Arc striking control method for double-electrode electric arc welding

A technology of arc welding and control method, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc. It can solve the problems of shallow penetration, poor edge of weld bead, and decline of mechanical properties of welding parts, so as to maintain welding state, penetration and Appropriate cross-section shape of weld bead and the effect of stable welding state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

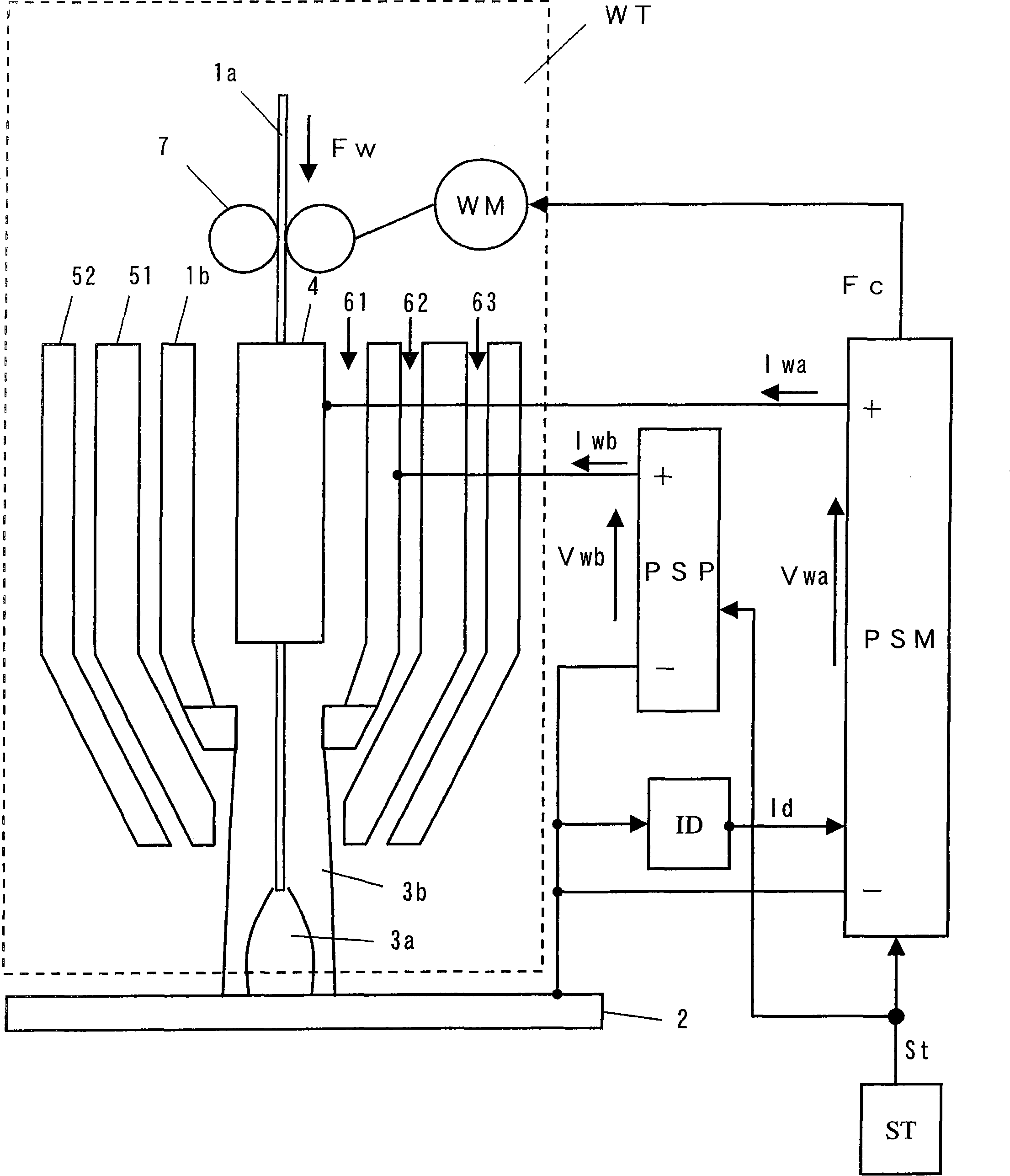

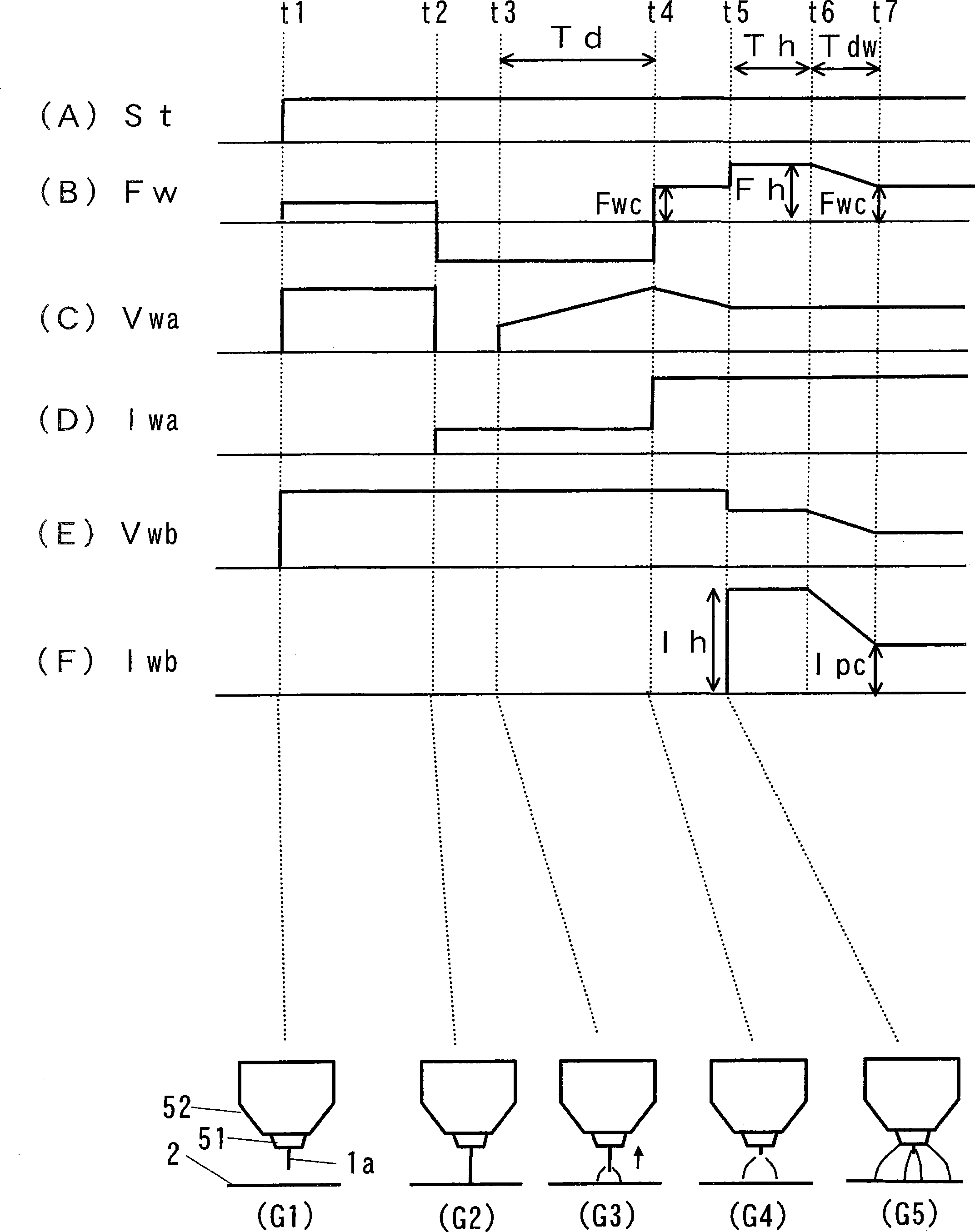

[0035] figure 1 It is a configuration diagram of a welding device for implementing the arc start control method of two-electrode arc welding according to the first embodiment of the present invention. This figure is similar to the above Figure 4 Correspondingly, for the same components, the same symbols are given, and no more details are given. The graph is in Figure 4 Add current detection circuit ID. Furthermore, the following uses figure 2 Describe the program control of the melting electrode arc welding power supply PSM and the non-melting electrode arc welding power supply PSP shown in the figure. Figure 5 different.

