Double-layer clean energy and pulverized coal coupled peak shaving pulverized coal boiler

A technology of clean energy and pulverized coal boilers, applied in the field of peak-shaving pulverized coal boilers, can solve the problems of energy waste and poor fault tolerance, and achieve the effect of avoiding energy waste and being easy to flexibly adjust peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

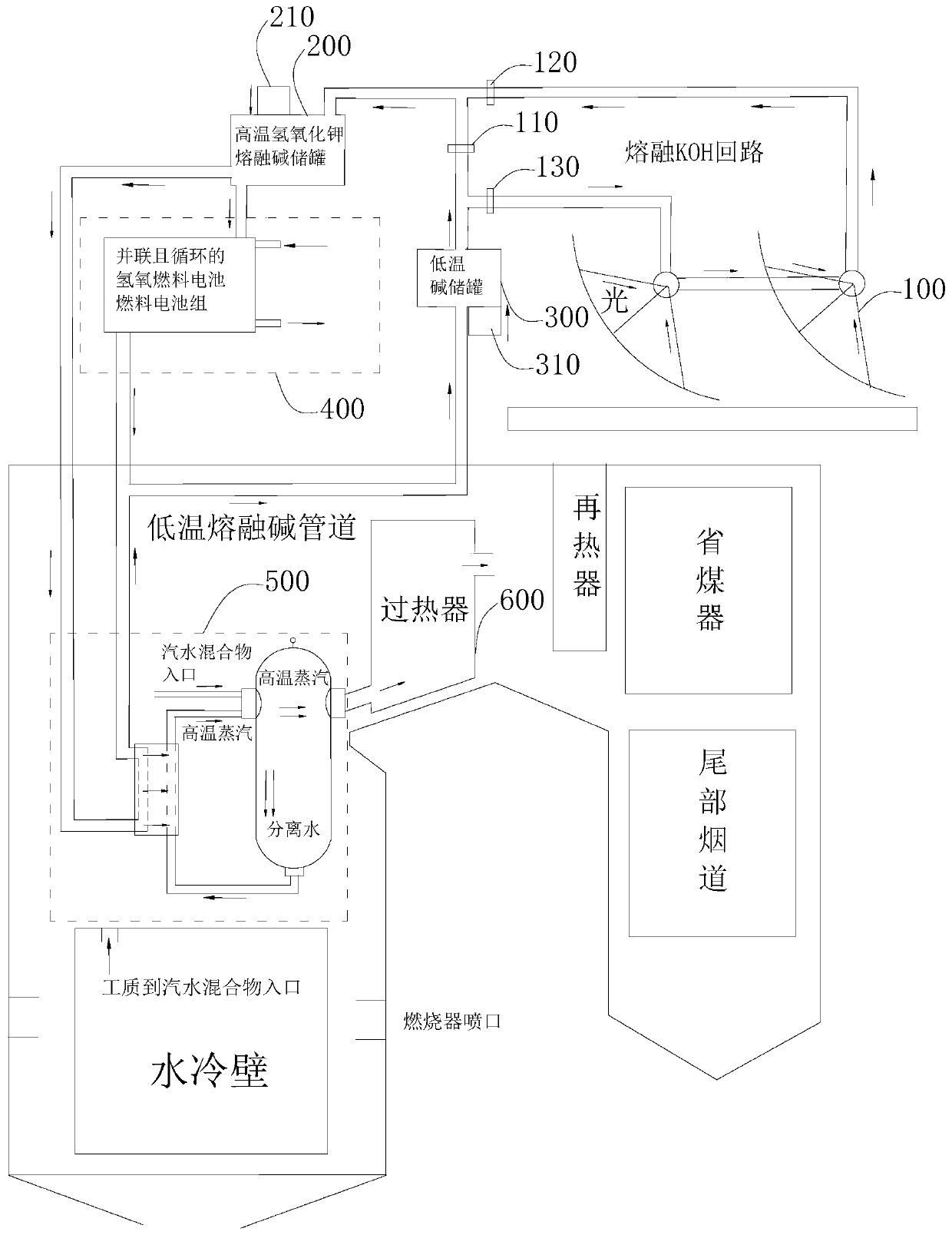

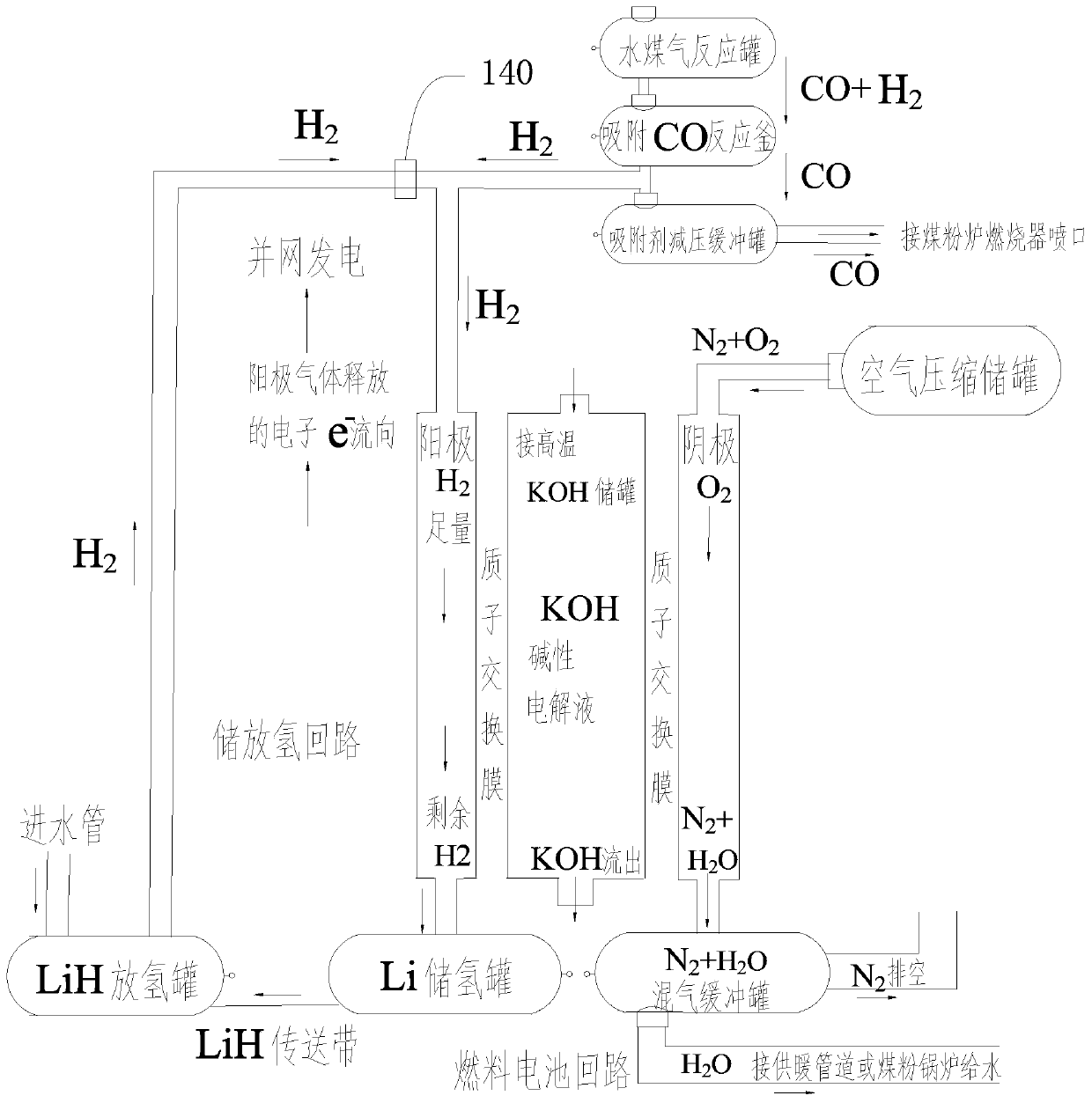

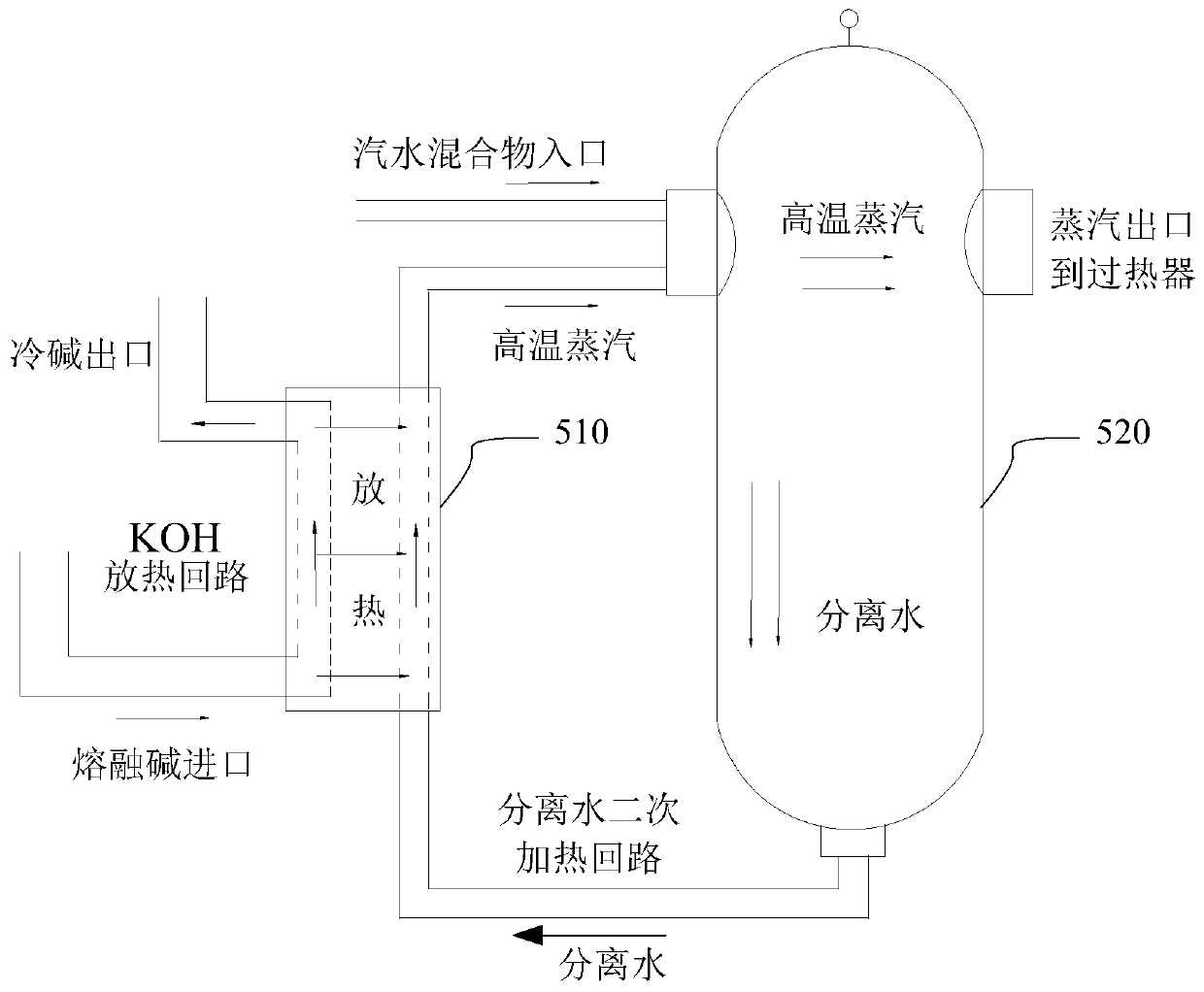

[0026] Specific implementation mode one: the following combination Figure 1 to Figure 3 Describe this embodiment. The peak-shaving pulverized coal boiler coupled with double-layer clean energy and pulverized coal in this embodiment includes a pulverized coal boiler, a trough-type photothermal collector group 100, and a high-temperature potassium hydroxide molten alkali storage tank. 200, low-temperature alkali storage tank 300, hydrogen storage energy hydrogen-oxygen fuel cell unit 400, molten alkali heat energy storage tank type photothermal unit 500 and superheater 600,

[0027] The molten alkali-heat energy storage tank type photothermal unit 500 is set in the furnace of the pulverized coal boiler;

[0028] The heating outlet of the trough-type photothermal collector group 100 is connected to the entrance of the high-temperature potassium hydroxide molten alkali storage tank 200 through a melting pipeline, and a No. 2 shut-off valve 120 is set on the melting pipeline; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com