Patents

Literature

64results about How to "Quick position adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

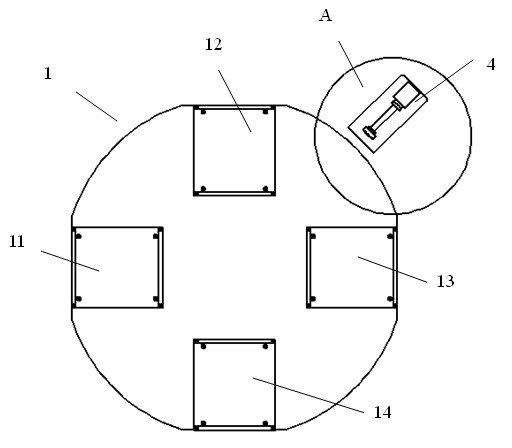

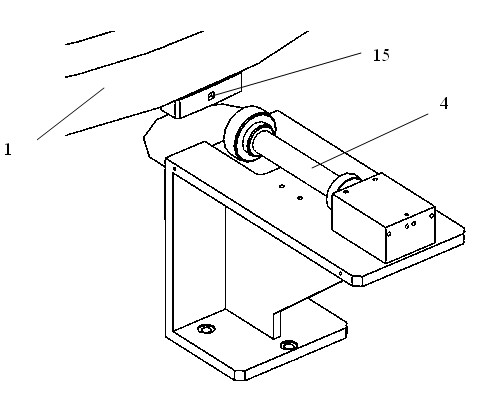

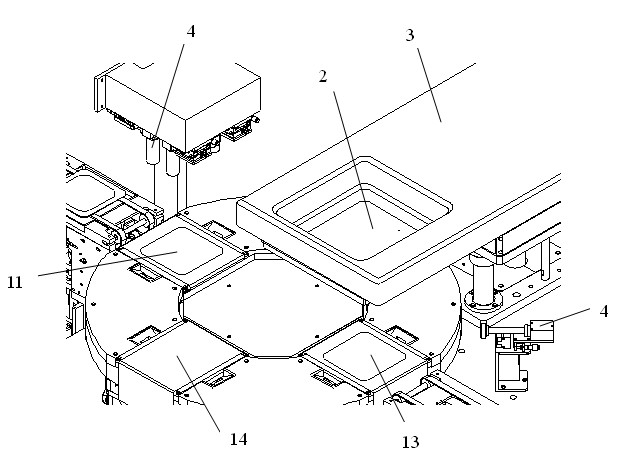

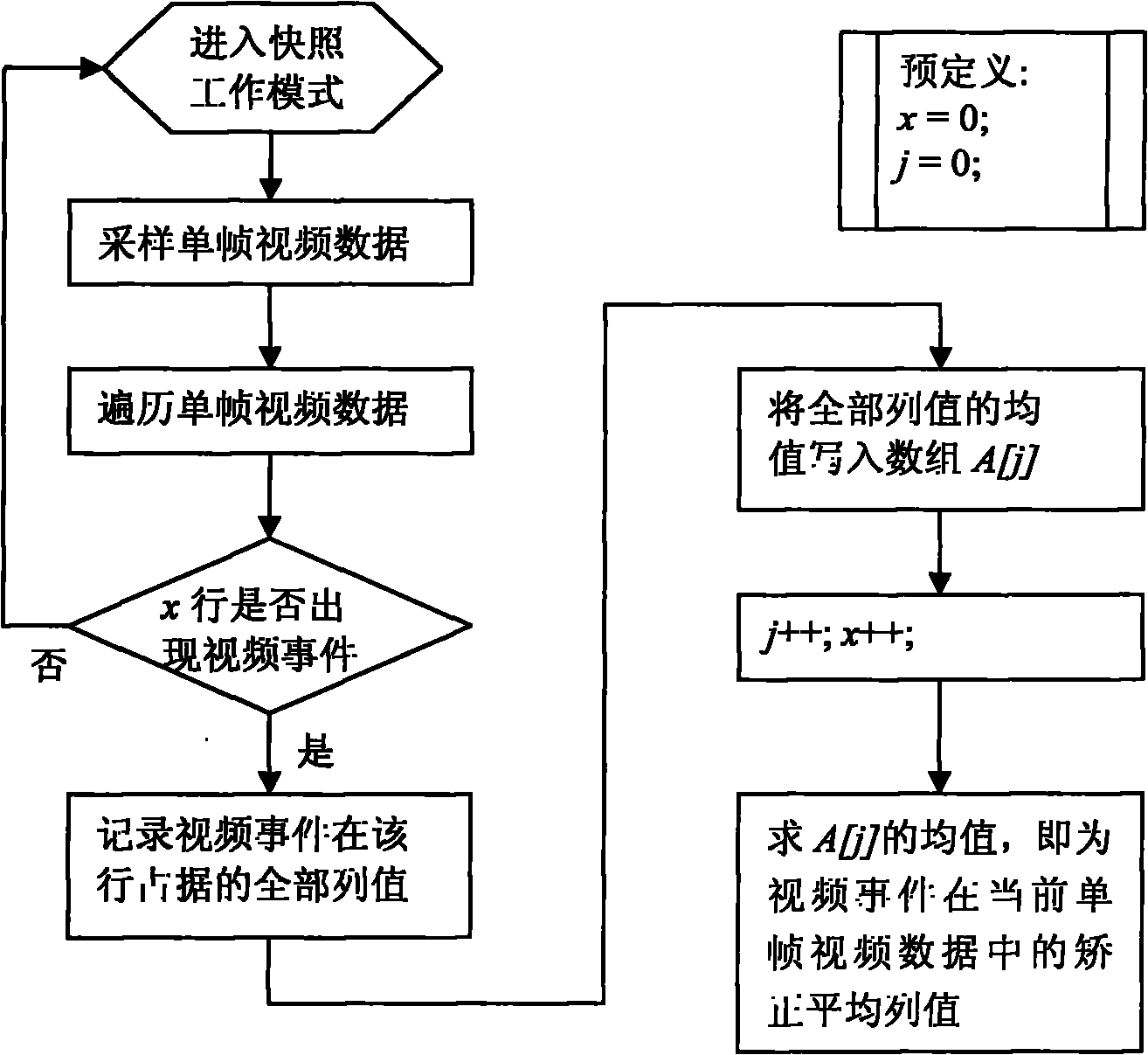

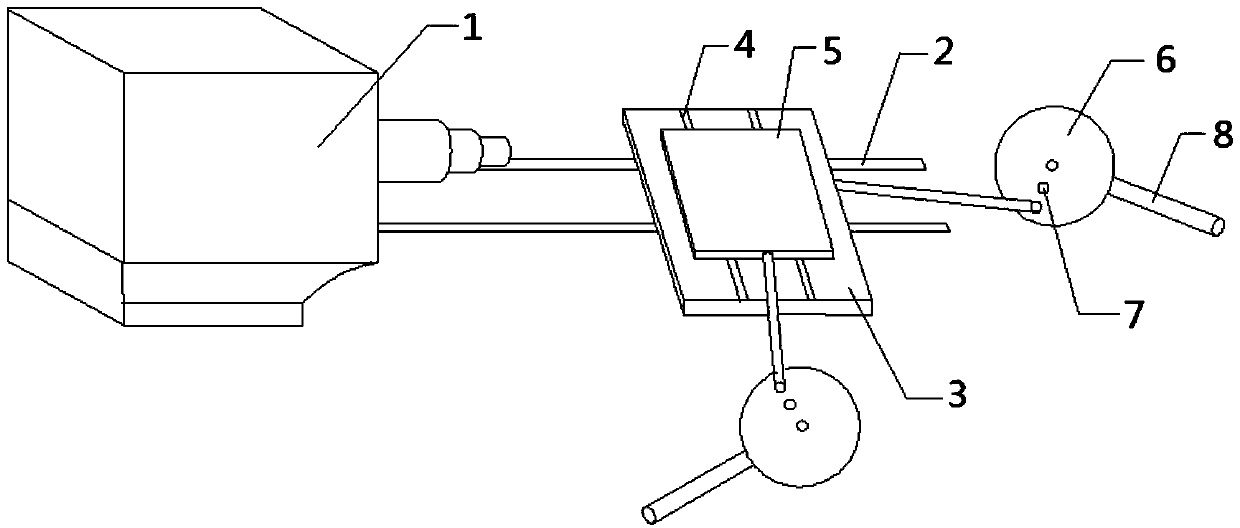

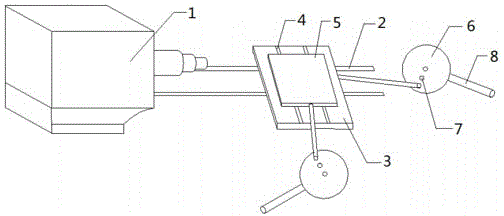

Printing deviation measuring method, printing method and printing device for solar cell plate

ActiveCN102001242AHigh precisionQuick position adjustmentScreen printersUsing optical meansEngineeringSolar cell

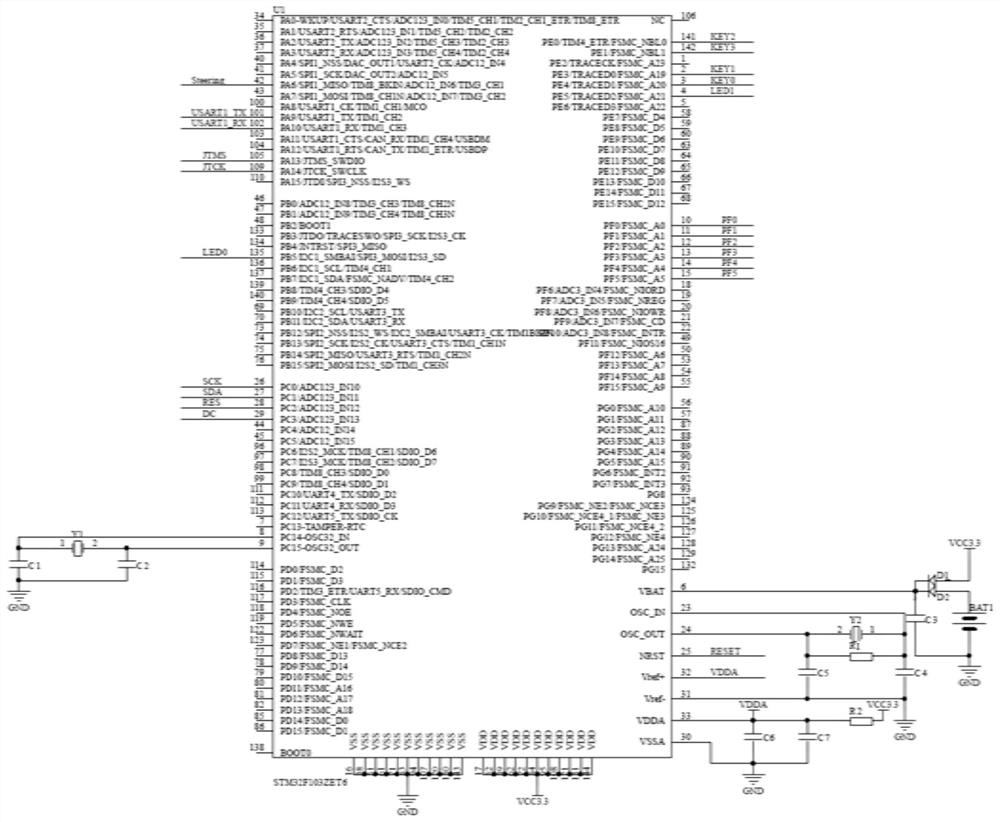

The invention relates to a printing deviation measuring method, a printing method and a printing device for a solar cell plate. The deviation measuring method comprises the following steps of: A. measuring the actual position P1' of the solar cell plate at a waiting station after plate feeding, and calculating the position deviation delta P1 of the solar cell plate according to a preset position P1 of the solar cell plate; B. measuring the actual position M' of one station of a rotating work table at the waiting station and the actual position N' of the rotating work table after the rotating work table rotates to a printing station, and calculating the position deviation delta M and delta N of the station respectively on the waiting station and the printing station by combining the actual positions M' and N' with the preset position M of the waiting station and the preset position N of the printing station; and C. calculating the integrated position deviation delta P of the solar cell plate according to the position deviations delta P1, delta M and delta N in the step A and the step B. The invention regulates the position of a printing screen of the printing device according to the integrated position deviation delta P so that the positions of the printing screen and the solar cell plate are sufficiently coincided, thereby outstandingly enhancing the accuracy of final printing.

Owner:SUZHOU MAXWELL TECH CO LTD

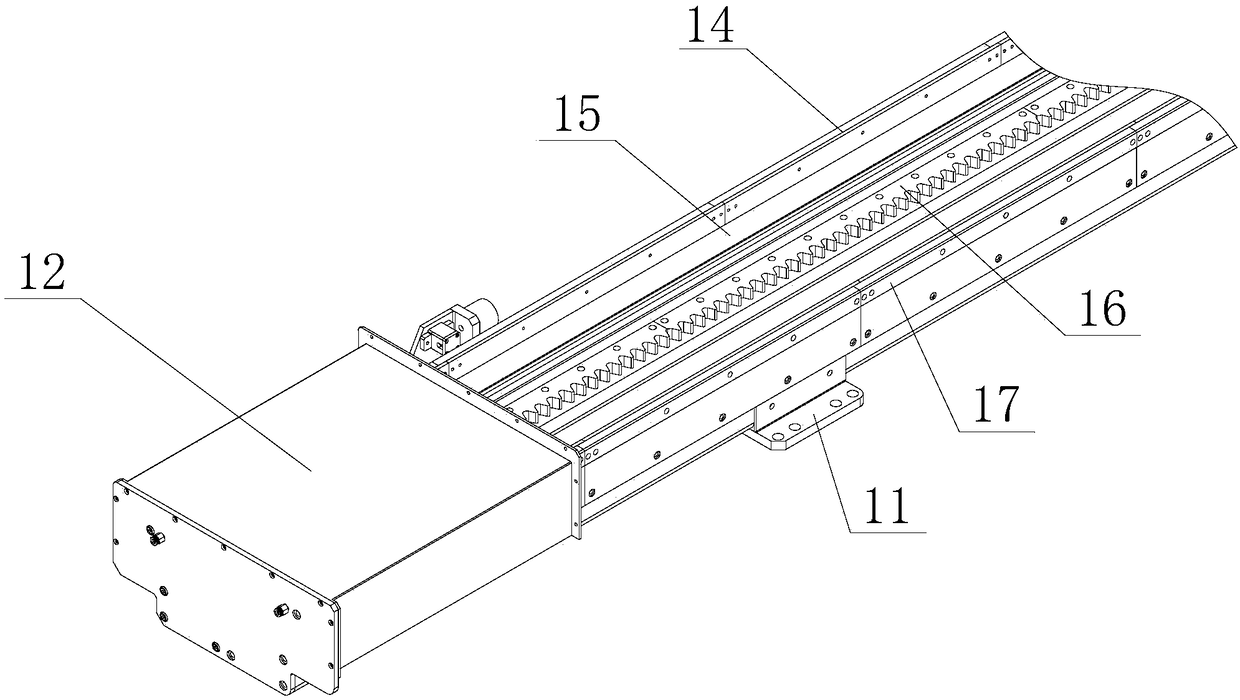

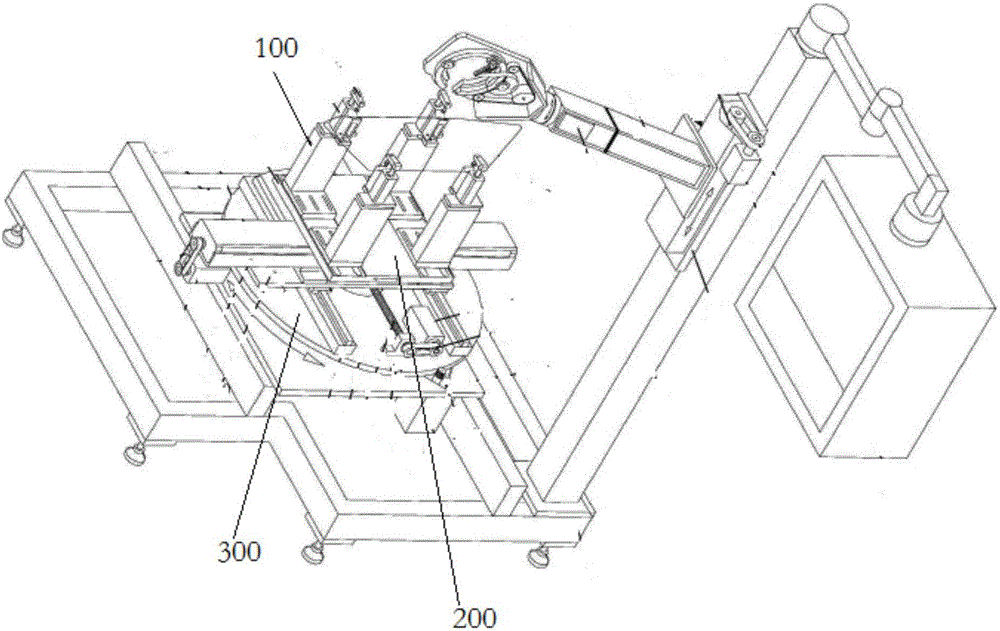

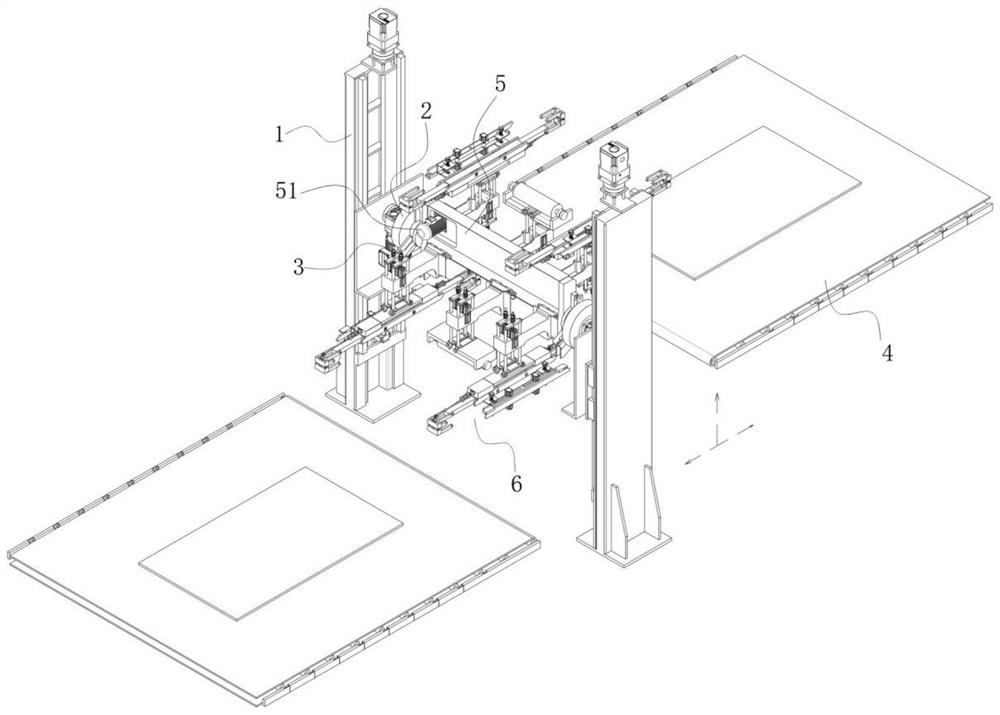

Spraying robot used for spraying large-dimension workpiece

PendingCN108406806ALarge working spaceSatisfy the spraying jobSpraying apparatusManipulatorEngineeringDrive motor

The invention provides a spraying robot used for spraying a large-dimension workpiece. The spraying robot comprises a position regulating device and a mechanical arm, wherein the mechanical arm is mounted on the position regulating device; the position of the mechanical arm is regulated by regulating the position regulating device; the position regulating device comprises an X-axis mobile platform; the X-axis mobile platform comprises a mobile guide rail and an X-axis slide block; a first drive motor is arranged above the X-axis slide block; the first drive motor is connected with a gear through a rotary shaft; the gear connected with the first drive motor corresponds to a rack; width of a rectangular groove is greater than that of a U-shaped rail; and the mechanical arm is arranged abovethe X-axis slide block. The spraying robot used for spraying the large-dimension workpiece provided by the invention is equipped with a three-dimensional mobile platform, so that space range is great,the whole object surface can be sufficiently and completely covered, and the whole-machine spraying operation is completed; and the position can be quickly regulated according to the dimension of theworkpiece, so that spraying operation of the large workpiece can be met.

Owner:清研同创机器人(天津)有限公司

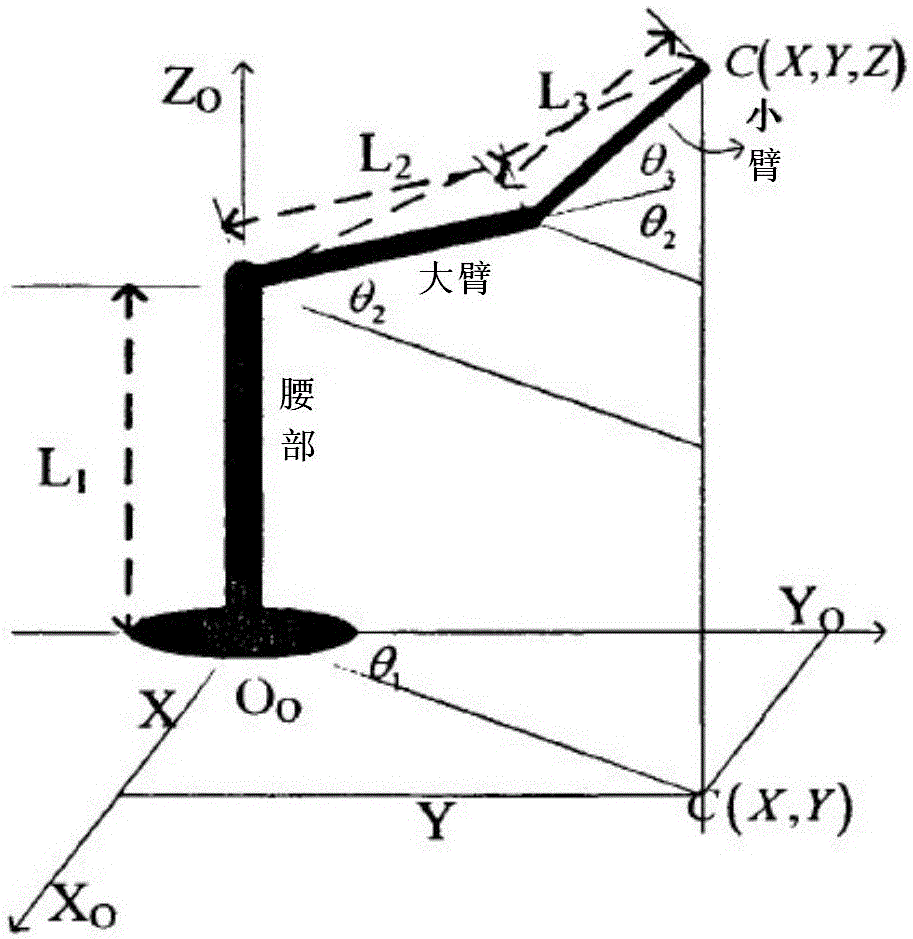

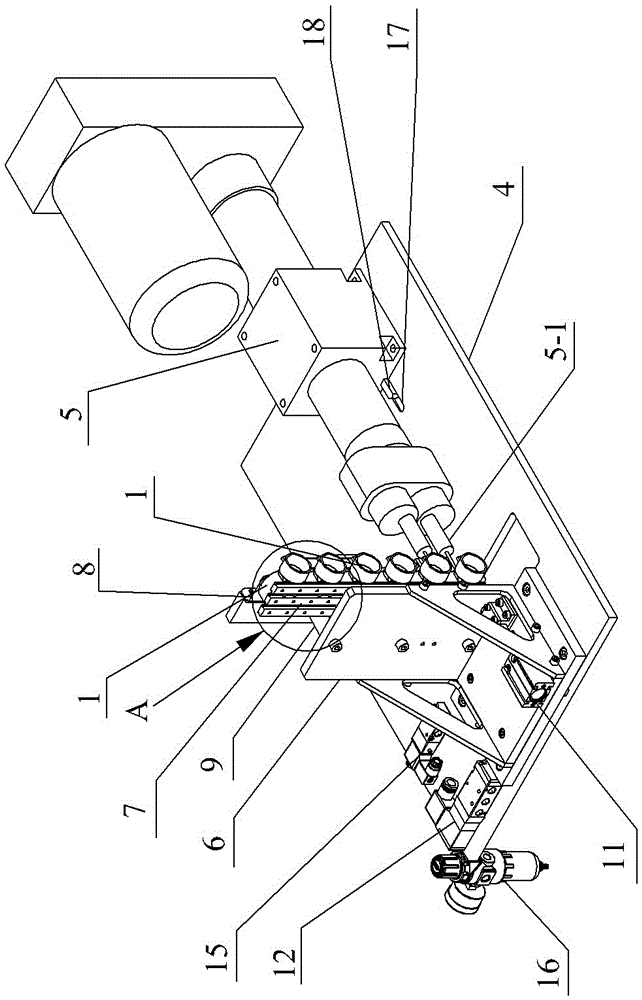

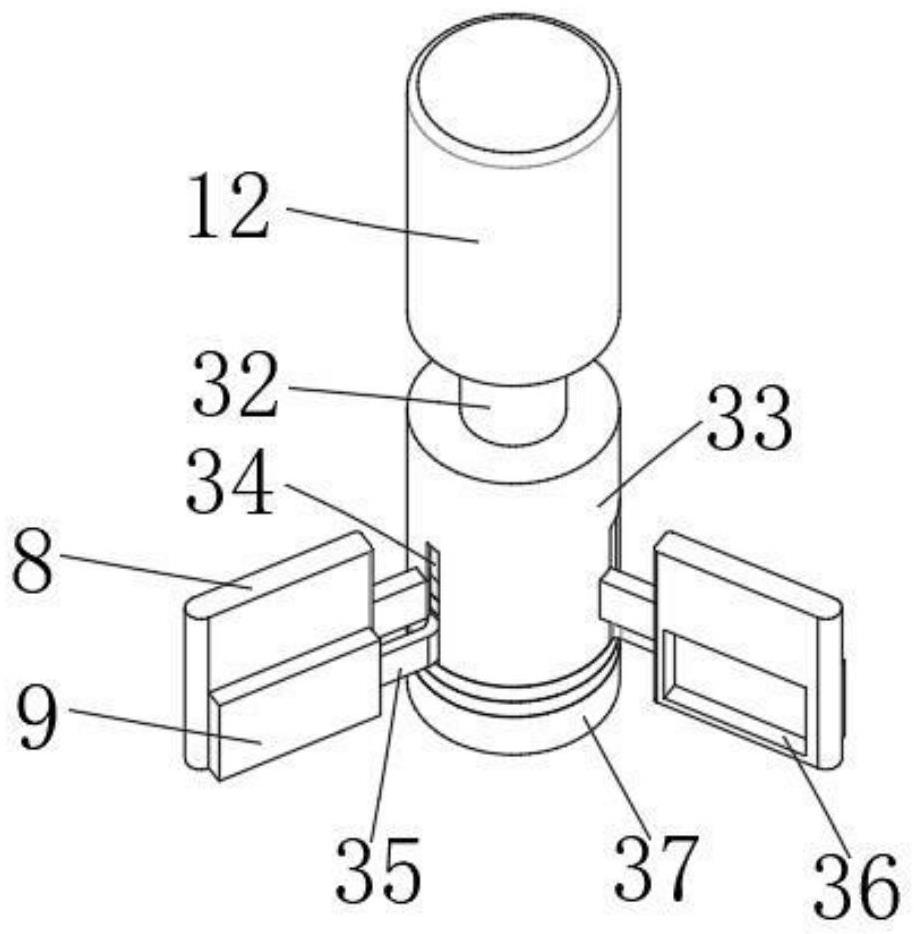

Wolfberry picking robot and control method thereof

InactiveCN105123127ARealize self-pickingRealize normal pickingPicking devicesControl mannerData acquisition

The invention discloses a wolfberry picking robot. A wolfberry picking robot system adopts a pinhole imaging technology and mainly comprises a data acquisition card and an analog-digital conversion module. A control method mainly adopts a fuzzy PID self-adaptive control way and is mainly used for controlling the vision. Hardware of the wolfberry picking robot mainly consists of a mechanical arm, a rotor structure, a picking head and various motors. By adopting the wolfberry picking robot, the automatic picking of wolfberry can be implemented, the manpower can be completely substituted, and the problem that the manual picking is subjected to the influence of the environment can be solved. The wolfberry picking robot is high in automation degree and high in picking efficiency.

