Thermal water utilization device and steam treatment device

A hot water and steam technology, which is applied in the fields of hot water utilization devices and steam treatment equipment, can solve the problem of not realizing the effective utilization of hot water, and achieve the effect of effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the drawings.

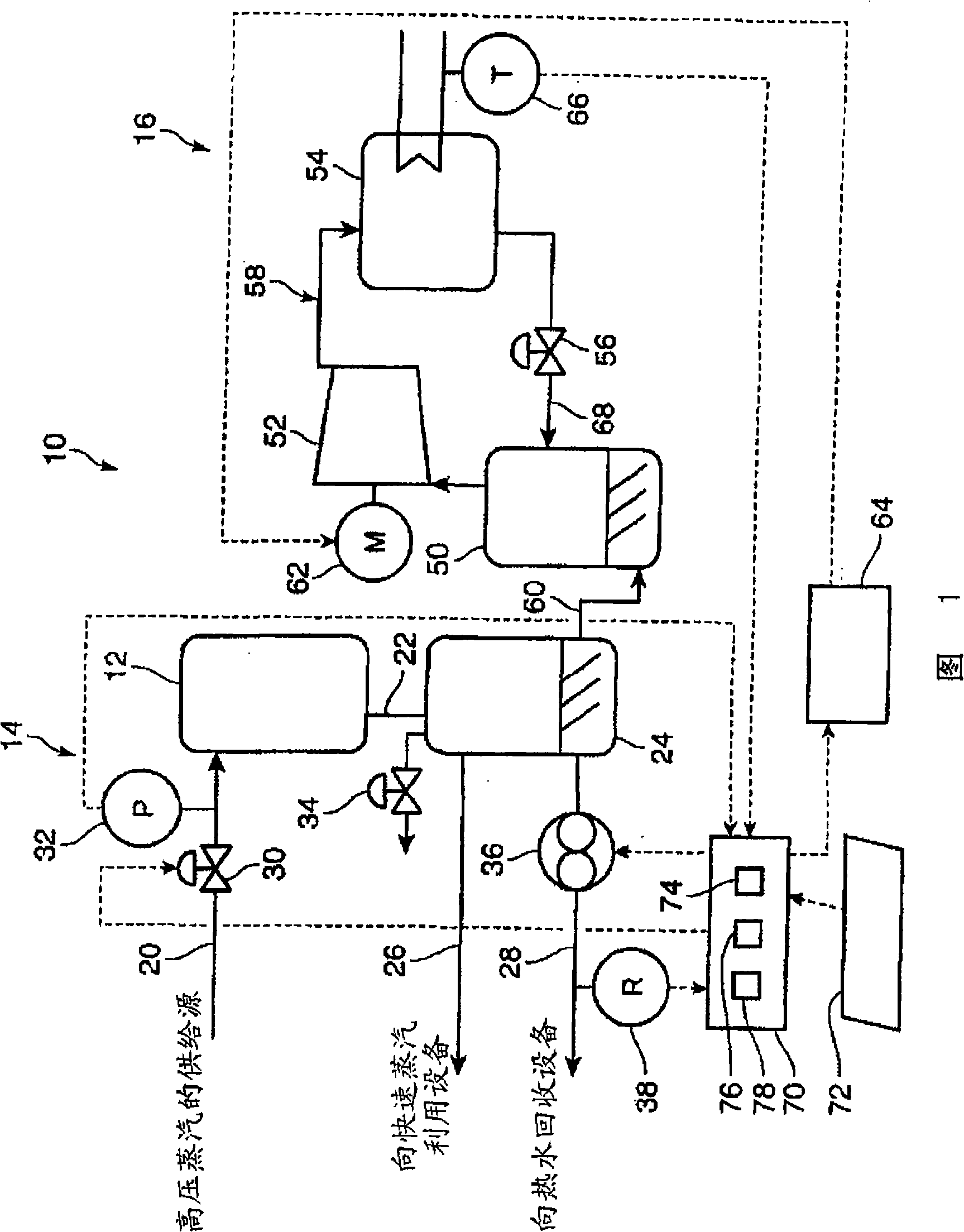

[0017] FIG. 1 schematically shows the configuration of a steam treatment facility using an embodiment of the hot water utilization device of the present invention. As shown in the figure, this steam processing facility 10 has a steam utilization system 14 having a process facility 12 for utilizing heat obtained from steam, and a hot water utilization device 16 attached to the steam utilization system 14 .

[0018] The steam utilization system 14 has a supply line 20 connected to a supply source of high-pressure steam, a process equipment 12 arranged at the downstream end of the supply line 20, a flash tank 24 connected to the process equipment 12 via a connection line 22, and the flash tank 24. The steam recovery line 26 and the hot water recovery line 28 are connected to the tank 24 . In the supply line 20 , high-pressure steam having a prede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com