Steam forming method achieved through buoyancy adjustment of inclination angle

A technology of inclination angle and steam, applied in steam generation method, steam generation method using heat carrier, steam generation, etc., can solve the problem of slow heat transfer speed of steam generator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be clearly and completely described below through specific embodiments in conjunction with the accompanying drawings.

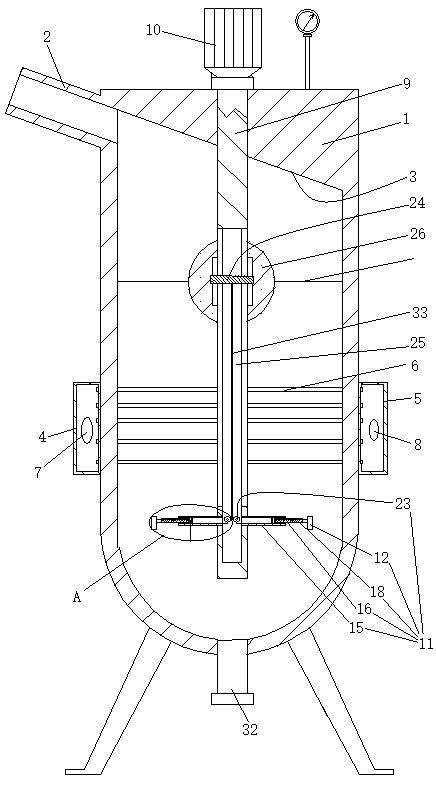

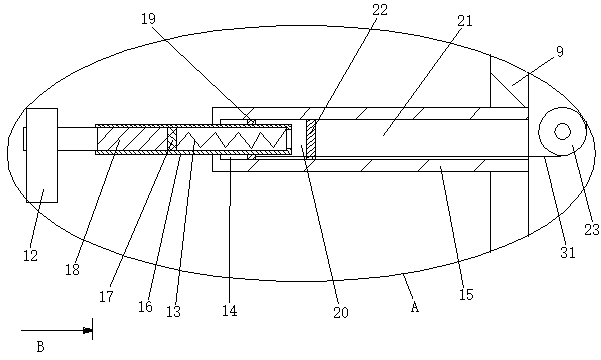

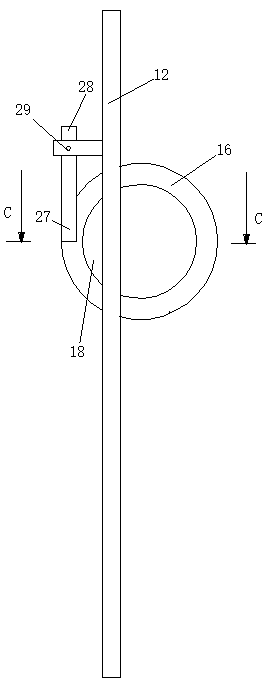

[0022] see figure 1 , figure 2 , image 3 and Figure 4 , a steam formation method that adjusts the inclination angle by buoyancy. The air heated by solar energy is input into the heat exchanger located in the water storage pipe through the air pump to heat the water in the water storage tank. After the water is heated, it evaporates to form steam from The steam is output from the output port. During the heating process of the heat exchanger, the water in the water storage tank is stirred by the stirrer. During the stirring process, the push plate in the stirrer produces a tilt angle change under the action of the buoyancy of the float and the tension of the spring. To change the force of pushing up the water when the push plate rotates, the change process of the inclination angle of the push pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com