Tubular steam generator

A steam generator and tubular technology, applied in the field of tubular steam generators, can solve the problems of large occupied space and large overall volume, and achieve the effects of high space utilization, reduced heat transfer area, and guaranteed length consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

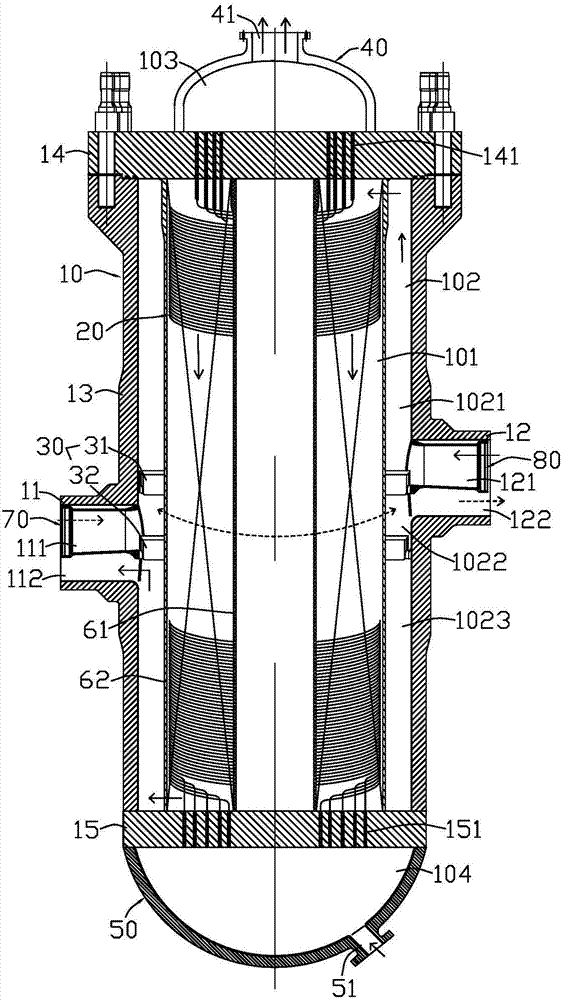

[0027] Such as figure 1 As shown, the tube steam generator according to an embodiment of the present invention includes a sealed container body 10, a heat exchange tube 20 and a partition assembly 30. Wherein, the container body 10 is provided with a first chamber 101 and a second chamber 102 which are radially distributed from the inside to the outside and are isolated from each other; the heat exchange tube 20 is arranged in the first chamber 101 and runs along the first chamber 101 Extending from top to bottom; the partition assembly 30 is disposed in the second chamber 102, and divides the second chamber 102 into an upper chamber 1021, a middle chamber 1022, and a lower chamber 1023 that are isolated.

[0028] The side of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com