Generator internal cooling water membrane purification and alkalization control treatment device

A technology for controlling treatment and generators, which is applied in the field of cooling water film purification and alkalization control treatment devices in generators, which can solve problems such as overheating of generator wire rods, accelerated copper corrosion, and insulation breakdown, etc., to reduce conductivity and increase pH value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

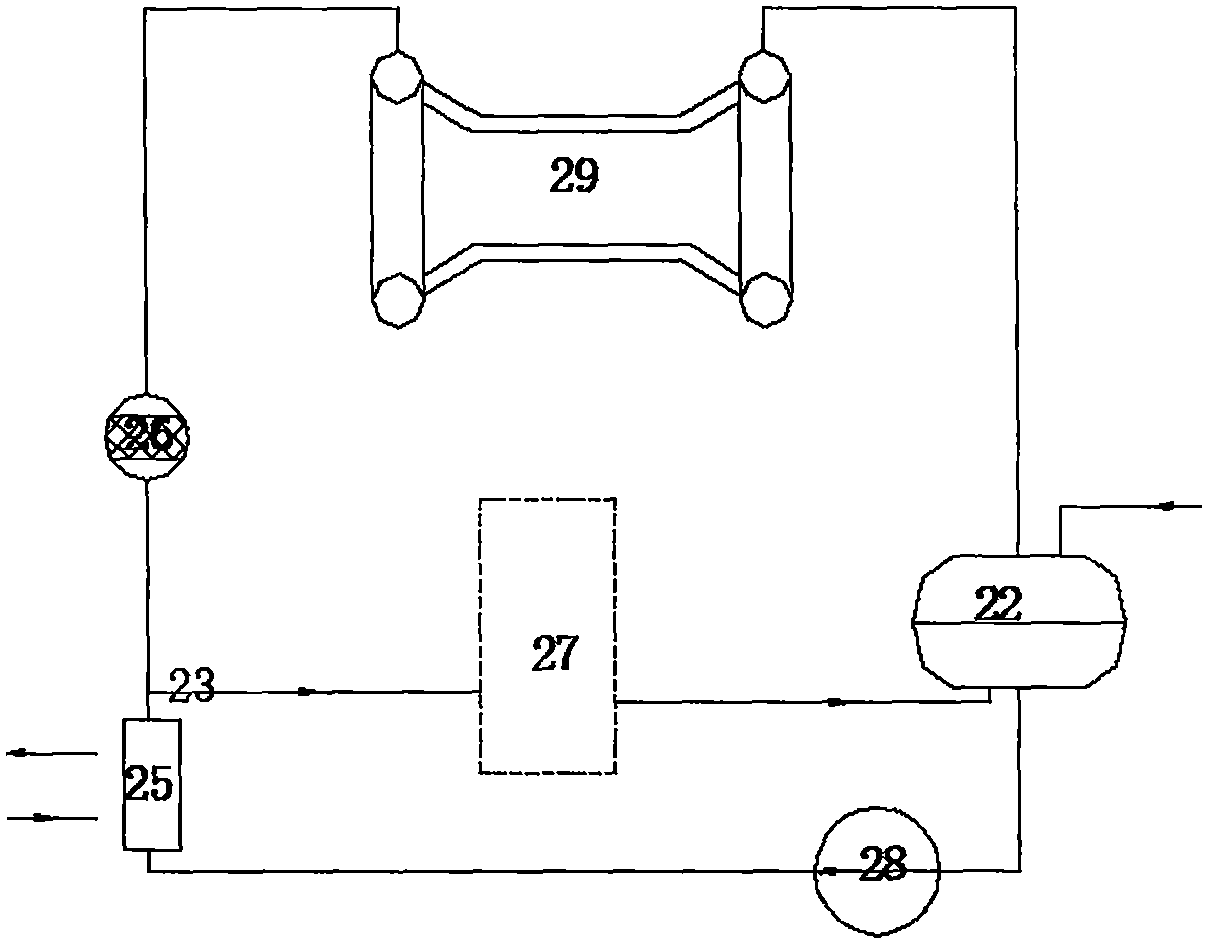

