Short circuit determination method for electrode fused arc welding

A technology of arc welding and melting electrodes, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of small judgment margin and misjudgment, and achieve the goal of preventing misjudgment, stabilizing welding state, and high-quality welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

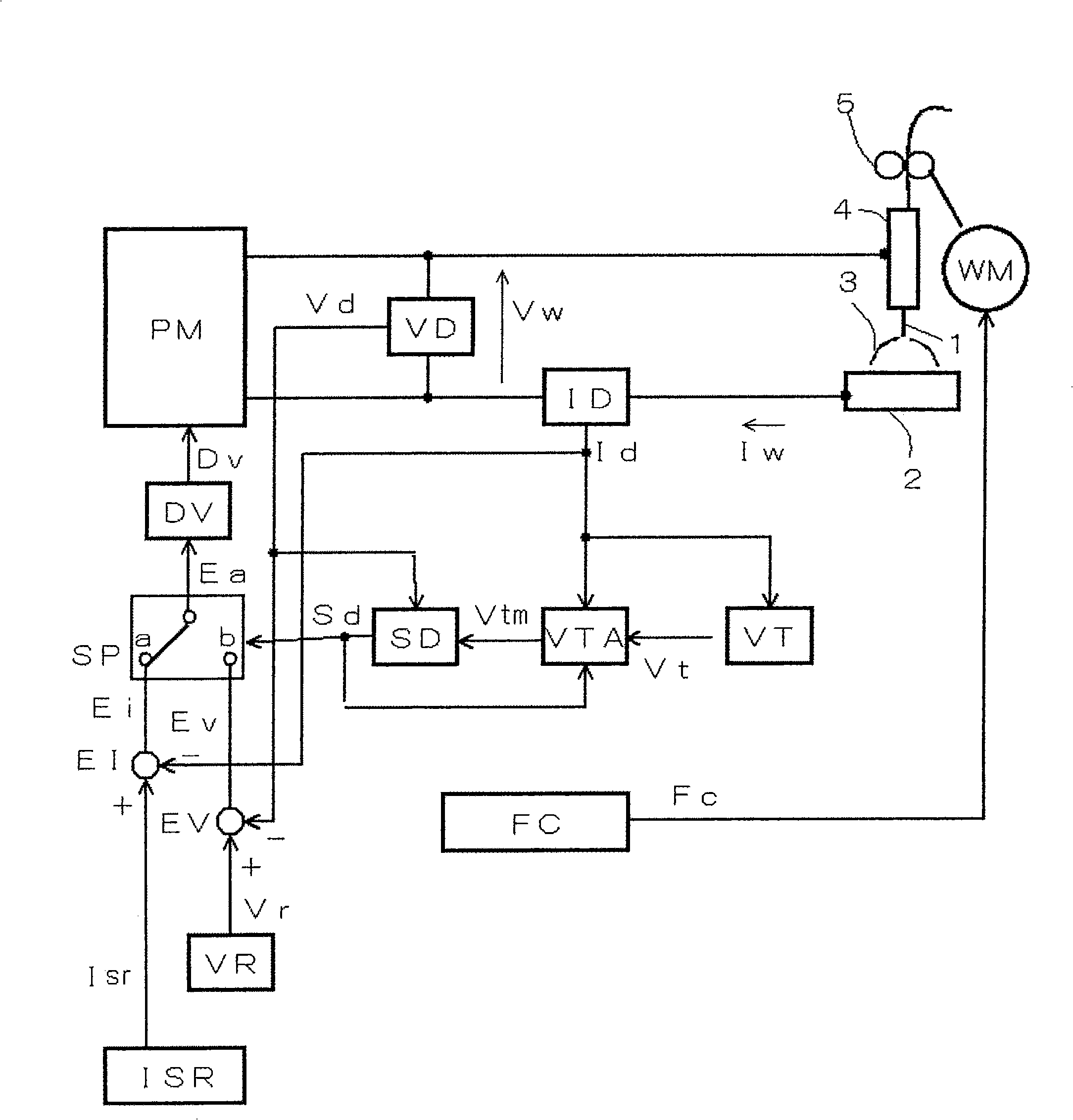

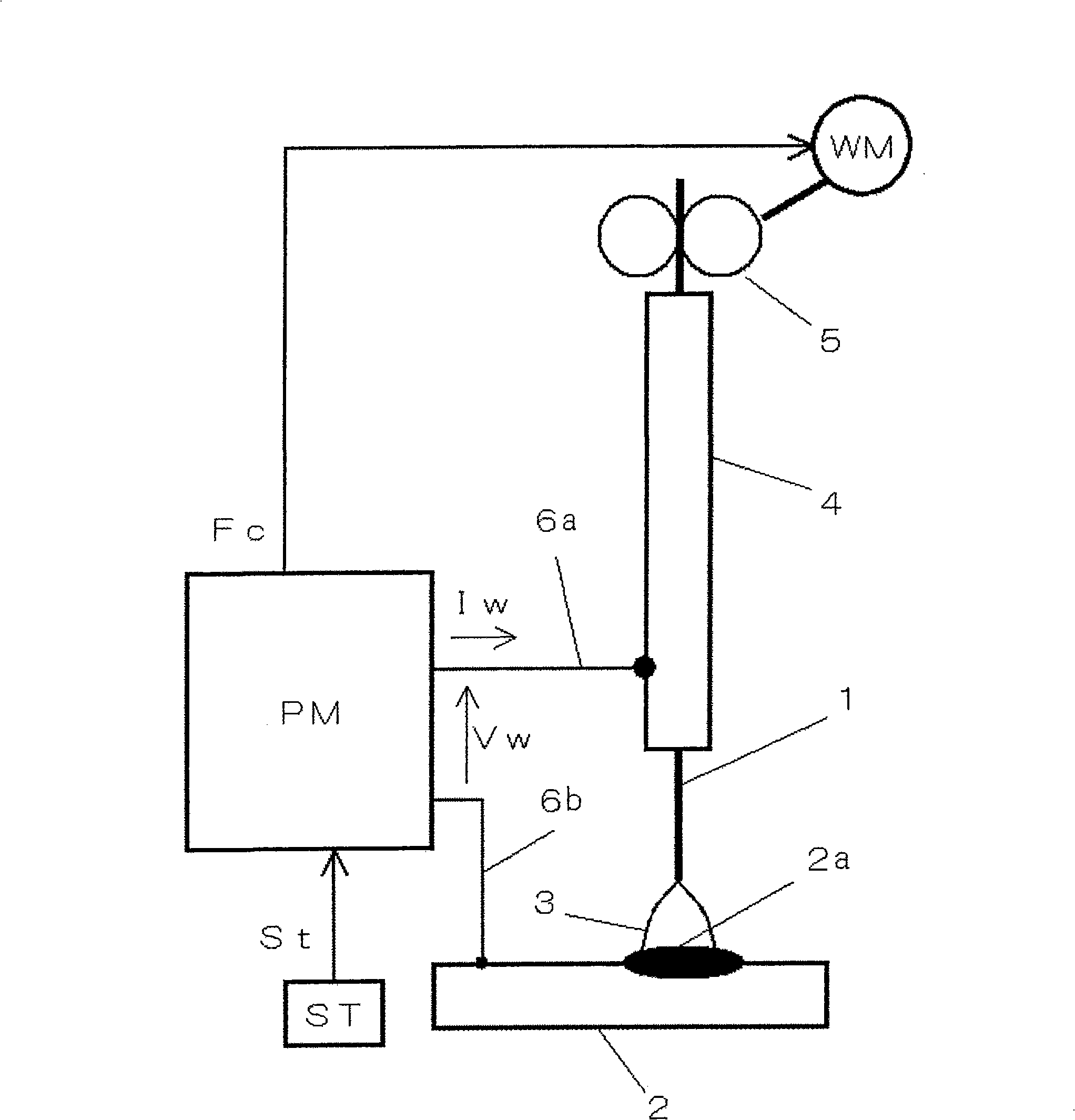

[0081] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