Owner:BEIFANG UNIV OF NATITIES

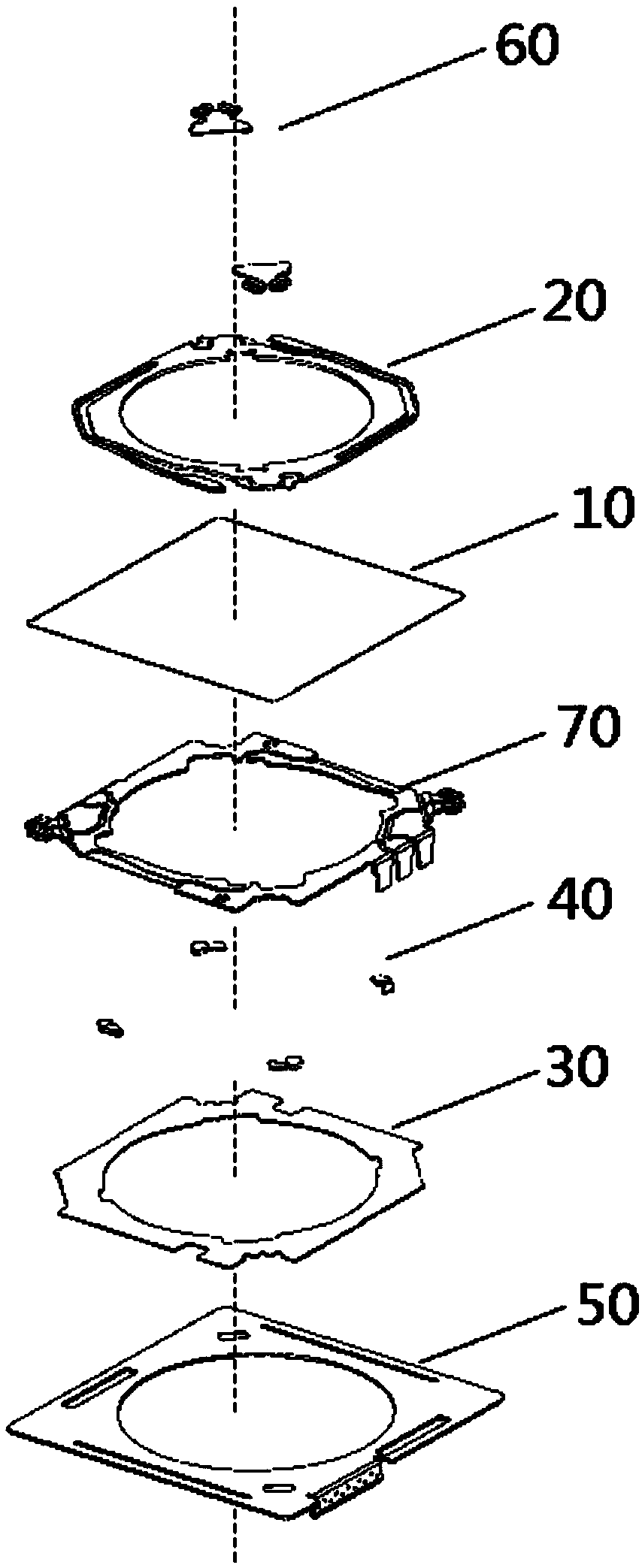

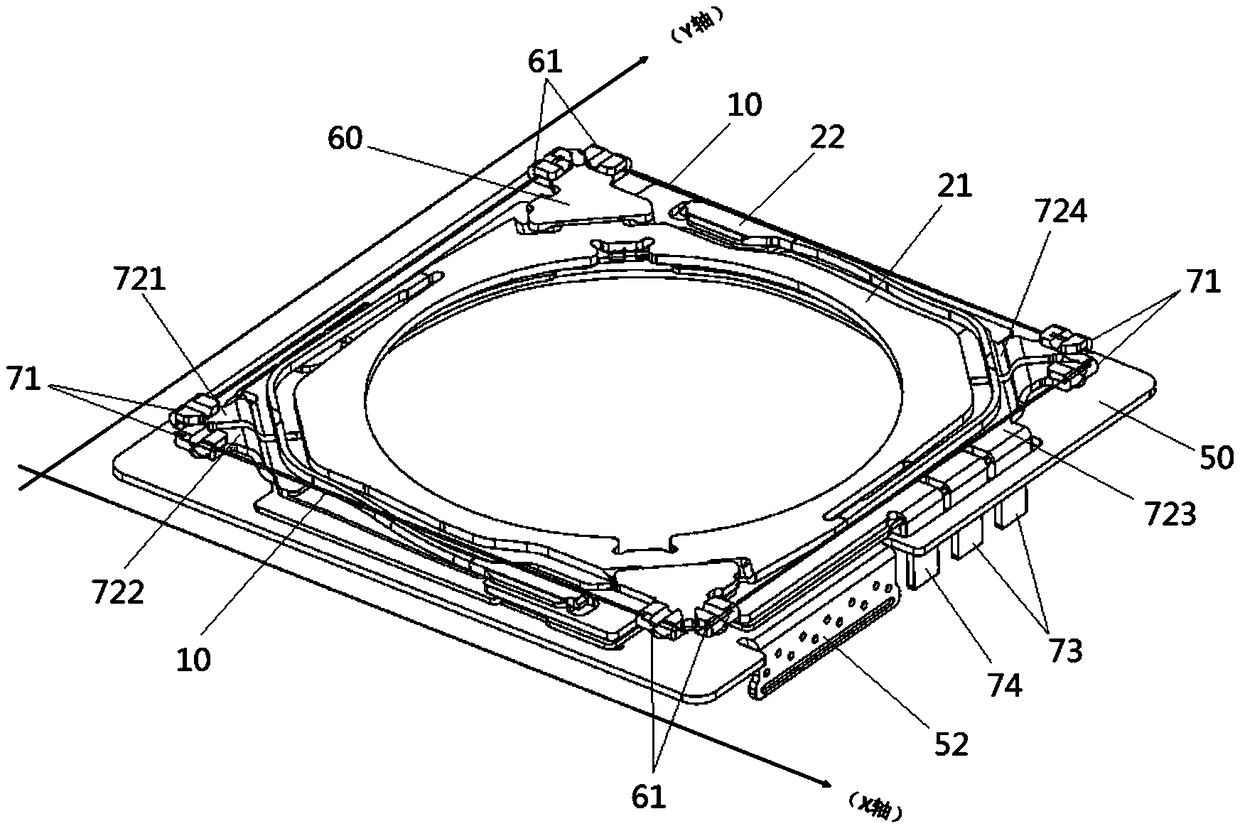

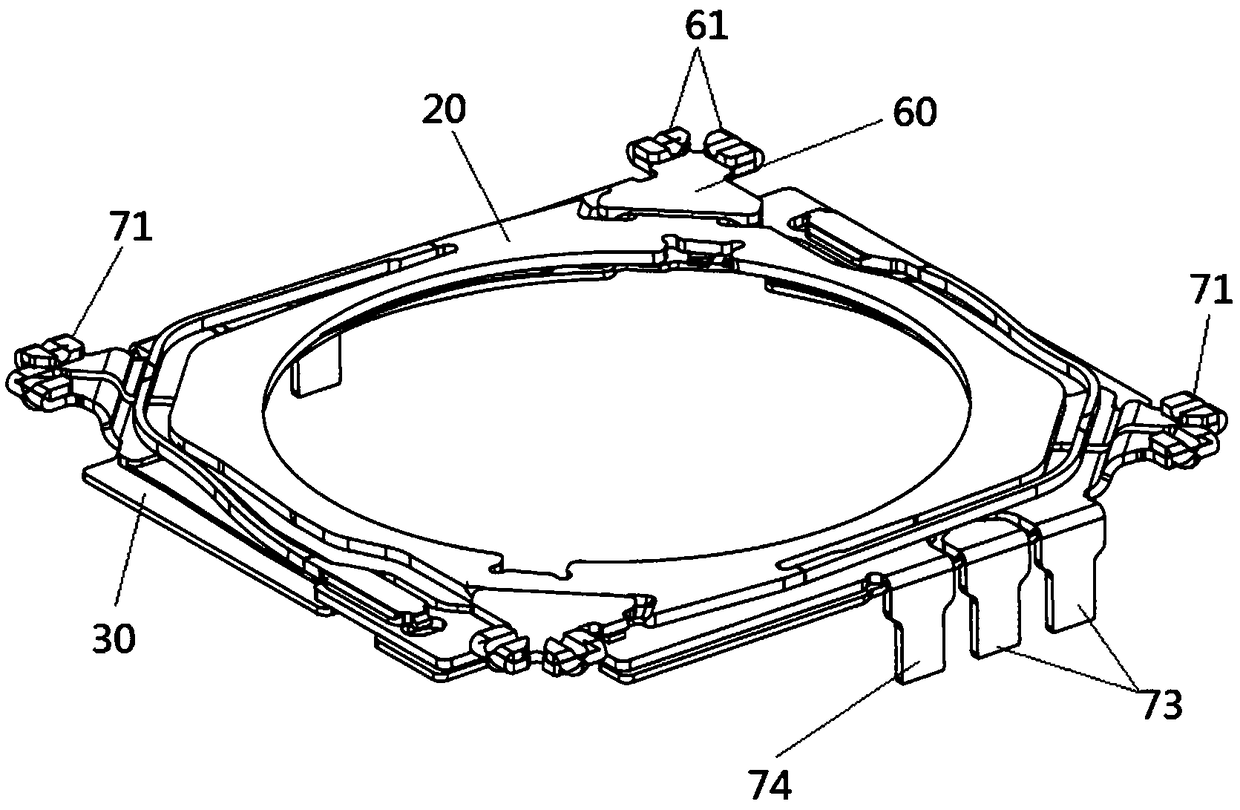

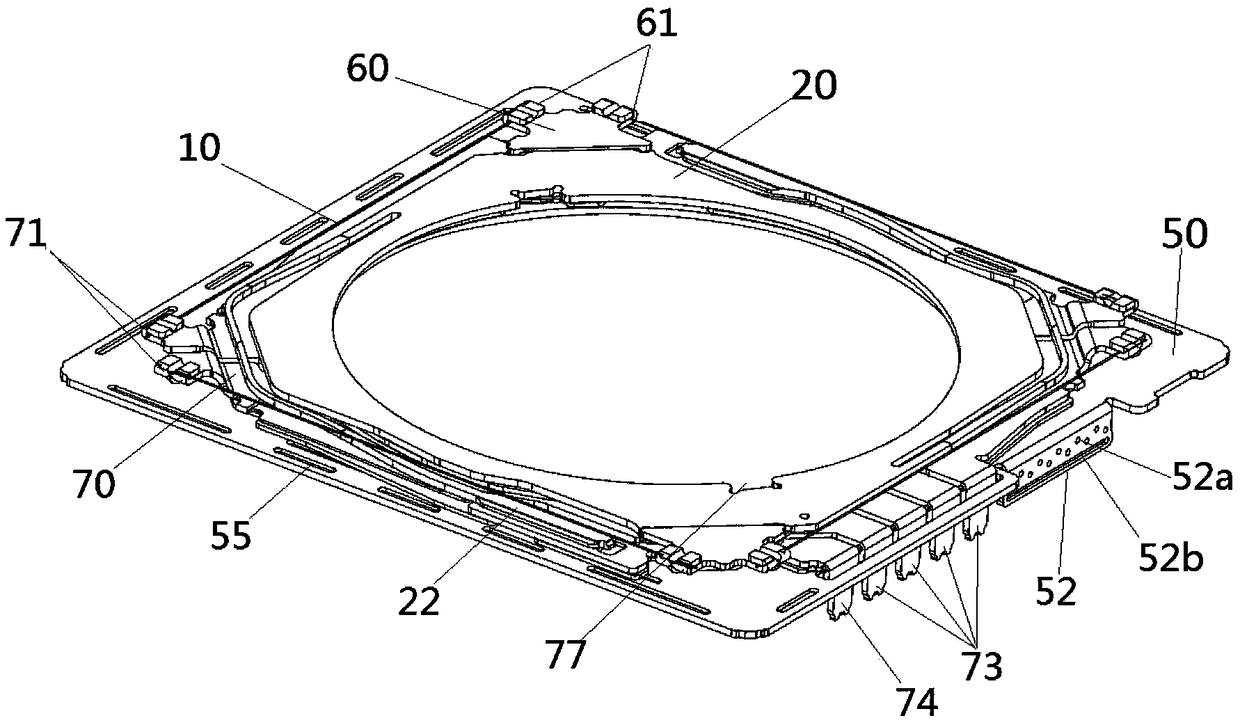

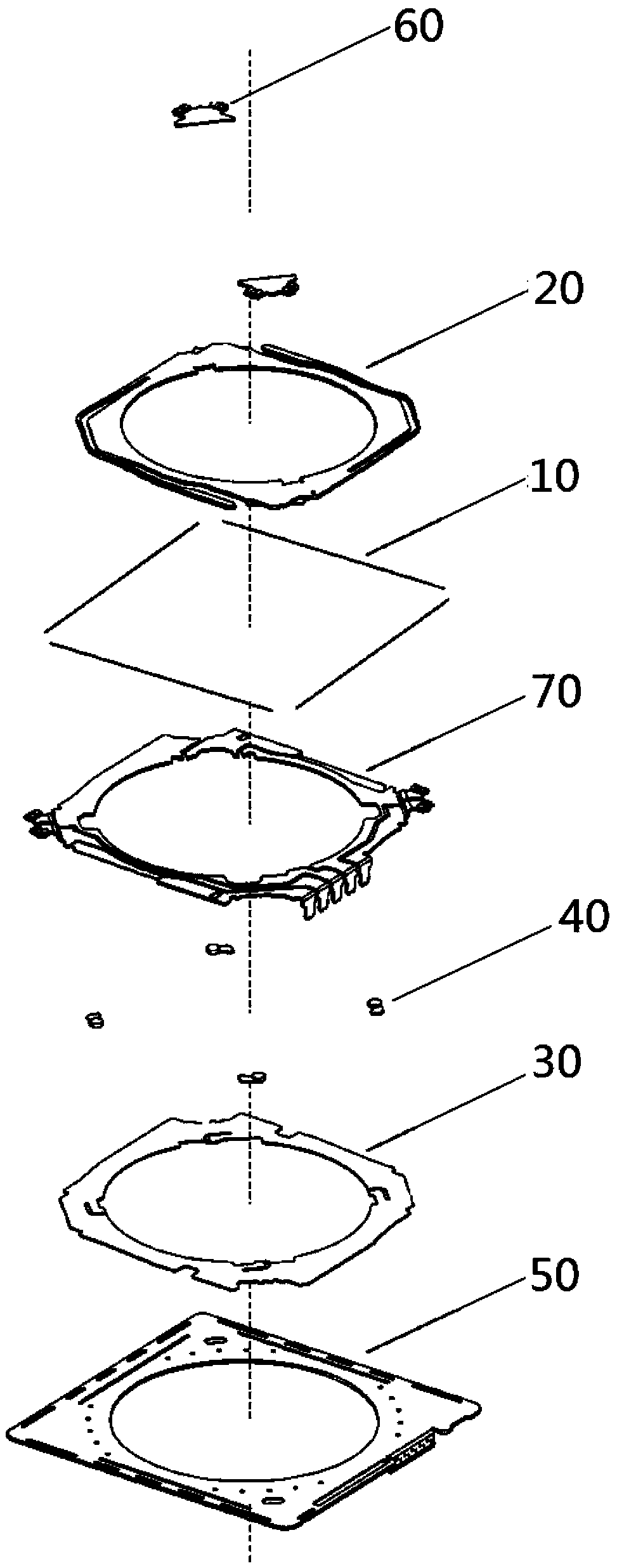

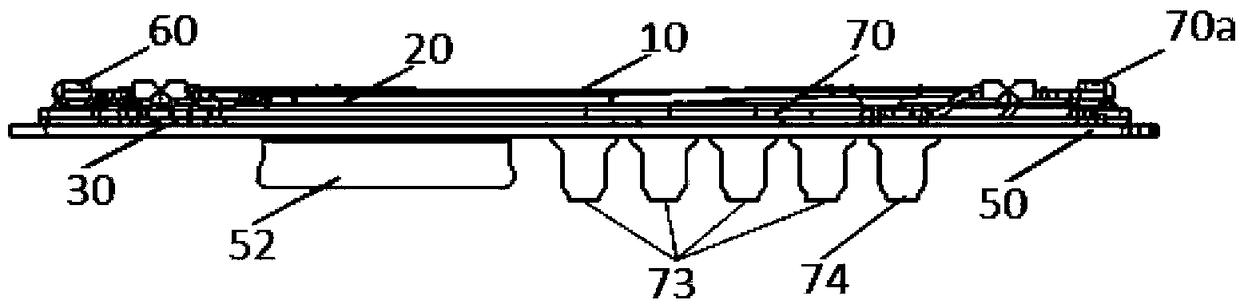

Anti-vibration structure, anti-vibration system and camera device with anti-vibration system

PendingCN109302556AQuick position adjustmentAchieve clear imagesTelevision system detailsColor television detailsElectricityHand shakes

The invention provides an anti-vibration structure, an anti-vibration system and a camera device with the anti-vibration system. The anti-vibration structure comprises SMA silk-covered wires; an OIS reed fixedly connected with the SMA silk-covered wires; an OIS substrate; a tablet assembly partially arranged on the OIS substrate, wherein the tablet assembly is electrically connected with the SMA silk-covered wires, thereby enabling the SMA silk-covered wire to shrink or expand under the current effect and drive at least partial OIS reed to move along a predetermined direction; an OIS arrangedon the OIS substrate and used for supporting the OIS reed; and an OIS base arranged at one side, far away from the OIS support, of the OIS substrate, and connected with the OIS substrate. Through thetechnical scheme provided by the application, the problem that the blurred image is photographed due to hand shaking in the shooting process can be solved.

Owner:SHANGHAI SMA TECH CO LTD

Anti-shake structure, anti-shake system and camera device with the same

PendingCN109495679AQuick position adjustmentAchieve clear imagesTelevision system detailsColor television detailsElectricityHand shakes

The invention provides an anti-shake structure, an anti-shake system and a camera device with the anti-shake system. The anti-shake structure comprises a SMA thread, an OIS reed fixedly connected withthe SMA thread; an OIS substrate; a sheeting module partially arranged on the OIS substrate and electrically connected with the SMA thread, thereby enabling the SMA thread to shrink or expand under the current effect and drive at least a part of the OIS reed to move along a predetermined direction, wherein the sheeting module is provided with an input terminal and an output terminal which are located at one side of the sheeting module; an OIS support arranged on the OIS substrate and used for supporting the OIS reed; and an OIS base arranged at one side, far away from the OIS support, of theOIS substrate and connected with the OIS substrate. Through the technical scheme provided by the application, the problem that the blurred photo is photographed due to hand shaking in the photographing process can be solved.

Owner:SHANGHAI SMA TECH CO LTD

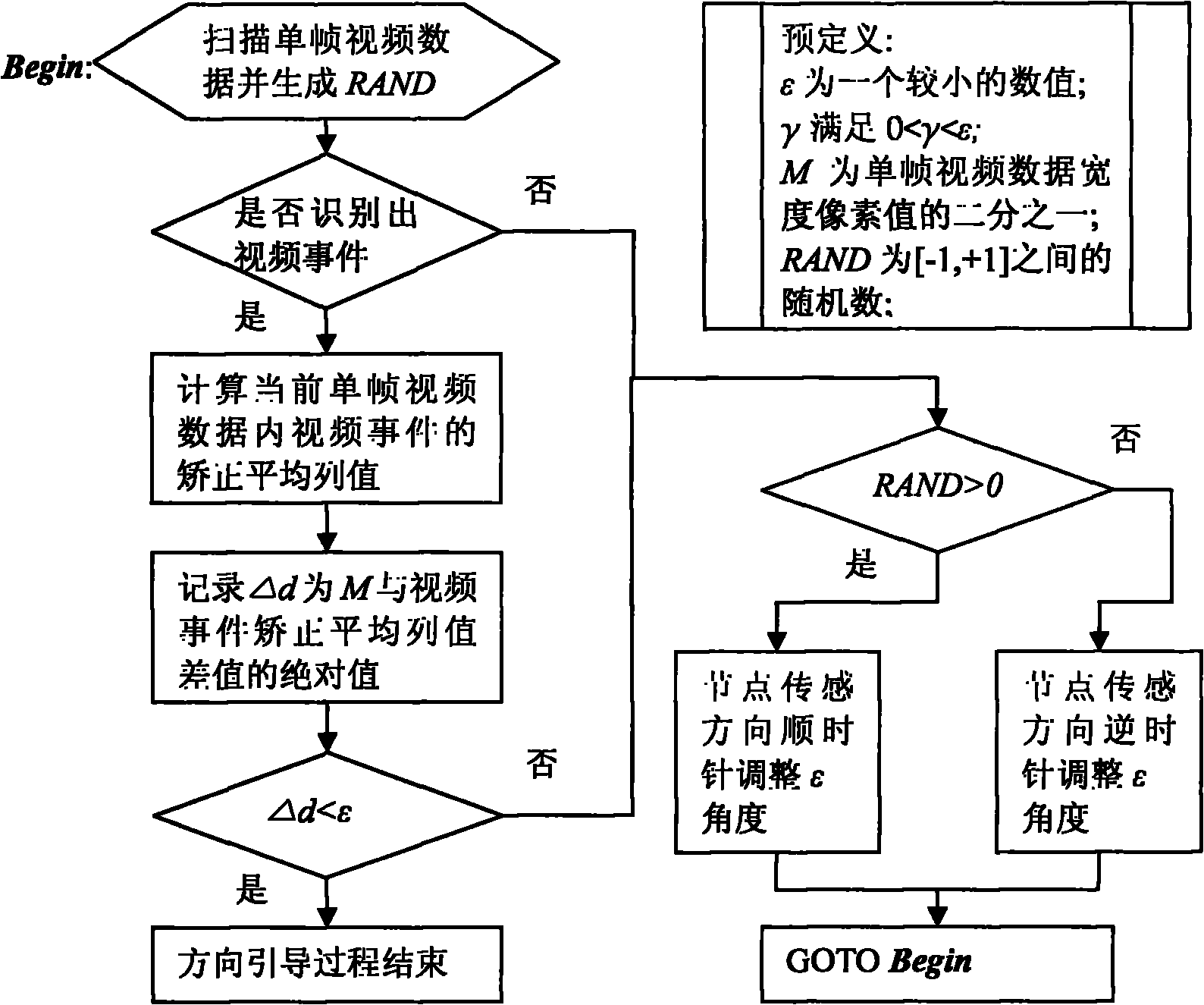

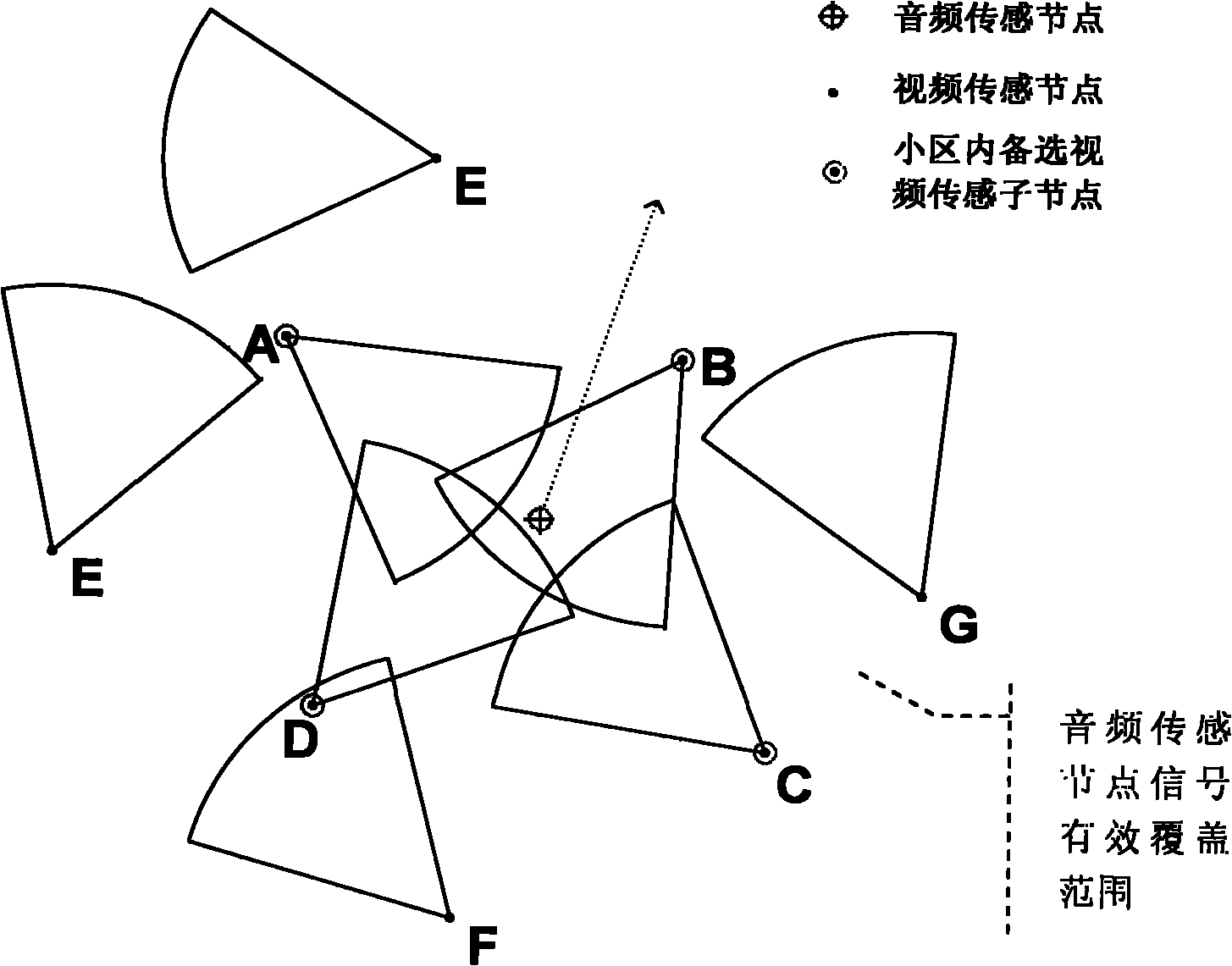

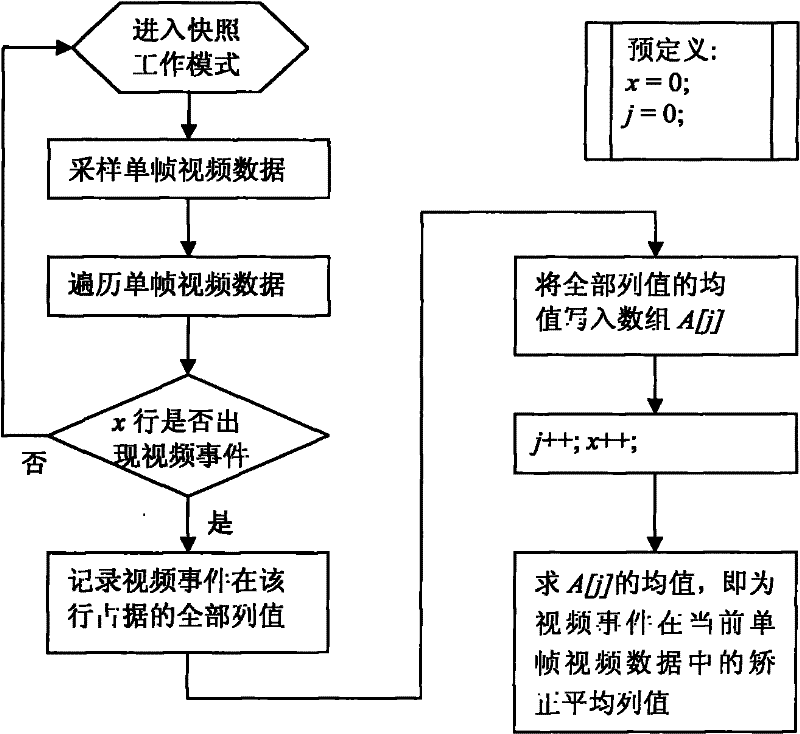

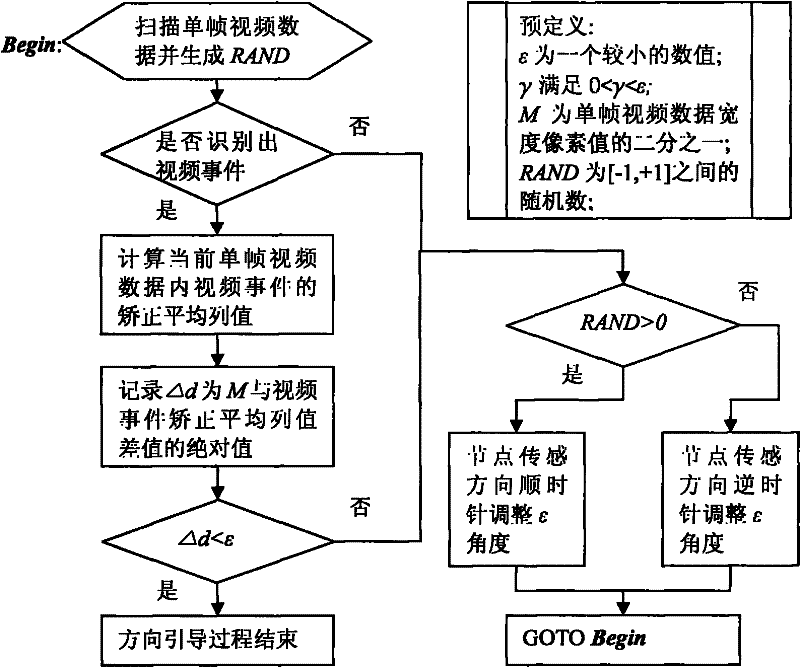

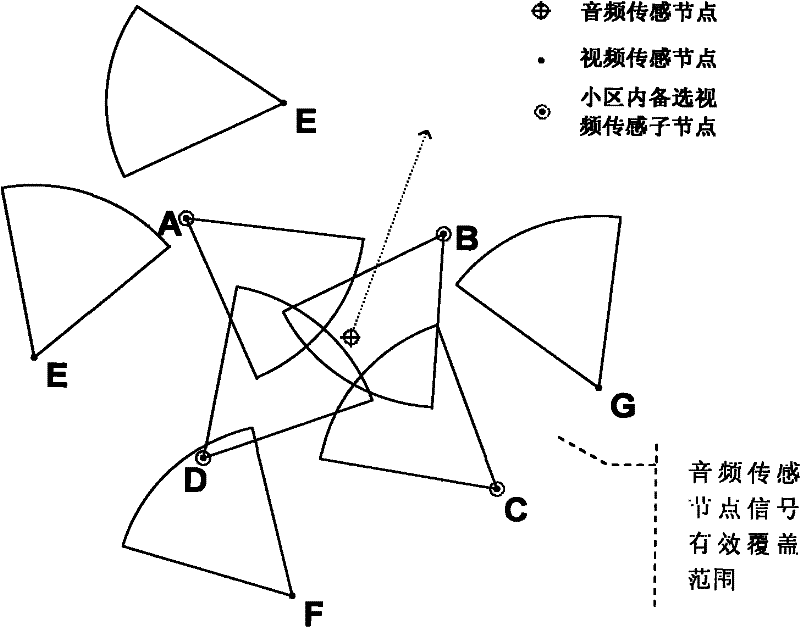

Node cooperative work method based on sensing direction guide in Internet of things environment

ActiveCN101841930AEasy to operateEasy to adjustTelevision system detailsNetwork topologiesRADIUSInternet of Things

The invention discloses a node cooperative work method based on the sensing direction guide in an Internet of things environment and mainly relates to an effective realization method monitored by an object in a multimedia sensor network. Based on a sensing node perceived radius theory and a video sensing model which are provided by the invention, the method is combined with practical application and meets different practical monitoring requirements according to two work modes of group and individual provided by different scenes. By elaborating a direction guiding method in the wireless multimedia sensor network from two views of theory and practicability and combining the characteristics of easy manipulation, conciseness, high efficiency, cost saving, low expenditure and energy consumption, high flexibility and the like of the wireless multimedia sensor network, the invention provides constructive suggestions for the application of the multimedia sensor network in the monitoring field.

