Plasma metal inert gas arc welding method

An arc welding method and plasma metal technology, applied in the direction of plasma welding equipment, arc welding equipment, welding equipment, etc., can solve problems such as instability and detachment, and achieve the effect of stable welding state and high-precision preheating state change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

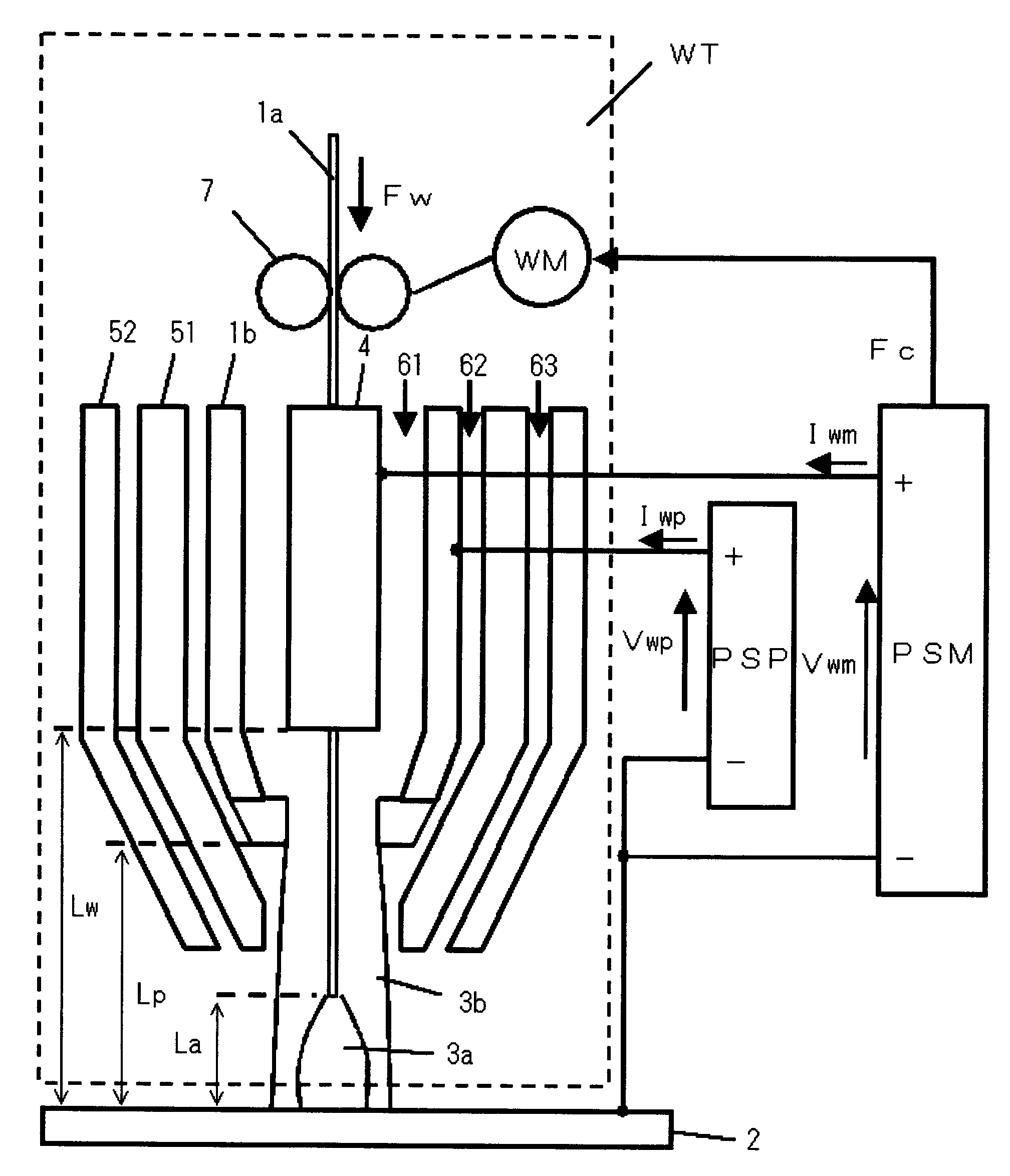

[0103] figure 1 It is a configuration diagram of a welding apparatus for carrying out the plasma metal inert gas arc welding method according to Embodiment 1 of the present invention. Hereinafter, each constituent will be described with reference to the same drawing.

