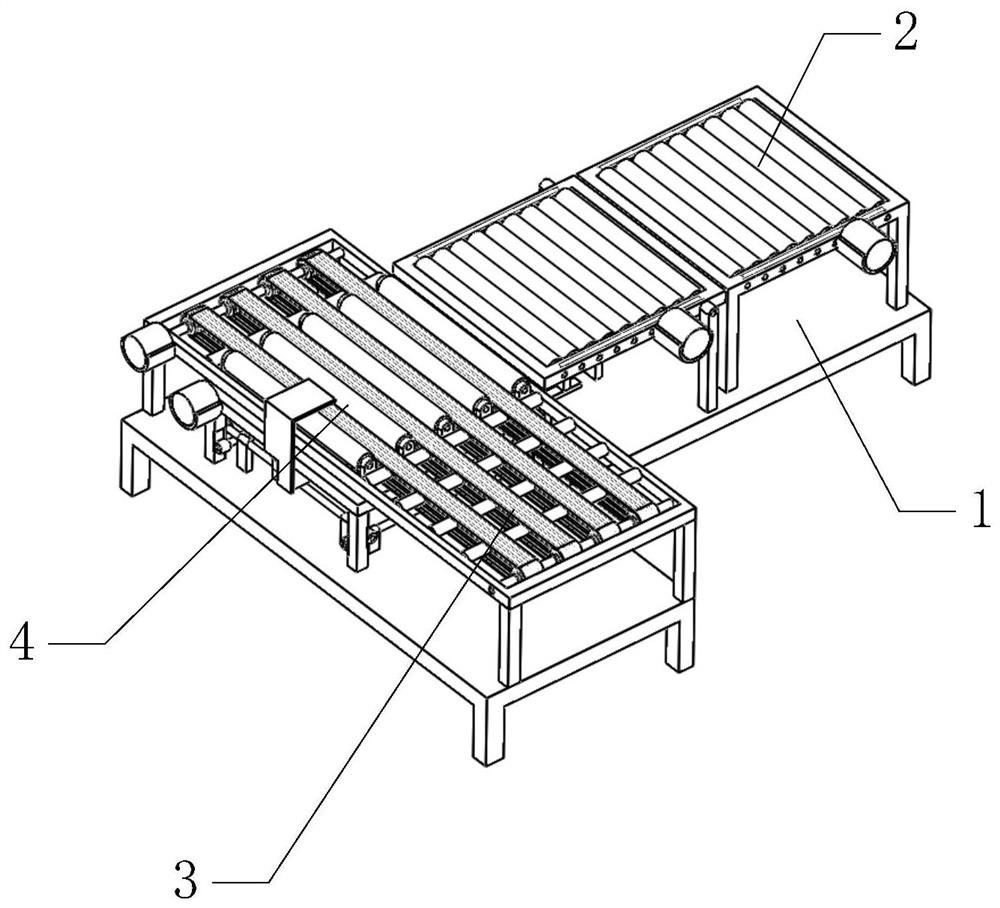

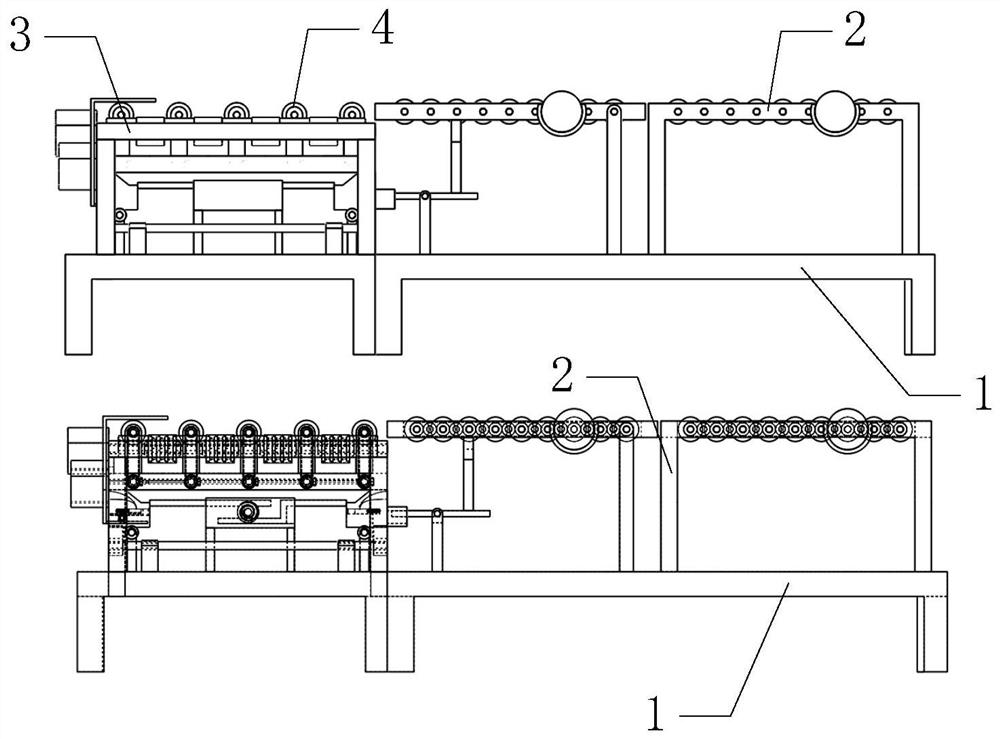

Corner conveying equipment for tile processing

A technology for conveying equipment and tiles, which is applied to conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of cumbersome operation and high cost, and achieve the effects of simple operation, removal of limit and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

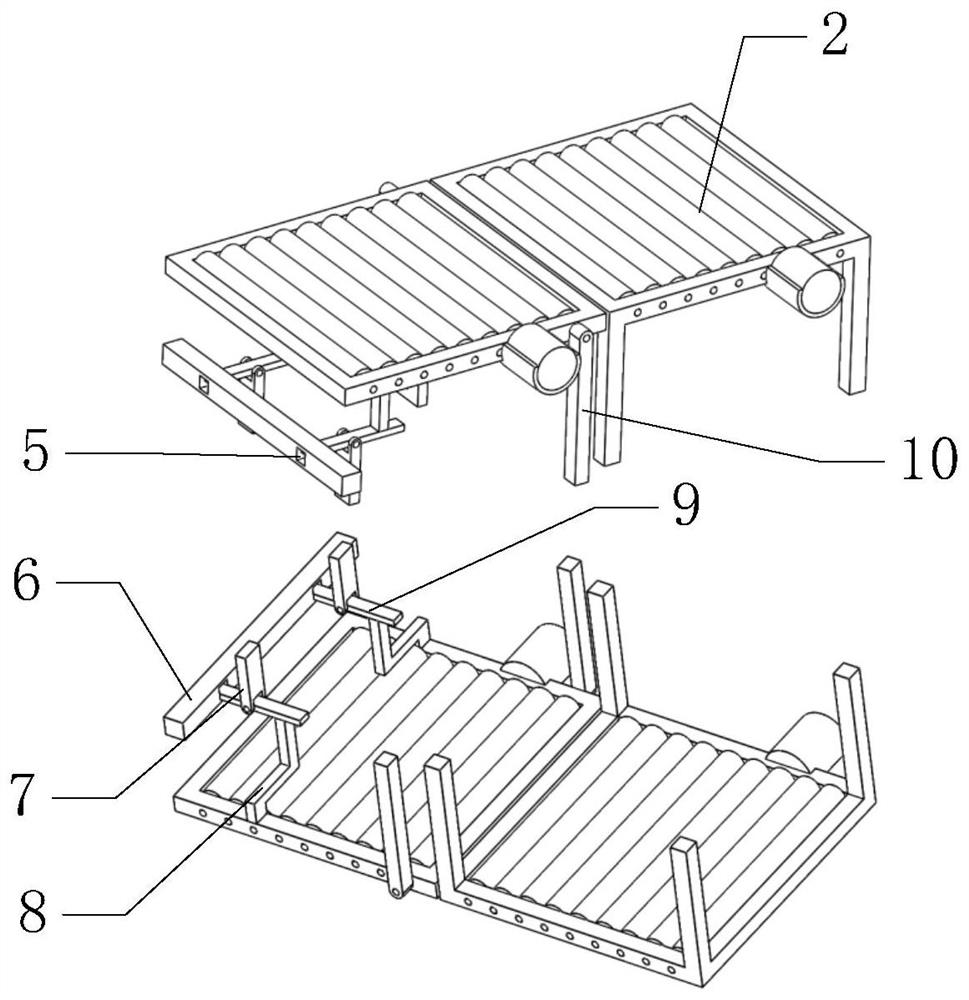

[0063] Embodiment: When using the equipment designed by the present invention, when no tiles are placed, the highest point of the first transmission mechanism 2 is higher than the highest point of the third transmission mechanism 4, and the highest point of the third transmission mechanism 4 is higher than the second transmission mechanism The highest point of the mechanism 3; the first limit rack 45 and the second limit rack 46 are located on the outside of the corresponding installation block 42 and contact the outer end surface of the installation block 42, and the scroll spring 48 is compressed; After the first transmission mechanism 2 of the three transmission mechanisms 4 is mounted, the first motor 11 in the first transmission mechanism 2 will drive the corresponding first installation shaft 14 to rotate, and the rotation of the first installation shaft 14 will be transmitted through the first gear 15. Drive the rest of the first installation shaft 14 to rotate together,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com