Fully submerged electrode boiler with internal water distributor structure

A technology of electrode boilers and internal water heaters, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of inconsistent water flow, different water conductivity, inconsistent resistance, etc., to ensure safe use The effect of strong resistance and flushing cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with each accompanying drawing, the present invention is described in detail.

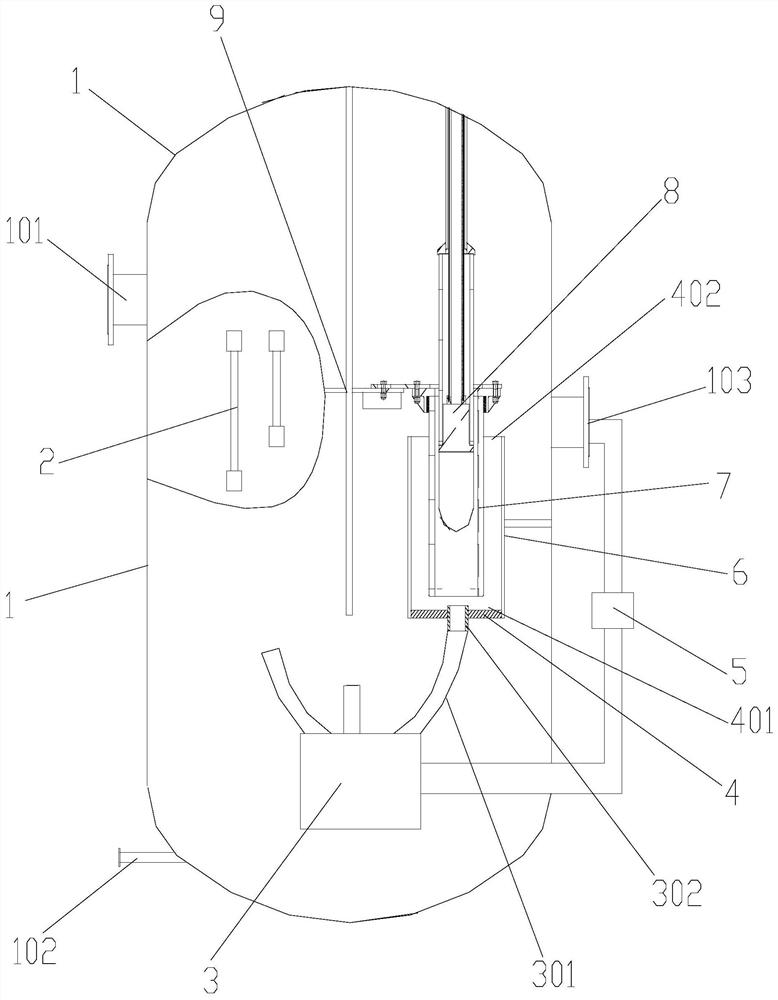

[0048] as attached figure 1 As shown, a fully submerged electrode boiler with an internal water distributor structure includes a pot shell 1, a phase electrode 8, a zero electrode 6 and an isolation shield 7, and the phase electrode 8 and the zero electrode 6 are fixed in the pot shell 1 , the phase electrode 8 is located in the zero electrode 6, the isolation shield 7 is movably arranged in the pot shell 1, and the isolation shield 7 is located between the phase electrode 8 and the zero electrode 6, and the phase electrode 8 and the zero electrode 6 are individually The numbers are equal, and the number of phase electrodes 8 is an integer multiple of 3, as attached figure 1 As shown, it also includes a water distributor, a connecting pipe and a flexible sealing sheet 4, a circulation outlet 103 is arranged on the pot shell 1, the water distributor is arranged in the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com