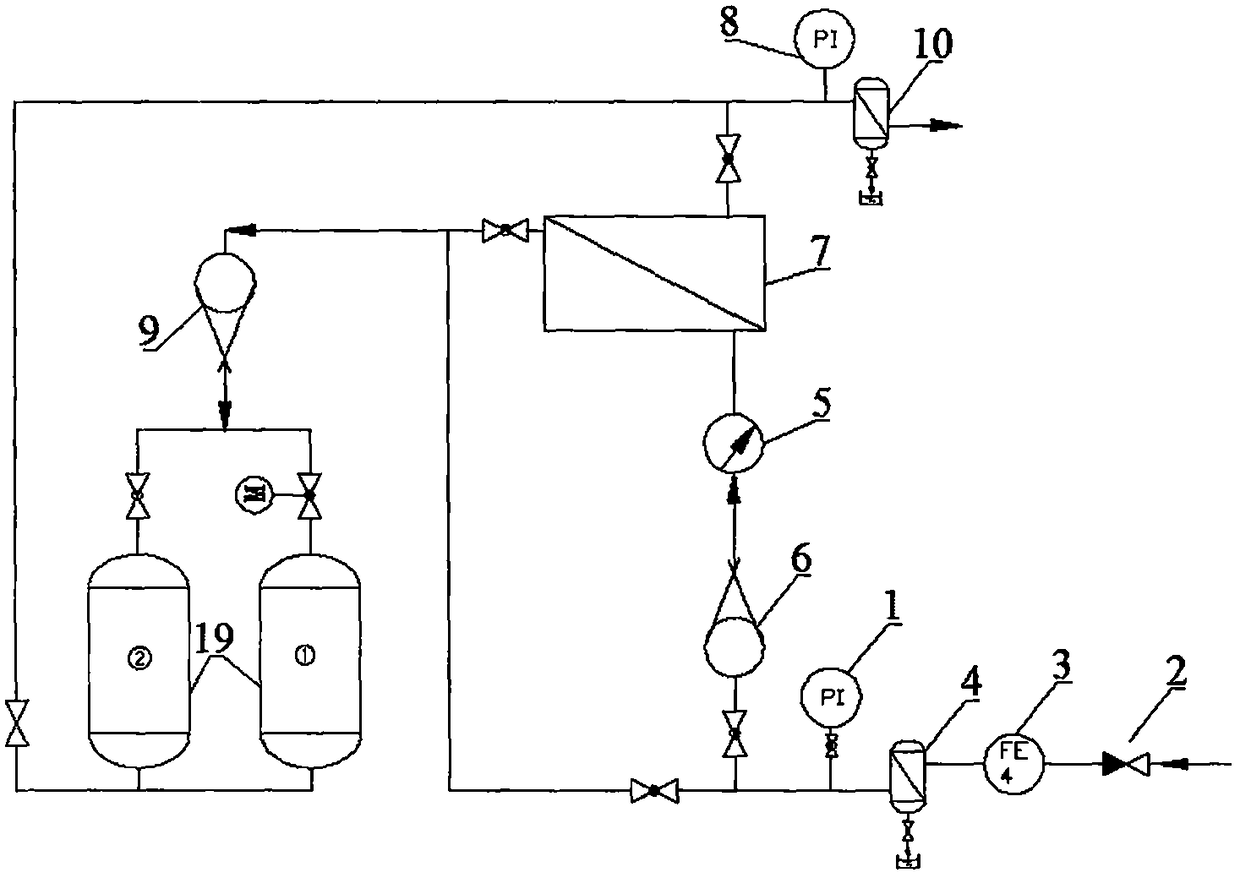

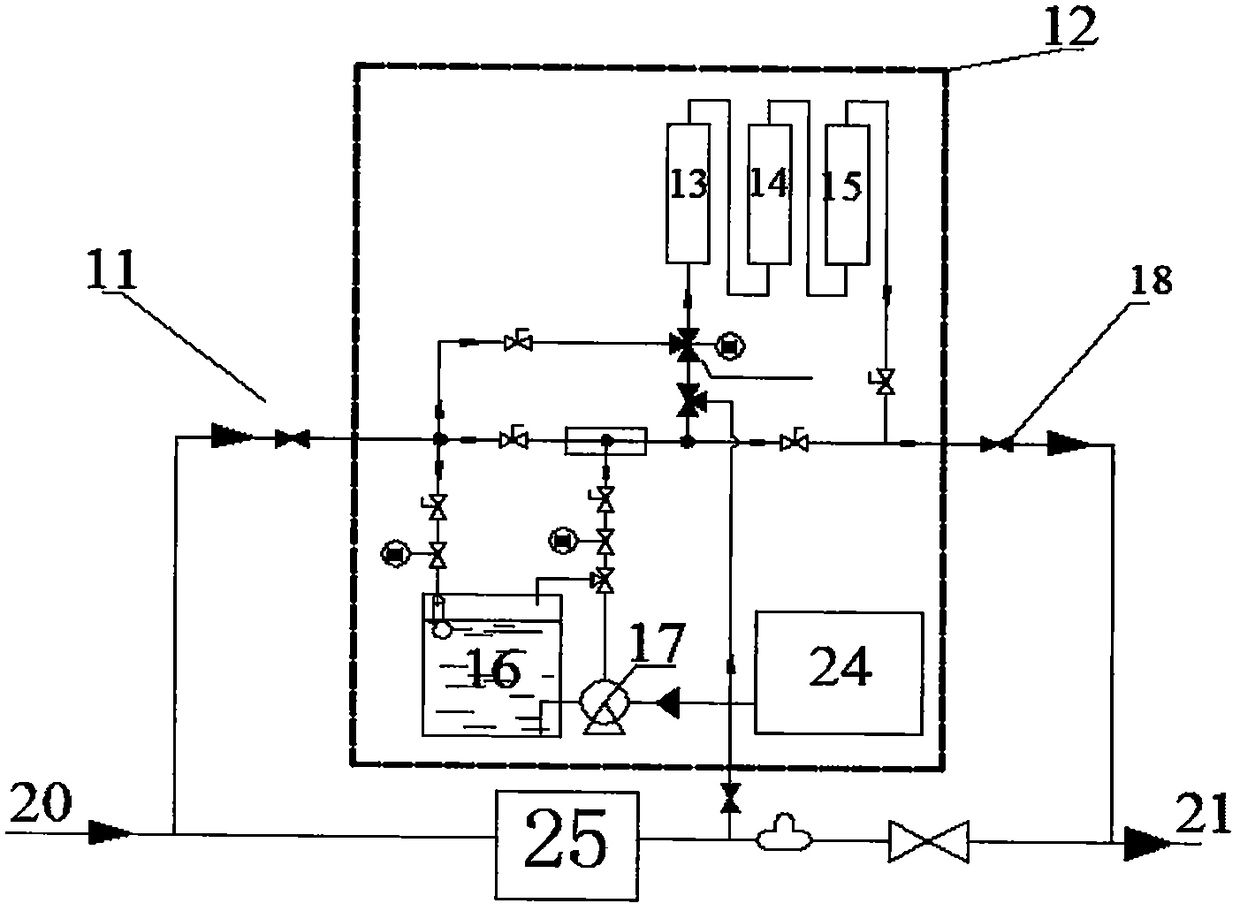

[0022] Such as figure 1 As shown, the inner cooling water membrane purification and alkalization control treatment device of the generator: the membrane treatment 7 and the ion exchanger 19 form a membrane purification system, and the water inlet pipe 20 of the device is connected to the ion exchanger 19 by connecting the concentrated water side of the membrane treatment 7 and the ion exchanger 19. The inner cooling water bypass 23 of the generator is connected, the water inlet pipe 20 of the device is connected with the inner cooling water bypass 23 of the generator, and the water outlet of the device directly returns to the inner cooling water tank 22 of the generator.

[0023] Such as figure 1 The generator internal cooling water system shown is composed of generator internal cooling water tank 22, generator water cooler 25, generator internal cooling water system filter 26, generator internal cooling water pump 28, and stator winding hollow wire 29. The connection positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com