Giant tire grabbing and transferring method and giant tire maintenance claw

A technology of tires and hooks, which is applied in the field of large tire maintenance hooks, can solve the problems of time-consuming and labor-intensive, and achieve the effect of labor-saving grabbing and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The method for grabbing and transporting large tires in this embodiment, the process is as follows:

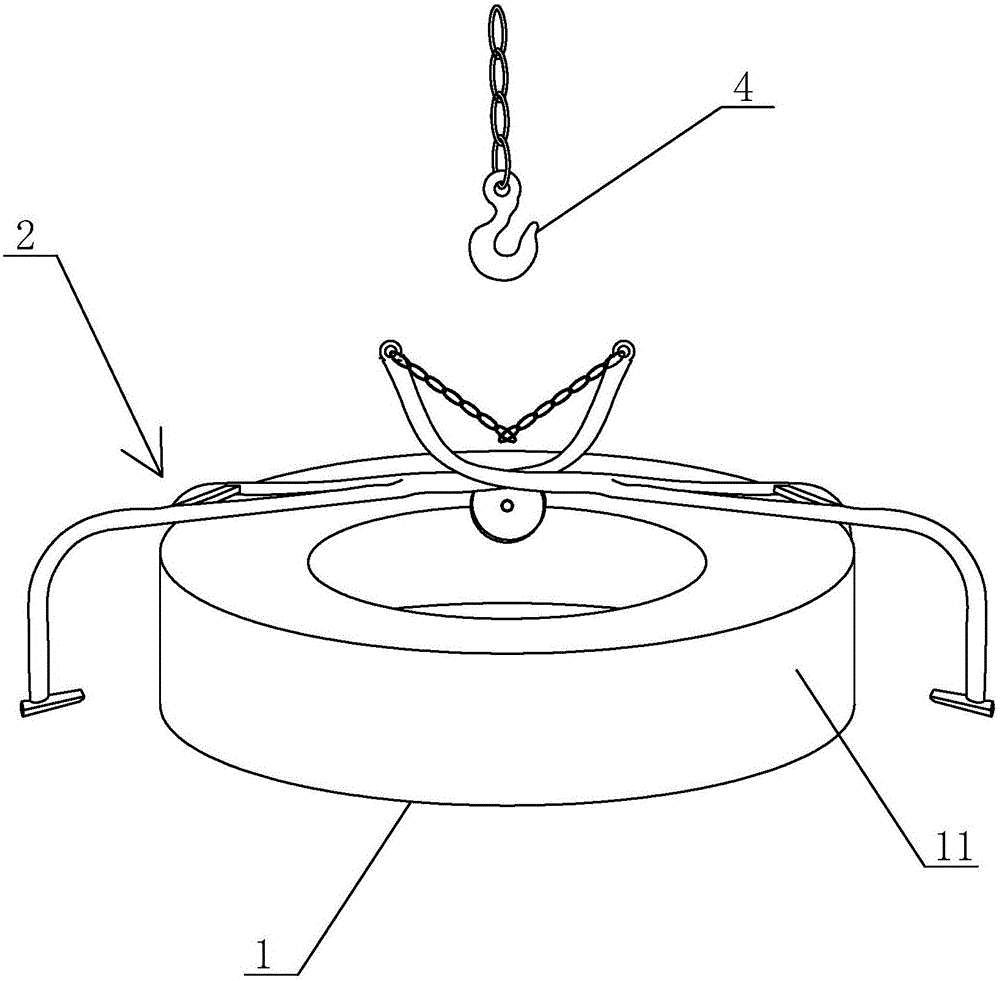

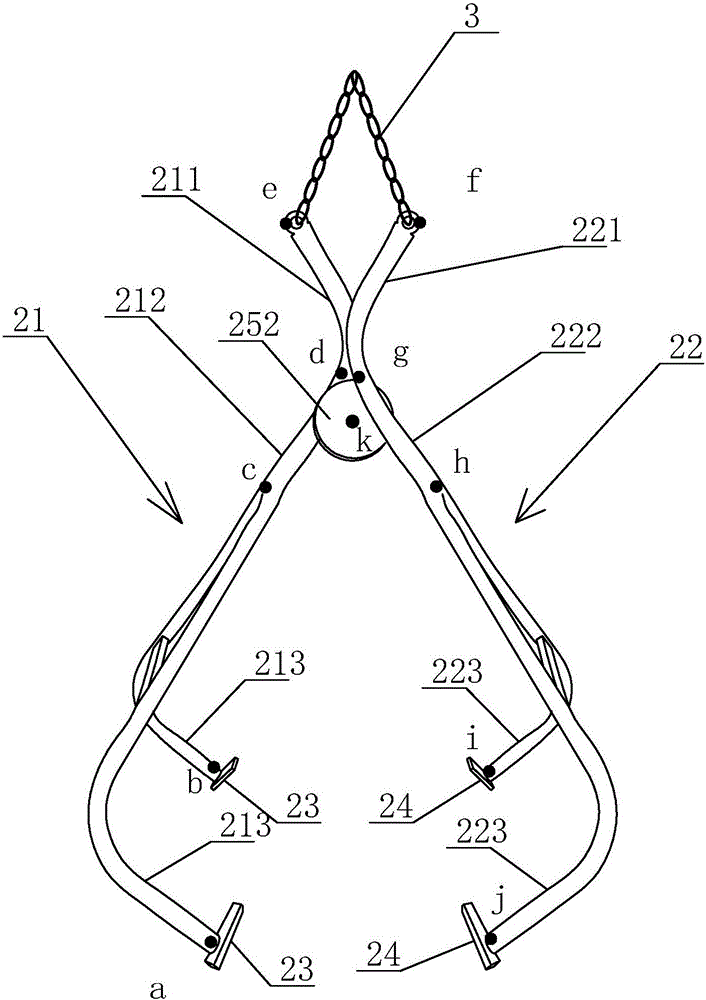

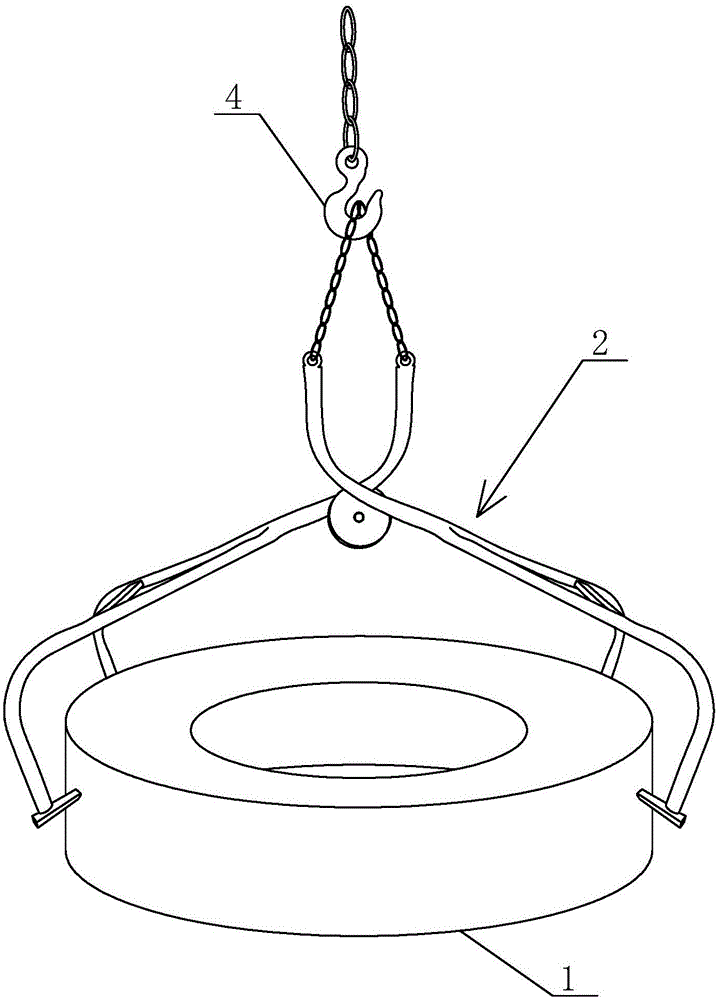

[0024] 1) Step 1, such as figure 1 As shown, the tire 1 is placed flat on the ground, one side of the tire 1 sticks to the ground, and the large tire maintenance hook 2 is placed on the other side of the tire 1, as shown in FIG. figure 2 As shown, the large tire maintenance claw 2 includes a first connecting frame 21 and a second connecting frame 22, and one end of the first connecting frame 21 is fixed with a first claw 23 for abutting against the crown 11 of the tire 1, One end of the second connecting frame 22 is fixed with a second claw 24 for abutting against the crown of the tire 1, and one end of the first connecting frame 21 and one end of the second connecting frame 22 are respectively connected to iron chains. 3, the first connecting frame 21 and the second connecting frame 22 are hinged, and the length of the hinged joint apart from the first claw 23 (ie ...

Embodiment 2

[0029] The structure of the large tire maintenance hook 2 in this embodiment is basically the same as that of the large tire maintenance hook 2 in Embodiment 1, the difference is that: Figure 5 As shown, the lower ends of the first claw 23 and the second claw 24 are fixed with a universal wheel 261, and the first upper rod 211 is fixed with a first limit rod for abutting against the second middle rod 222. 262, the second upper rod 221 is fixed with a second limit rod 263 for abutting against the first middle rod 212, with this structure, the distance between the first connecting frame 21 and the second connecting frame 22 can be limited angle of rotation, such as Image 6 As shown, under the situation of detaching from the suspension hook 4, under the action of gravity, the first connecting frame 21 and the second connecting frame 22 can maintain an angle, so as to promote the large-scale tire maintenance hook 2 through the universal wheel 261, and the large-scale tire The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com