Steam generation system for solar photo-thermal power station and operation method of steam generation system

A generation system and operation method technology, which is applied in the steam generation method using heat carrier, solar thermal power generation, steam generation method, etc. Reliability and the effect of saving plant electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

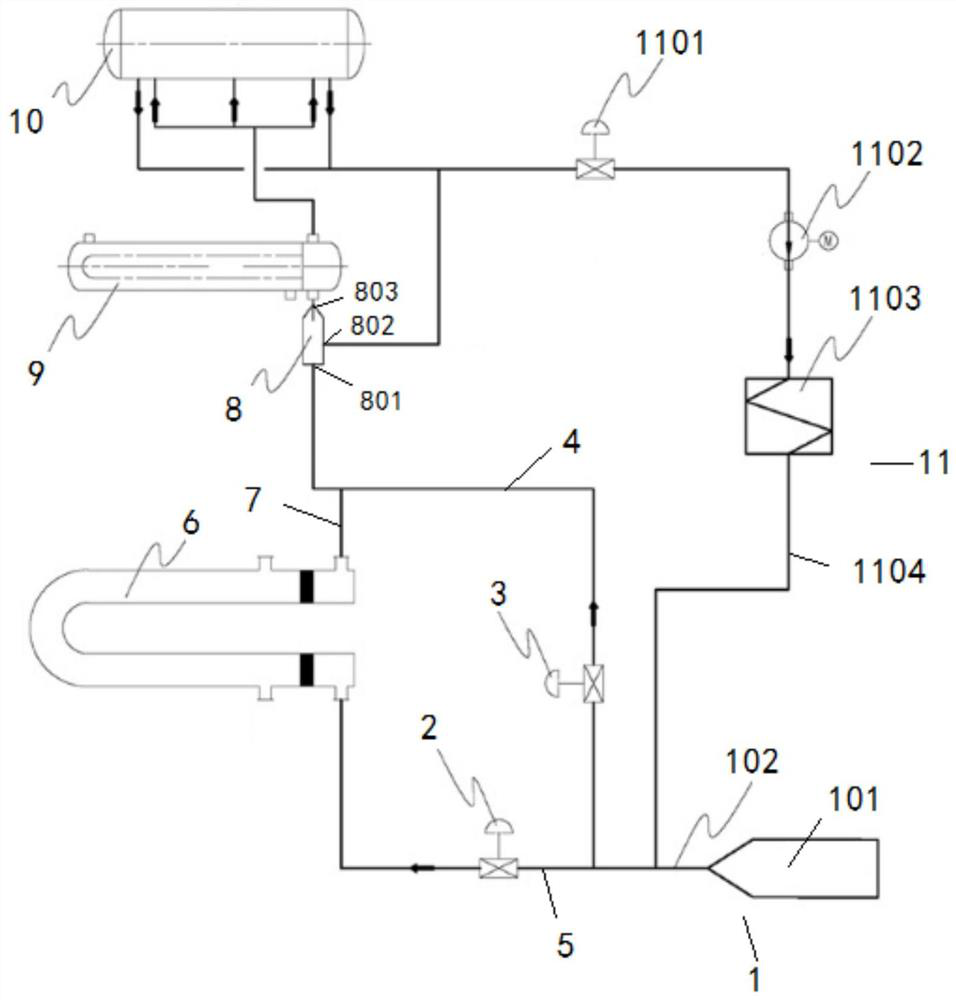

[0044] Please refer to figure 1 , a steam generation system for solar thermal power plants, the steam generation system provides water working fluid through the water supply unit 1; the steam generation system includes a preheater 6, a Venturi nozzle 8, an evaporator 9, a steam Package 10 and boot unit 11.

[0045] In this embodiment, the water supply unit 1 includes a water supply source 101 and a water supply pipeline 102 , and the water supply source 101 provides hydraulic fluid to the steam generation system through the water supply pipeline 102 . The water supply source 101 can also be connected to the water supply pipeline 102 through a regulating valve or a water supply pump, etc., in order to control the on-off of the water supply pipeline 102 . In order to facilitate water supply to the steam generation system from the water supply source 101 , in this embodiment, after the water supply source 101 pressurizes the hydraulic medium, water is supplied to the steam gener...

