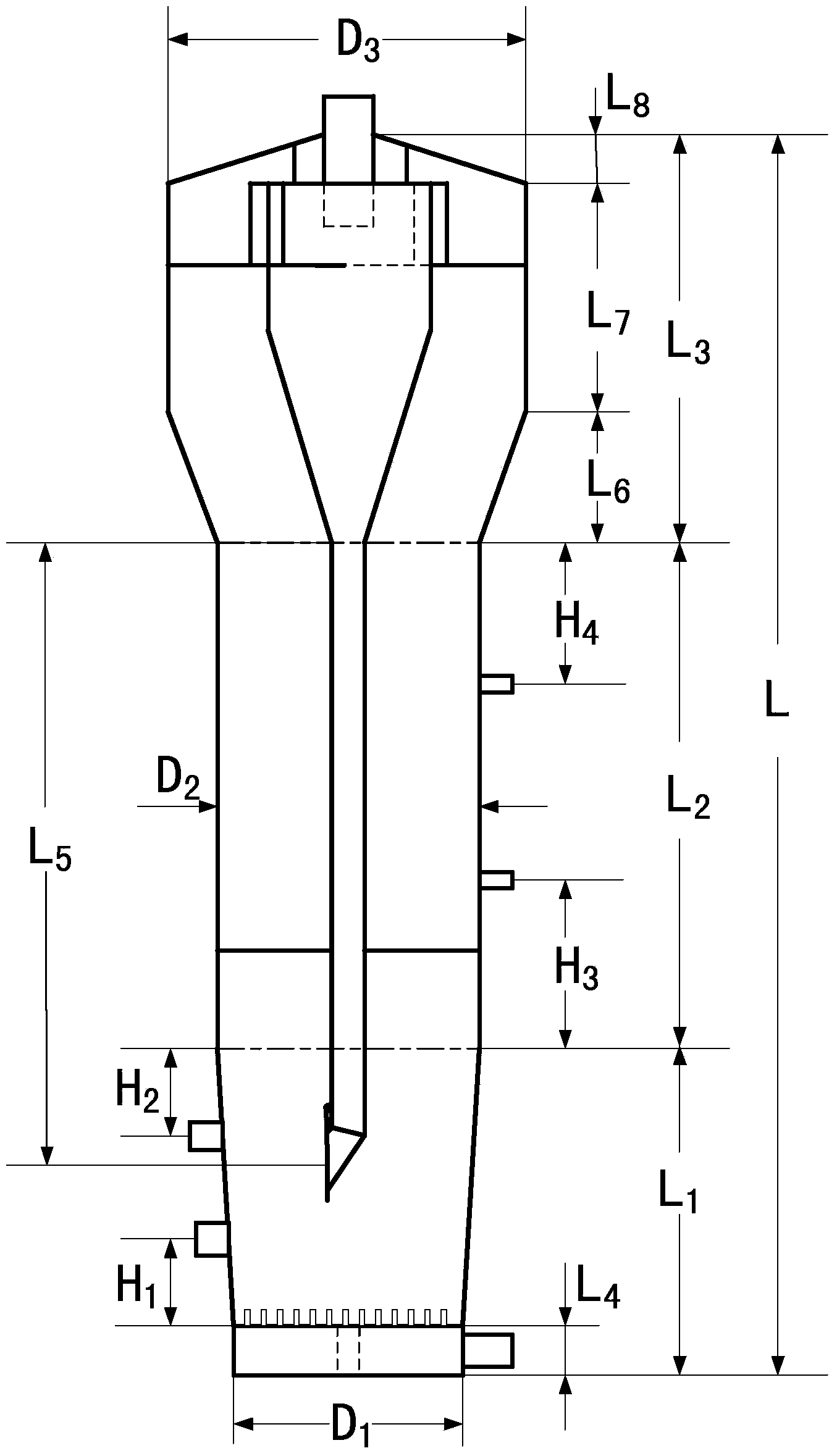

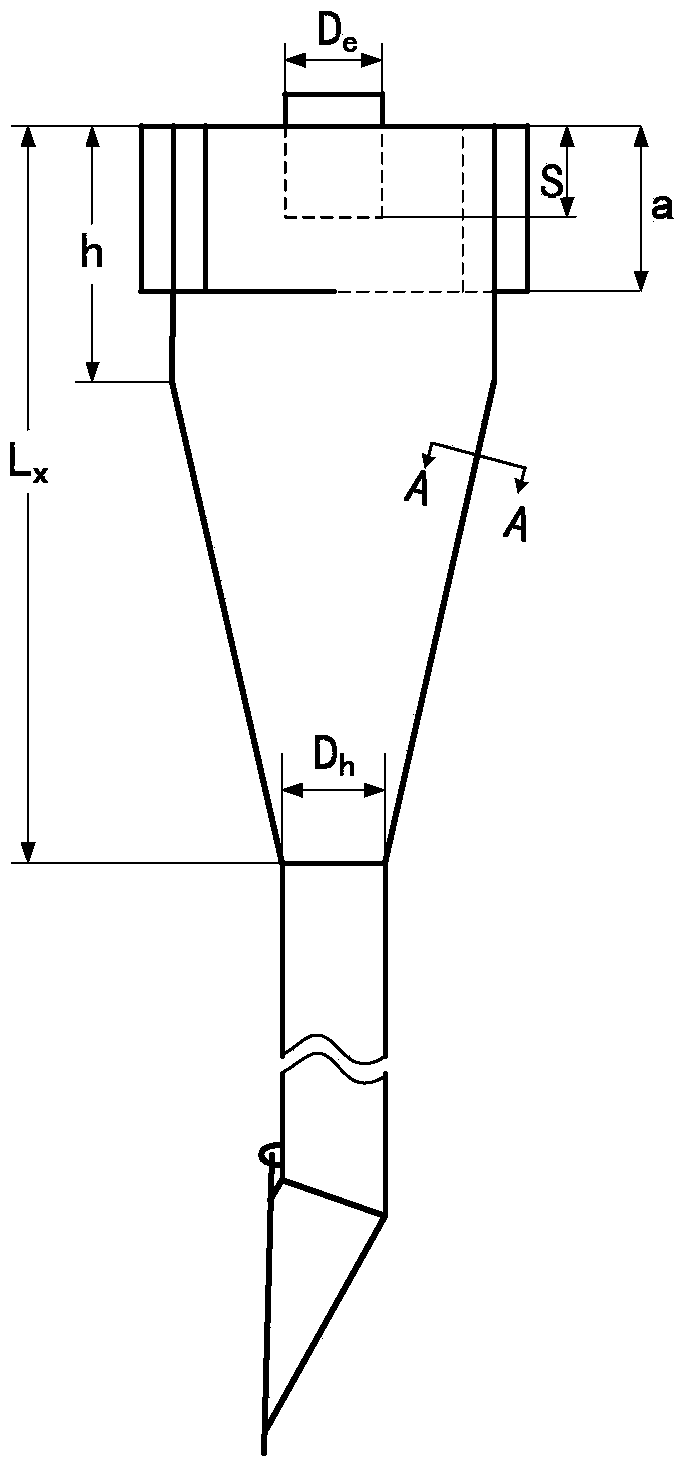

[0042] The circulating fluidized bed combustion device based on the built-in double-inlet cyclone separator provided by the present invention is composed of a furnace body, a double-inlet cyclone separator, a return material downcomer, and a steam-water separator device. The present invention changes the external layout of the cyclone separator. The cyclone separator is placed inside the circulating fluidized bed. The main body is bent and welded by a steam-cooled pipe. The solid particles fall directly from the return downcomer into the dense phase area of the furnace. The cyclone separator is placed inside the furnace, which can effectively simplify the mechanical components of the circulating fluidized bed, make it compact, and reduce the space occupied by the unit; it can greatly reduce the weight and volume of the cyclone s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com