[0104] This welding apparatus includes a welding torch WT surrounded by a dotted line, a metal inert gas arc welding power source PSM, and a plasma welding power source PSP. The welding torch WT has a structure in which the plasma nozzle 51 , the plasma electrode 1 b , and the power supply chip 4 are arranged concentrically within the shielding gas nozzle 52 . A shielding gas 63 such as argon or a mixed gas of argon and carbon dioxide is supplied from a gap between the shielding gas nozzle 52 and the plasma nozzle 51 . Between the plasma nozzle 51 and the plasma electrode 1b, a plasma gas 62 such as argon gas or a mixed gas of argon gas and carbon dioxide is supplied. Between the plasma electrode 1 b and the...

Embodiment approach 2

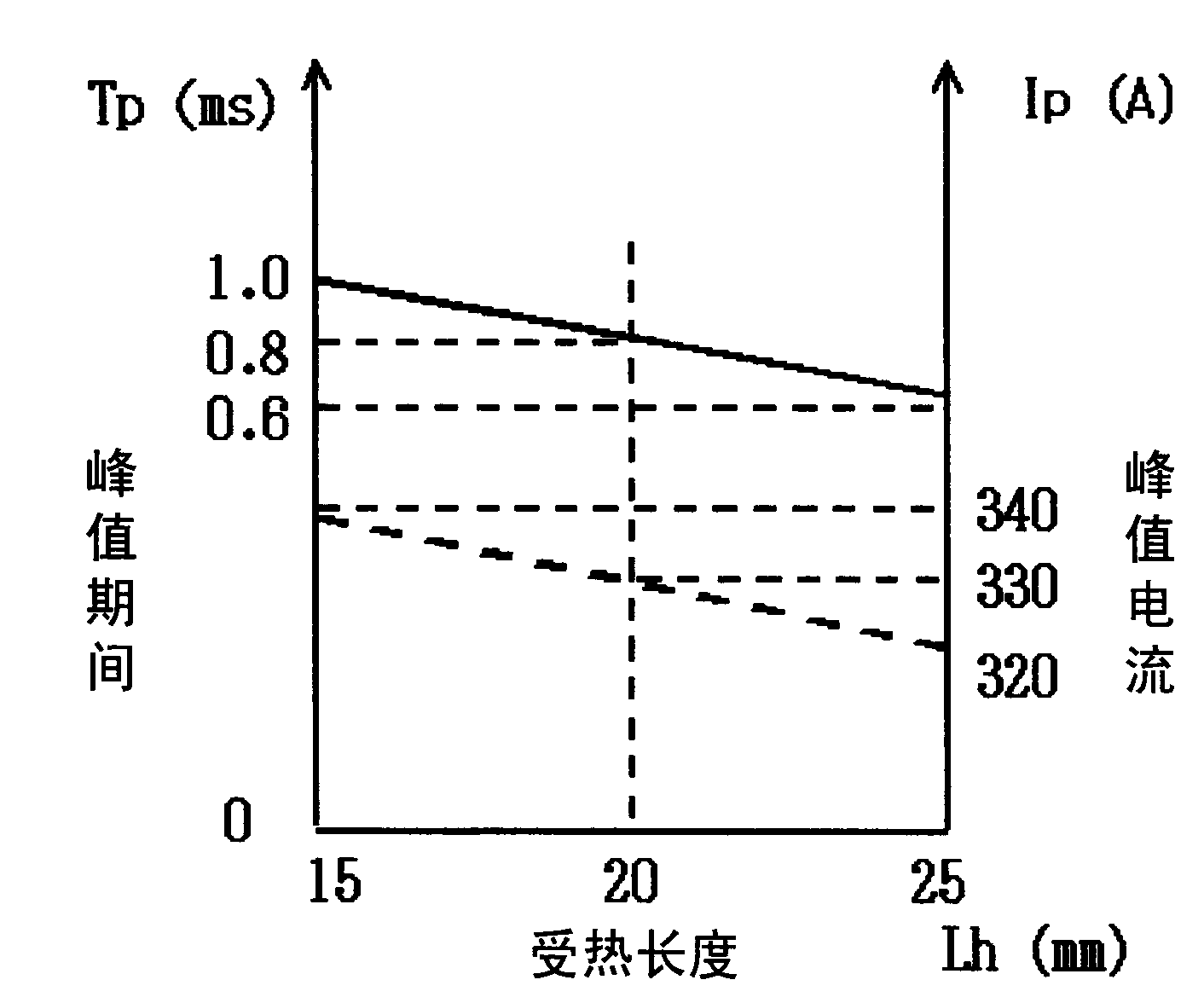

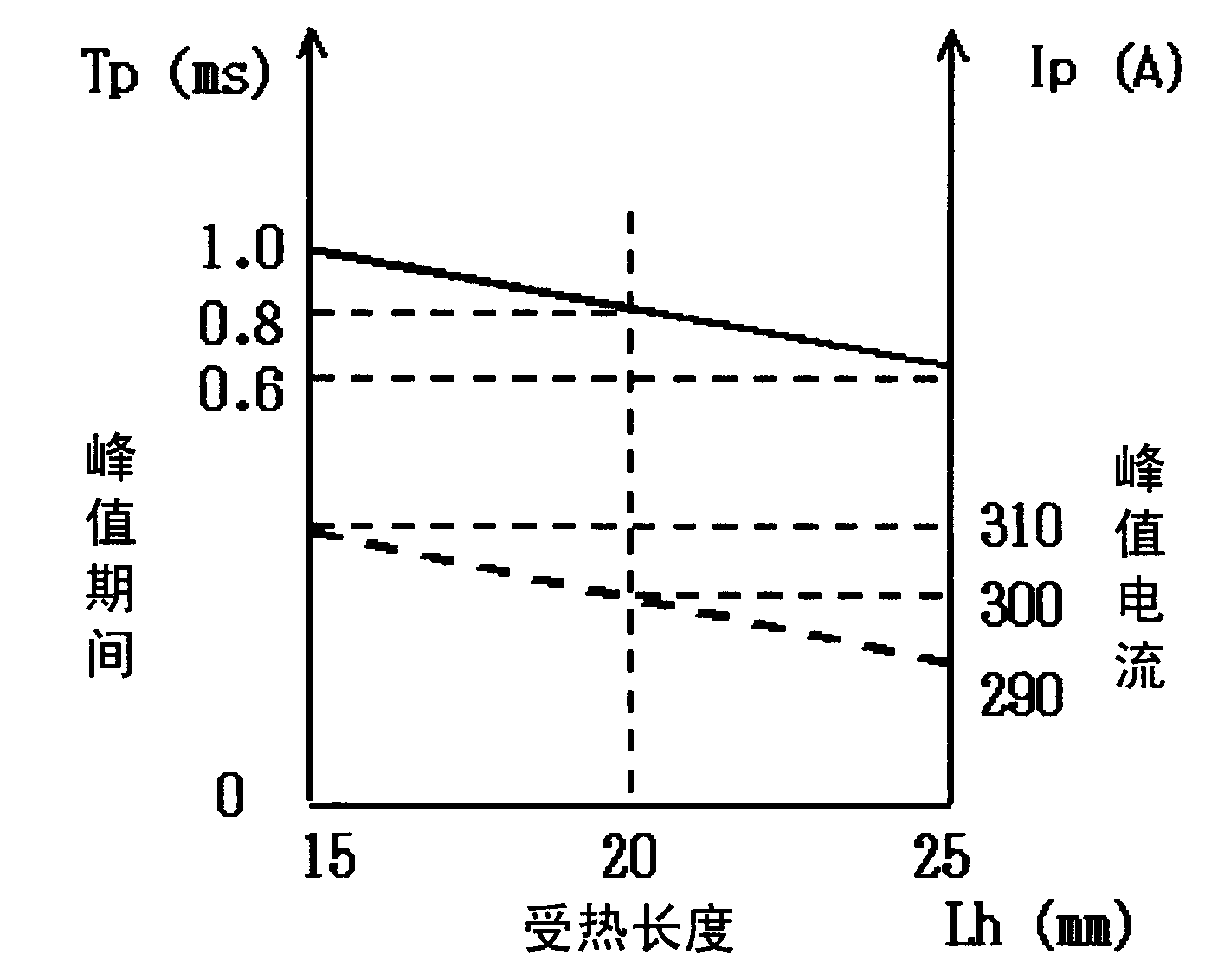

[0140] Embodiment 2 of the present invention is a case where the heated length Lh=Lp-La. Here, as described above, Lp is the distance between the tip of the plasma electrode and the base material, and La is the arc length of the metal inert gas arc. The detection method of the distance Lp between the tip of the plasma electrode and the base material is the same as that of the first embodiment. As a method of setting the arc length La, there are three methods shown below.

[0141] (1) When the arc length La is preset

[0142] An appropriate range of the arc length La for good welding is about 3 to 5 mm. Therefore, the arc length La is set to a preset constant (for example, 4 mm). In this way, although there is an error of about 1 mm from the actual arc length La, an error of this magnitude has little influence on the calculated value of the heated length Lh. If this method is used, there is an advantage that the calculation method of the heated length Lh is simple.

[0143...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com