A double-station automatic tooth palm welding and process grinding equipment and welding method

A double-station, automatic technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low efficiency and great dependence on human skills, and achieve stable welding status, high production efficiency, and good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

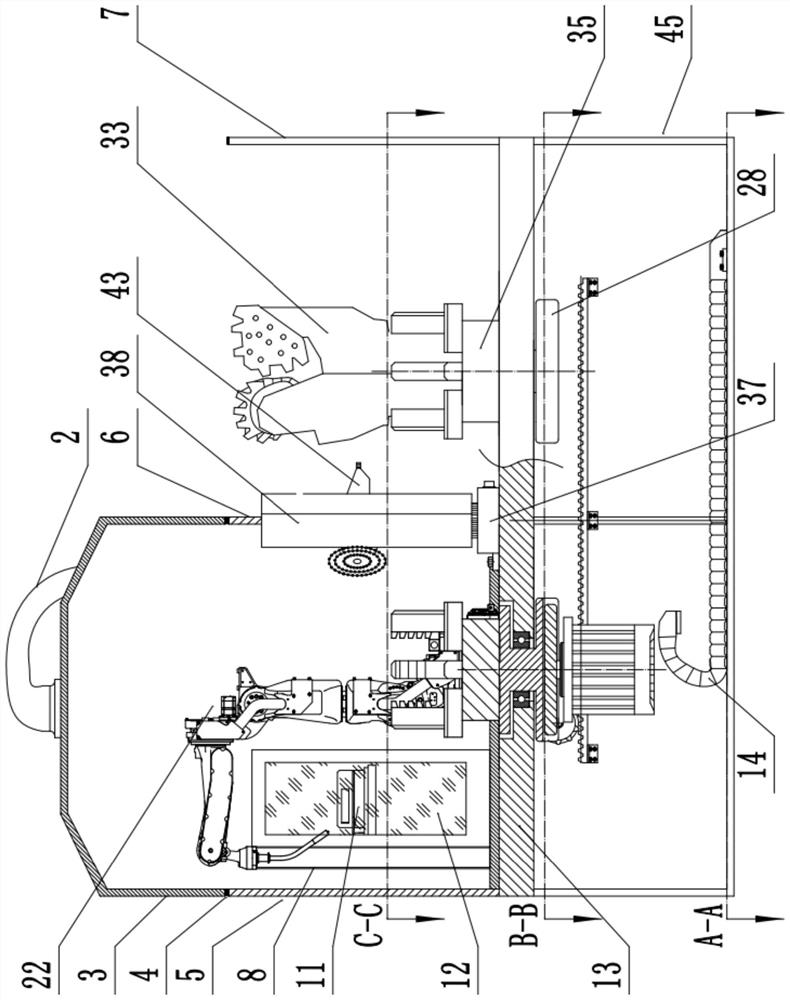

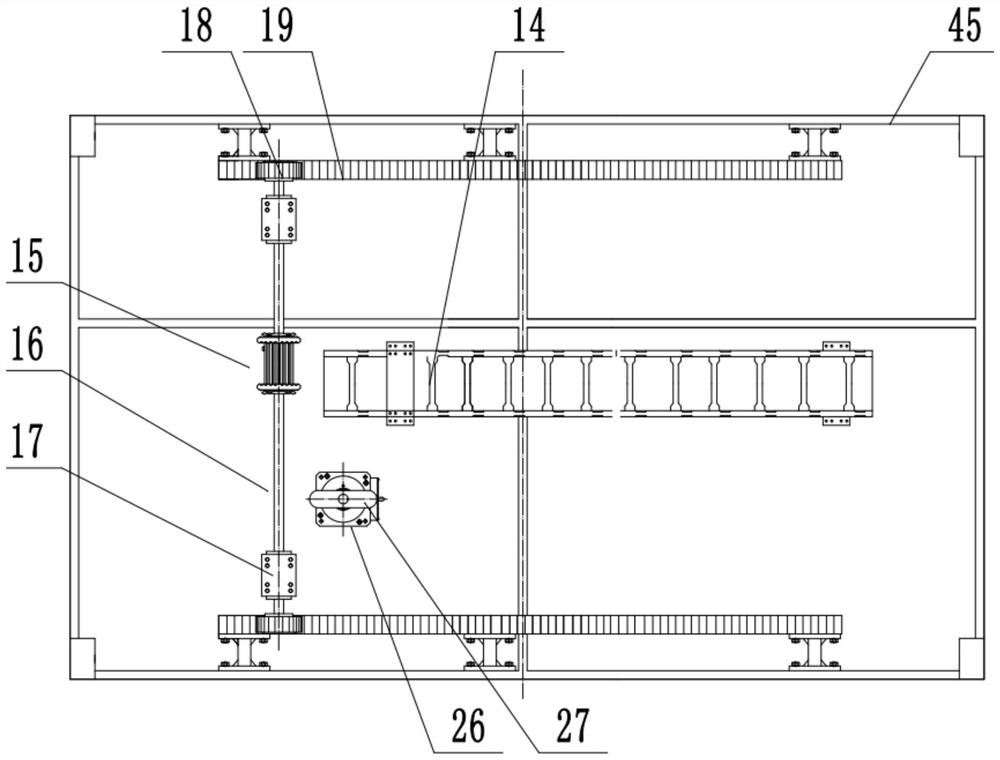

[0032] As a preferred embodiment 1, the translation drive motor (15) is a biaxial extension motor, and its motor shaft (16) passes through the connecting plate (17), and the connecting plate (17) is fixed on the bottom of the translation carriage (20). The LMF round flange linear bearing of SKF brand can be installed in the connecting plate (17), so that the connecting plate (17) can freely rotate around the motor shaft (16).

[0033] The relative movement of the gear (18) and the rack (19) is driven by the motor shaft (16), thereby driving the moving cover (3) to move. The rack (19) is fixed on the frame (45), and the gear (18) is driven by the motor shaft (16).

[0034] As a preferred embodiment two, the left fixed sealing plate (5), the middle fixed sealing plate (6), and the right fixed sealing plate (7) are fixed on the frame (45), and the mobile cover (3) can be connected with the left Fixed sealing plate (5), middle fixed sealing plate (6) forms the area of relative ...

specific Embodiment approach

[0044] For the welding method, in addition to the automatic welding of the weld seam, the surface can also be surfacing. If the welding consumables of the welding seam are different from the surfacing welding consumables, it is necessary to replace the welding consumables before continuing to weld. The specific implementation method is:

[0045] After completing the described butt weld seam welding, then carry out surface overlay welding along the circumference or palm surface formed by each of the palm sheets; the specific steps are:

[0046] K) The mobile cover (3) moves to the left side, forms a relatively closed area with the left fixed sealing plate (5) and the middle fixed sealing plate (6); the rotary motor (26) drives the left automatic chuck (31) to rotate;

[0047] L) the laser radar (11) is driven by the direct driver (10), and scans the drill bit (33) to be welded layer by layer from top to bottom or bottom to top;

[0048] M) the three-dimensional laser point cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com