System for removing fine particulate matters in gas-phase mixture

A technology for fine particles and mixtures, applied in the separation of dispersed particles, chemical instruments and methods, auxiliary pretreatment, etc., can solve the problems of large floor space, waste of resources, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

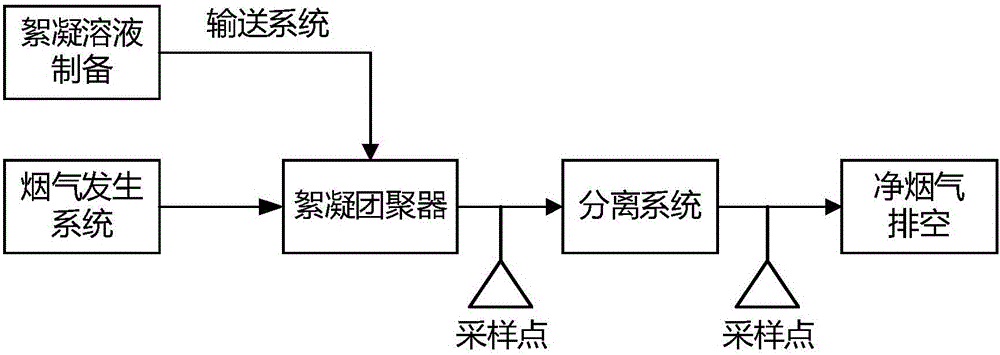

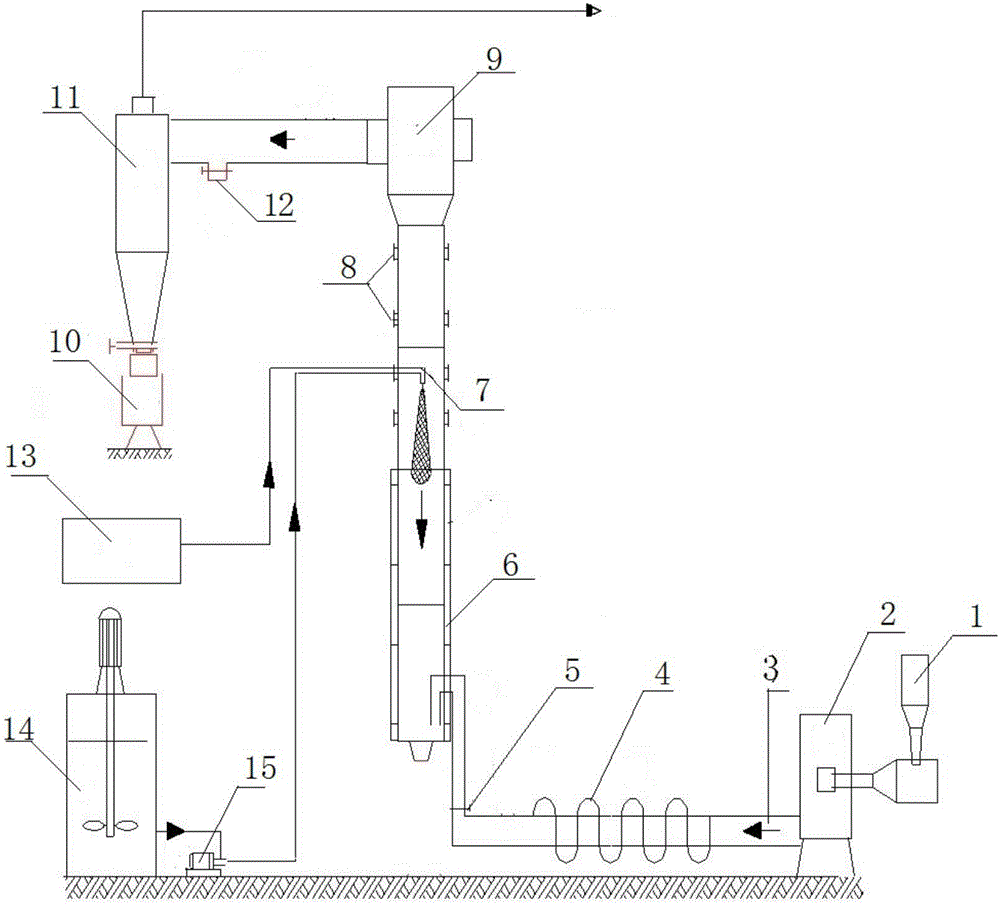

[0053] Such as figure 2 As shown, a system for removing fine particles in a gas-phase mixture includes a flue gas generation system, a flocculation agglomerator 9, a flue gas particle separation system, and a flocculation solution preparation and delivery system; all flue gas generation systems are connected to the flocculation agglomerator 9, and the flocculation The solution preparation delivery system is connected to the flocculation agglomerator 9, and the flue gas particle separation system is connected to the flocculation agglomerator 9; through the flocculation solution preparation delivery system, chemical substances are added to the flue gas to make fine particles aggregate in the flocculation agglomerator, Increase the particle size and quality of fine particles, and then remove the flocculated fine particles through the flue gas particle separation and capture system.

[0054] The flue gas generation system generates dust-laden flue gas and transports it to the flo...

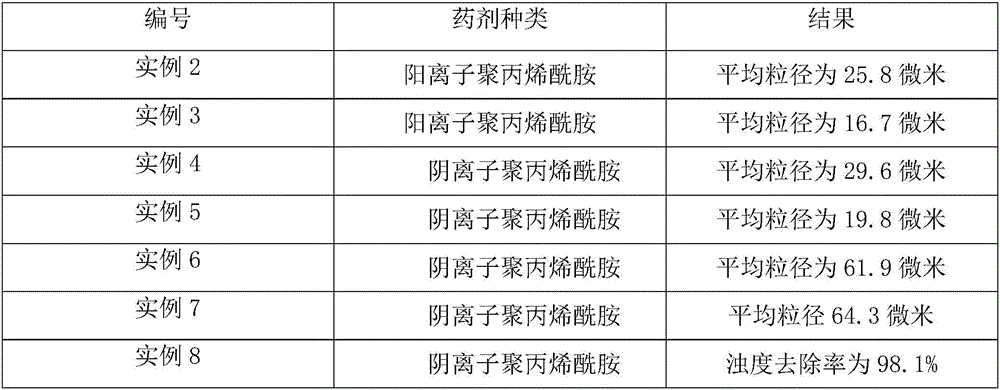

Embodiment 2

[0061] A certain amount of flocculant solution with a concentration of 10mg / L and 0.2wt% fine particle solution (the surface of the fine particle is negatively charged, and the average particle diameter is D X 50=2.57μm) was mixed according to 20000:3, stirred at a speed of 300r / min for 1min, and the average particle size was measured to be 25.8μm.

Embodiment 3

[0063]A certain amount of flocculant solution with a concentration of 10mg / L and 0.2wt% fine particle solution (the surface of the fine particle is negatively charged, and the average particle diameter is D X 50=2.57μm) was mixed according to 20000:3, and stirred at a speed of 300r / min for 1min, and the average particle size was measured to be 16.7μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com