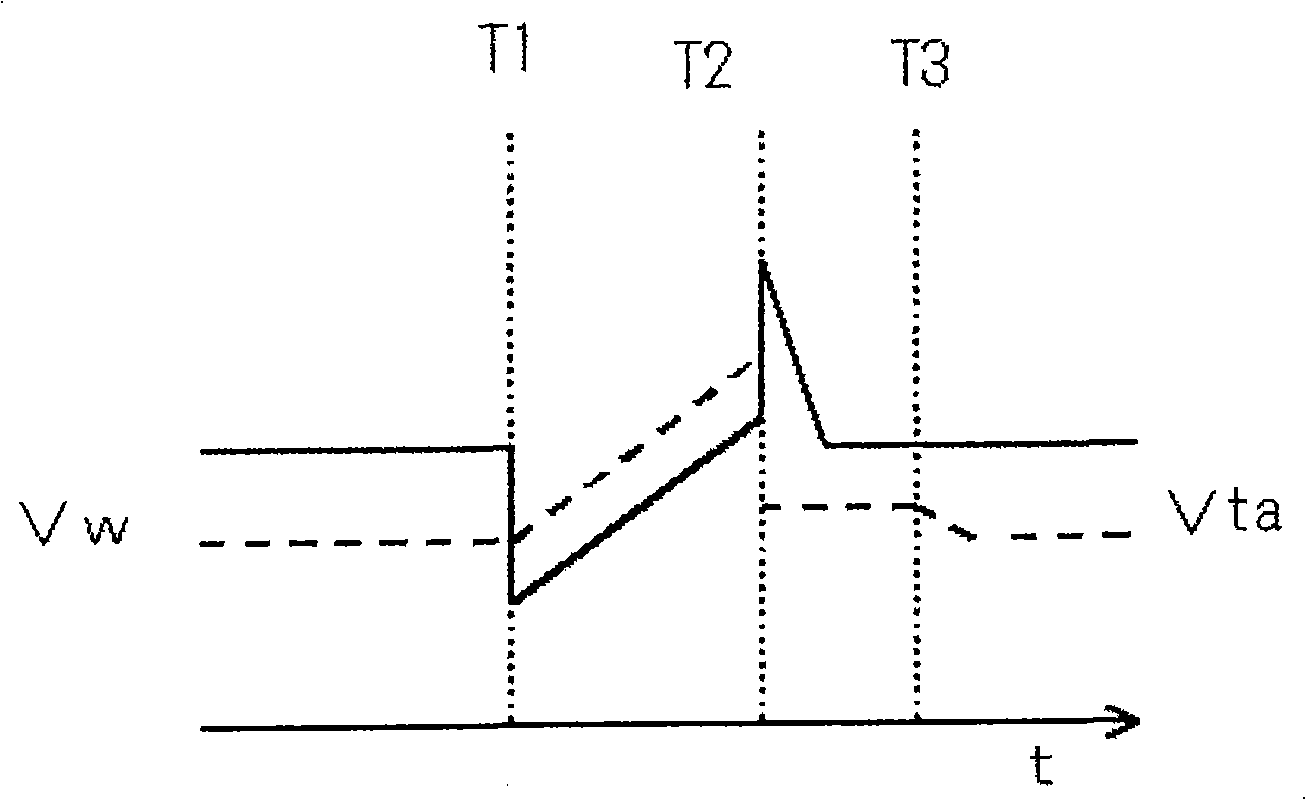

[0082] figure 1 It is a waveform diagram showing the welding voltage Vw of the short-circuit judging method of the molten electrode arc welding according to the embodiment of the present invention. In the figure, the solid line represents the welding voltage Vw, and the dotted line represents the short-circuit reference value Vt. This figure is similar to the above Figure 5 Correspondingly, it is a case where the resistance value (Rc+Rx+Rp) is large. In this figure, the short-circuit period Ts from time t1 to t2 can correctly determine the short-circuit state by the conventional short-circuit determination method, so the operation during this period is the same as that of Figure 5 same. Hereinafter, with reference to this figure, the sum after time t2 Figure 5 Describe the different actions.

[0083] The short-circuit reference value Vt is set by the above for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com