A ccd positioning correction die-cutting machine

A die-cutting machine and die-cutting technology, which is used in conveyor objects, thin material processing, metal processing, etc., can solve the problems of reducing die-cutting accuracy, inaccurate die-cutting, and material surface wear, and prevent the die-cutting position from being offset. The effect of moving, avoiding taking up too much space, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

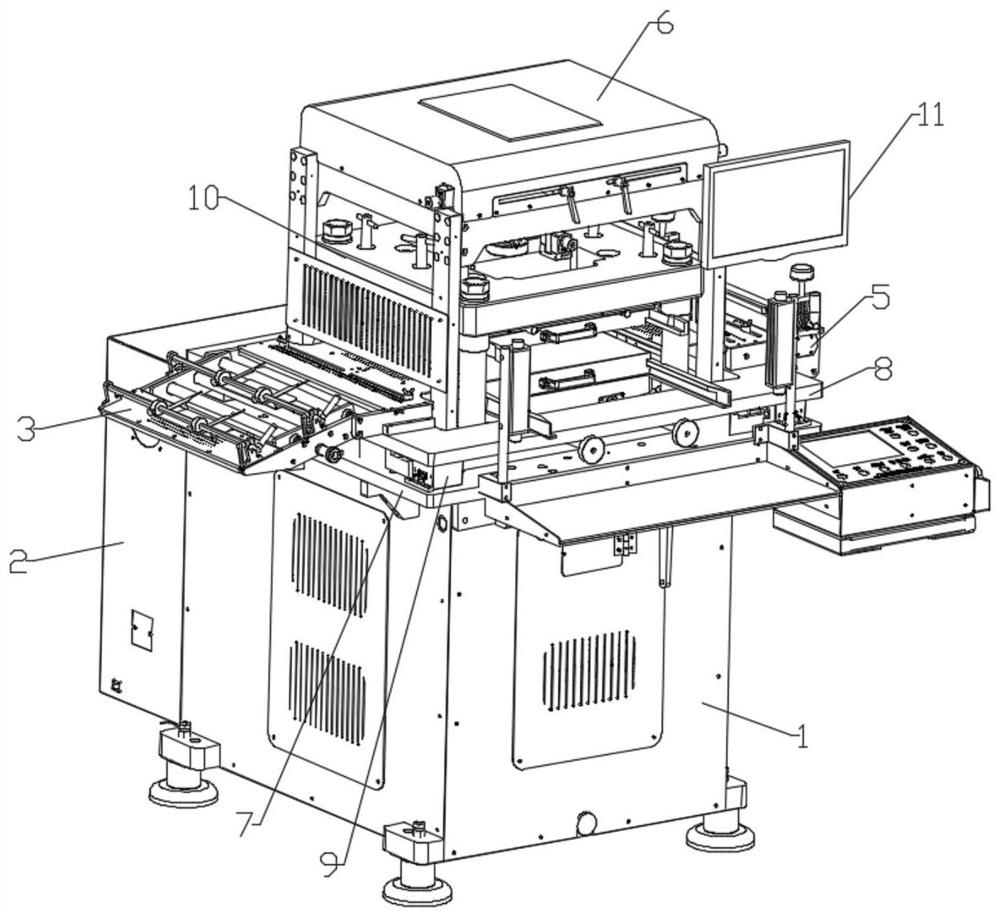

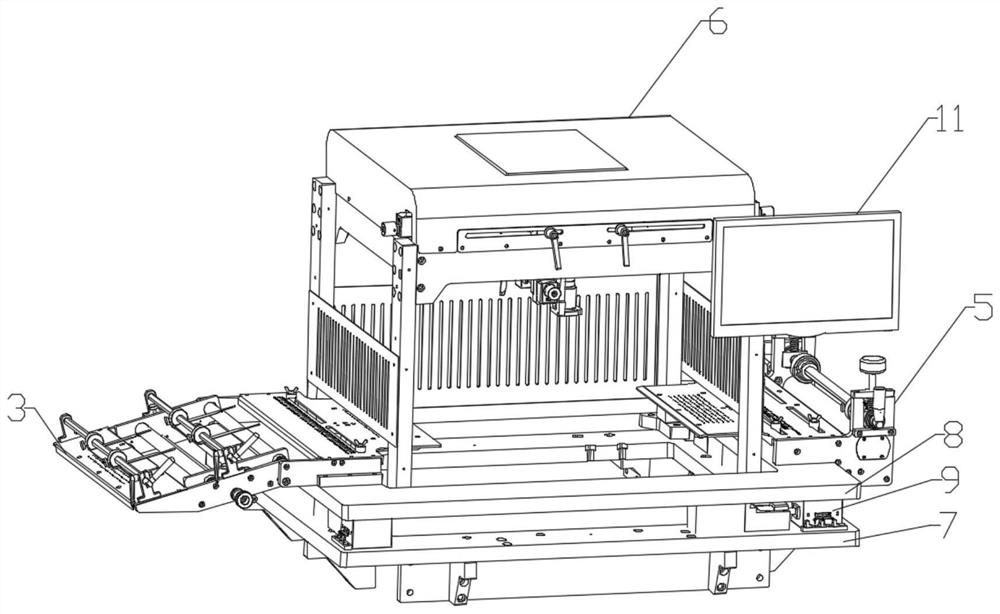

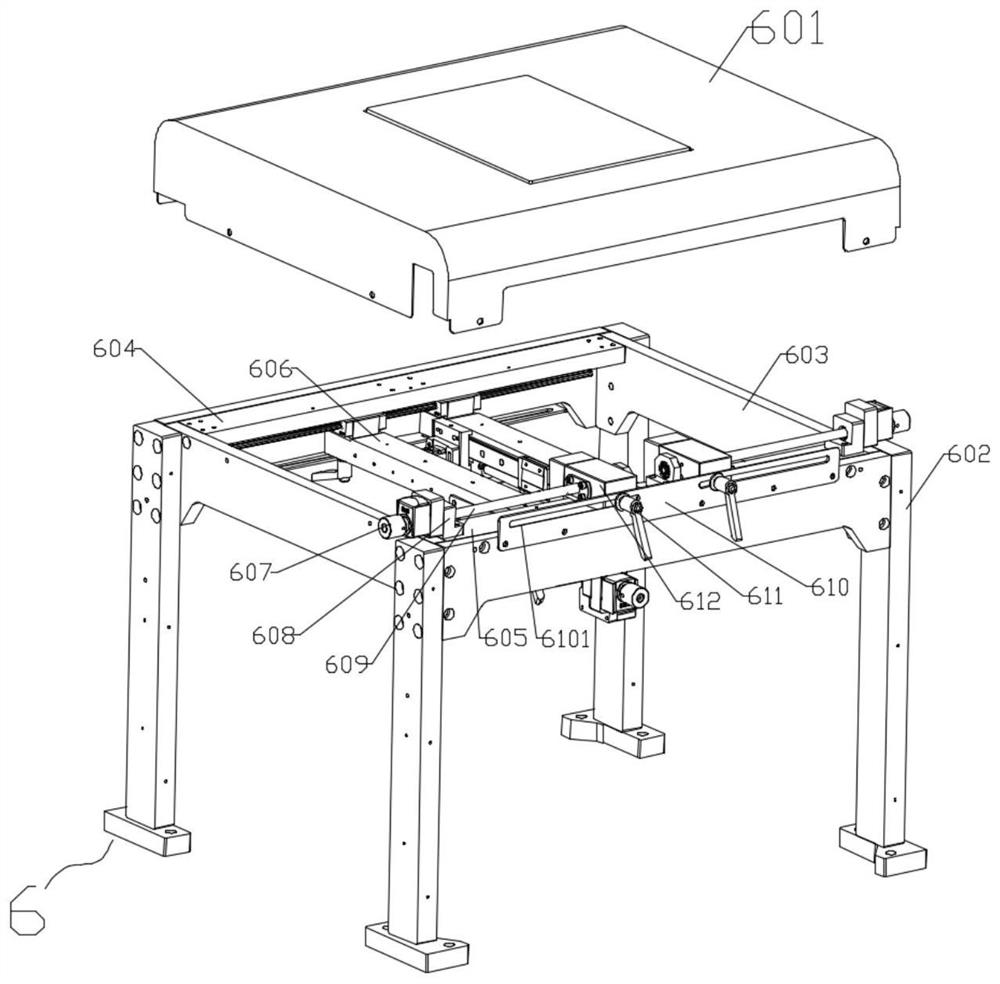

[0046] combine Figure 1-2 As shown, a CCD positioning correction die-cutting machine is disclosed in this embodiment, including a die-cutting host 1 for the die-cutting process, a power chassis 2 for providing power for the die-cutting machine, and a feeder for material feeding Component 3, a material pulling component 5 for material discharge and material transmission power, and a visual positioning mechanism 6 for locating the position of the material in the die-cutting host. The bottom of the die-cutting host 1 is provided with four sets of supporting bases. The supporting base is used to keep the die-cutting host 1 stably placed on the level ground, the power chassis 2 is installed on the rear side of the die-cutting host 1, and the feeding assembly 3 and the pulling assembly 5 are relatively installed on the die-cutting host 1 The visual positioning mechanism 6 is installed directly above the die-cutting host 1.

[0047] Specifically, the die-cutting main engine 1 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com