Functional textile fabric and manufacturing method thereof

A manufacturing method and textile technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of low production efficiency, labor and time consumption, and inability to apply evenly, and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

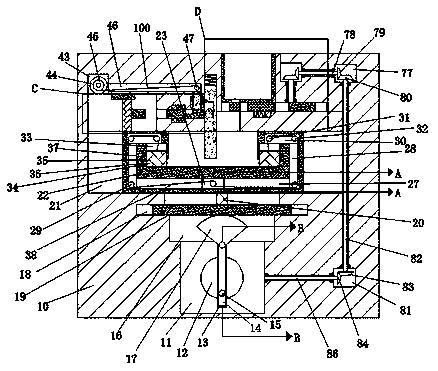

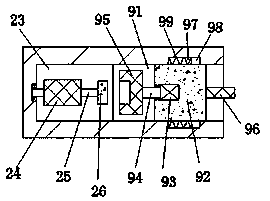

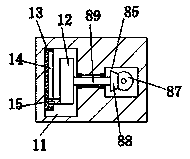

[0022] like Figure 1-Figure 5 As shown, a functional textile of the present invention and its manufacturing method, the device used in this method includes a device body 10, a moving device arranged in the device body 10 and a waxing device arranged in the device body 10 , the displacement device includes a first rotating chamber 11 arranged in the device main body 10, a power wheel 12 is rotatably arranged in the first rotating chamber 11, and the front end of the power wheel 12 is provided with a The rotating rod 13 that rotates in the first rotating chamber 11, the rotating rod 13 is provided with a restricting chamber 14 that opens backward, and the front end of the first rotating chamber 11 is fixedly connected with a rod that extends into the restricting chamber 14 The first fixed rod 15, the inner wall of the upper side of the first rotating chamber 11 communicates with the second rotating chamber 16, and the upper end of the rotating rod 13 is connected with a hinge t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com