Owner:NANJING UNIV OF POSTS & TELECOMM

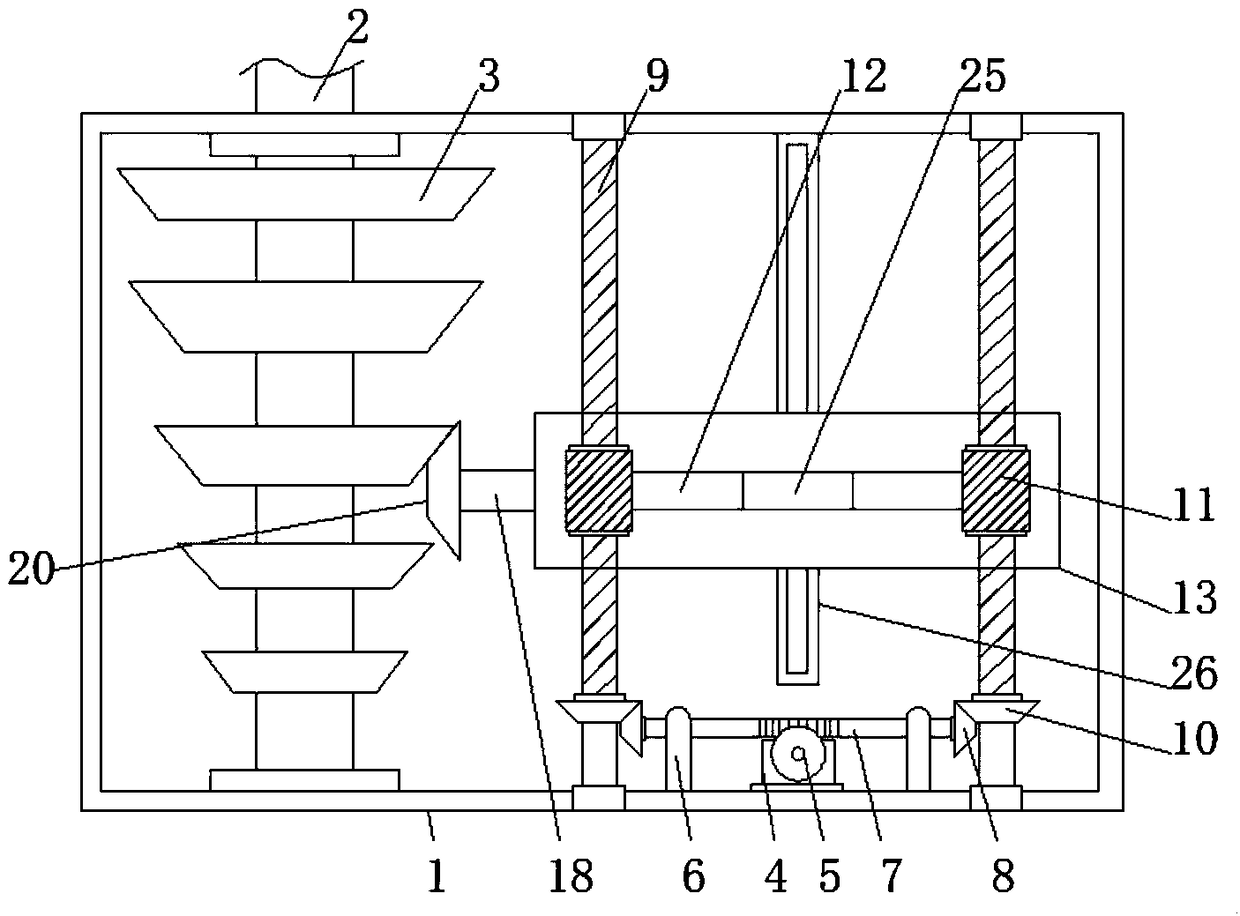

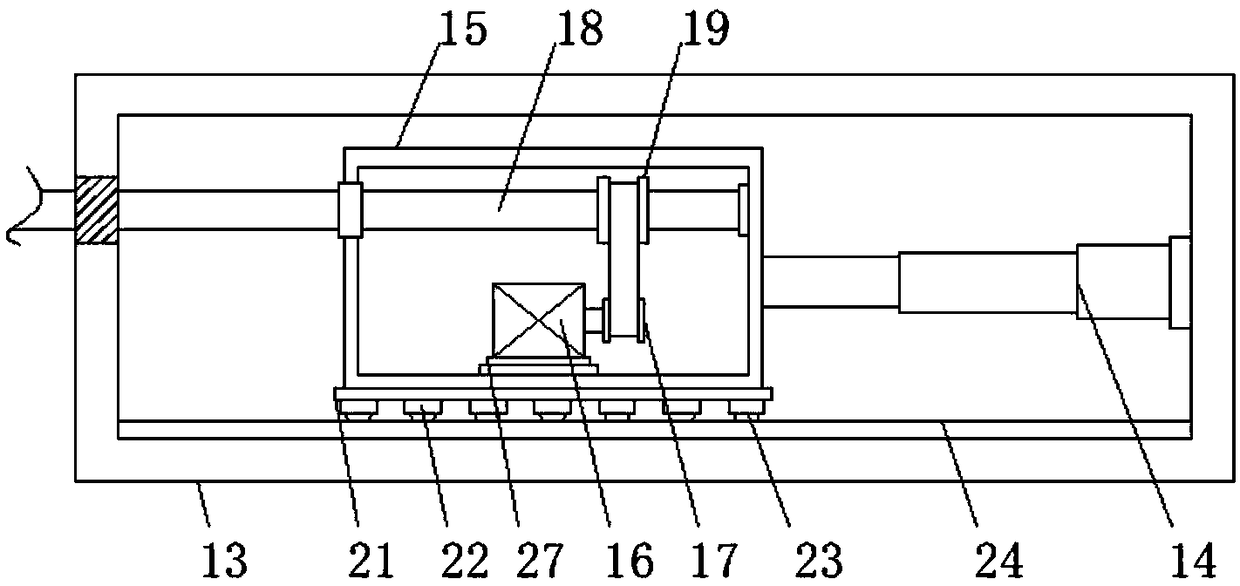

Fine adjusting device for machining

InactiveCN109175410AQuick position adjustmentImprove efficiency and accuracyLarge fixed membersEngineeringBevel gear

Owner:WUHU LE CHUANG ELECTRONICS TECH CO LTD

Automatic car seat system with automatic measurement and memory functions

InactiveCN103448575AEasy to adjust the positionQuick position adjustmentMovable seatsCar seatKey pressing

The invention discloses an automatic car seat system with automatic measurement and memory functions. The automatic car seat system comprises a seat, a chair back, transmission shafts, a chair back adjusting motor, Hall sensors, a horizontal adjusting motor, a single-chip microcomputer, height adjusting motors, turbine mechanisms and adjusting buttons, memory pulse data are detected and stored by the aid of the Hall sensors, the single-chip microcomputer automatically controls direct current motors to drag and adjust the seat and the chair back to horizontally and vertically move according to the stored memory pulse data, so that the height of the seat is adjusted, and the dip angle of a horizontal backrest is automatically adjusted. The automatic car seat system has the functions of automatically measuring mounting position limits of the seat, memorizing a plurality of seat positions and the like, so that the electric seat is more simply and conveniently mounted, the positions of the seat are conveniently and rapidly adjusted, controllability of the seat can be greatly improved, comfort of a rider is improved, the positions of the car seat can be easily adjusted even when a car runs, and the feeling of fatigue of a driver is relieved.

Owner:党庆风

Multi-target material X light tube

InactiveCN101644689AIncrease profitExtended service lifeMaterial analysis using wave/particle radiationX-ray tube electrodesFluorescenceLight spot

The invention discloses a multi-target material X light tube, relating to the technical field of X-ray light tubes in an X fluorescence analyzer. The multi-target material X light tube comprises a shell, high pressure oil, a glass tube, a cathode, an anode target, an anode, electron beam, X-ray and an X-ray window, wherein the cathode and the anode are respectively arranged at both ends of the glass tube in which vacuum is formed; the anode target is arranged at an end face of the anode which is close to the cathode; the electron beam ejected by the cathode ejects on the anode target to form X-ray which passes through the X-ray window; the anode target consists of a plurality of small target faces; and at least one magnet and an automatic light spot locating device are arranged around theperiphery of the X-ray window. The invention aims at providing a multi-target material X light tube of which the target face consists of multiple target materials, with high target face use ratio, increased analysis range and improved service life of the target face.

Owner:JIANGSU SKYRAY INSTR

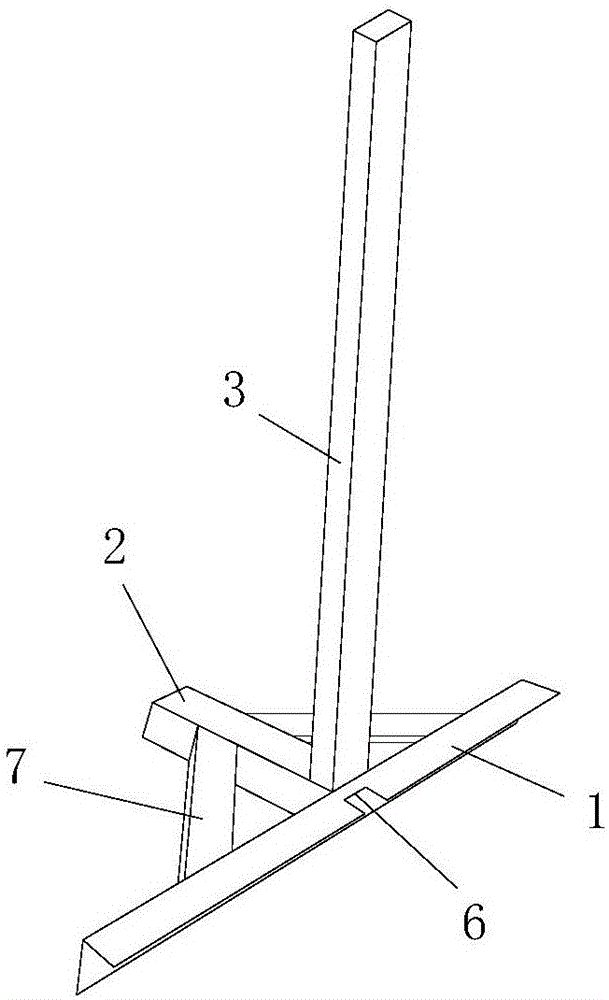

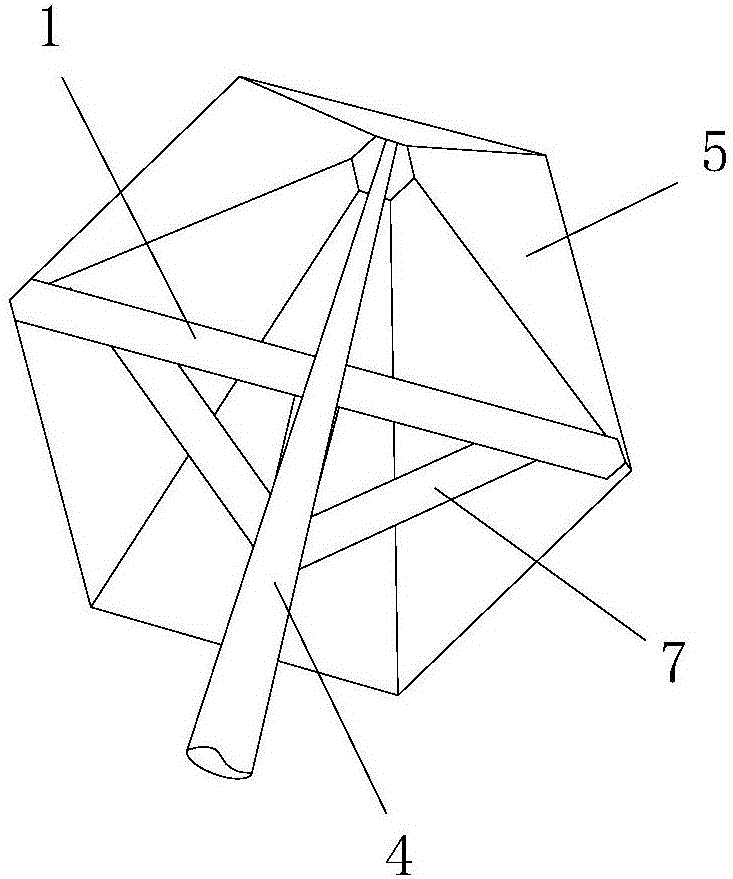

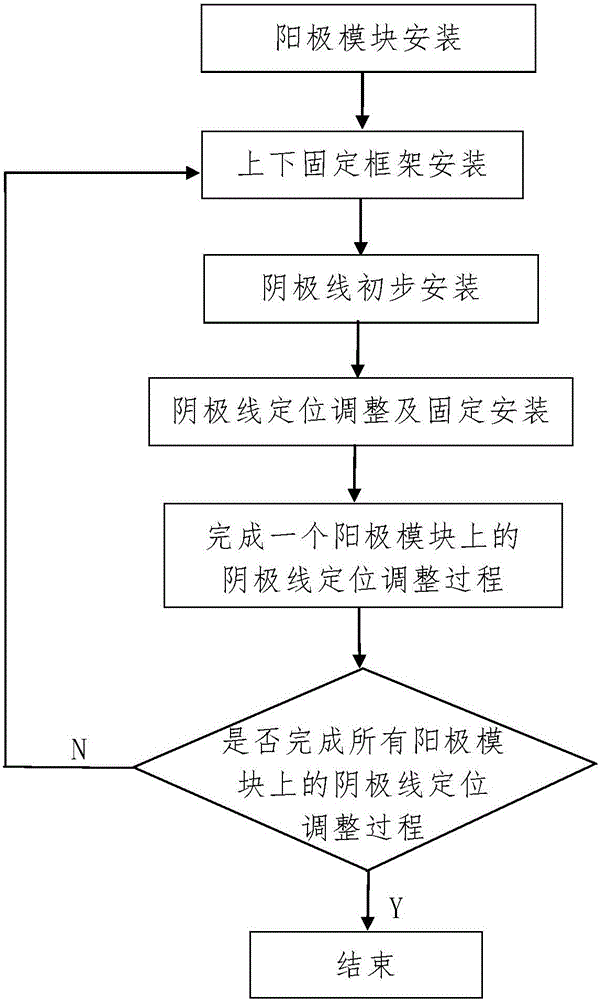

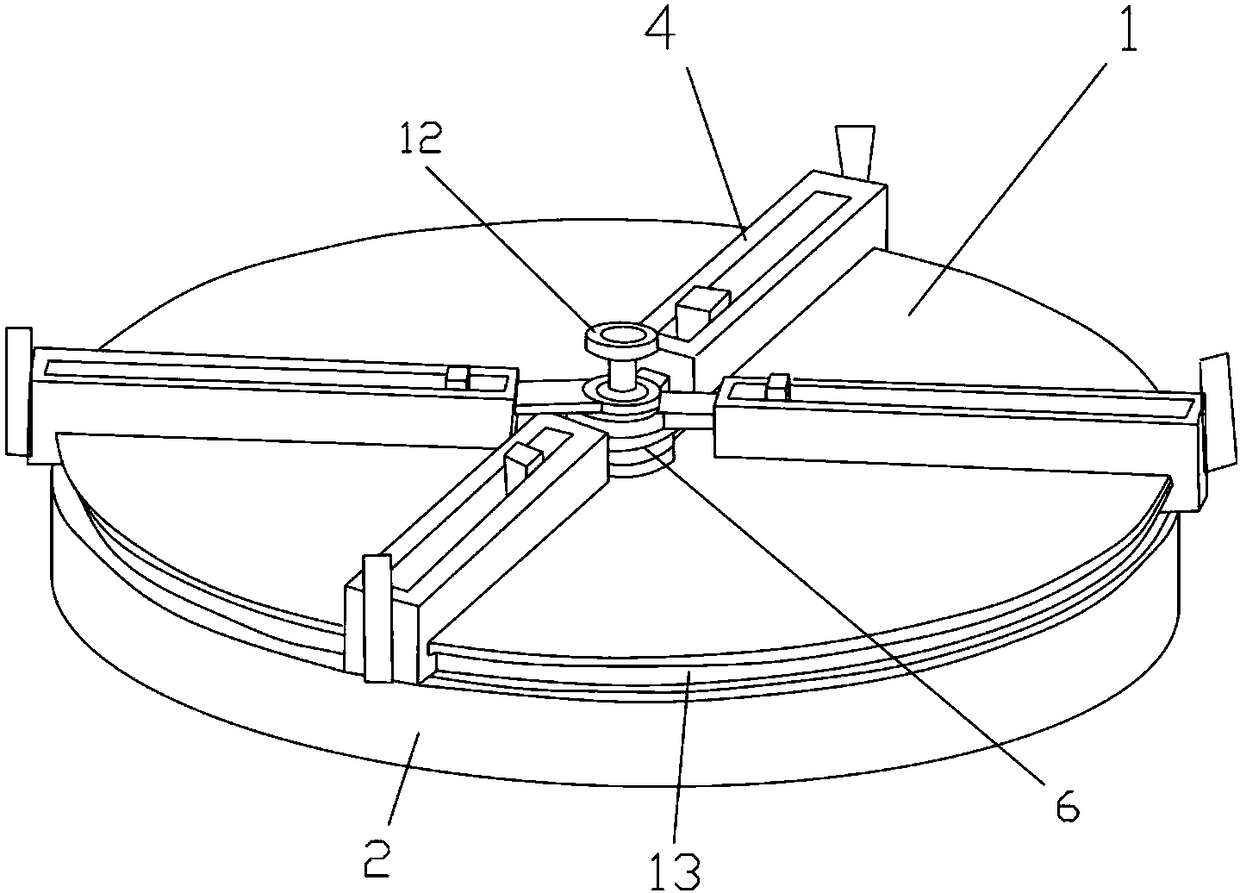

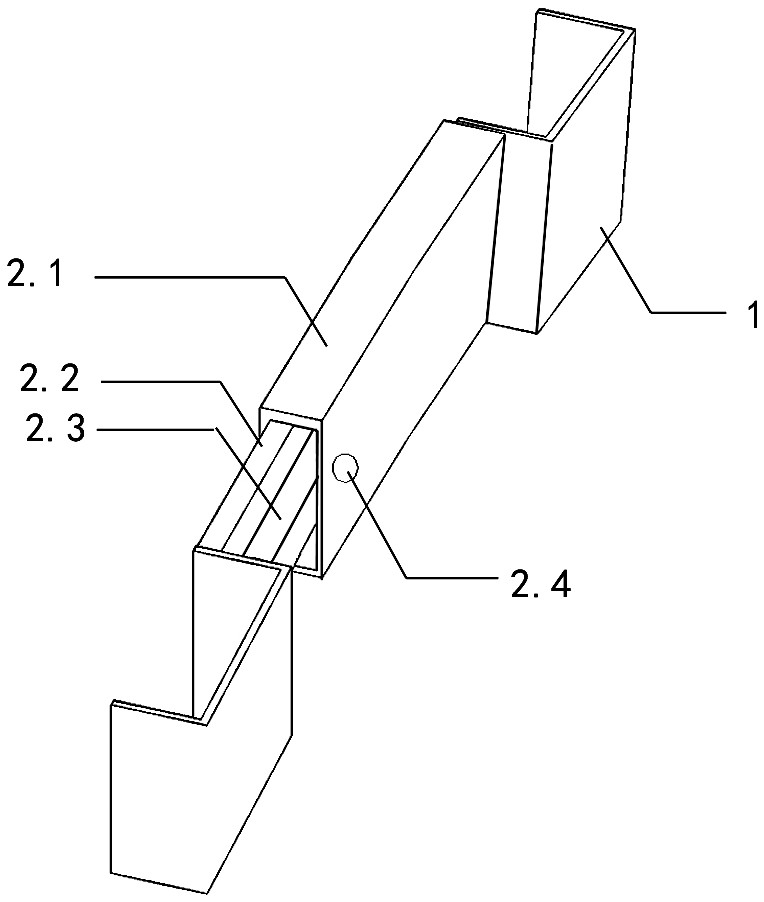

Cathode line positioning die and cathode lien positioning and adjustment construction method

ActiveCN106238212ASimple structureEasy to processElectrostatic separation detailsArchitectural engineeringAnode

The invention discloses a cathode line positioning die and a cathode lien positioning and adjustment construction method. The positioning die comprises a rear measuring rod, a front measuring rod arranged on the front side of the middle of the rear measuring rod and a vertical rod fixed behind the rear portion of the front measuring rod, wherein the front measuring rod and the vertical rod are located in front of the rear measuring rod, the rear measuring rod, the front measuring rod and the vertical rod are straight rods, the rear measuring rod and the front measuring rod are arranged in a perpendicular mode, the rear measuring rod and the front measuring rod form a horizontal positioning rack, and a clamping groove for positioning an adjusted cathode line is formed in the rear side of the middle of the rear measuring rod. The constriction method comprises the steps that 1, anode module installation is performed; 2, cathode line installation construction is performed: when the cathode line is installed on any group of anode modules, the process is that 201, upper and lower fixing frames are installed; 202, preliminary cathode line installation is performed; 203, cathode line positioning, adjustment and fixing installation are performed. The cathode line positioning die is reasonable in design, simple and convenient to use and operate, good in using effect and capable of simply, conveniently and rapidly perform accurate cathode line positioning and ensuring cathode line installing precision.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

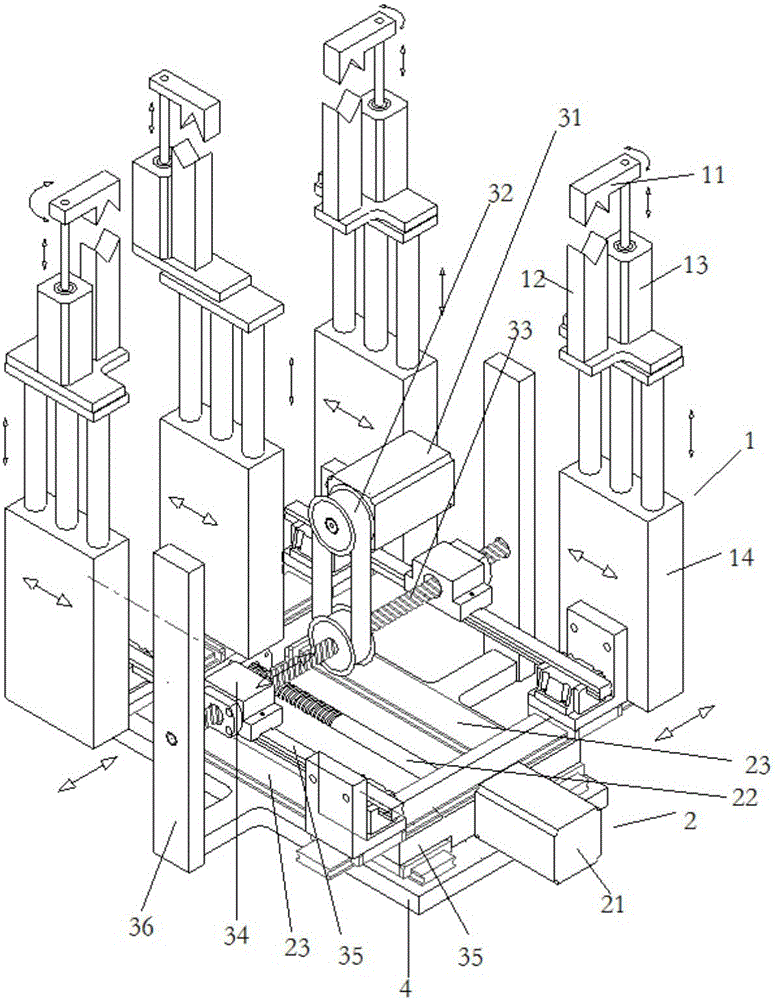

Rotating platform fixture for inertial product detection

InactiveCN108312092AAvoid positional shiftsPrecise position controlWork holdersEngineeringMechanical engineering

The invention discloses a rotating platform fixture for inertial product detection. The rotating platform fixture comprises a fixture platform surface, a rotating platform and at least two adjustabletype installation mechanisms, the fixture platform surface is fixedly installed to the rotating platform, each adjustable type installation mechanism comprises a guide rail, a connection part, a sliding block, a rotating rod and a threaded rod, the connection part is fixedly connected with the sliding block, the rotating rod is fixedly connected with the threaded rod, the threaded rod is arrangedinside the sliding block in a penetrating manner, the upper portion of the guide rail is provided with a first sliding cavity, detected inertial products can be placed on the first sliding cavity, theproducts of different sizes and models are conveniently clamped and are prevented from being thrown out, so that accurate measurement is performed. The rotating platform fixture for the inertial product detection is simple in structure, stable and convenient, easy to operate, low in cost, quite reliable and dependable.

