Fine adjusting device for machining

A fine-tuning device and mechanical processing technology, applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve problems such as the inability to adjust the coarse and fine adjustments of the rotating device when used together, so as to improve mobility, improve efficiency and Accurate, fast position adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

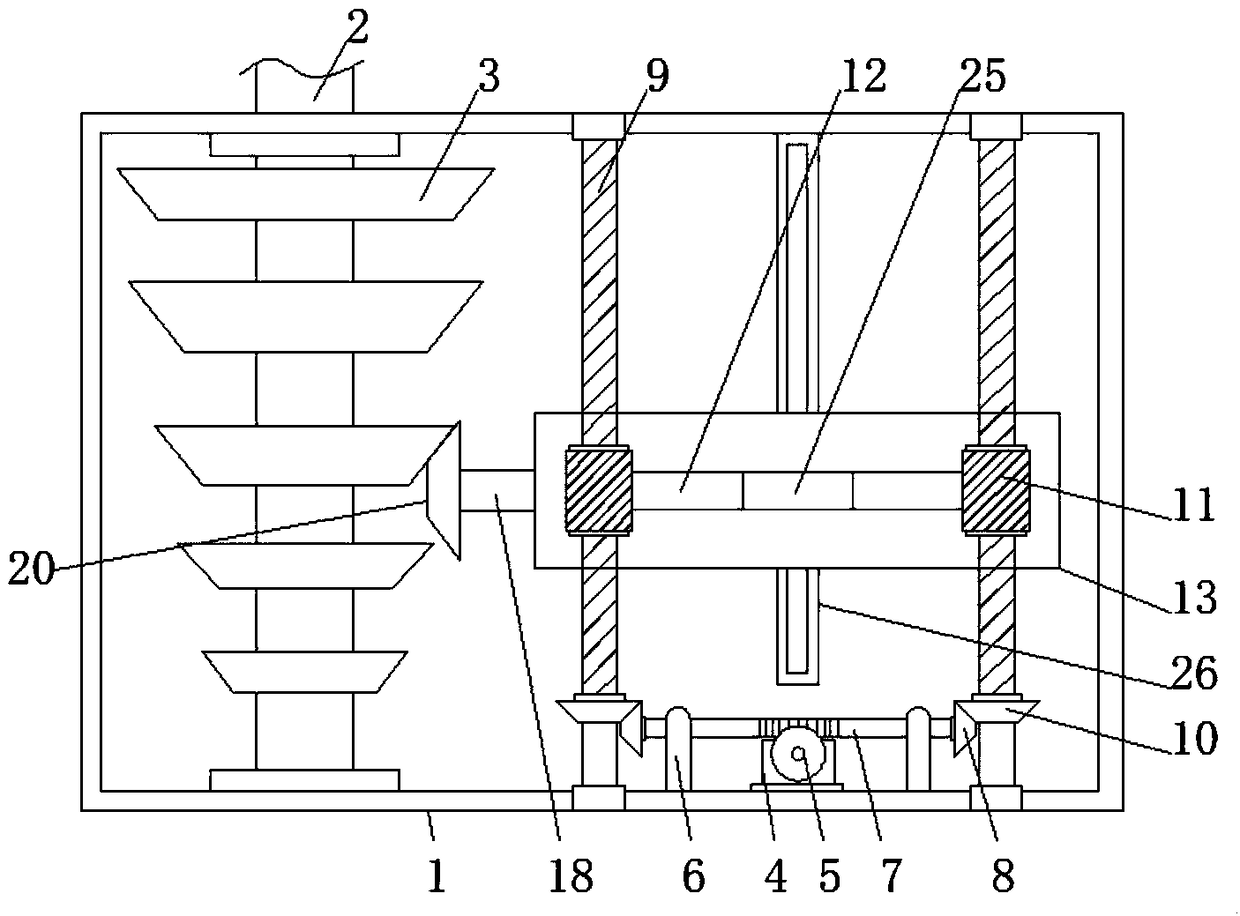

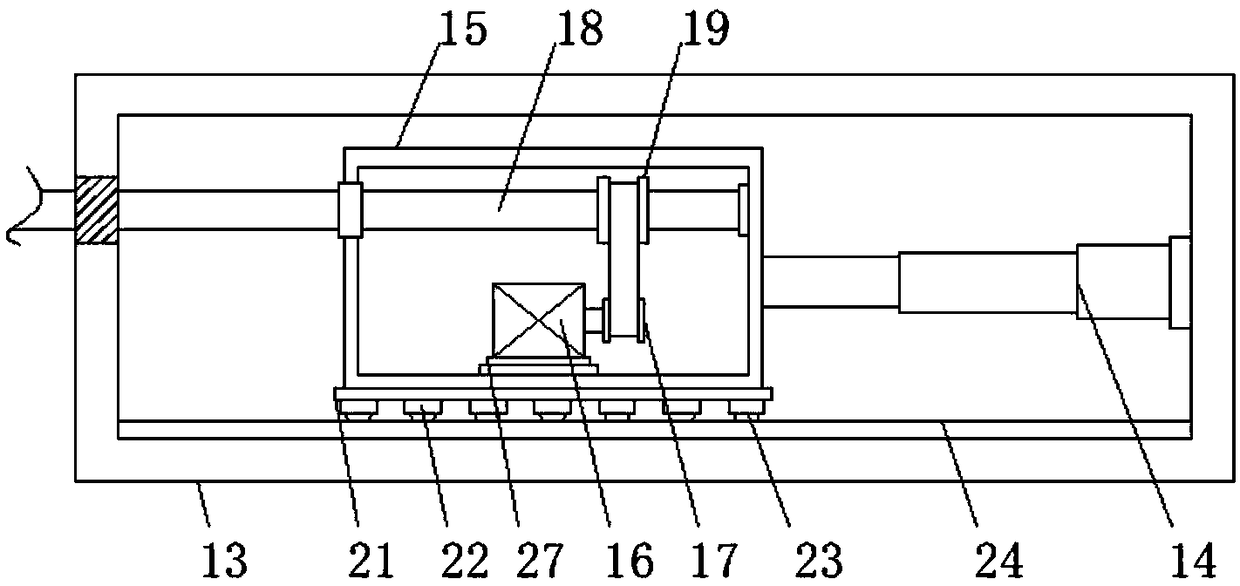

[0020] Such as Figure 1-2 As shown, the present invention provides a technical solution: a fine adjustment device for machining, including an adjustment box 1, a rotating rod 2 is inserted on the left side of the top of the adjusting box 1, and the bottom of the rotating rod 2 penetrates the adjusting box 1 The top part is fixedly connected to the bottom of the inner wall of the adjustment box 1 through a bearing. The rotating rod 2 is provided with a bevel gear set 3, which is a combination of multiple bevel gears, and the diameter of the bevel gear set 3 is from top to The lower part is reduced sequentially. The speed can be adjusted through the combination of bevel gears of different sizes, so that the speed of the adjustment can be controlled according to the demand. The bottom of the inner wall of the adjustment box 1 is fixedly connected with the forward and reverse motor 4, which is forward and reverse. The output end of the motor 4 is fixedly connected with a worm whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com