Throttle element for direct-current vapor generator

A technology for steam generators and throttling elements, which is applied in boiler water pipes and promotes water circulation, etc., and can solve the problems of large frictional pressure drop of fluid on the pipe side and failure to provide resistance coefficients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

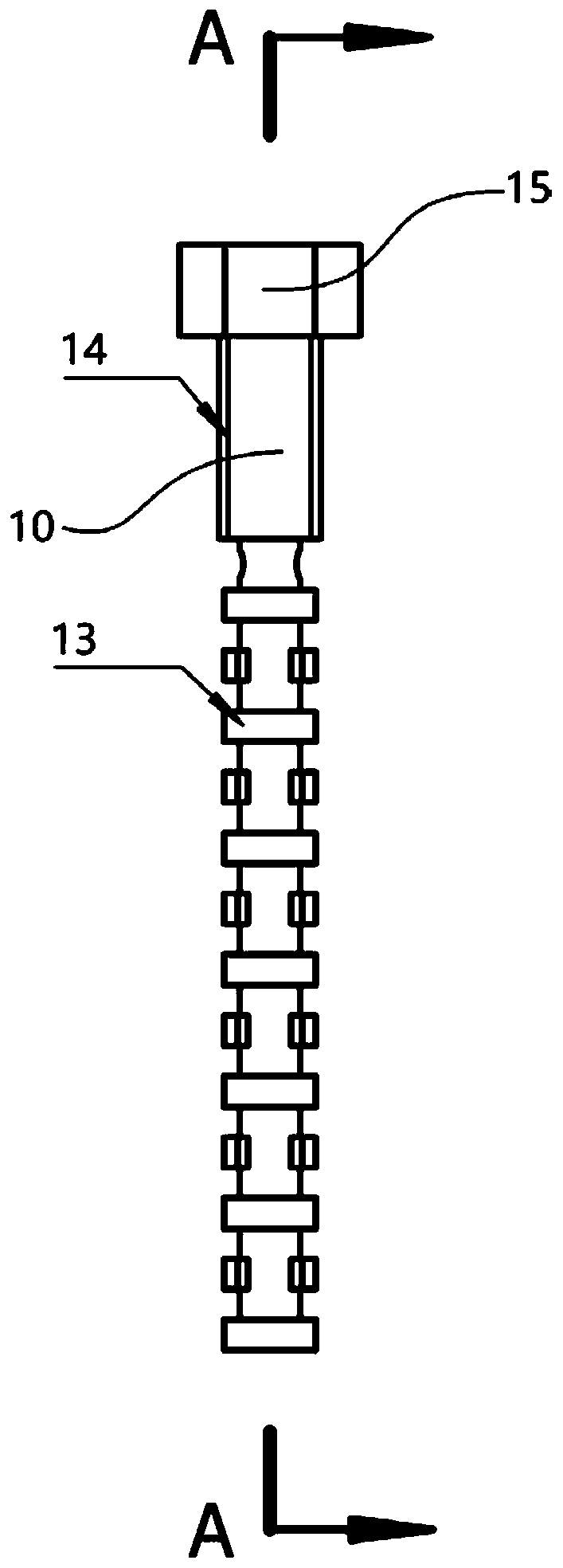

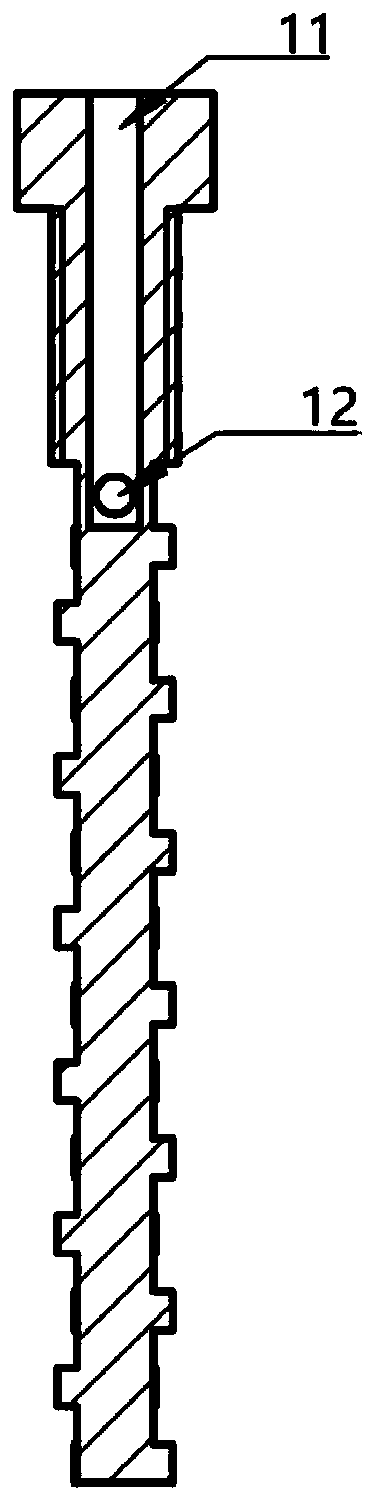

[0019] Such as Figure 1 to Figure 3 As shown, the throttling element for a once-through steam generator of the present invention includes a cylindrical main body 10, an inlet flow channel 11 is arranged at the center of the main body 10, and flow holes 12 are symmetrically arranged on both sides of the bottom of the inlet flow channel 11, and the main body A multistage impeller 13 is arranged on the outside of the lower part of the body 10 , and a sealing thread 14 is arranged on the outside of the upper part of the main body 10 .

[0020] In this embodiment, the main body 10 is installed at the inlet end of the heat transfer tube, and the main body 10 is connected with the inner wall of the heat transfer tube through a sealing thread 14 .

[0021] In this embodiment, the top of the main body 10 is provided with a hexagonal column 15 to facilitate tightening.

[0022] In this embodiment, different numbers of impellers 13 are set according to different resistance coefficient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com