Owner:方丹卉

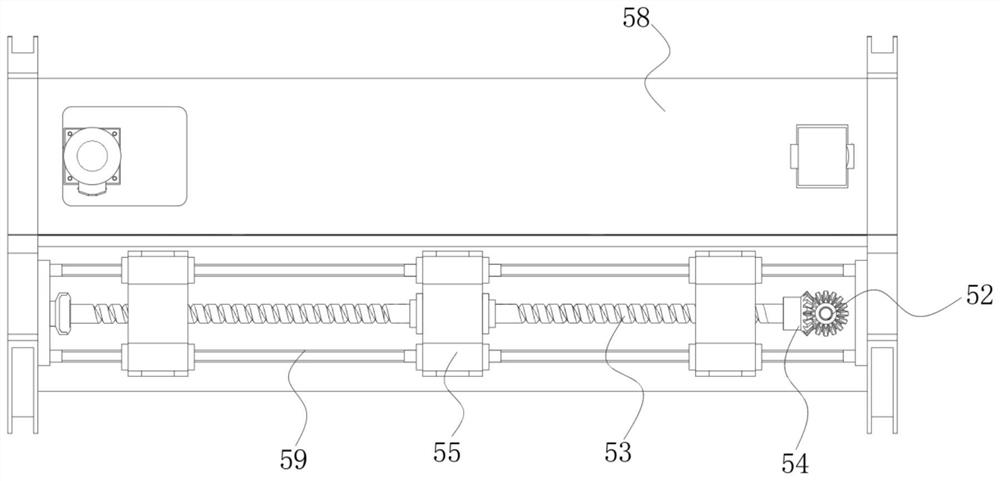

Position adjusting mechanism for taping machine clamping mechanism

ActiveCN106160370ADecrease productivityIncrease labor costManufacturing dynamo-electric machinesContour formEngineering

The invention discloses a position adjusting mechanism for a taping machine clamping mechanism. The clamping mechanism comprises a plurality of clamping units arranged according to a coil contour. The plurality of clamping units form a clamping contour adapted to the coil contour. The position adjusting mechanism is connected between the plurality of the clamping units. The plurality of clamping units can be driven to generate relative shift through the adjustment of the position adjusting mechanism, and thus the clamping contour formed by the plurality of clamping units is changed. The position adjusting mechanism connected between the clamping units can effectively avoid the trouble, and the relative position between the clamping units can be adjusted through buttons on an operation panel of a taping machine according to the coil contours with different sizes so as to be adapted to the coil without dismounting the clamping units. The operation is simple and fast. The work efficiency is greatly improved. The artificial cost is reduced, and the equipment service life is prolonged.

Owner:温州市桑德拉自动化科技有限公司

Support frame for mounting precast beam jack

ActiveCN103787203ALabor-saving handlingQuick position adjustmentBase supporting structuresBraking devices for hoisting equipmentsEngineeringJackscrew

The invention provides a support frame for mounting a precast beam jack. The support frame at least comprises a primary support frame and a working platform arranged on the primary support frame, and also comprises a secondary support frame, wherein the secondary support frame is reliably connected with the primary support frame; the support frame also comprises a rail which is longitudinally arranged on the primary support frame and the secondary support frame, and a lifting system which is arranged on the rail, can move along the rail and is used for lifting the jack; the rail can transversely move on the primary support frame. The jack can be rapidly transported to a specified place in the precast beam site in a labor-saving mode and can be rapidly and accurately aligned, and the working efficiency is improved.

Owner:饶枭宇

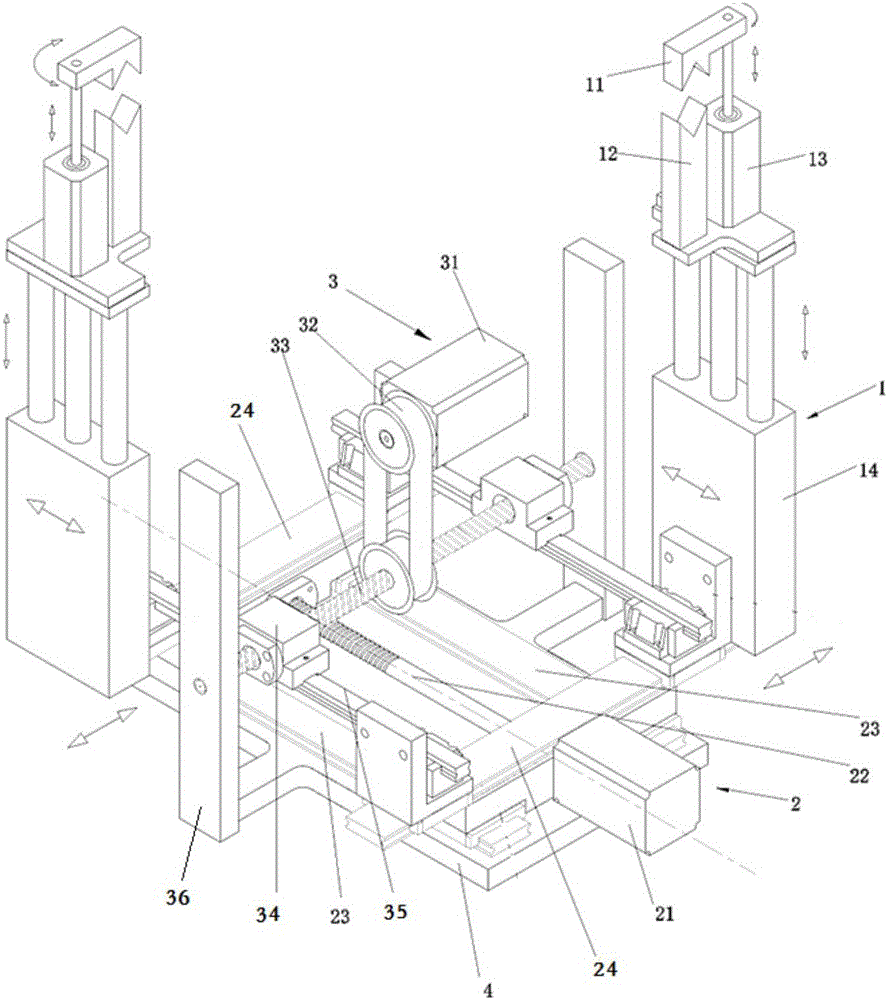

Drilling machine

ActiveCN103990833AQuality improvementImprove drilling efficiencyBoring/drilling componentsBoring/drilling machinesMechanical engineeringDrilling machines

The invention discloses a drilling machine. The drilling machine conducts drilling on an object to be drilled through a drill bit installed on a driving part (1). The drilling machine comprises a first guide rail (2), a first movable plate (3), a second guide rail (4), a second movable plate (5) and two regulating parts (6), wherein the driving part (1) and the first movable plate (3) are both movably installed on the first guide rail (2), the second guide rail (4) is located on the upper surface of the first movable plate (3), the length direction of the second guide rail (4) is perpendicular to the length direction of the first guide rail (2), the second movable plate (5) is movably installed on the second guide rail (4) to be used for installation of a clamp used for clamping the object to be drilled, and the two regulating parts (6) are connected with the first movable plate (3) and the second movable plate (5) respectively to regulate the positions of the first movable plate (3) and the second movable plate (5). The drilling machine can conduct drilling accurately and quickly.

Owner:芜湖皖拓机械科技有限公司

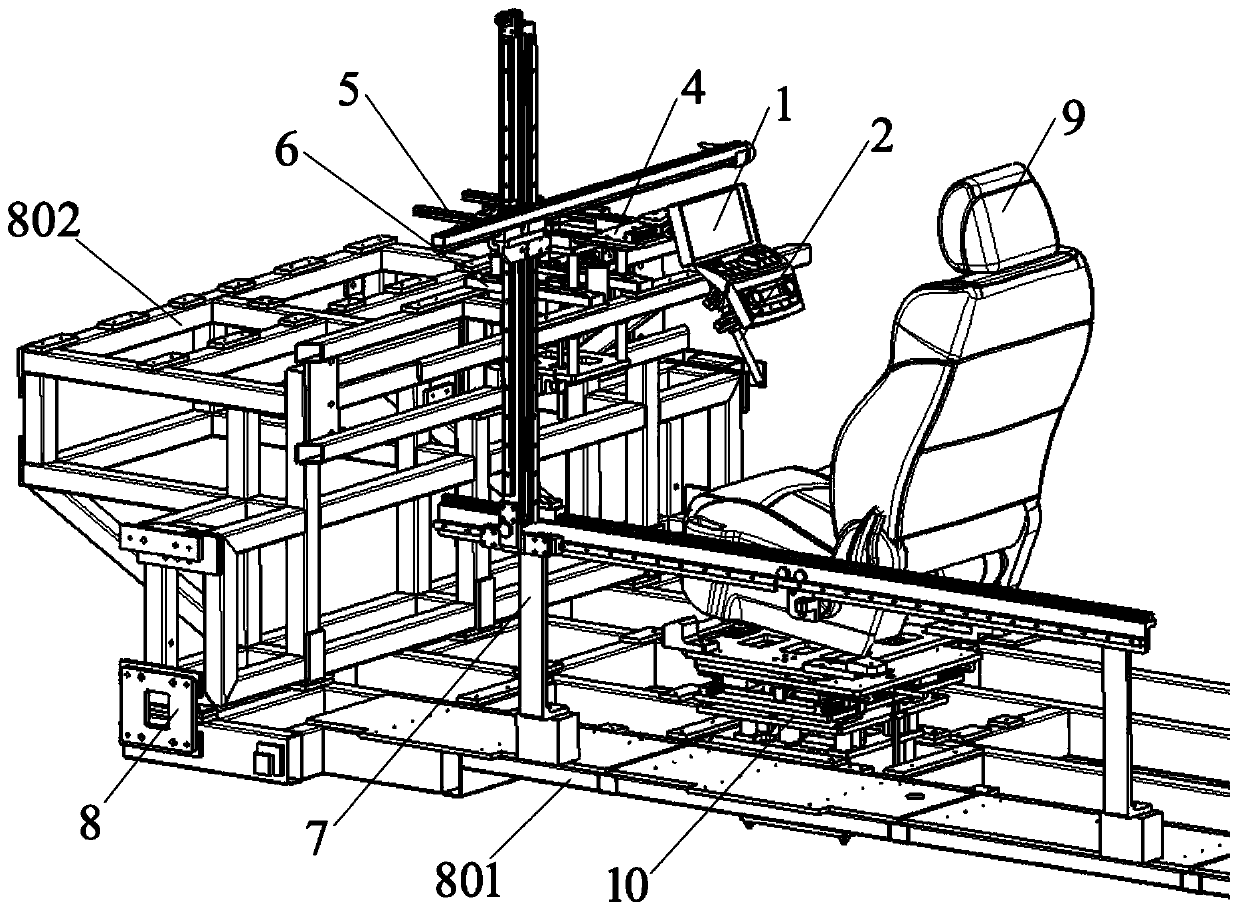

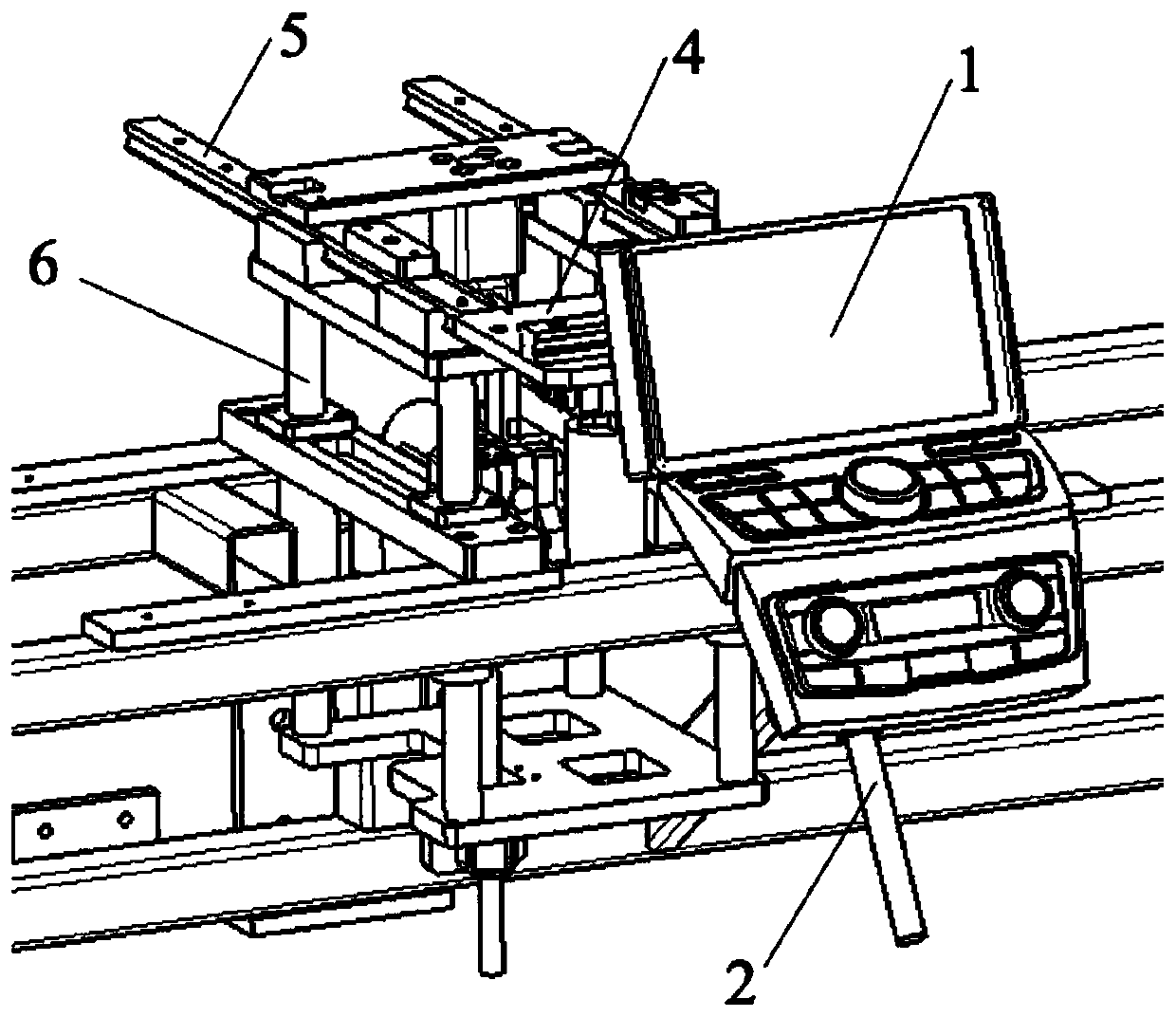

Automobile instrument board middle layout test device and verification method thereof

ActiveCN111413108AQuick position adjustmentShorten the timeVehicle testingDashboardEvaluation result

The invention discloses an automobile instrument board middle layout test device. The device comprises a plurality of independent instrument board middle modules, the instrument board middle module isfixedly connected with an angle adjusting mechanism, the angle adjusting mechanism is detachably hinged with a fixing rod, the fixing rod is movably connected with an instrument board middle module translation mechanism, the instrument board middle module translation mechanism is fixed on a test framework, a mobile measuring mechanism is fixedly arranged on the test framework, and the test framework is also connected with a seat through a seat adjusting mechanism. The invention also discloses a verification method of the test device. The method comprises the following steps of 1) adjusting the measurement pointer to an initial zero position, 2) determining coordinates of an instrument board middle module, 3) adjusting the instrument board middle module to be aligned with the measurement pointer, 4) adjusting the relative position of the seat for comfort evaluation, and 5) selecting whether to continue verification or output a result according to the evaluation result. Multi-degree-of-freedom adjustment can be carried out, multiple samples do not need to be manufactured in a trial mode, the verification time is shortened, and the verification cost is reduced.

Owner:DONGFENG MOTOR CORP HUBEI

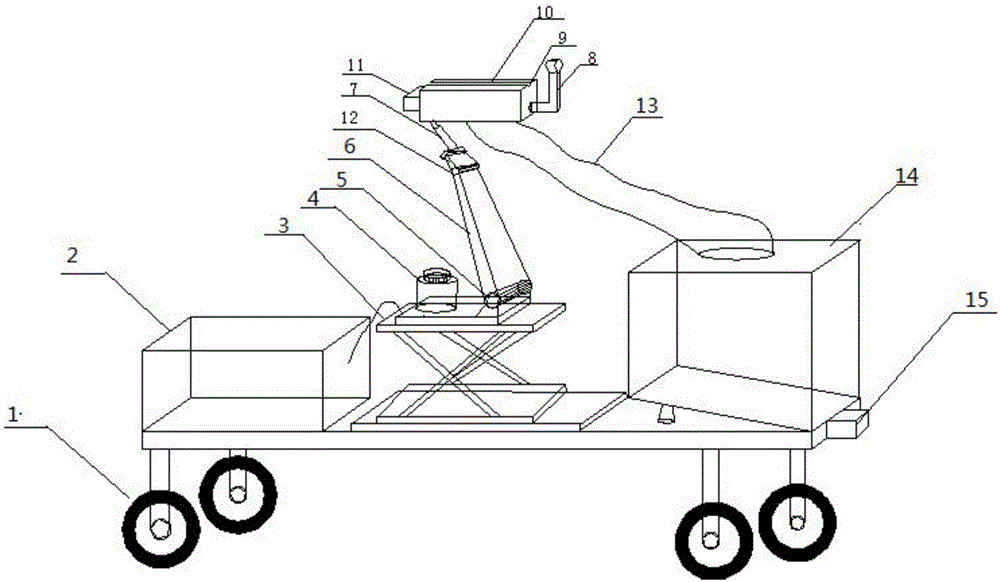

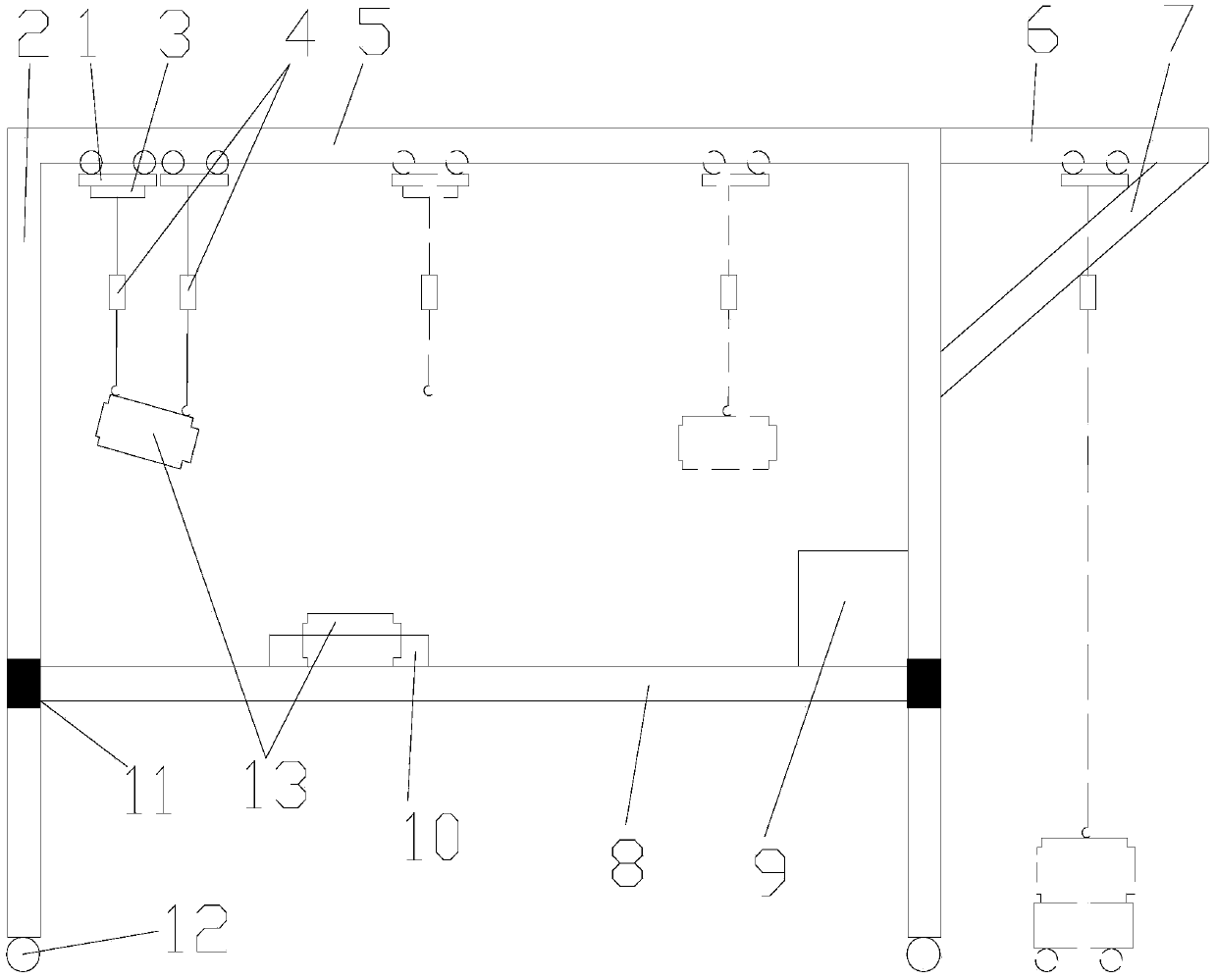

Intelligent assisting platform for dismounting and mounting of GIS (Gas Insulated Substation)

The invention discloses an intelligent assisting platform for dismounting and mounting of a GIS (Gas Insulated Substation). The intelligent assisting platform comprises a base, a hoisting mechanism, a sliding mechanism, an oil tank, a forward pushing mechanism and a front gear mechanism, wherein the sliding assembly comprises a guide rail which is mounted on the base, and two sliding tables which are movably mounted on the guide rail; a pitch-variable oil cylinder is arranged between the sliding tables; the hoisting mechanism comprises uplifting oil cylinders, hoisting arms, hoisting hooks, coiling barrels and gear motors, wherein the uplifting oil cylinders, the hoisting arms, the hoisting hooks, the coiling barrels and the gear motors are correspondingly arranged on the sliding tables; the forward pushing mechanism comprises lead screw assemblies, forward pushing oil cylinders and forward pushing clamping jaws, wherein the lead screw assemblies, the forward pushing oil cylinders and the forward pushing clamping jaws are correspondingly vertically arranged on the two sliding tables; the front gear mechanism comprises front gear oil cylinders and front gear clamping jaws; the front gear oil cylinders and the front gear clamping jaws are horizontally arranged on the uplifting oil cylinders. The intelligent assisting platform can effectively avoid natural shaking of an air chamber caused by hoisting a GIS air chamber through a soft sling and various resulting potential risks, so that GIS devices can be accurately, quickly and stably hoisted and adjusted, and as a result, the safety and quality can be ensured, and the labor intensity can be also reduced.

