Quick automatic refrigeration aerated drink cup

A beverage cup and standard technology, applied in beverage preparation devices, household utensils, food science, etc., can solve problems such as unstable material supply and influence on gas production effect, achieve convenient operation, prevent dew condensation, and increase storage time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

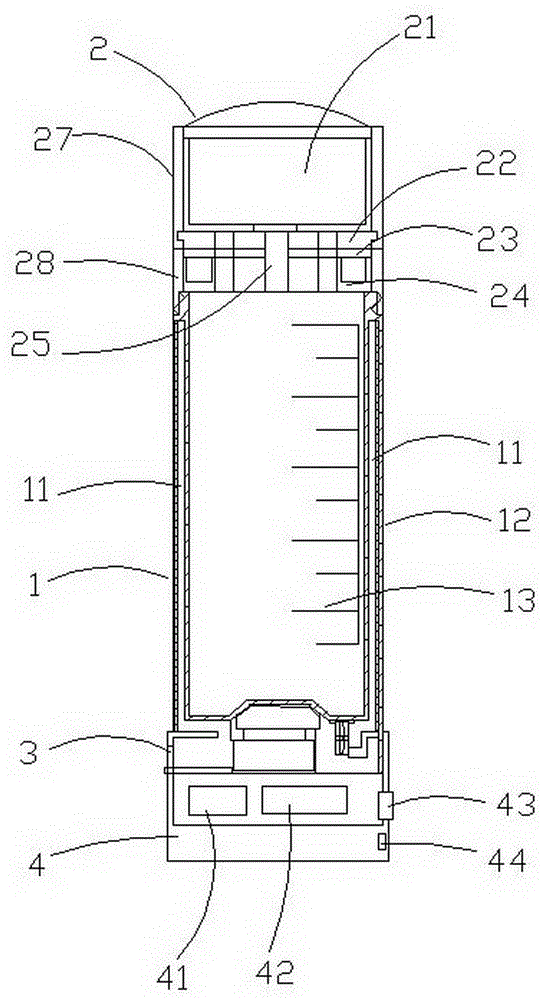

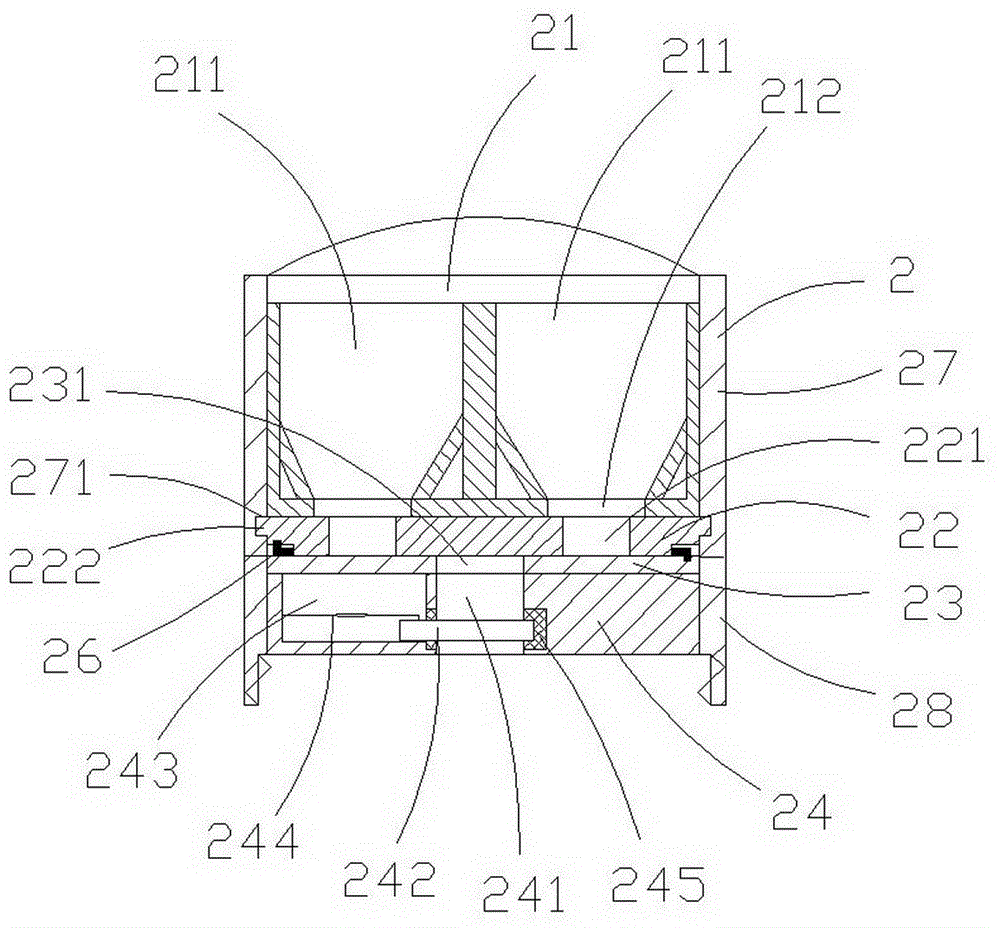

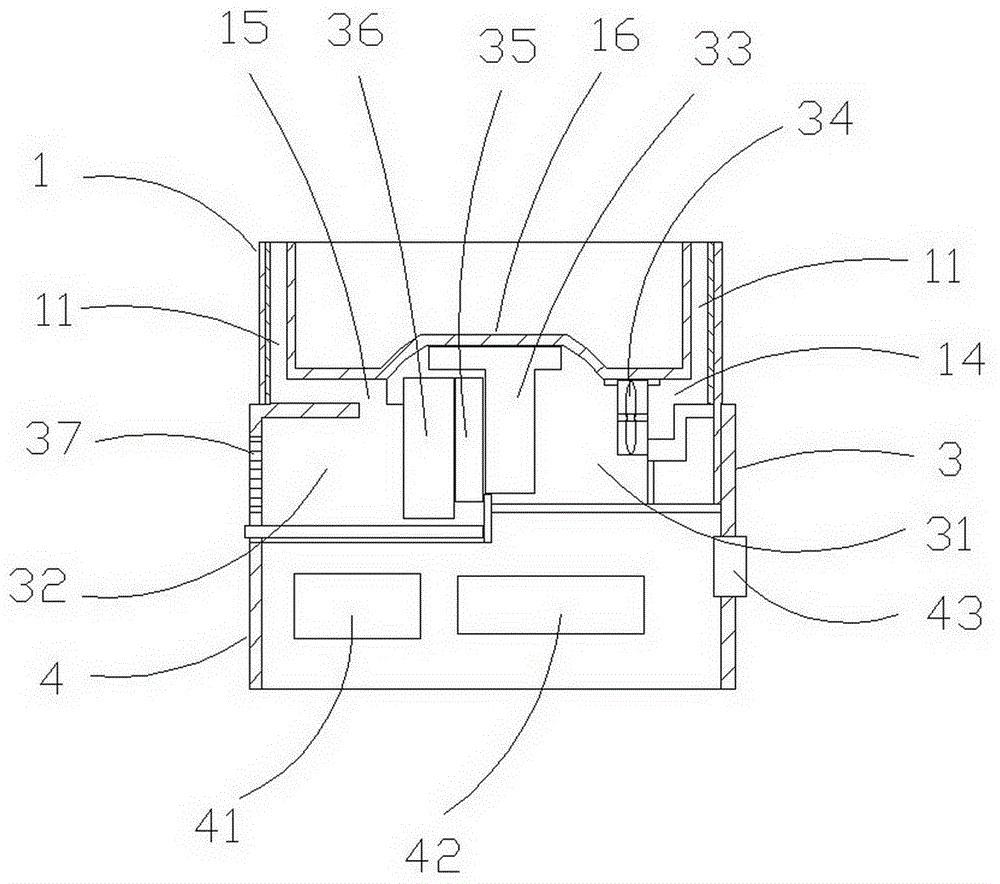

[0018] Such as figure 1 As shown, a quick-run automatic refrigeration gas-producing beverage cup includes a cup body 1, a steam-making mechanism 2, and a refrigeration device 3. The opening of the cup body is provided with a steam-making mechanism 2, and the outer shell of the steam-making mechanism 2 is formed The upper part 27 and the lower part 28 are movably connected, and the upper part 27 of the steam making mechanism 2 can rotate. The inner cavity of the upper part 27 is provided with a storage bin 21 and a metering plate 22, and the inner cavity of the lower part 28 of the steam-making mechanism is provided with a partition 23 and a discharge tray 24, and the lower part 28 of the steam-making mechanism is detachable from the opening of the cup body. threaded connection. The storage bin 21 and the metering disc 22 at the upper part of the steam making mechanism are connected with the dividing plate 23 and the discharge disc 24 at the lower part by the mandrel 25 in seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com