[0036] After the current detection circuit ID detects the non-melting electrode arc welding current Iwb, the current detection signal Id is input to the melting electrode arc welding power source PSM. The reason for this is as follows figure 2 This is for synchronizing the non-melting electrode arc welding current Iwb with the feeding speed Fw of...

no. 2 Embodiment approach

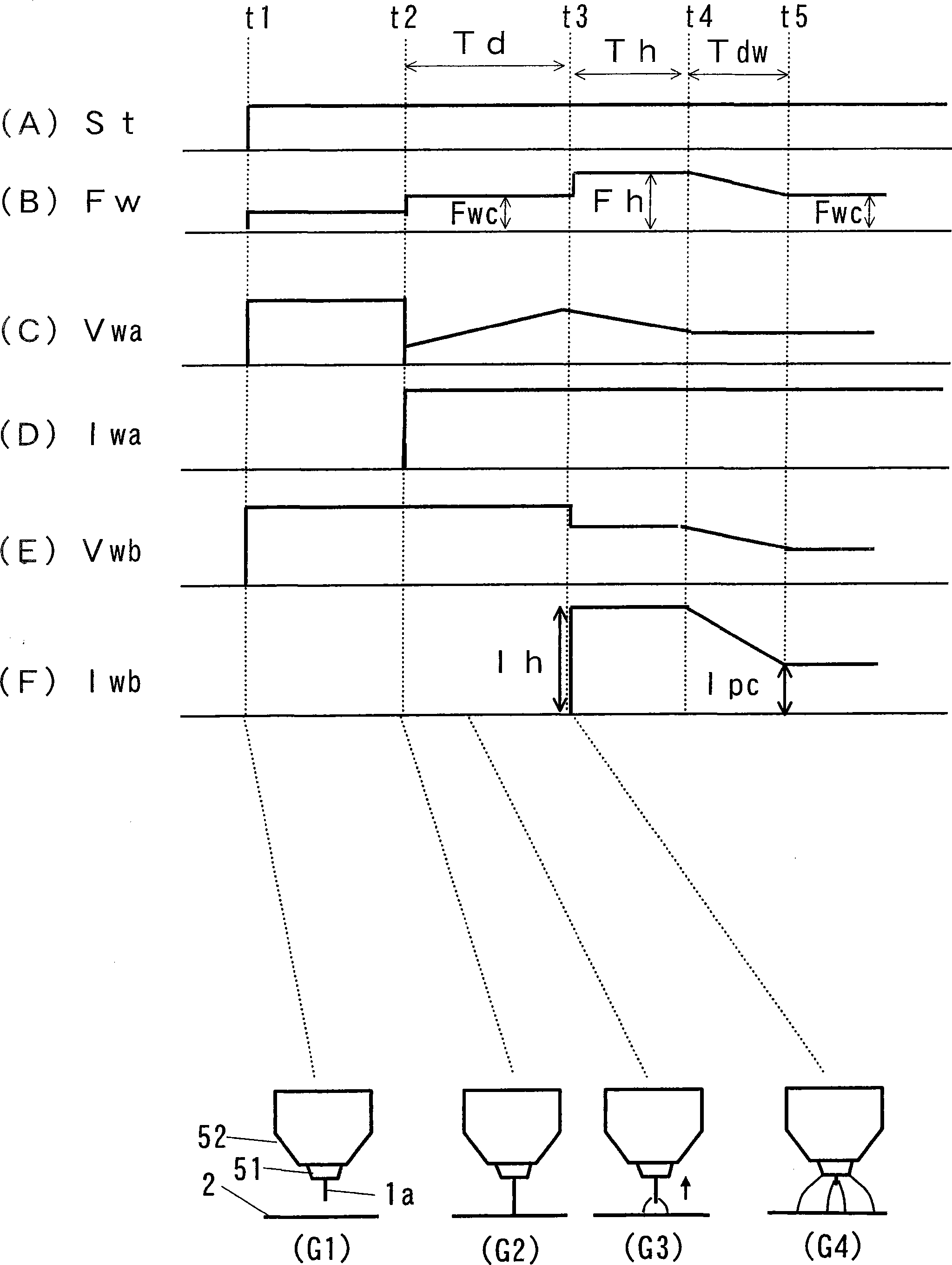

[0048] The second embodiment of the present invention differs from the first embodiment in the method of generating a melting electrode arc. That is, in the first embodiment, as in the period from time t2 to time t4 in Fig. (2), the welding wire is moved back and the melting electrode arc is generated. On the other hand, in the second embodiment, the arc is generated by advancing and feeding the welding wire in the same manner as the normal arc starting method in the metal electrode arc welding. Next, an arc start control method for two-electrode arc welding according to the second embodiment will be described.

[0049] The welding apparatus for implementing the arc start control method of two-electrode arc welding according to the second embodiment is the same as the above-mentioned figure 1 Same. However, the program control of the melting electrode arc welding power source PSM and the non-melting electrode arc welding power source PSP is different from that of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com