Hydraulic pressure type vapor recovery device

A recovery device, hydraulic technology, applied in the field of hydraulic steam recovery device, can solve the problems of heavy management and pipe network maintenance workload, environmental and noise pollution, equipment environment deterioration, etc., to reduce boiler water supply and low operating costs , the effect of reducing boiler blowdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

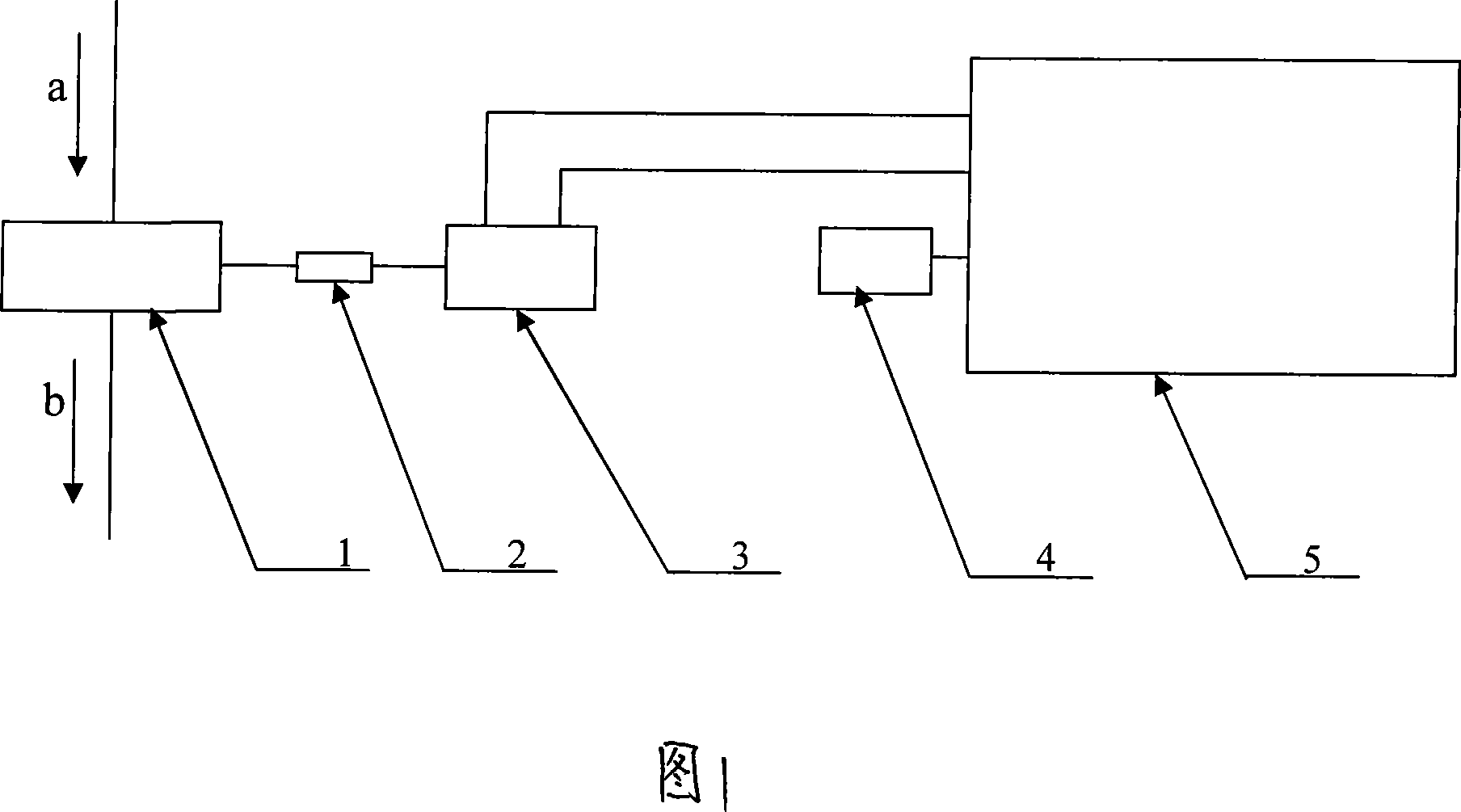

[0012] Embodiment 1, referring to Figure 1, install the electrical control device 4 on the hydraulic station 5, connect the hydraulic station 5 with the hydraulic cylinder 3 at the same time, and then connect the hydraulic cylinder 3 with the pressurizer 1 through the heat insulation coupling 2;

[0013] When in use, one end of the pressurizer 1 is connected to the steam pipeline to be recovered, and the other end is connected to the boiler through the pipeline.

[0014] The hydraulic steam recovery device of the present invention uses an electrical control device to automatically control the hydraulic station during operation, and then the hydraulic cylinder drives the pressurizer through the thermal insulation coupling to perform the reciprocating movement of the piston, and the high-temperature steam-water mixture (by The pipeline a enters) pressurization, and then directly returns to the boiler drum through the pipeline b. The reciprocating speed of the hydraulic cylinder can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com