High-precision full-automatic binding machine

A fully automatic, binding machine technology, applied in binding and other directions, can solve problems such as troublesome, inability to bind a stack of paper, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

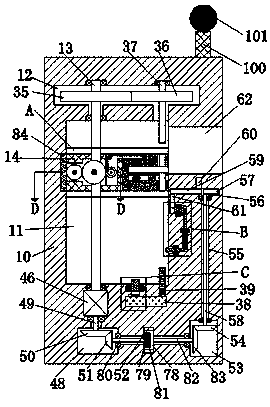

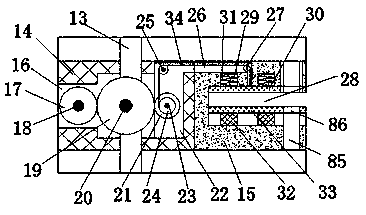

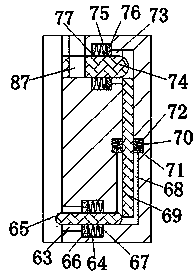

[0019] Such as Figure 1-Figure 5As shown, a high-precision automatic binding machine of the present invention includes a device body 10, a binding device arranged in the device body 10, a conveying device arranged in the device body 10, and a device body arranged in the device body 10, the lighting device at the upper end, the binding device includes a first cavity 11 arranged in the device main body 10, a first motor 46 is fixedly arranged in the inner wall of the lower side of the first cavity 11, and the first cavity A second cavity 12 is provided in communication with the inner wall on the upper side of the cavity 11. The upper end of the first motor 46 is power-fitted with a connection extending through the first cavity 11 and extending into the second cavity 12 and can The first screw mandrel 13 that rotates, the first slider 14 that can slide up and down in the first cavity 11 is threaded on the first screw mandrel 13, and the right end of the first slider 14 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com