Support frame for mounting precast beam jack

A support frame and jack technology, which is applied in hoisting devices, transportation and packaging, trolley cranes, etc., can solve problems such as low efficiency, large manpower, and affecting construction efficiency, and achieve accurate and fast alignment, convenient manufacturing, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

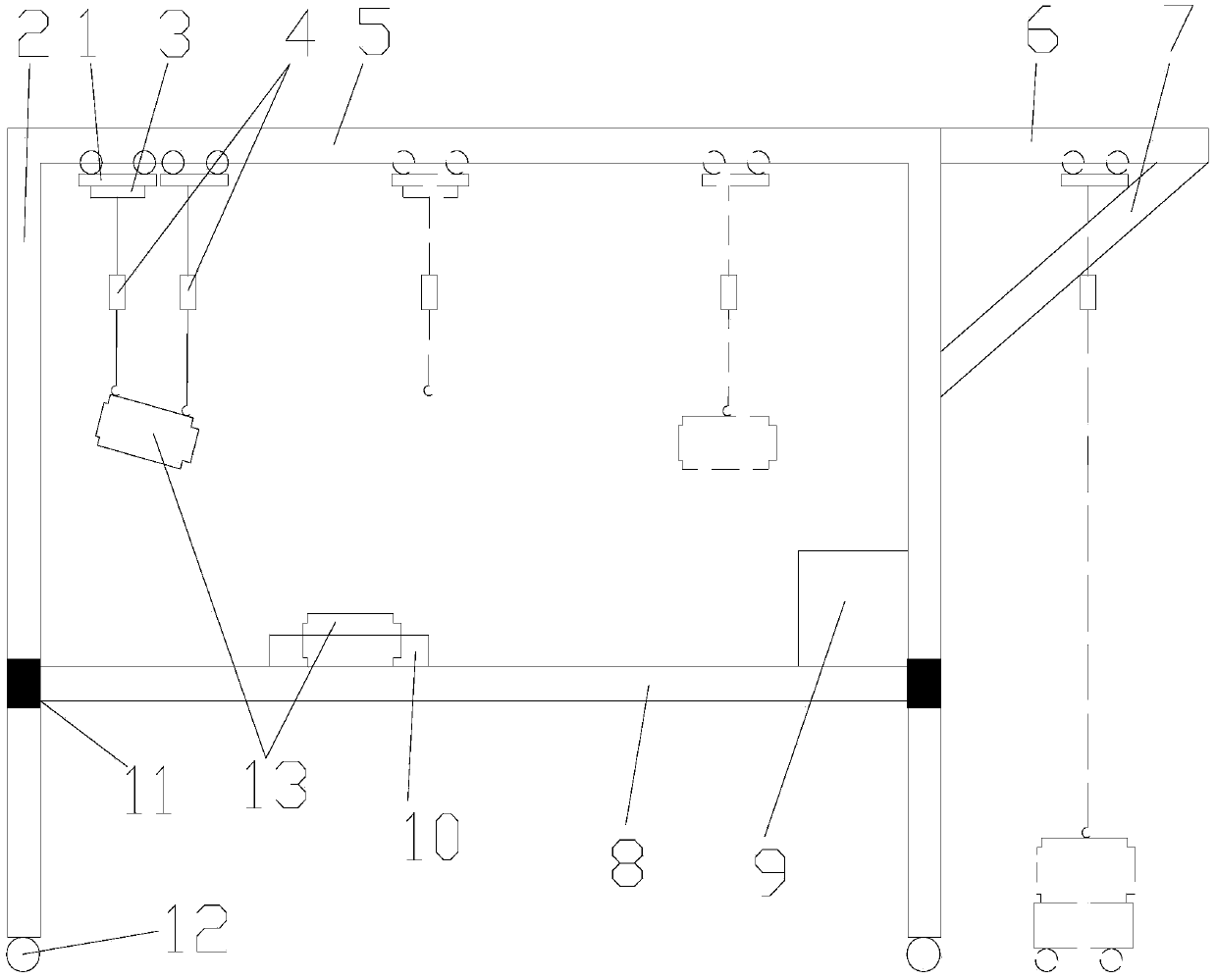

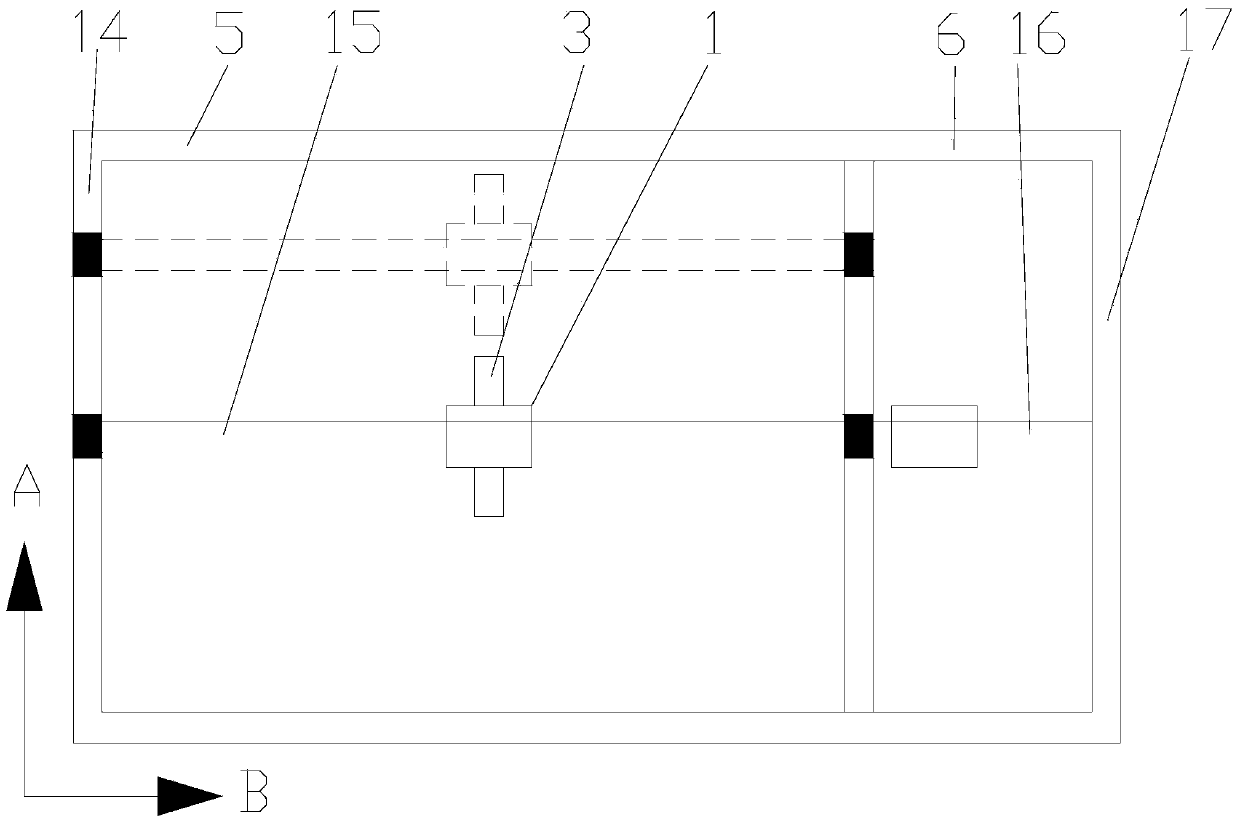

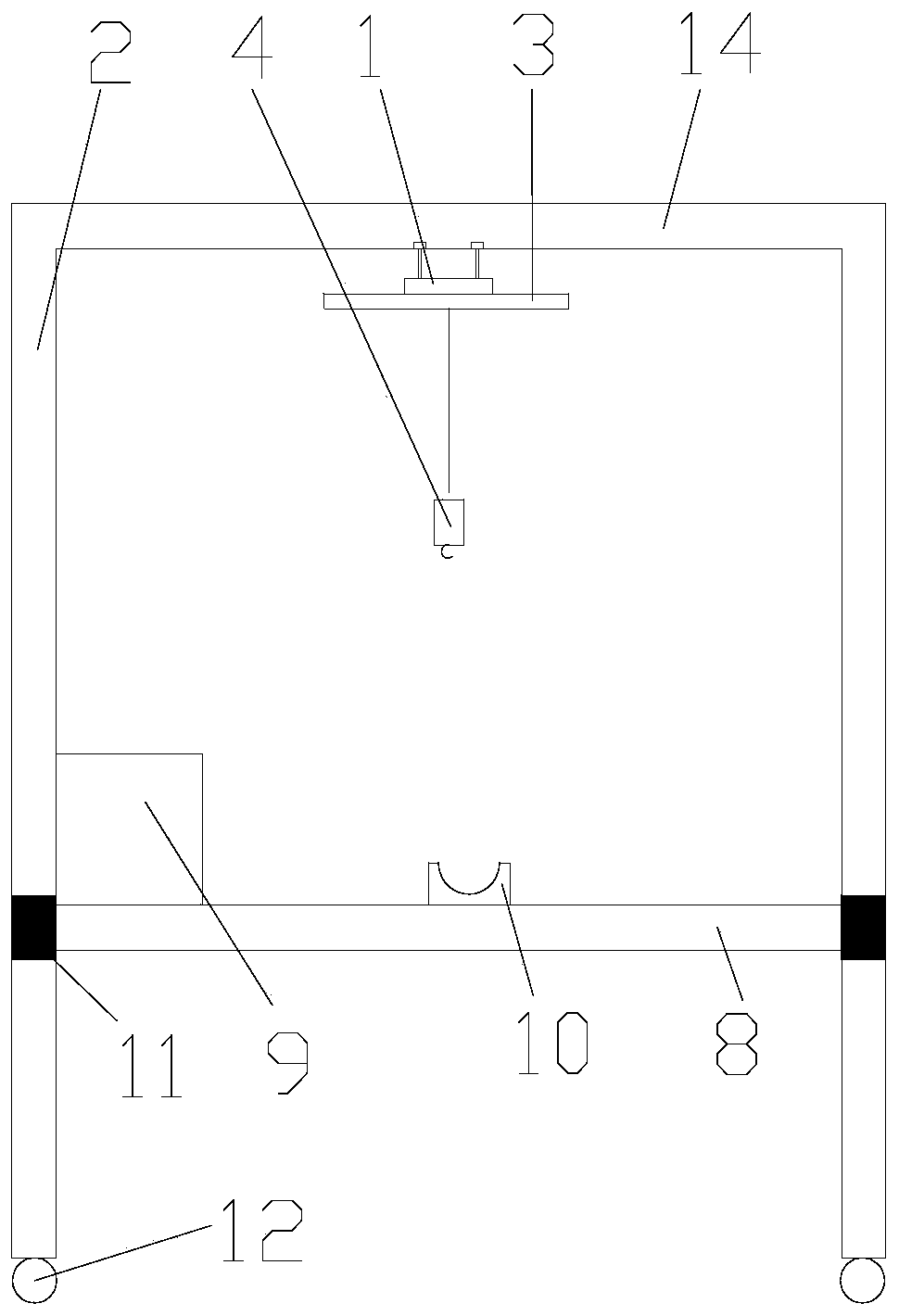

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 top view, image 3 for figure 1 In the middle left view, as shown in the figure, a support frame for installing a prefabricated beam jack provided by the present invention includes at least a main support frame and a working platform 8 arranged on the main support frame, and also includes an auxiliary support frame, the auxiliary support frame The support frame is reliably connected with the main support frame; it also includes a track vertically arranged on the main support frame and the auxiliary support frame and a hoisting system for hoisting a jack that is arranged on the track and can walk along the track. Walk horizontally on the main support frame; the jack can be quickly and effortlessly transported to the designated location of the prefabricated beam yard, and the jack can be quickly and accurately aligned to improve work efficiency; for the convenience of descrip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com