Forward and reverse feed AC arc welding method

A technology of AC arc and welding method, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., and can solve problems such as unstable welding status and changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

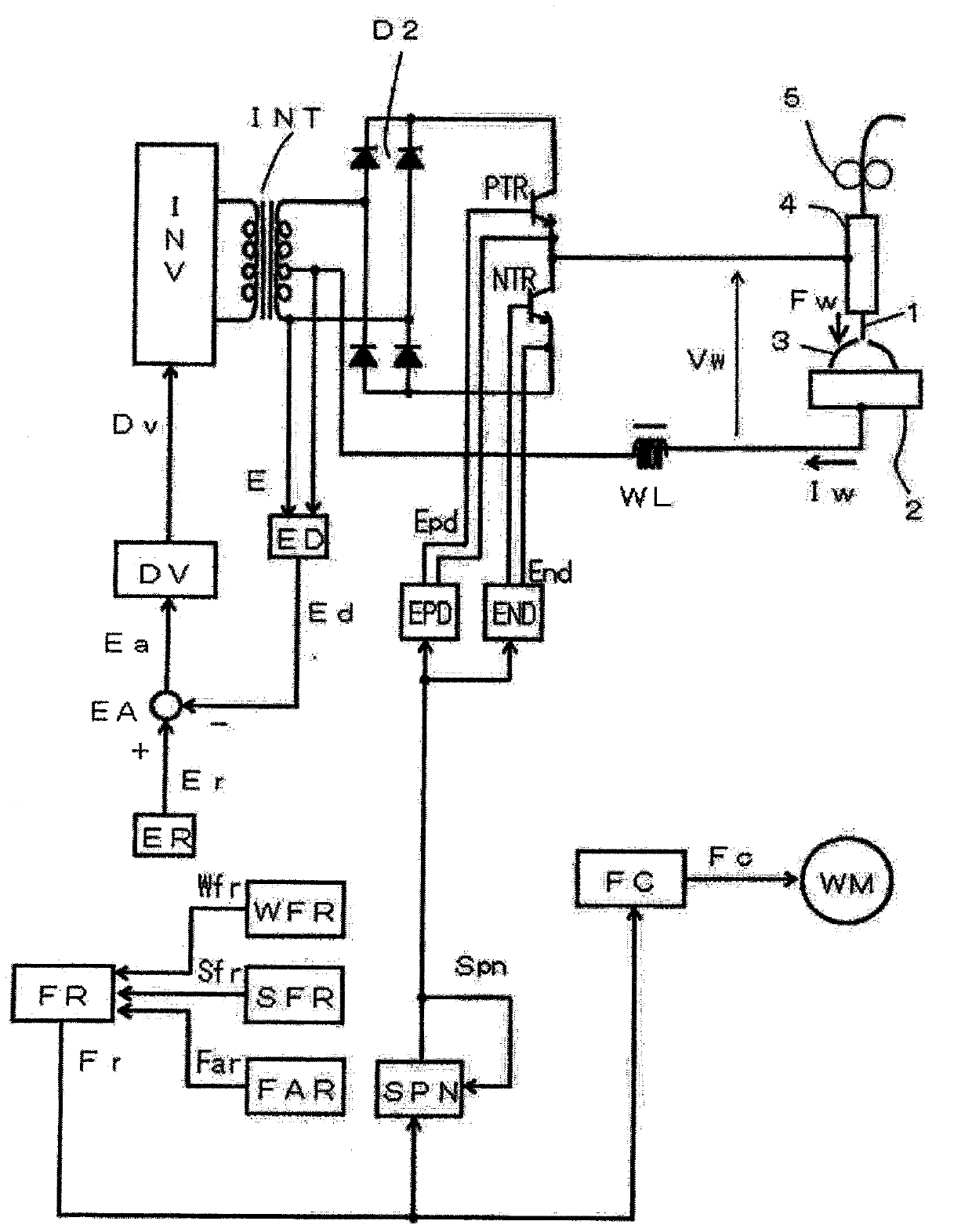

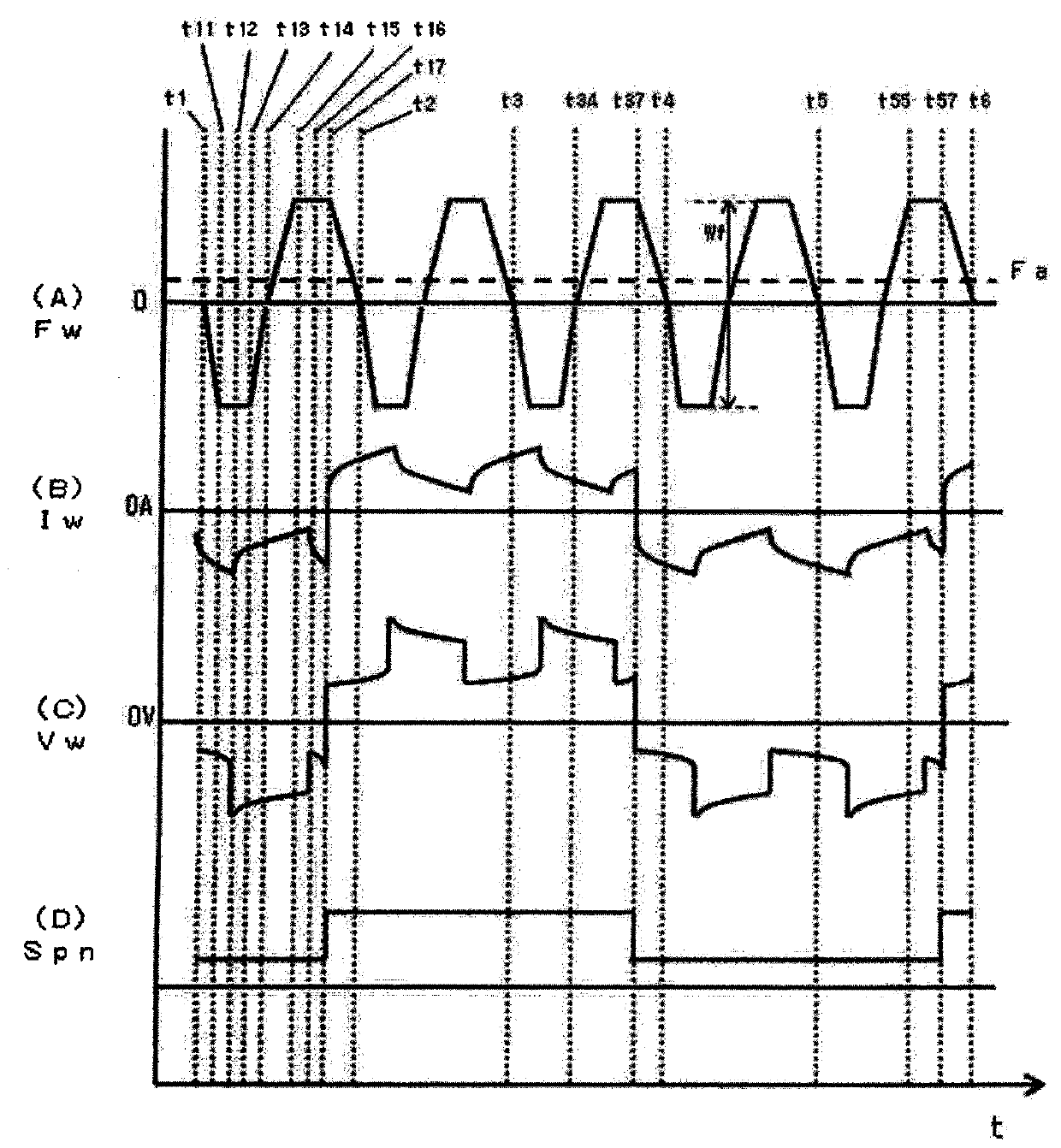

[0064] figure 1 It is a block diagram of a welding device for carrying out the forward and reverse feed AC arc welding method according to Embodiment 1 of the present invention. The following reference figure 1 to illustrate the blocks.

[0065] The inverter circuit INV takes a 3-phase 200V AC commercial power supply (not shown) as an input, rectifies and smoothes the AC commercial power supply to generate a DC voltage, and performs inverter control on the DC voltage according to a drive signal Dv described later. , thus outputting high-frequency AC.

[0066] The high-frequency transformer INT changes the high-frequency AC into a voltage value suitable for welding. The secondary rectifier group D2 rectifies the converted high-frequency AC, and outputs positive and negative DC voltages.

[0067] The output polarity of the welding device is switched by ON / OFF control of the electrode positive polarity switching element PTR and the electrode negative polarity switching elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com