Auxiliary clamping device for galvanizing

A technology of clamping device and outer surface, applied in hoisting device, hoisting device braking device, transportation and packaging, etc., can solve the problems of inconvenient movement, time-consuming and laborious, requiring manual lifting, etc., to achieve easy transfer, Meet the needs of use and realize the effect of multi-function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

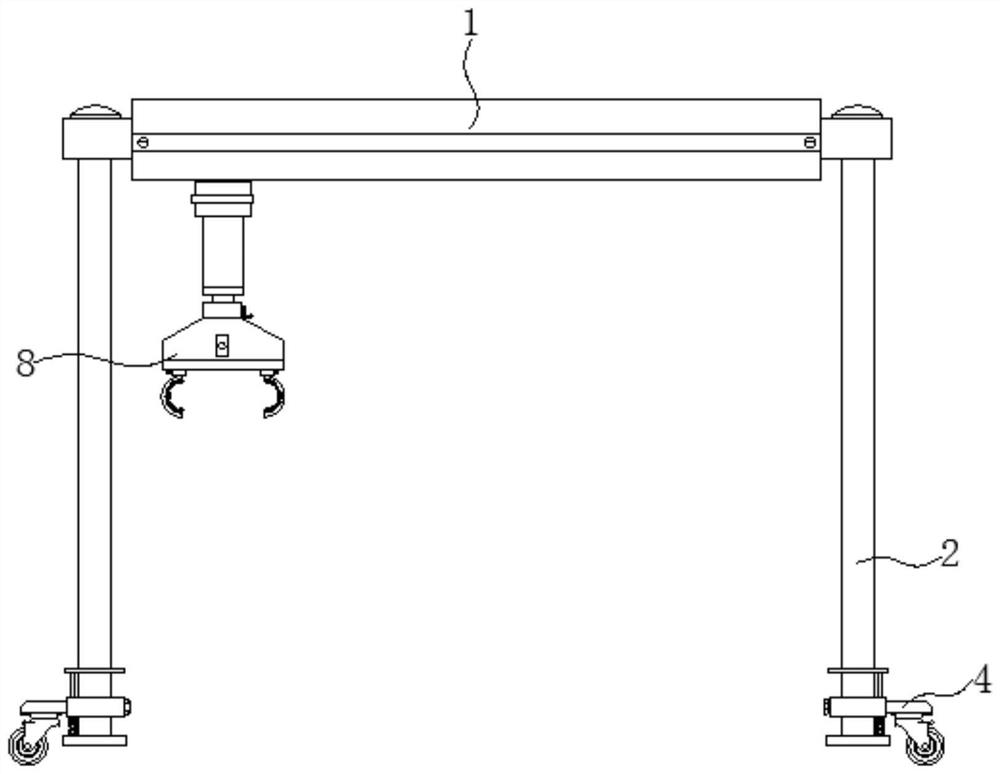

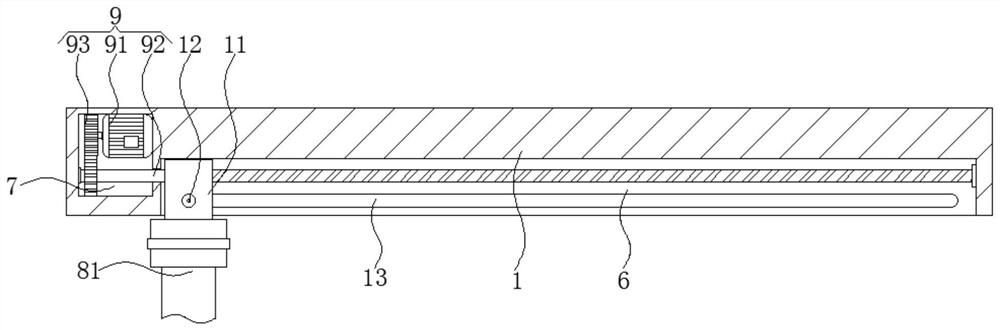

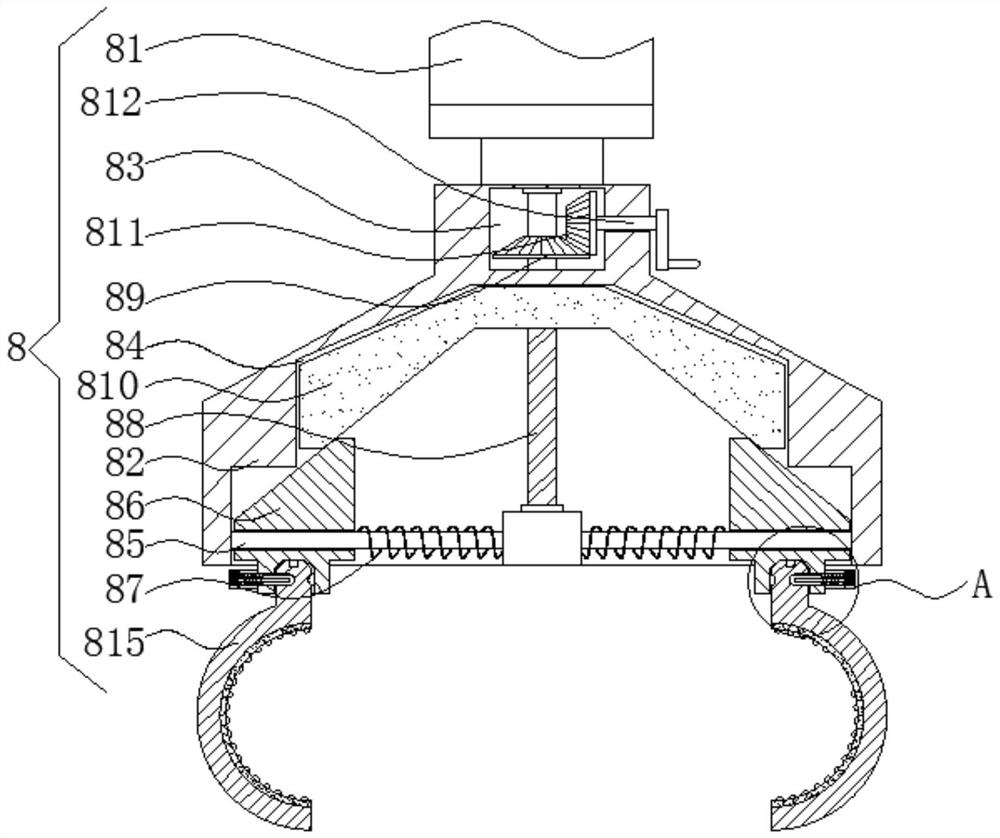

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 Schematic diagram of the external structure of the galvanized auxiliary clamping device provided by the present invention; figure 2 for figure 1 The schematic diagram of the internal structure of the device board shown; image 3 for figure 1 The schematic diagram of the internal structure of the connector shown; Figure 4 for image 3 The enlarged schematic diagram of part A shown; Figure 5 for figure 1 Schematic diagram of the structure of the pulley structure shown. Galvanized auxiliary clamping device, including:

[0030] device board 1;

[0031] Support column 2, the two support columns 2 are respectively fixedly connected to the left and right sides of the device plate 1, the outer surface of the support column 2 is sleeved with a fixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com