Owner:STATE GRID SHAOXING POWER SUPPLY +2

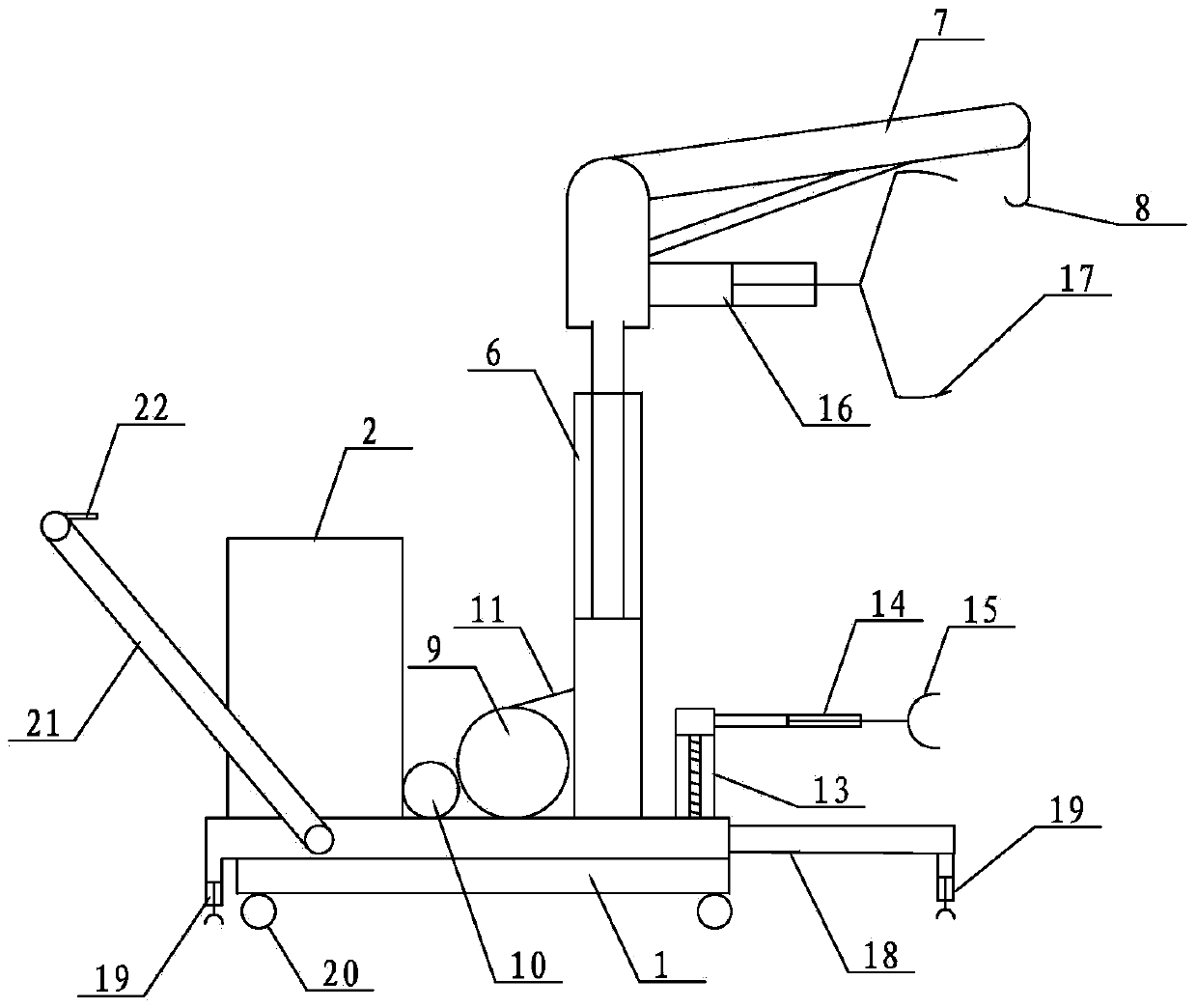

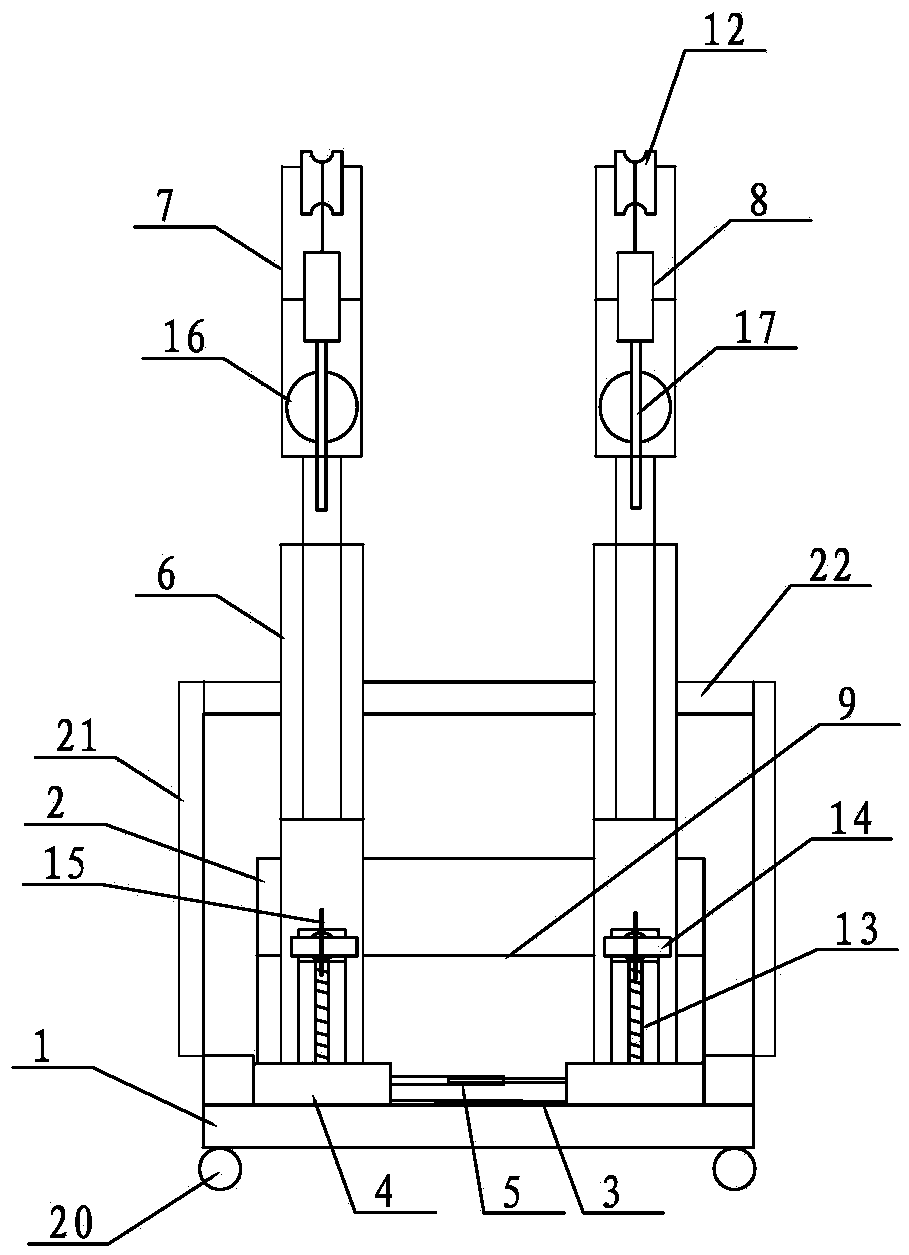

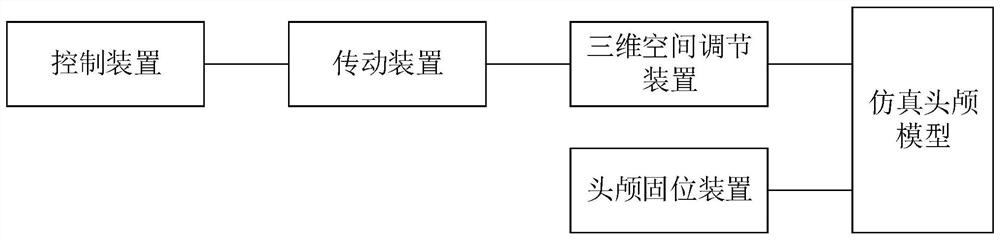

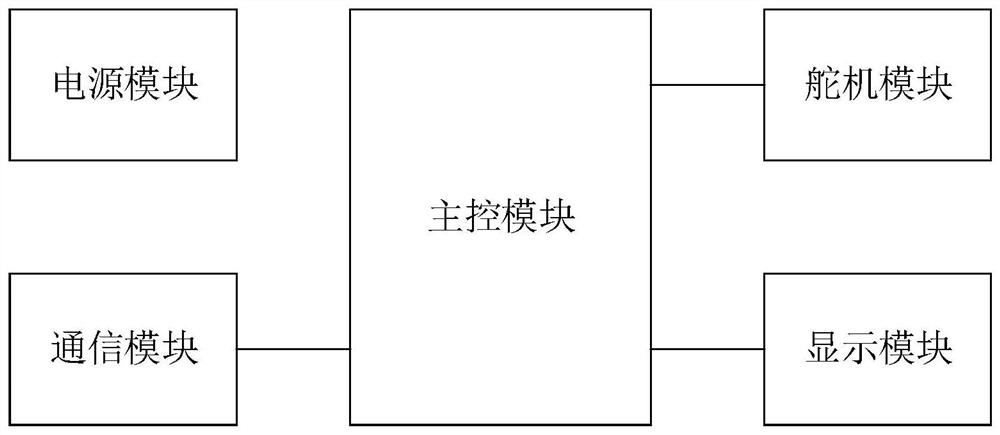

Temporal-mandibular joint in-vitro simulation simulator

ActiveCN112700703AGuaranteed continuous outputStable outputEducational modelsPhysical medicine and rehabilitationControl signal

The present invention discloses a temporal-mandibular joint in-vitro simulation simulator comprises a simulation skull model, a skull fixing device, a three-dimensional space adjusting device, a control device and a transmission device. The control device is used for generating a control signal, the transmission device is used for transmitting power to the three-dimensional space adjusting device, and the three-dimensional space adjusting device is used for adjusting the position, so that the upper jawbone and the lower jawbone in the simulation skull model complete double-side linkage simulation opening and closing movement with the condyle process as the axis; and functional motion of temporomandibular joints can be fully simulated, and joint motion in physiological and various pathological states can be simulated by adjusting joint motion frequency.

Owner:SICHUAN UNIV

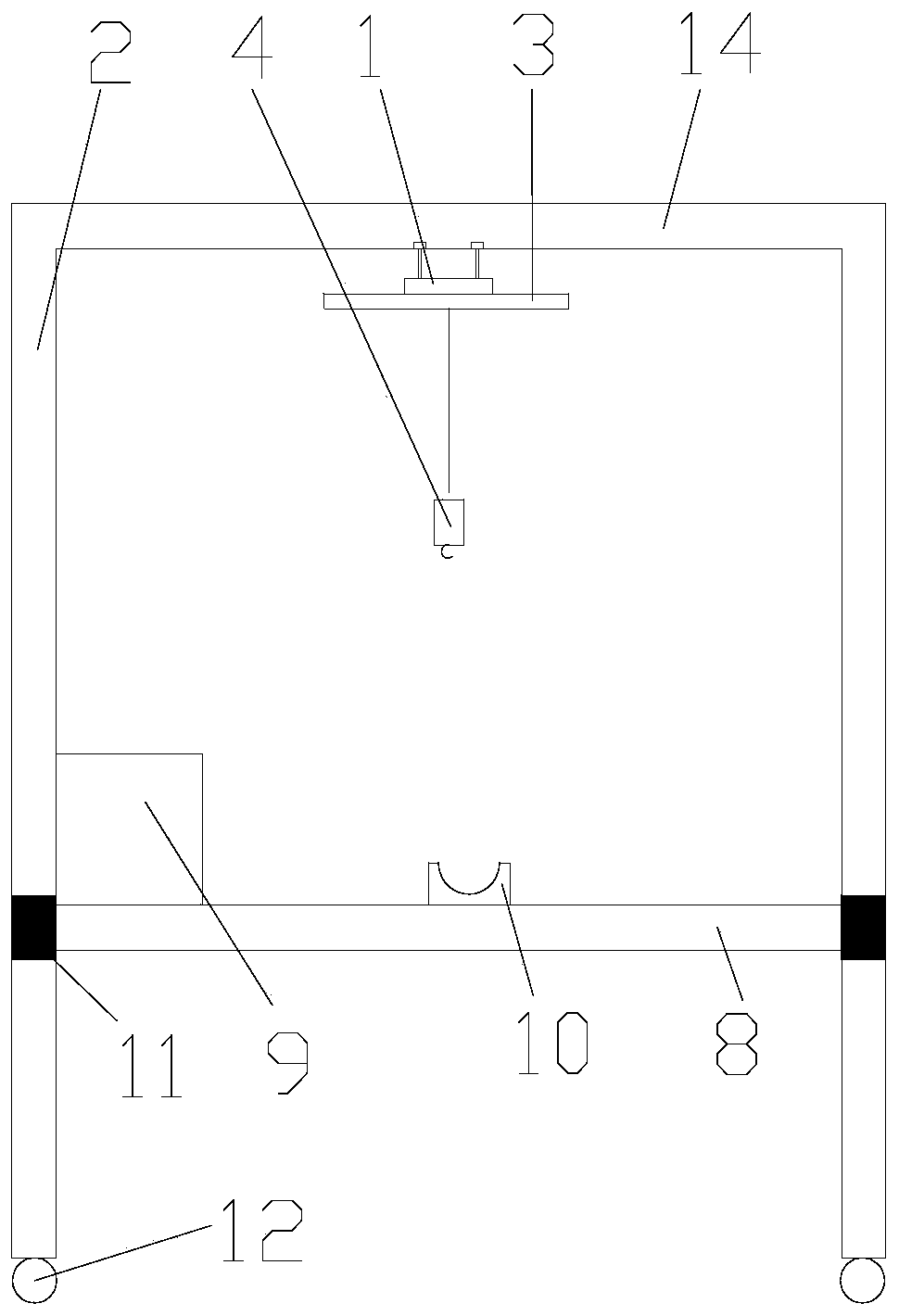

Double-end tapping device for sphygmomanometer watchcase

ActiveCN106670593AEasy to adjust the positionQuick position adjustmentThread cutting machinesSphygmomanometerControl system

The invention provides a double-end tapping device for a sphygmomanometer watchcase, and solves the problems that when an internal thread of the sphygmomanometer watchcase is machined by adopting a conventional machining method, not only is the machining efficiency low, but also the machining precision is easily influenced by repeated workpiece clamping and the labor intensity of workers is very high. The double-end tapping device comprises a baseplate, a double-end automatic tapping machine and a PLC control system, wherein a vertically-arranged workpiece limiting groove is arranged at the front end of a bracket; a first air cylinder and a first electromagnetic valve are mounted on the rear side of the bracket; a supporting plate is fixedly connected with the front end of a piston rod of the first air cylinder; a second air cylinder and a second electromagnetic valve are mounted on the front side of the bracket; an inductive switch, directly facing a workpiece positioned at the bottom of the workpiece limiting groove, is mounted on the bracket; two screw taps of the double-end automatic tapping machine are aligned with the to-be-machined position of the workpiece positioned at the bottom of the workpiece limiting groove; a first contact rod and a second contact rod are mounted on a main shaft of the double-end automatic tapping machine; and a first travel switch and a second travel switch are mounted in the double-end automatic tapping machine.

