Process for dust removing, cooling and tar oil recovering of pyrolysis coal gas

A pyrolysis gas and tar recovery technology, which is applied in gas dust removal, tar processing, petroleum industry, etc., can solve the problems of complicated recovery process, increased processing cost, and difficulty in recovering light oil, so as to simplify the tar recovery process and improve waste heat Effect of recovery efficiency and improvement of tar quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

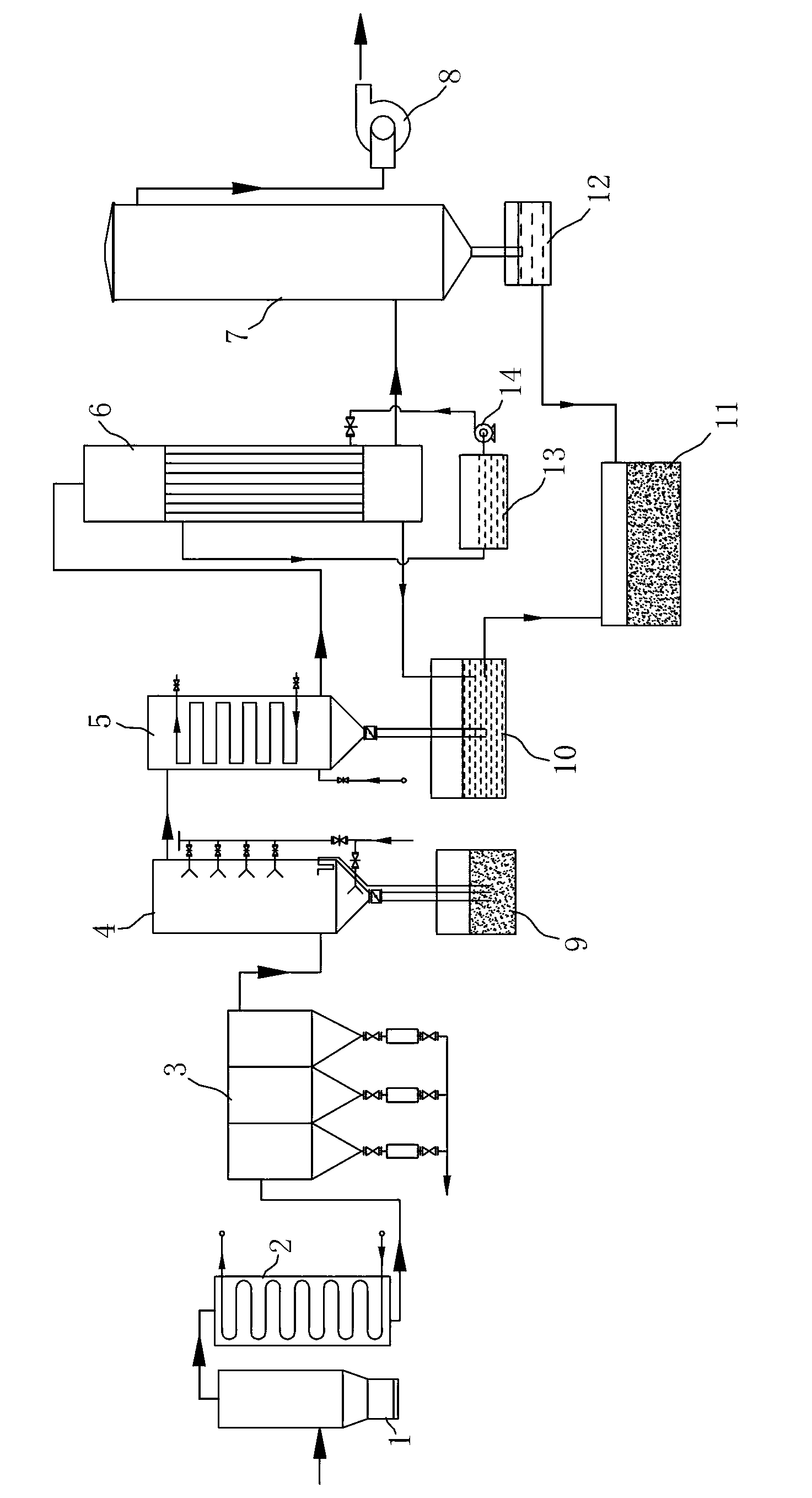

[0039] The pyrolysis gas produced by the pyrolysis gasification furnace 1 has an analysis temperature of about 600°C and a dust content of 10g / Nm 3 , water vapor content is 25%, tar content is 108g / Nm 3 ; The pyrolysis gas first enters the superheater 2 and is cooled to about 500°C; then it is dedusted by the high-temperature electric precipitator 3, and the dust removal rate reaches 98%; then the waste heat is recovered through the waste heat recovery boiler 5, and the gas is cooled to At about 60°C, the waste heat recovery efficiency is 88%, and water and tar are condensed and precipitated at the same time; then the gas is passed into the intercooler 6, cooled to 25°C, and water and tar are condensed again; finally, the gas is passed into the electric tar catcher 7 , recycle the tar mist and water mist carried;

[0040] Sampling and analysis of the gas after the process treatment shows that the dust removal rate of pyrolysis gas treated with this process is 98%, the total was...

Embodiment 2

[0042] The pyrolysis gas produced by the pyrolysis gasification furnace 1 has an analysis temperature of about 750°C and a dust content of 8g / Nm 3 , water vapor content is 30%, tar content is 90g / Nm 3 ; The pyrolysis gas first enters the superheater 2 and is cooled to about 600°C; then it passes through the high-temperature filter cartridge dust collector 3 to remove dust, and the dust removal rate reaches 99.5%; Cool to about 80°C, the waste heat recovery efficiency is 87%, and water and tar are condensed and precipitated at the same time; then the gas is passed into the intercooler 6, cooled to 15°C, and water and tar are condensed again; finally, the gas is passed into the electric tar trap Device 7 reclaims the tar mist and water mist it carries;

[0043] Sampling and analysis of the gas after the process treatment shows that the dust removal rate of pyrolysis gas treated with this process is 99.5%, the total waste heat recovery rate is 89.4%, the tar recovery rate is 99....

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com