Embodiment 2

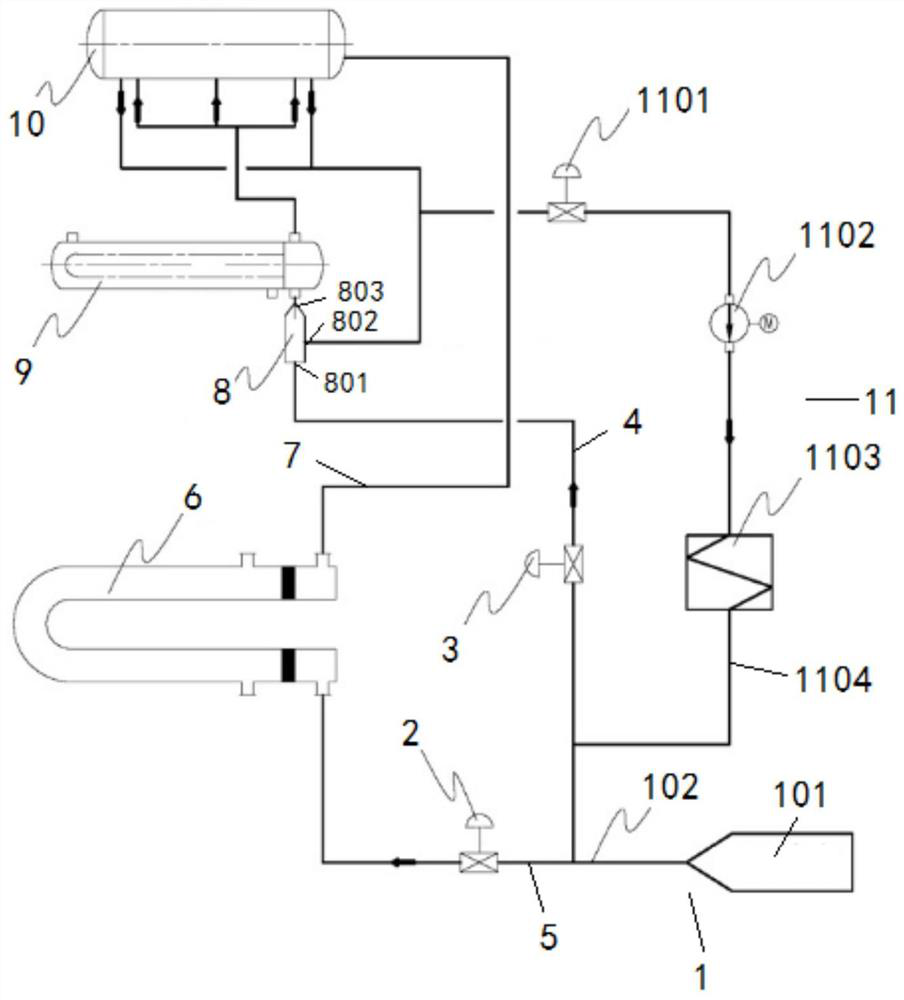

[0059]The difference between the steam generating system provided in this embodiment and the steam generating system provided in Embodiment 1 is that the preheater 6 in Embodiment 1 is connected to the nozzle inlet 801 of the Venturi nozzle 8 through its water outlet pipe 7, while in this embodiment Example preheater 6 is connected to the water supply pipe of steam drum 10 through its outlet pipe 7, please refer to figure 2 .

[0060] In this embodiment, when the steam generating system is started in a cold state, the start-up operation process is as follows:

[0061] First, open the water supply unit 1, close the water supply bypass regulating valve 3, open the water supply regulating valve 2 and start the circulation pump inlet switch valve 1101, and the pressurized hydraulic medium flows in the water supply pipeline 102, and the hydraulic engineering Substance flows into preheater 6, steam drum 10, Venturi nozzle 8, evaporator 9, steam drum 10, start circulation pump inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com