Owner:来安县永阳知识产权运营有限公司

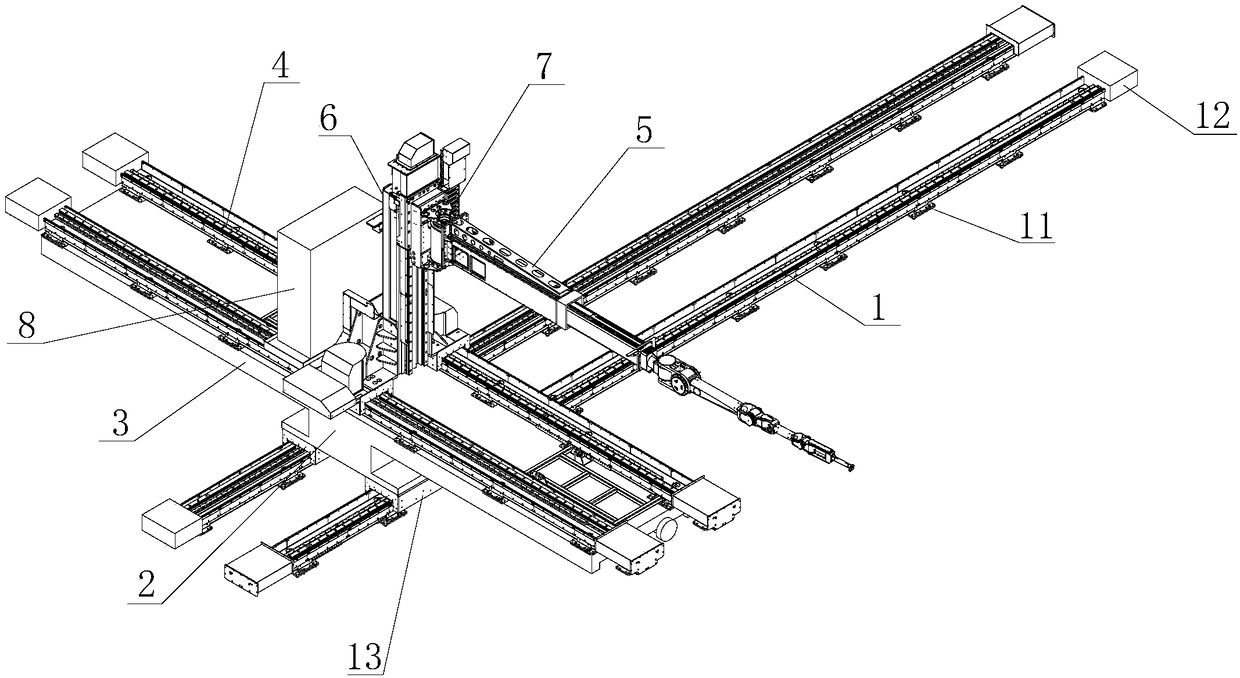

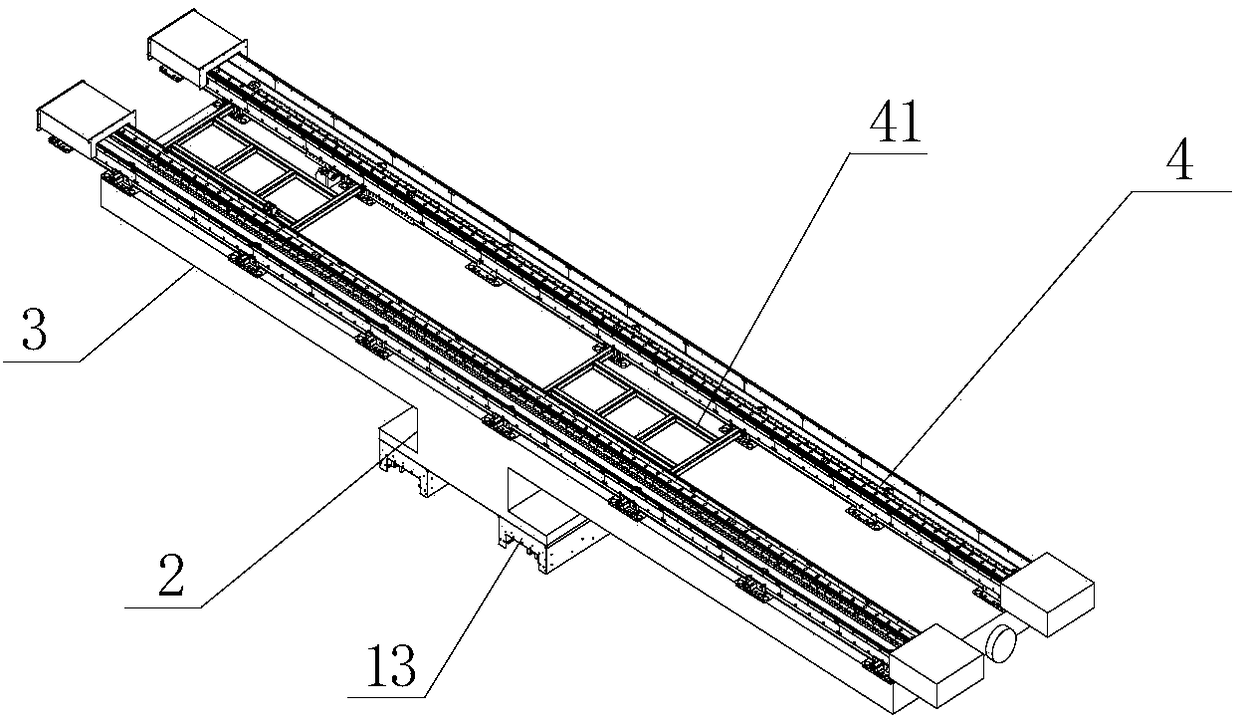

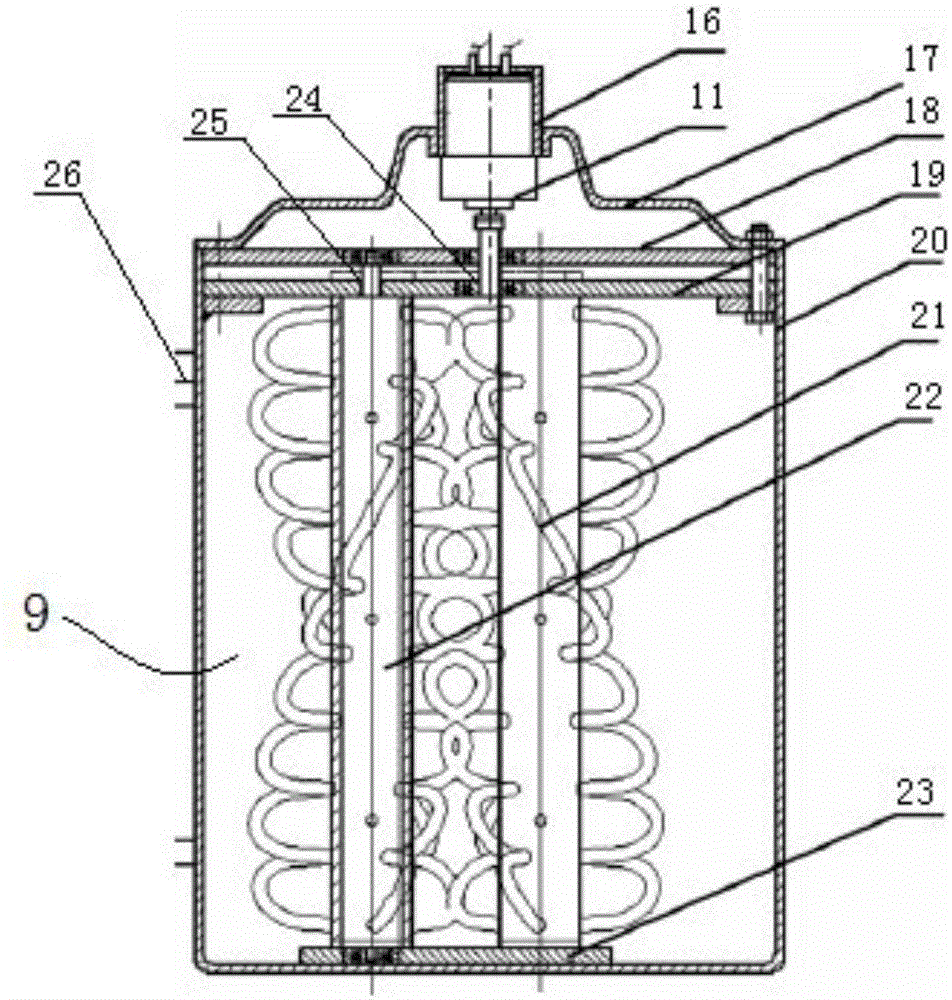

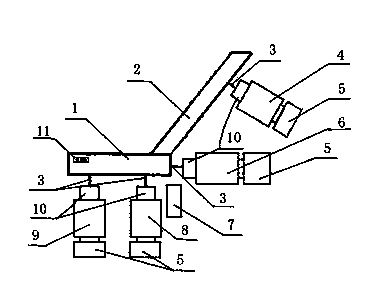

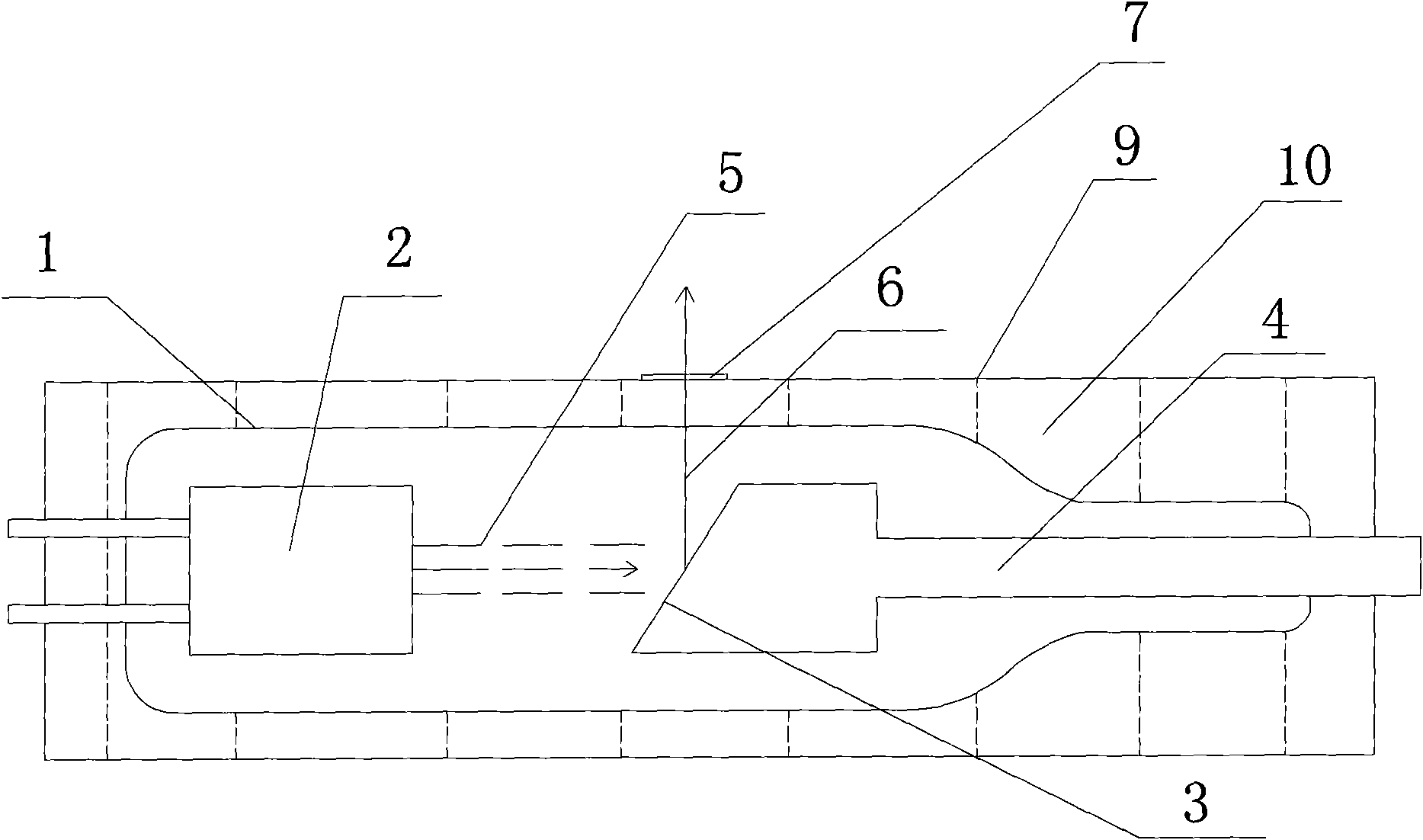

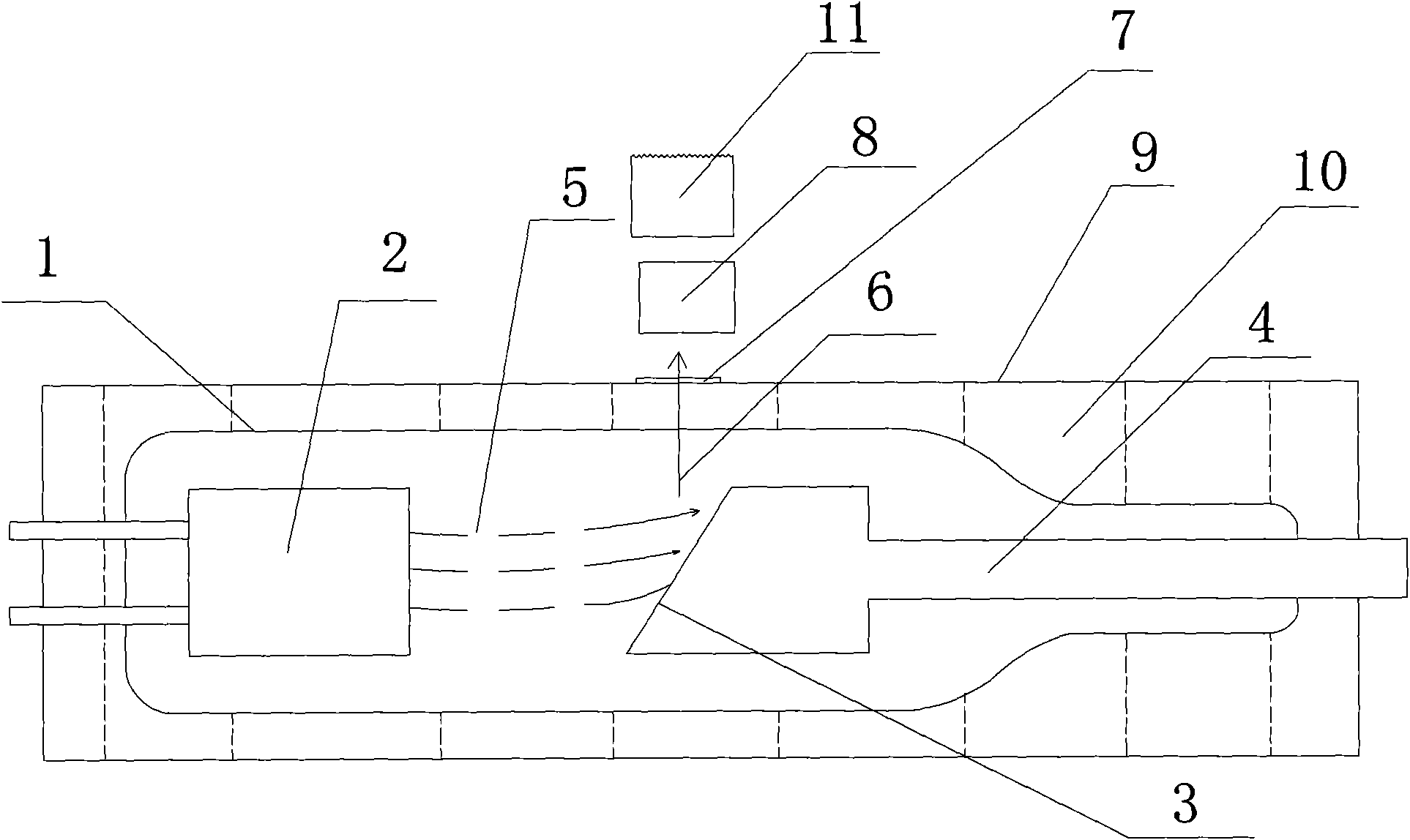

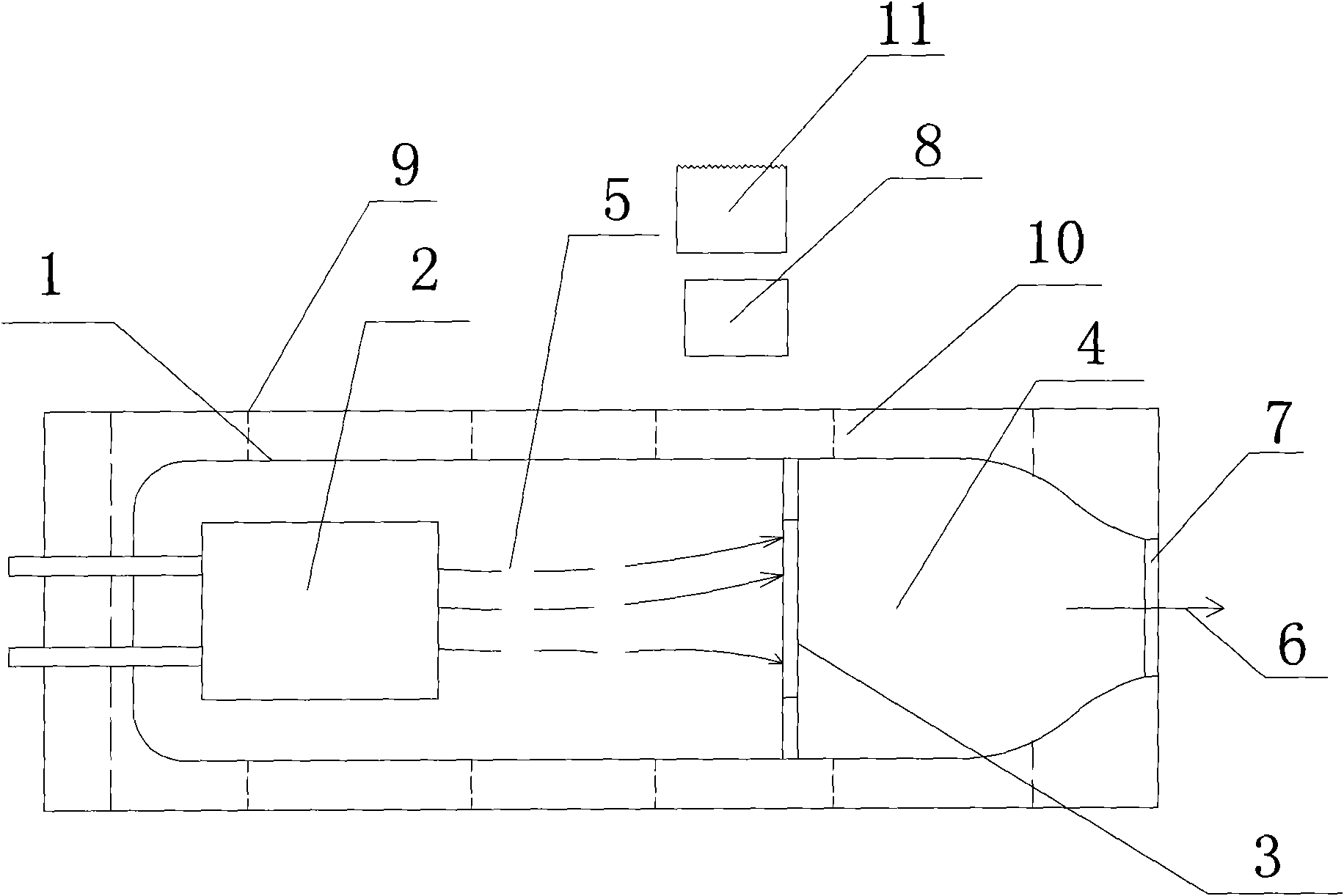

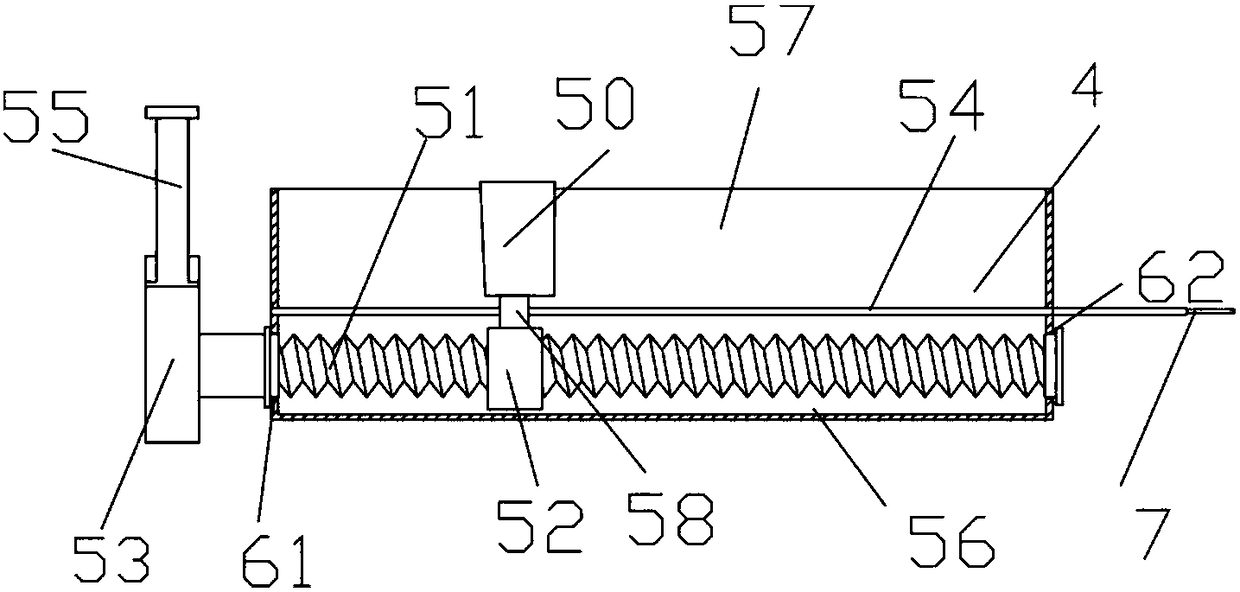

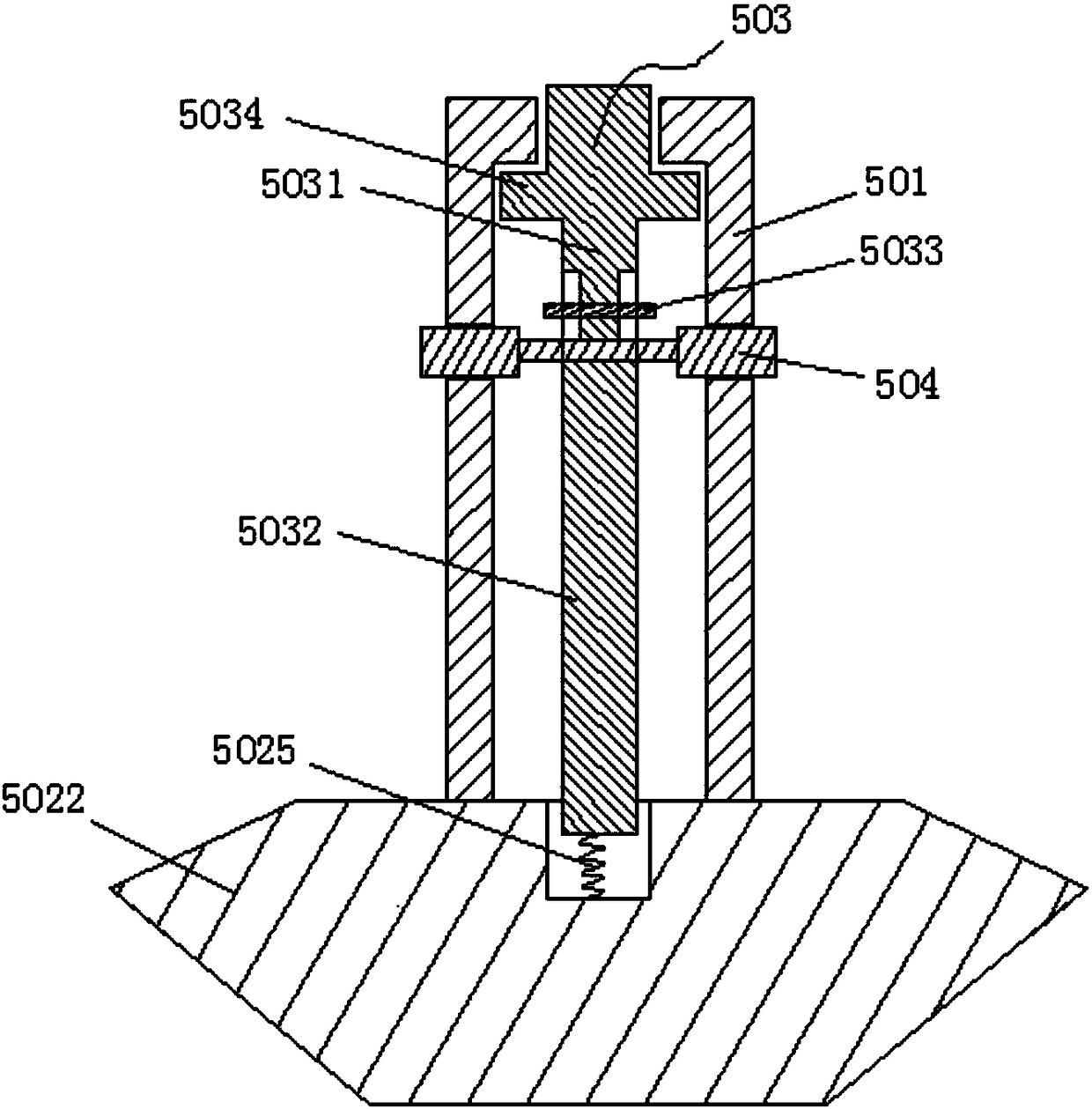

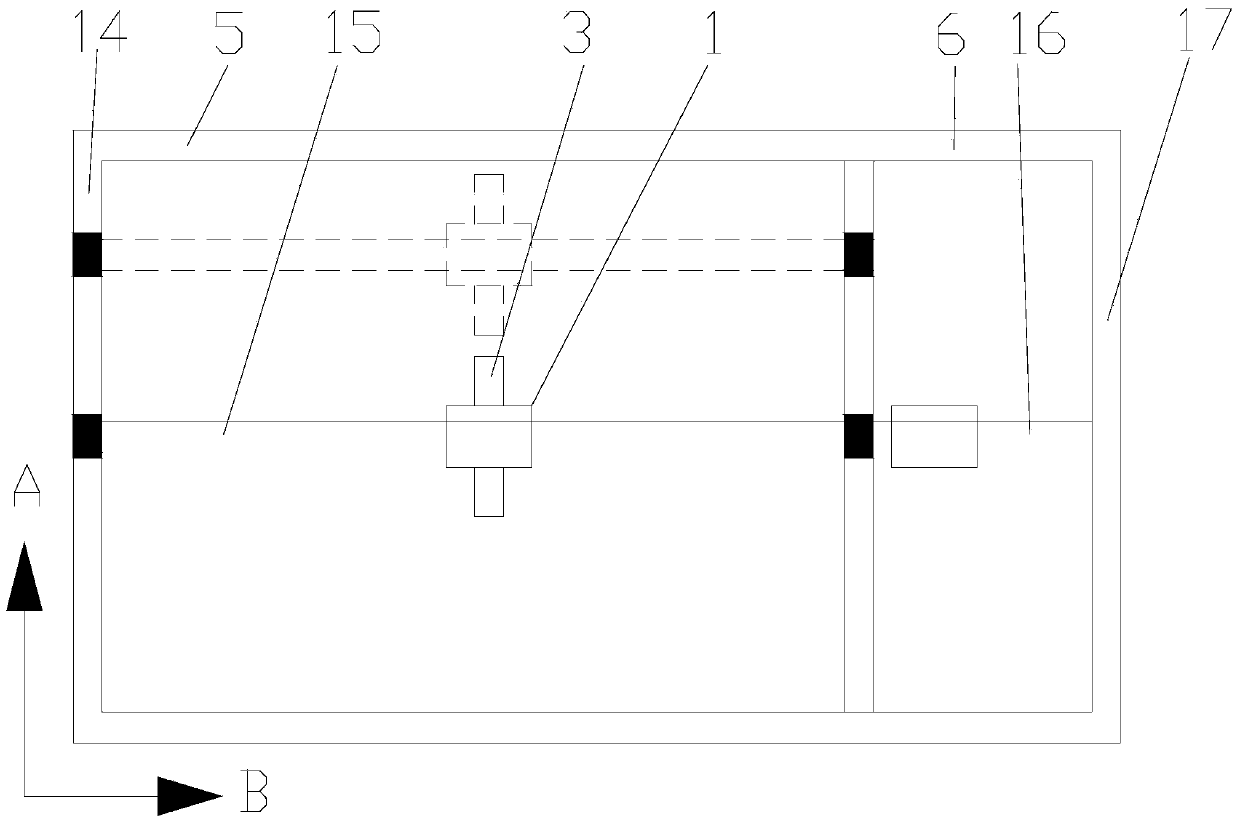

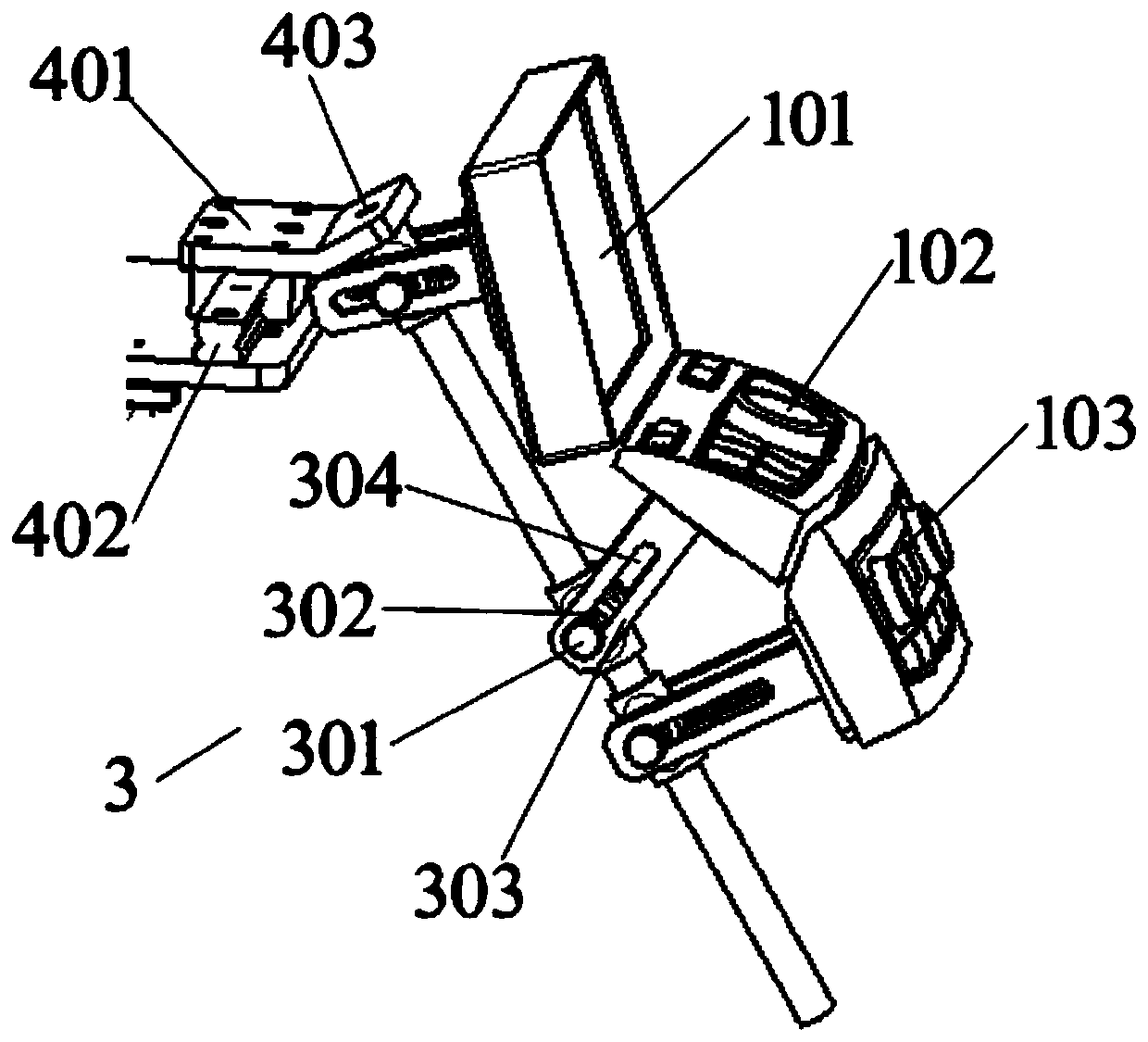

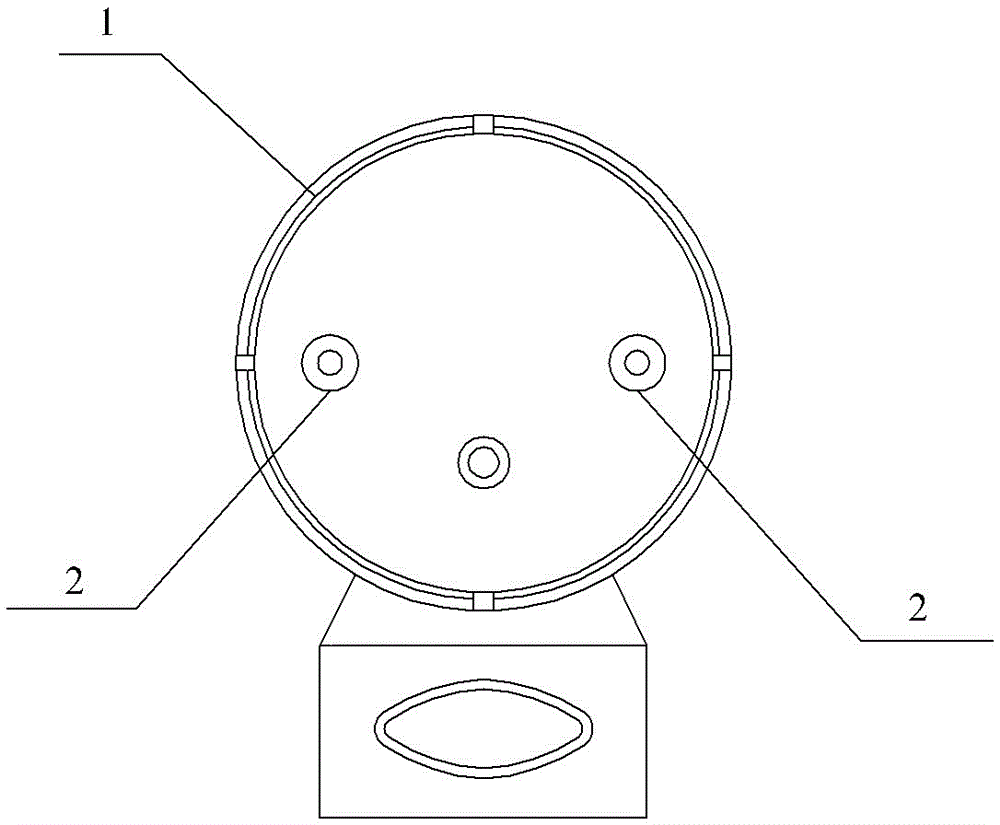

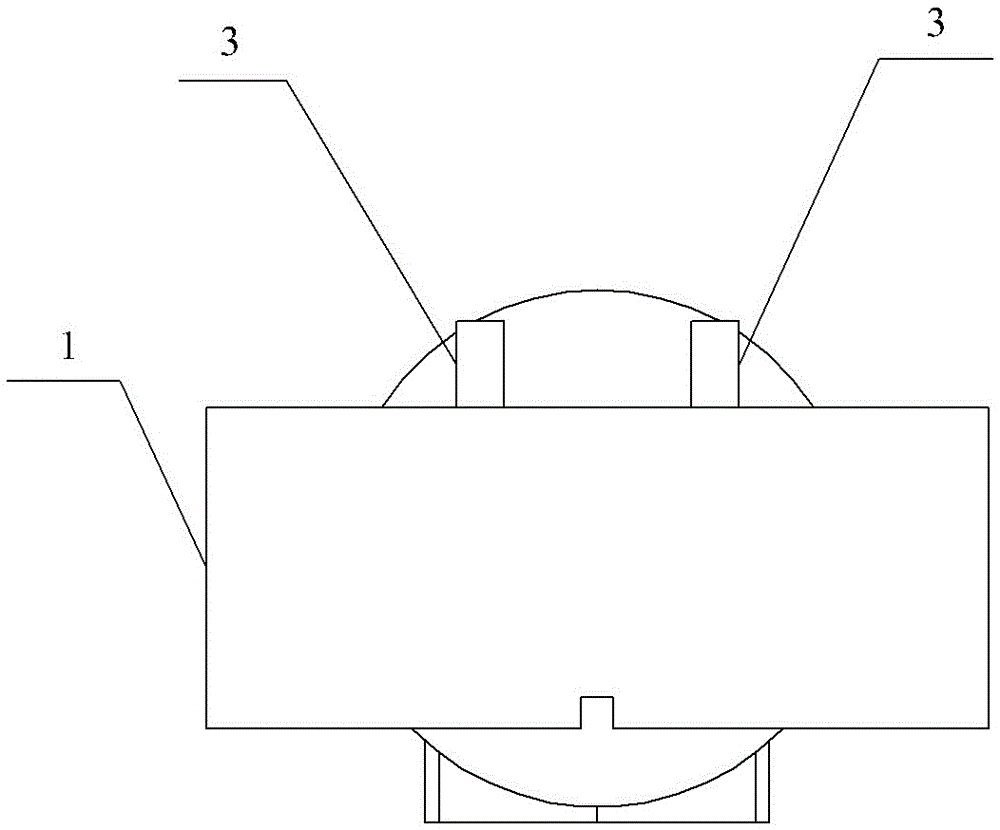

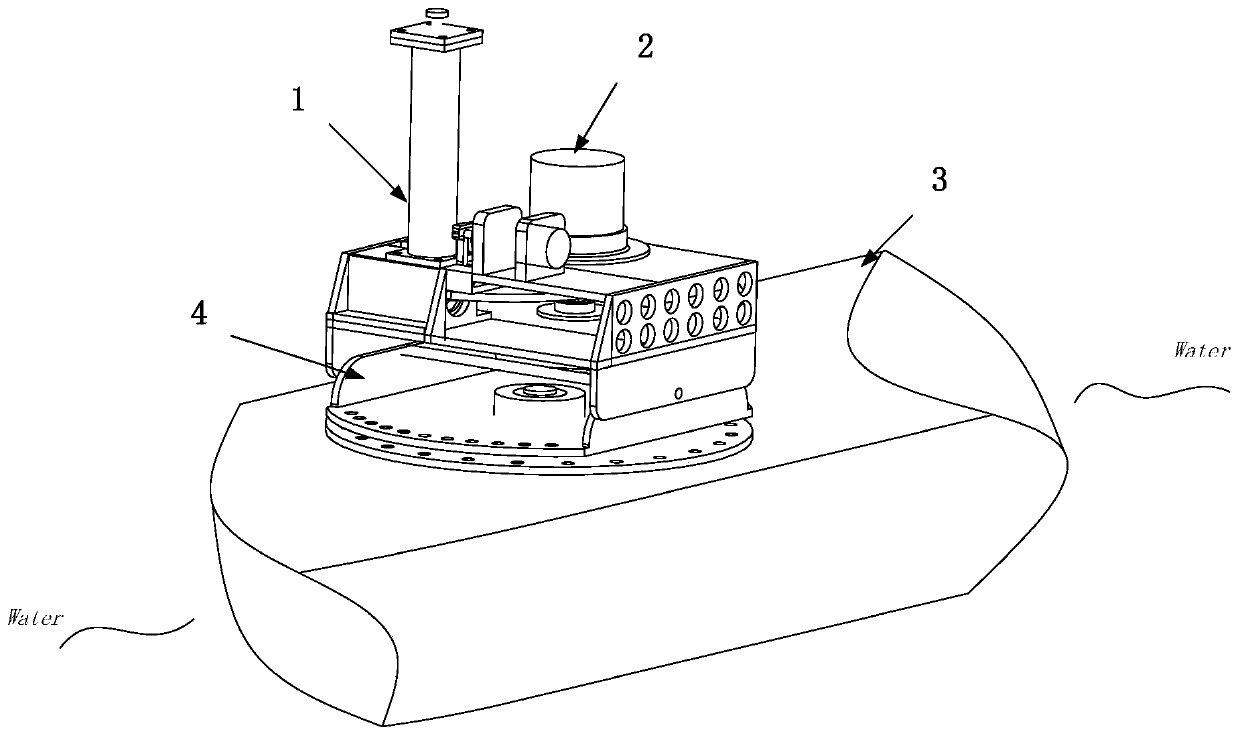

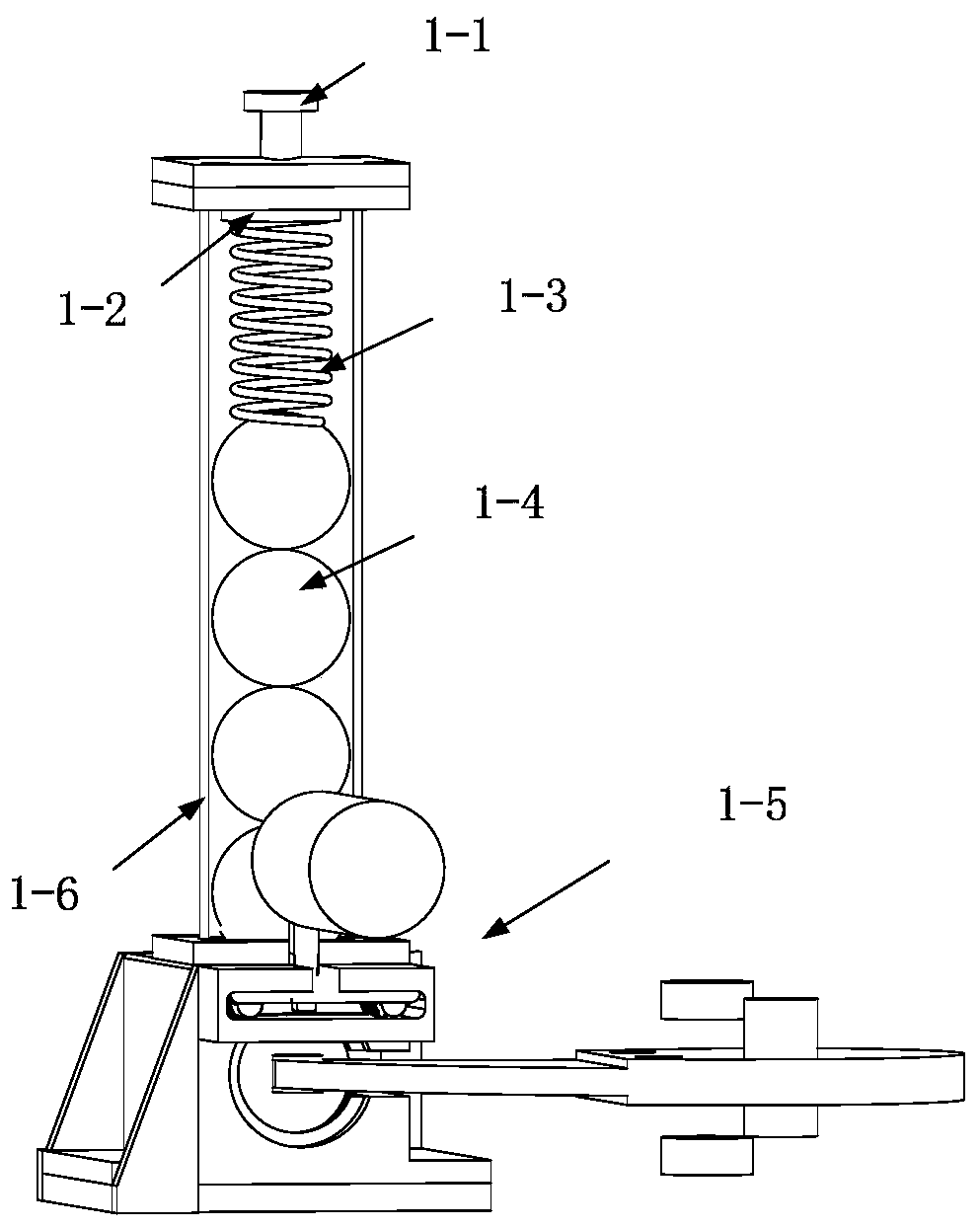

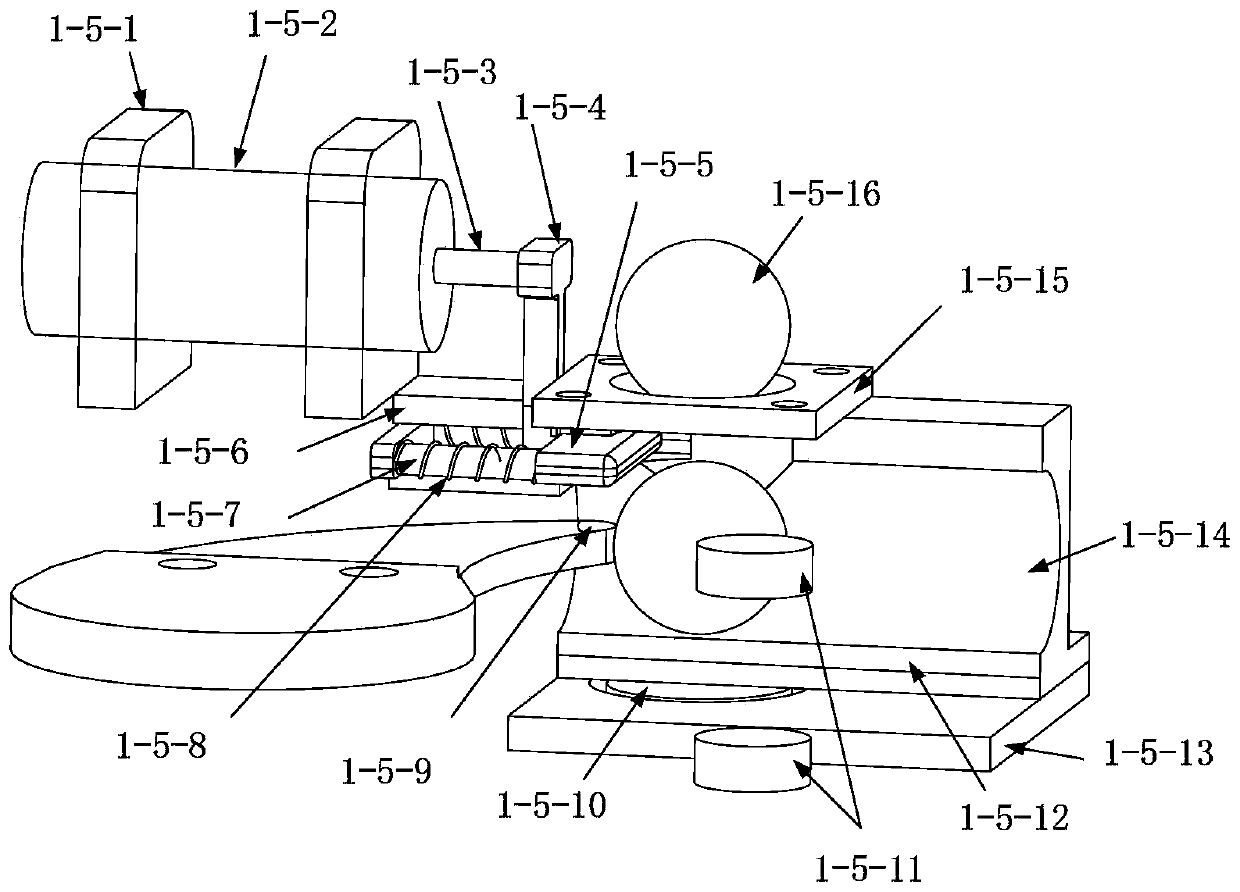

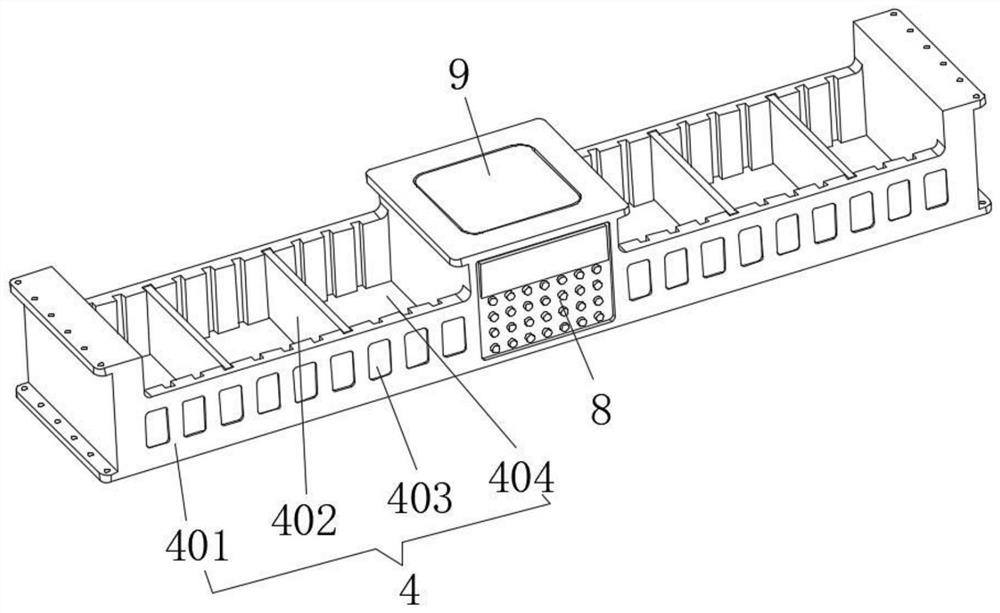

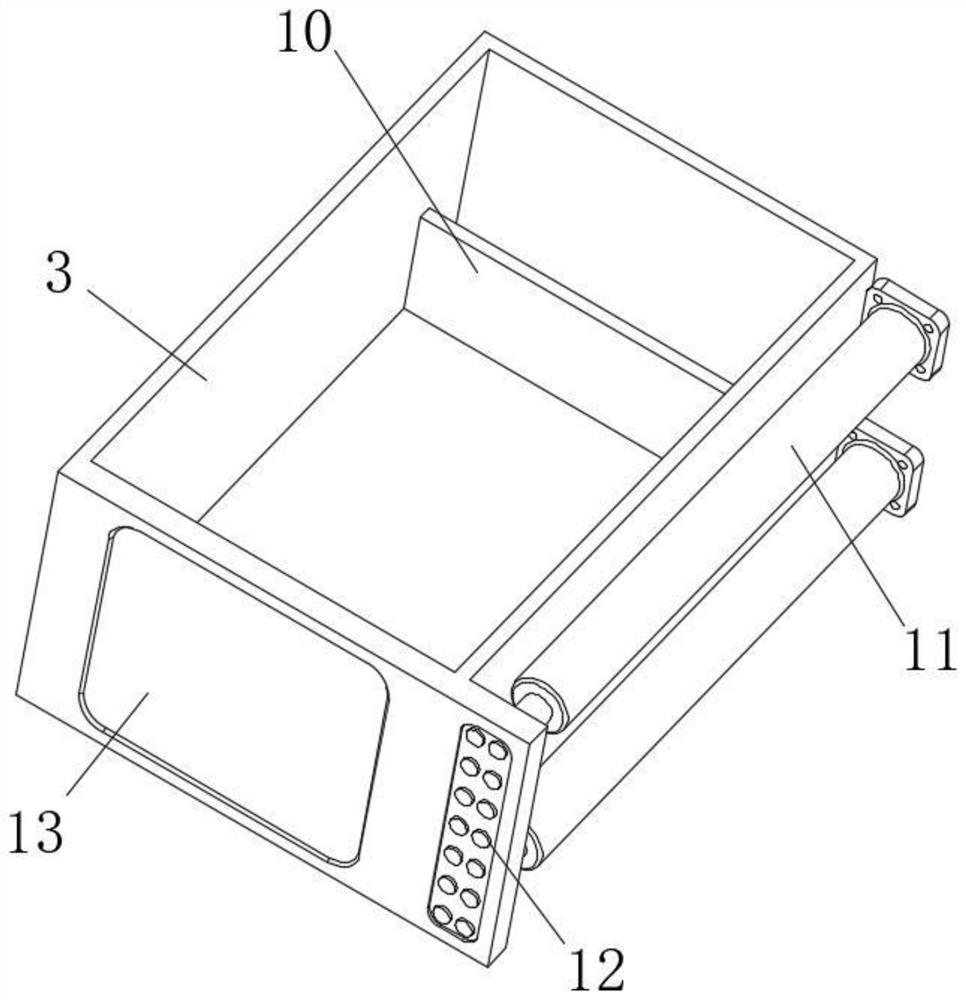

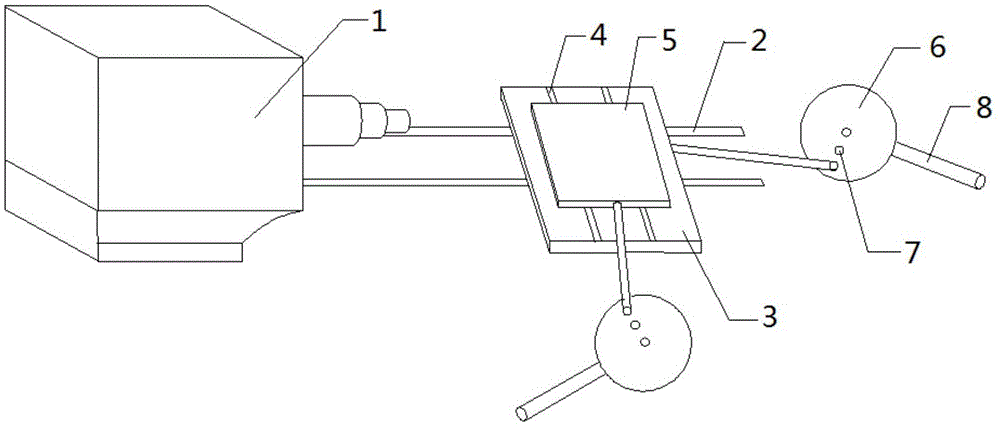

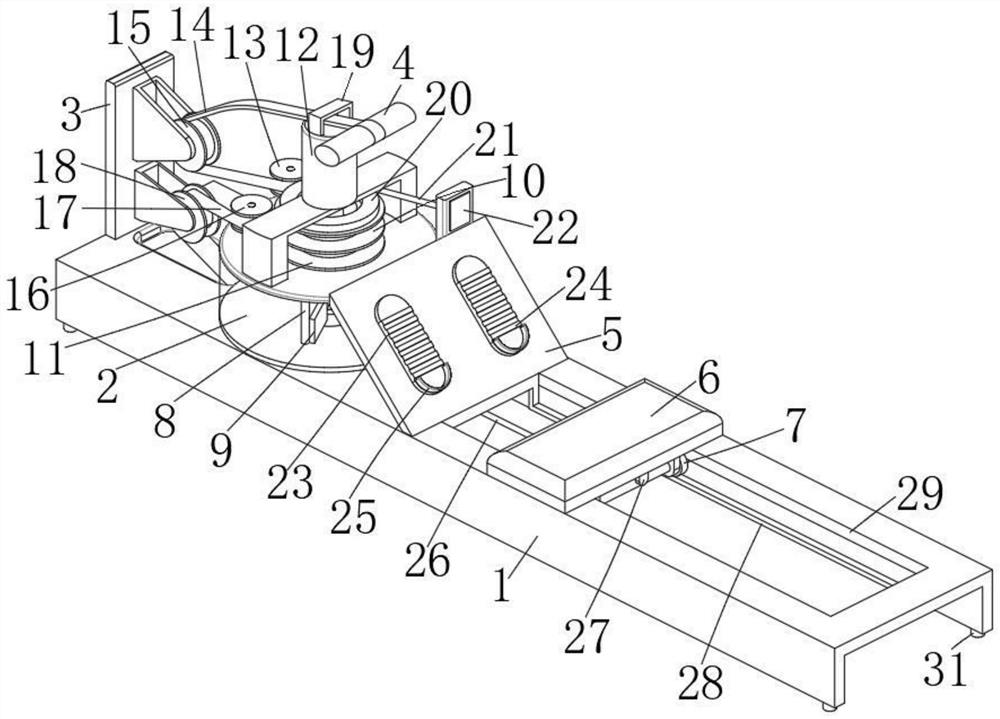

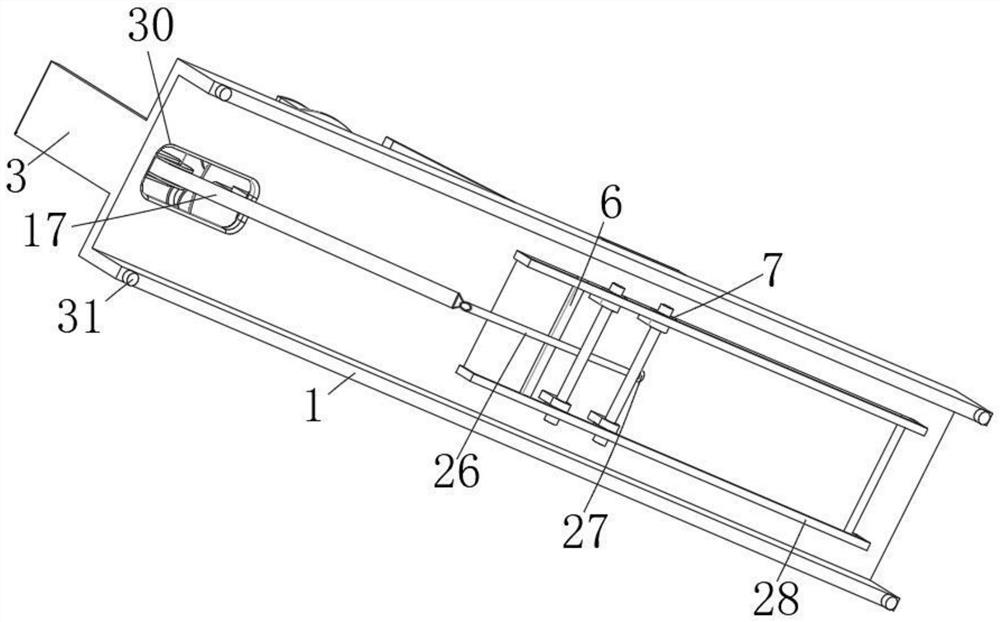

Novel hydrodynamic high-frequency cannonball launching reoil simulation test device

ActiveCN111336861ASimulate the realAvoid stabilityTraining adaptationEducational modelsScale modelClassical mechanics

The invention relates to a novel hydrodynamic high-frequency cannonball launching recoil simulation test device, and belongs to the technical field of hydrodynamic test simulation systems. In order tosolve the technical problems that the stability of a ship under a special operation condition is not considered in the existing ship body stability test, the defects exist in the test process, the influence of the continuous pulse type cannonball recoil on the ship body attitude angle in the high-frequency launching process of the ship cannonball is not studied and analyzed and the like, the invention designs a simulation test device comprising a cannonball positioning and conveying device 1, a cam rotating high-frequency knocking structure 2, a ship model upper end face 3 and a cannonball direction adjusting structure 4, equivalent high-frequency cannonball launching impulse action conditions can be provided for a test model, and the test environment of a scaling model water surface shooting operation can be simulated more truly. The defect that a traditional stability test does not consider the influence condition of cannonball shooting on the ship body is overcome, so that the hydrodynamic stability of a naval vessel is simulated more truly, and the accuracy of the hydrodynamic test of the naval vessel is improved.

Owner:CHINA SPECIAL TYPE FLIER RES INST +1

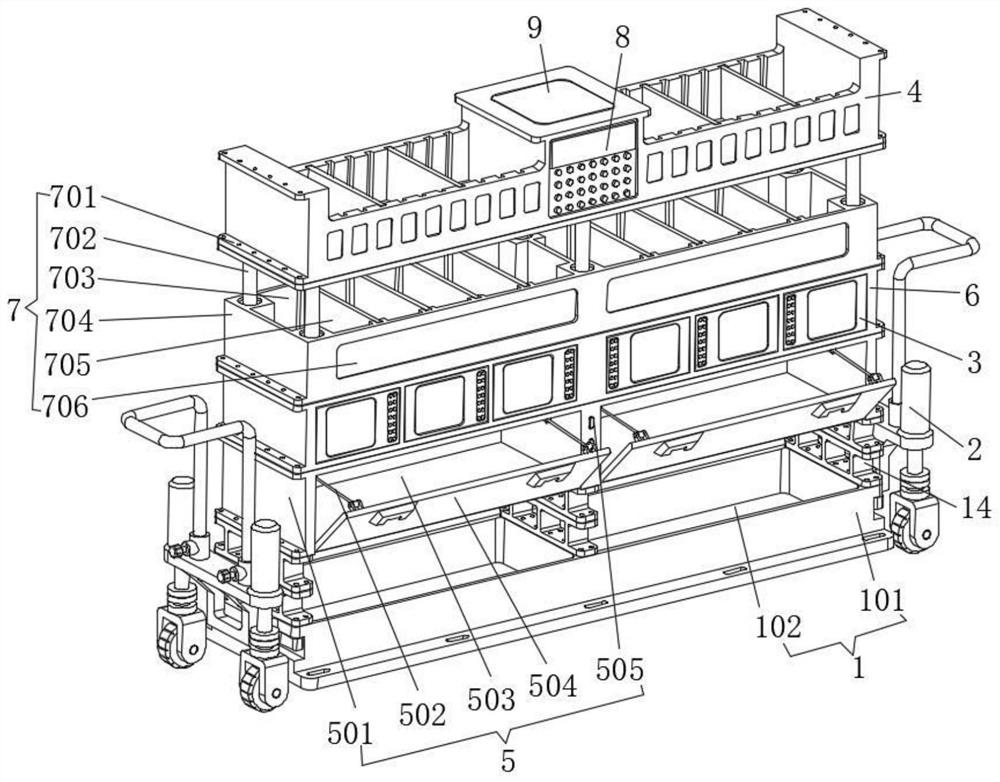

Common part classified storage device for automobile maintenance

The invention relates to the technical field of automobile maintenance, in particular to a common part classified storage device for automobile maintenance. The common part classified storage device comprises a bottom mounting frame, the bottom mounting frame comprises a base placed on the ground, and the base is provided with a bottom storage cavity for placing large parts; and at least one height adjusting support is installed above the base in a series connection manner through bolts, and a large part sealing frame is arranged above the height