Natural circulation boiler

A natural circulation and boiler technology, applied in the direction of promoting water circulation, etc., can solve the problems of water flooding in the horizontal separator and reducing the separation capacity of steam and water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

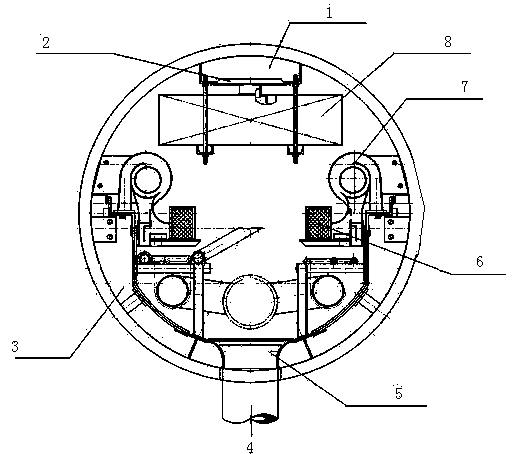

[0012] A natural circulation boiler, consisting of a steam collecting chamber 1, a steam equalizing orifice plate 2, a jacket space 3, a downcomer 4, an anti-rotation device 5, a steel mesh separator 6, a horizontal separator 7 and a louver separator 8, After the saturated steam is drawn out from the drum, it is introduced into the upper header of the inlet flue of the steam-cooled cyclone separator through the saturated steam connecting pipe, and after descending the cooling flue, it is introduced into the lower header of the steam-cooled cyclone separator through the connecting pipe, and is connected by the cladding wall The tubes are introduced into the lower headers of the front and rear cladding walls, and go upwards into the lower headers of the tundish wall, that is, the inlet header of the low-temperature superheater. The high-temperature superheater in the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com