adjusting support. The common part classified storage device has the beneficial effects that the classified storage device designed by the invention can utilize the bottom storage cavity, a sealing cavity, a storage drawer, a middle part storage cavity and a spare part storage cavity to carry out classified storage and sealing management on automobile parts with various sizes, so that maintenance personnel can quickly find the required parts effectively and conveniently, damage to the parts due to direct exposure to air can be effectively reduced, the use safety is effectively improved, and all layers of structures in the device can be freely purchased and assembled according to use requirements.

Owner:费青龙

driller

ActiveCN103990833BQuality improvementImprove drilling efficiencyBoring/drilling componentsBoring/drilling machinesEngineeringMechanical engineering

Owner:芜湖皖拓机械科技有限公司

Household water resistance rowing machine

ActiveCN114515407AAdjust resistanceQuick position adjustmentMuscle exercising devicesMovement coordination devicesHome useWater use

The invention relates to the field of exercise and fitness equipment. The household water resistance rowing machine comprises a base, a resistance water tank arranged on the base, a supporting frame, a pull rope mechanism, a reset rope mechanism, a handle connected with the pull rope mechanism, a pedal device and a cushion part, and a water resistance device is arranged in the resistance water tank and rotationally installed in the resistance water tank. The water resistance device comprises a rotating blade and is characterized in that a resistance adjusting mechanism is arranged at the water resistance device, and the resistance adjusting mechanism is matched with the rotating blade to achieve resistance adjustment. According to the domestic water resistance rowing machine, the arranged resistance adjusting mechanism can adjust the position of the adjusting baffle quickly and accurately, the good resistance adjusting effect is guaranteed, and the domestic water resistance rowing machine is more suitable for home use and can meet the use requirements of people of different genders and different age groups.

Owner:浙江力玄运动科技股份有限公司

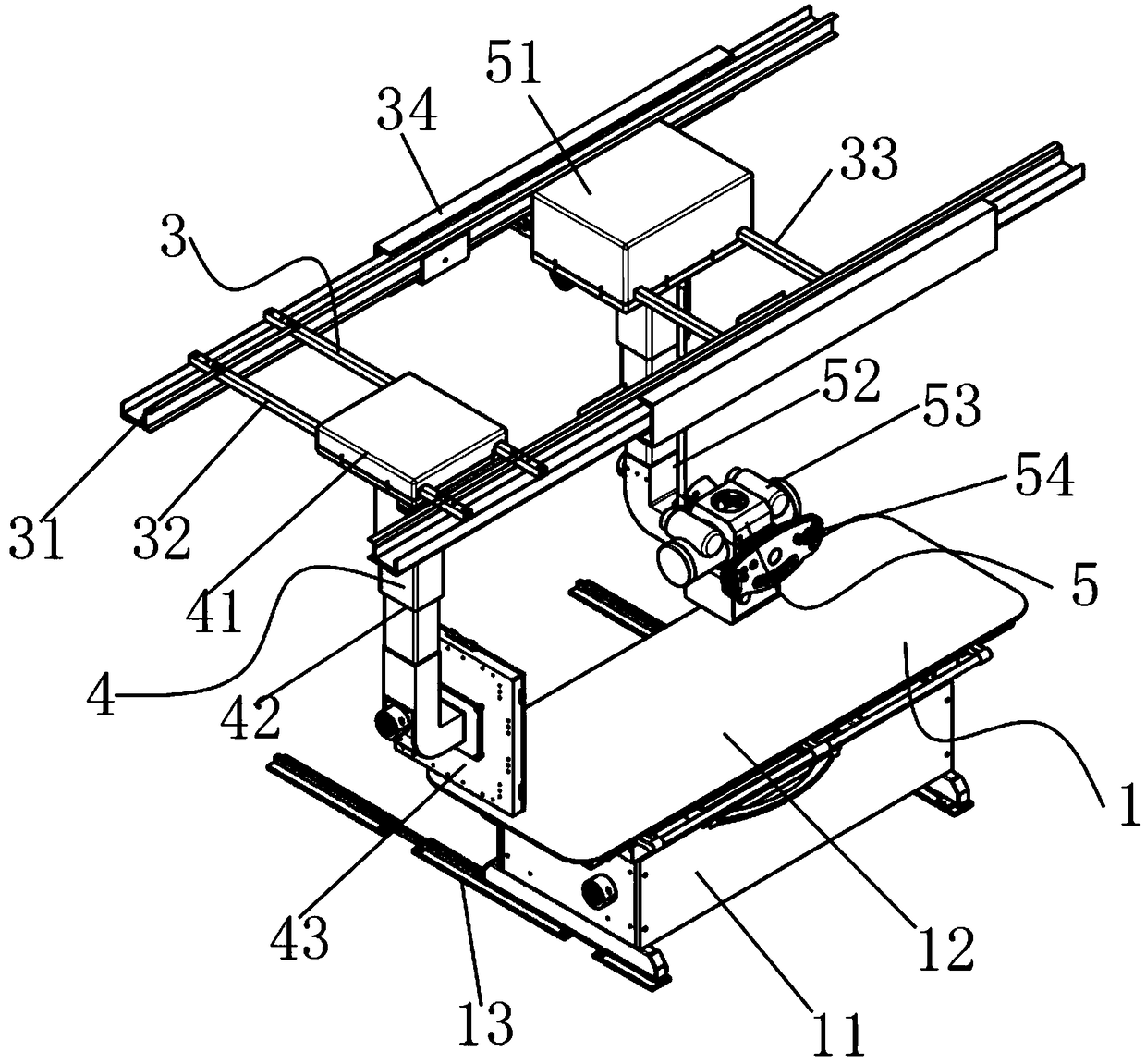

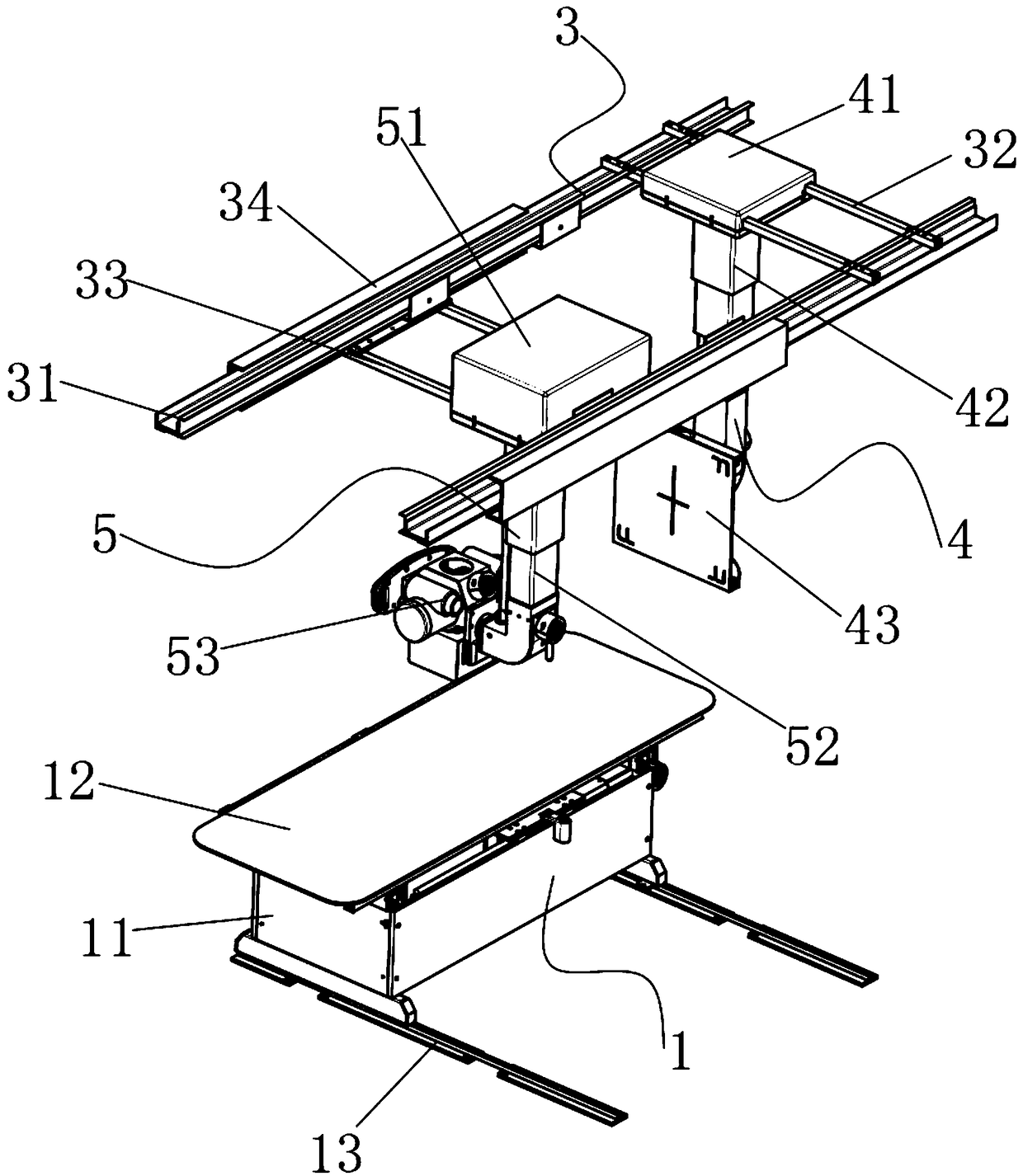

Dual-suspension DR

PendingCN108852395ASmall footprintExpand the scope of workPatient positioning for diagnosticsRadiation generation arrangementsX-rayEngineering

The invention discloses a dual-suspension DR. The dual-suspension DR includes an X-radiography bed and a dual-suspension device arranged above the X-radiography bed. The dual-suspension device includes a suspended frame, a suspended rack and a suspended X-ray generating device, and the suspended rack and the suspended X-ray generating device are both slidingly connected with the suspended frame. By means of the design above, the disclosed dual-suspension DR solves the problem that digital X-radiography machines in the prior art occupy a large working space. The dual-suspension DR has the advantages of being convenient to operate, wide in application range and the like.

Owner:石家庄华东医疗科技有限公司

Node cooperative work method based on sensing direction guide in internet of things environment

ActiveCN101841930BEasy to understandAchieve transparencyNetwork topologiesHigh level techniquesCooperative workEnergy consumption

Owner:NANJING UNIV OF POSTS & TELECOMM

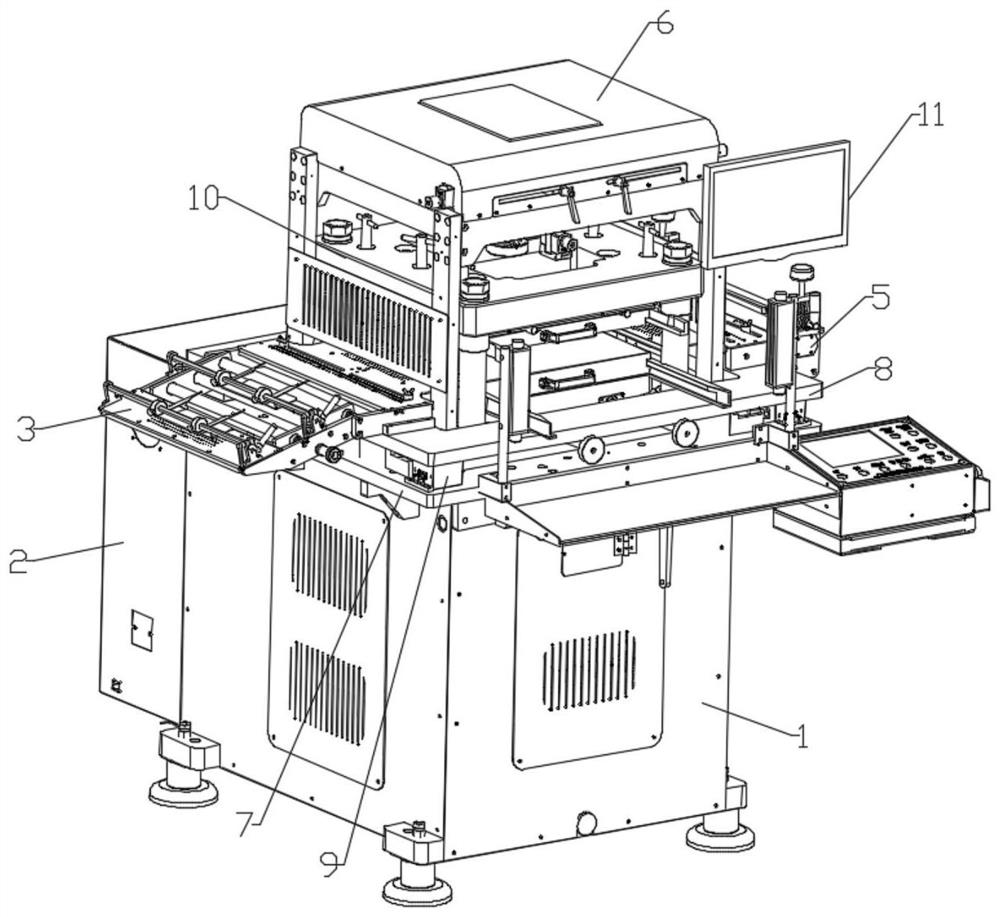

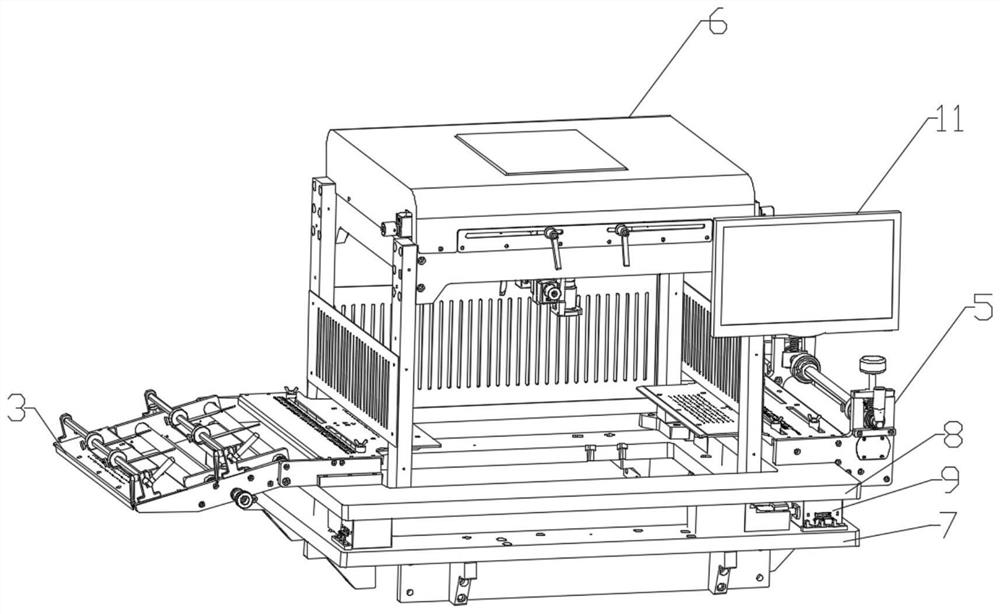

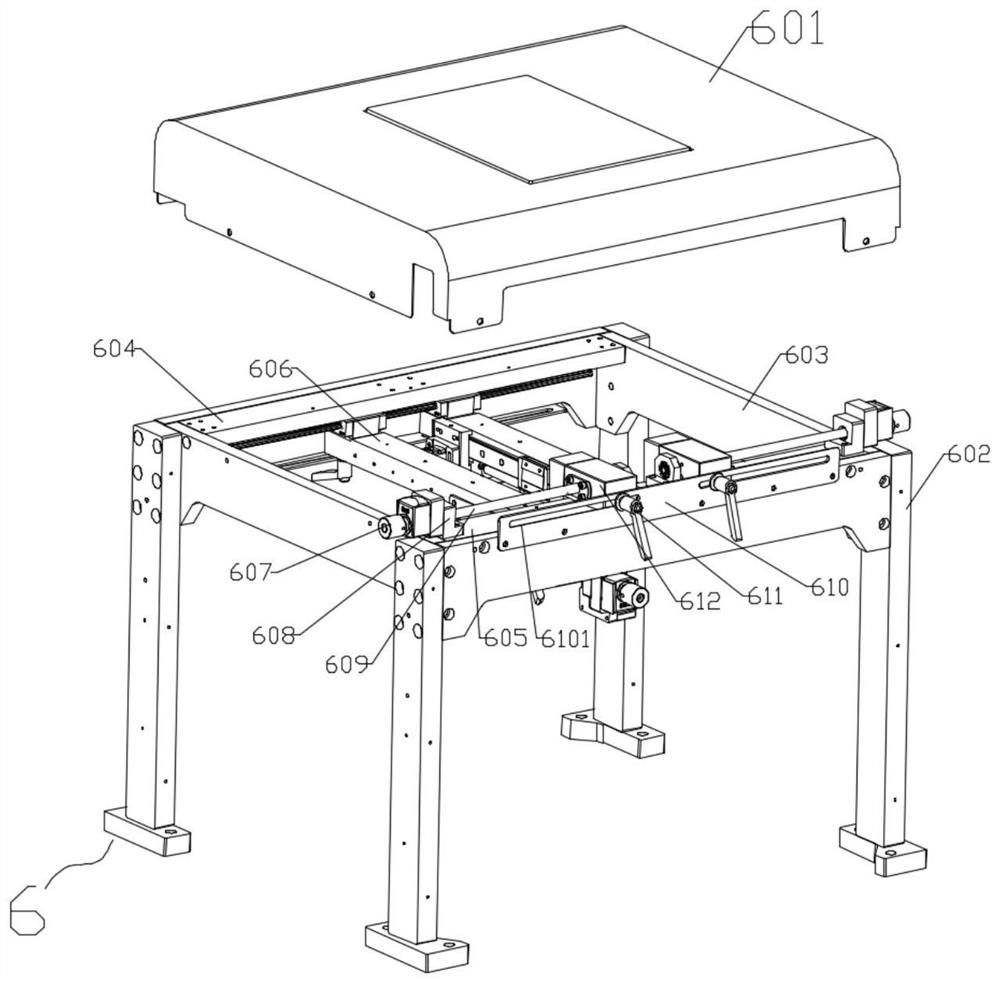

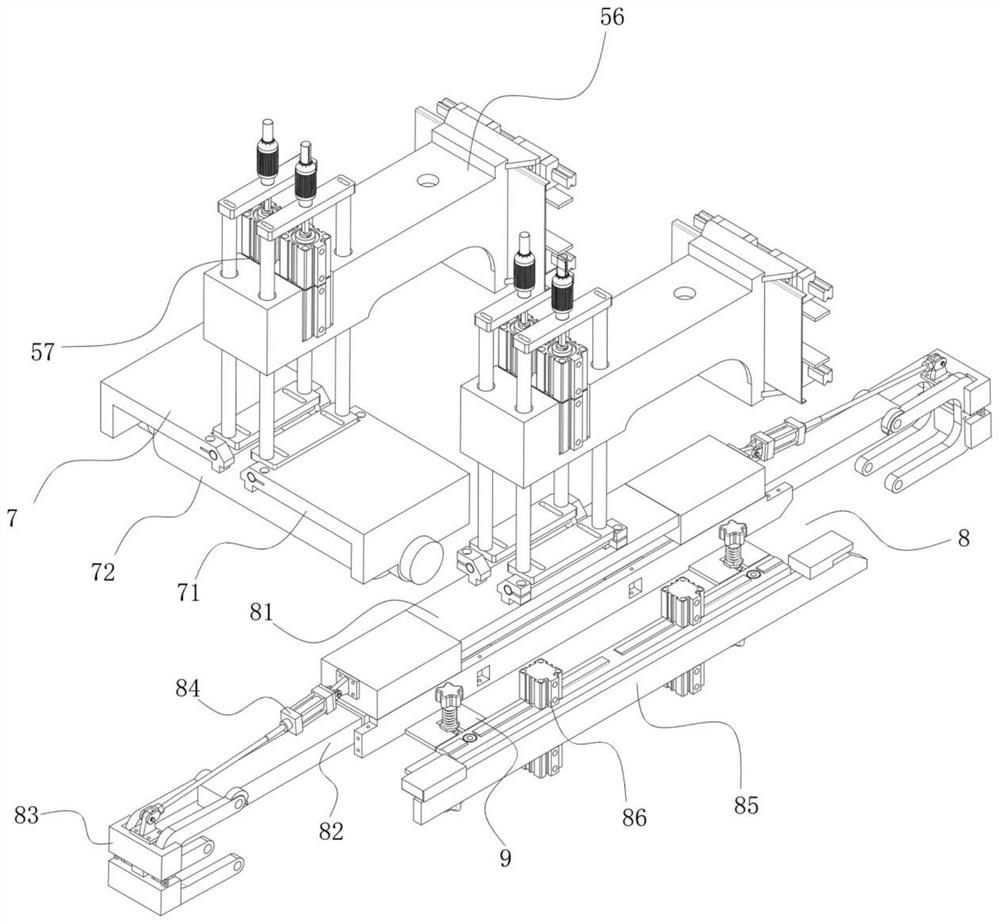

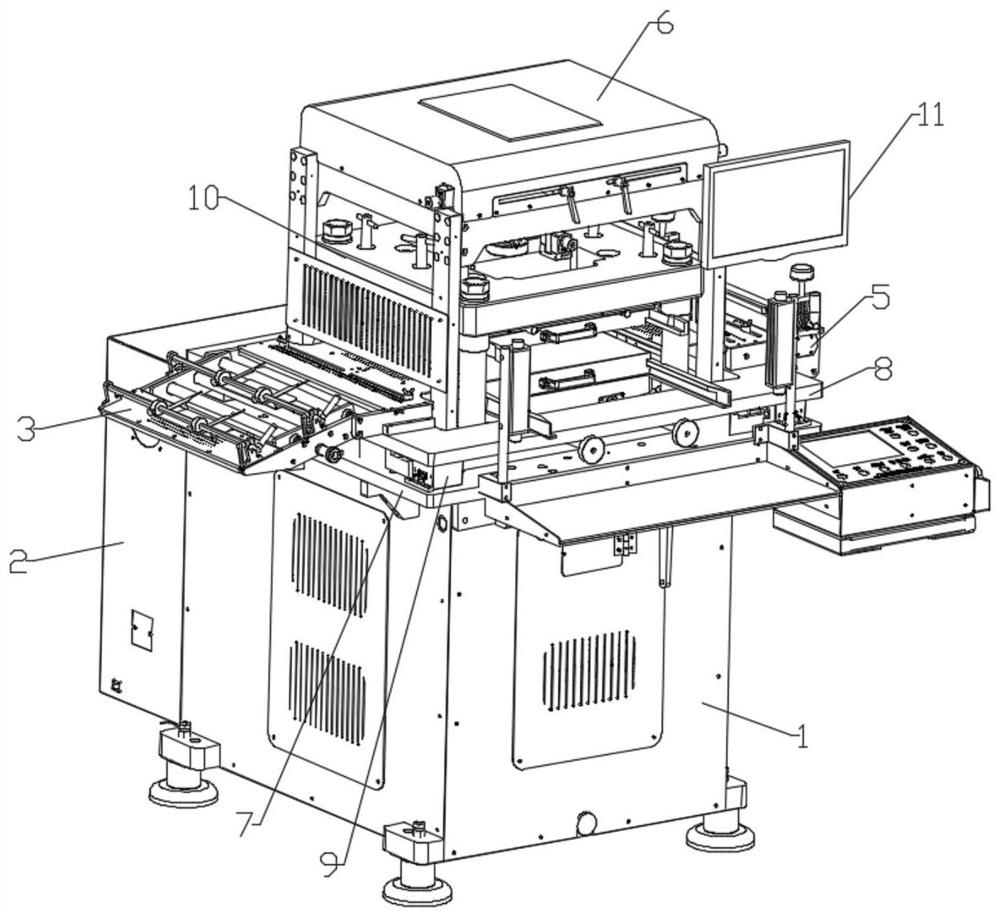

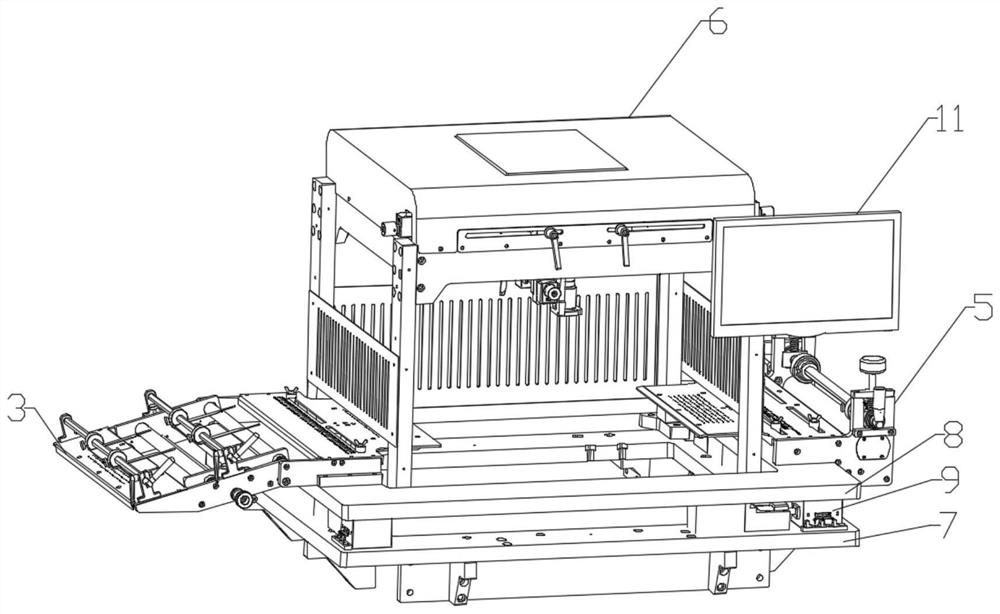

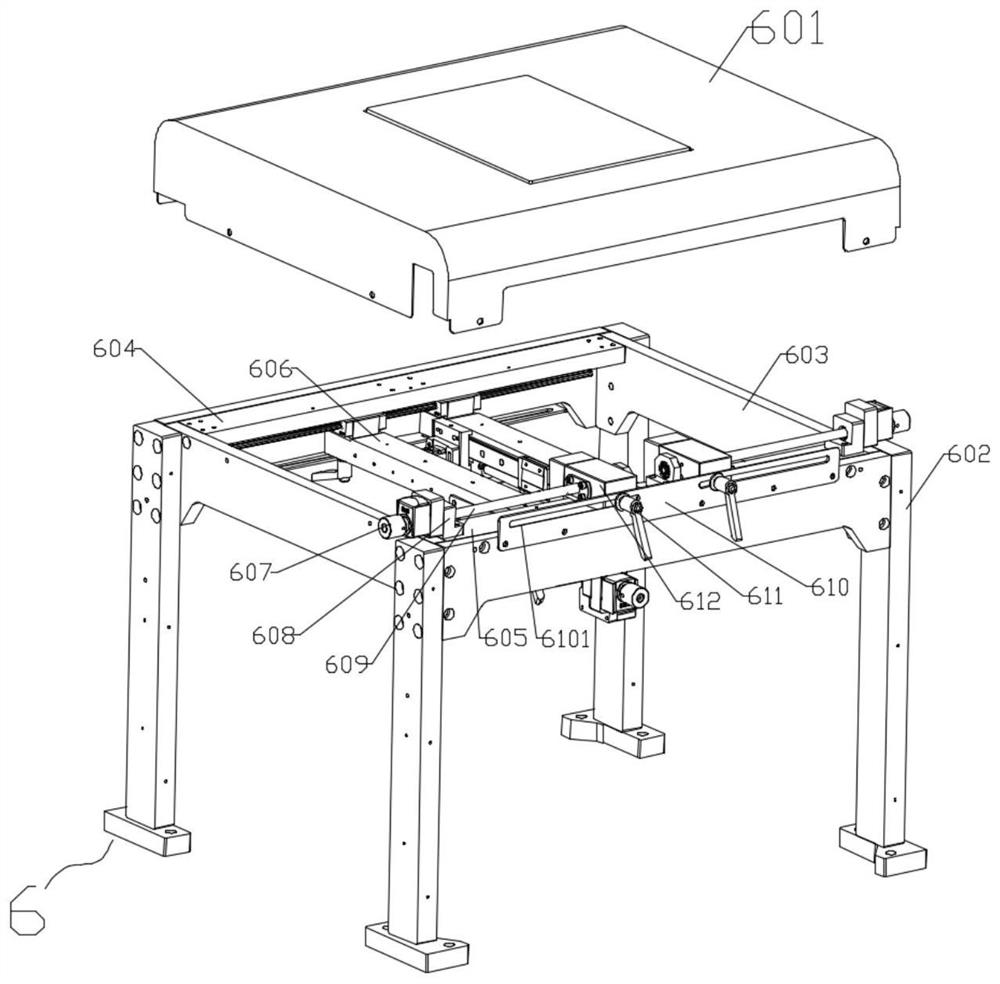

CCD positioning and correcting die-cutting machine

ActiveCN112720693ACompact structureQuick position adjustmentMetal working apparatusConveyor partsEngineeringCcd camera

The invention relates to a CCD (Charge Coupled Device) positioning and correcting die-cutting machine which comprises a die-cutting main machine used in a die-cutting process, a power case used for providing power for the die-cutting machine, a feeding assembly used for feeding materials, a pulling assembly used for discharging the materials and providing material transmission power, and a visual positioning mechanism used for positioning the materials in the die-cutting main machine, The die-cutting main machine is stably placed on the horizontal ground, the power case is installed on the rear side face of the die-cutting main machine, the feeding assembly and the material pulling assembly are oppositely installed on the two sides of the die-cutting main machine, and the visual positioning mechanism is installed over the die-cutting main machine. According to the die-cutting machine, the two sets of X-axis driving mechanisms and the two sets of Y-axis driving mechanisms which are independently controlled are utilized, each camera is rapidly, conveniently and independently adjusted to any position in the horizontal direction, in the adjusting process, shaking of the CCD camera is small, and the positioning precision is higher.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

Back stacking type ultrathin glass thinning method

PendingCN114315164AHigh strengthQuick position adjustmentFlexible article cleaningAdhesiveStructural engineering

The invention discloses a method for thinning back-stacked ultrathin glass. The method comprises the following steps: S1, providing two pieces of glass to be thinned; s2, attaching an isolating membrane to the non-thinned surface of the glass; s3, the periphery of the glass attached with the isolating membrane is subjected to edge sealing with UV glue, and UV photocuring is carried out; s4, the faces, attached with the isolating membranes, of the two pieces of glass are attached together in a back-to-back mode and put into an etching basket to be thinned; and S5, after completion, taking out the two pieces of glass, cleaning, tearing off the UV glue and the isolating membrane, and then cleaning. According to the invention, the non-thinned surface of the glass is covered and protected by the isolating membrane, and the edge is sealed by the UV adhesive, so that the side wall of the glass is protected, and the protecting effect is prevented from being influenced by the flanging of the isolating membrane. The size of the isolating membrane is slightly smaller than that of the glass, so that the attaching effect is improved, and edge warping during attaching is avoided. And during attachment, water is used as a lubricant, so that the position of the isolating membrane can be conveniently and quickly adjusted to ensure that the isolating membrane is attached in place, and the protection effect of the isolating membrane is ensured.

Owner:SUZHOU CRANE OPTOELECTRONICS TECH

Fabricated building material transportation device

PendingCN113511584AImprove securityAccelerated Flip PositioningVibration suppression adjustmentsLoad-engaging elementsConstruction engineeringStructural engineering

The invention discloses a fabricated building material transportation device which comprises two sets of lifting devices, a turnover device and conveying devices. The two sets of lifting devices face each other and drive the turnover device to move up and down; the conveying devices are arranged on the left sides and the right sides of the lifting devices correspondingly; the conveying device on the left side is lower than the conveying device on the right side; two sets of positioning and clamping devices are installed in the turnover device, are arranged on the left side and the right side and correspond to the conveying devices correspondingly; each set of positioning and clamping device comprises two sets of clamping assemblies and an auxiliary pressing assembly; and each two sets of clamping assemblies are horizontally arranged in parallel and located on the front side and the rear side of the corresponding auxiliary pressing assembly on the same plane.

Owner:GUANGZHOU CITY CONSTR COLLEGE

Drilling machine

InactiveCN104942330AQuality improvementImprove drilling efficiencyLarge fixed membersBoring/drilling machinesControl theoryDrilling machines

The invention relates to a drilling machine. The drilling machine is characterized by comprising a first guide rail, a first movable plate, a second guide rail, a second movable plate and two regulating and control portions. Due to the fact that the first guide rail and the second guide rail are arranged, the position of a driving portion and the position of the first movable plate can be adjusted along the first guide rail, and the position of the first movable plate can be adjusted along the second guide rail. Therefore, the position of a drilled object on the second movable plate can be adjusted in the transverse direction and the longitudinal direction, the quality of a drilled hole is more excellent, and drilling efficiency is higher. The regulating and control portions are further arranged, the position of the first movable plate and the position of the second movable plate can be adjusted more conveniently and faster, and work efficiency is improved.

Owner:XINCHANG HUAXIONG MACHINERY

A ccd positioning correction die-cutting machine

ActiveCN112720693BCompact structureQuick position adjustmentMetal working apparatusConveyor partsEngineeringCcd camera

The invention relates to a CCD positioning deviation correcting die-cutting machine, which includes a die-cutting host used in the die-cutting process, a power chassis used to provide power for the die-cutting machine, a feeding assembly used for material feeding, and a A material pulling assembly that provides power for material transmission and a visual positioning mechanism for locating the position of the material in the die-cutting host. The die-cutting host is placed stably on a level ground. The material component and the material pulling component are relatively installed on both sides of the die-cutting main machine, and the visual positioning mechanism is installed directly above the die-cutting main machine. In this die-cutting machine, two sets of X-axis drive mechanisms and two sets of independently controlled X-axis drive mechanisms are used. The Y-axis drive mechanism can quickly and conveniently adjust the arbitrary position of each camera individually in the horizontal direction. During the adjustment process, the CCD camera shakes less and the positioning accuracy is higher.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

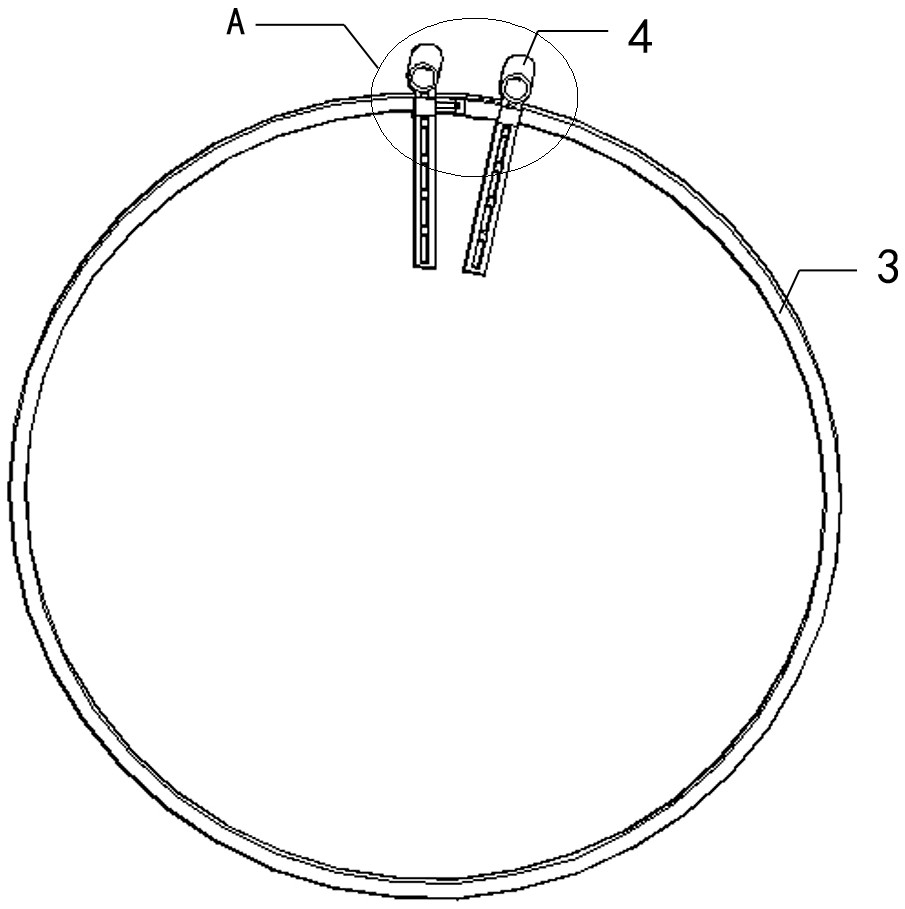

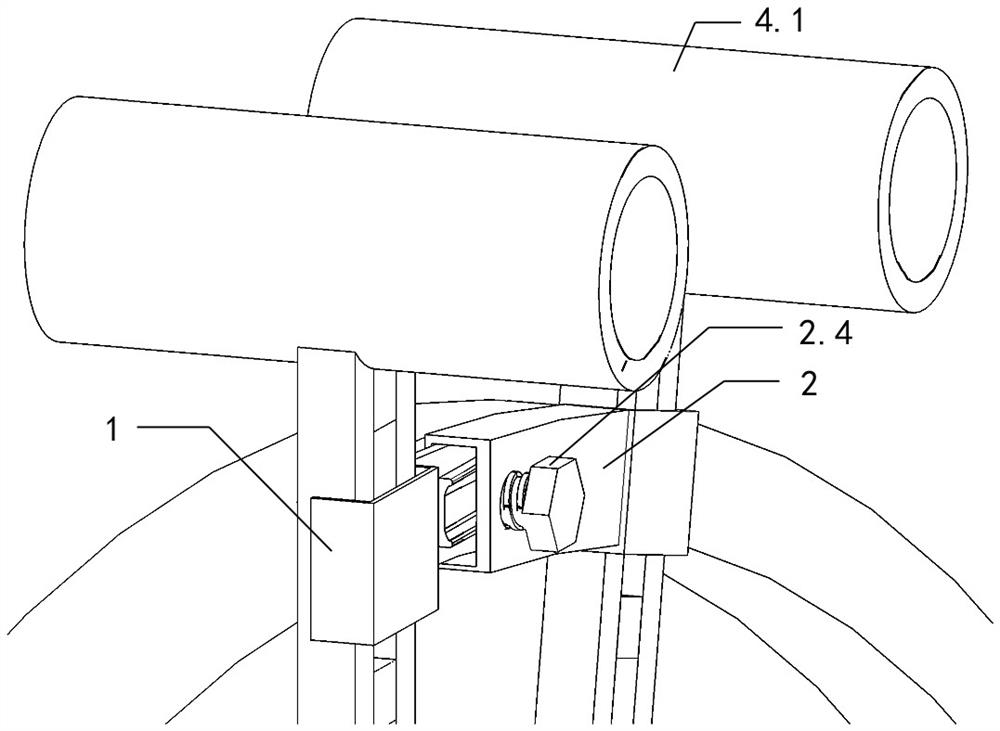

Positioning device, positioning structure and construction method of steel bar fixture for steel cage roll welding machine

ActiveCN112171156BSpeed up productionEasy to manufactureWelding/cutting auxillary devicesWire networkEngineeringSeam welding

The positioning device, positioning structure and construction method of the steel bar fixture of the steel cage roll welding machine relate to the field of pile foundation steel bar processing. The chute between the card slots. The chute includes an outer sleeve with a rectangular arc shape in cross section and an inner block with a rectangular arc shape in cross section that is adapted to be movably inserted into the outer sleeve. Adjacent; the middle part of the outer surface of the inner inserting block is fixedly connected with a C-shaped clamping block along the long axis. Go through the bolt holes and tighten on the C-shaped clamping block. The invention solves the problems in the prior art that when a steel cage roll welder processes steel cages with different diameters and different numbers of main bars, it needs to be stopped to replace the clamps in place, and workers hold a ruler to adjust the distance between the clamps. The process is time-consuming and has low precision.

Owner:中国建筑土木建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com