Positioning device, positioning structure and construction method of steel bar fixture for steel cage roll welding machine

A technology of positioning device and steel cage, which is applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve the problems of time-consuming accuracy and low accuracy, and achieve the effects of high installation accuracy, simplified production process, and improved processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

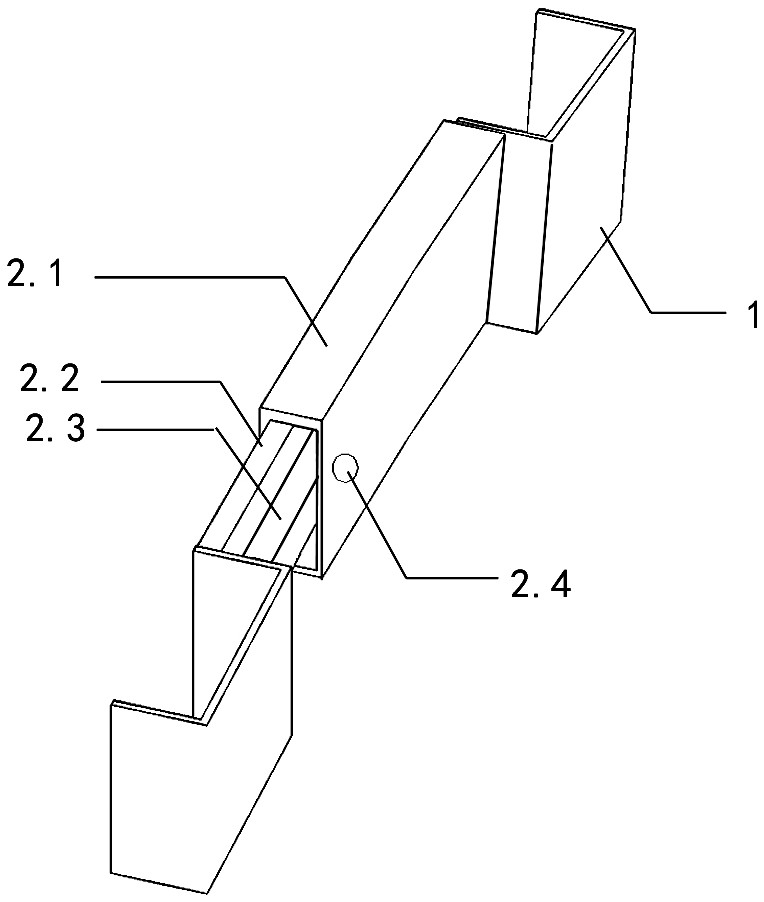

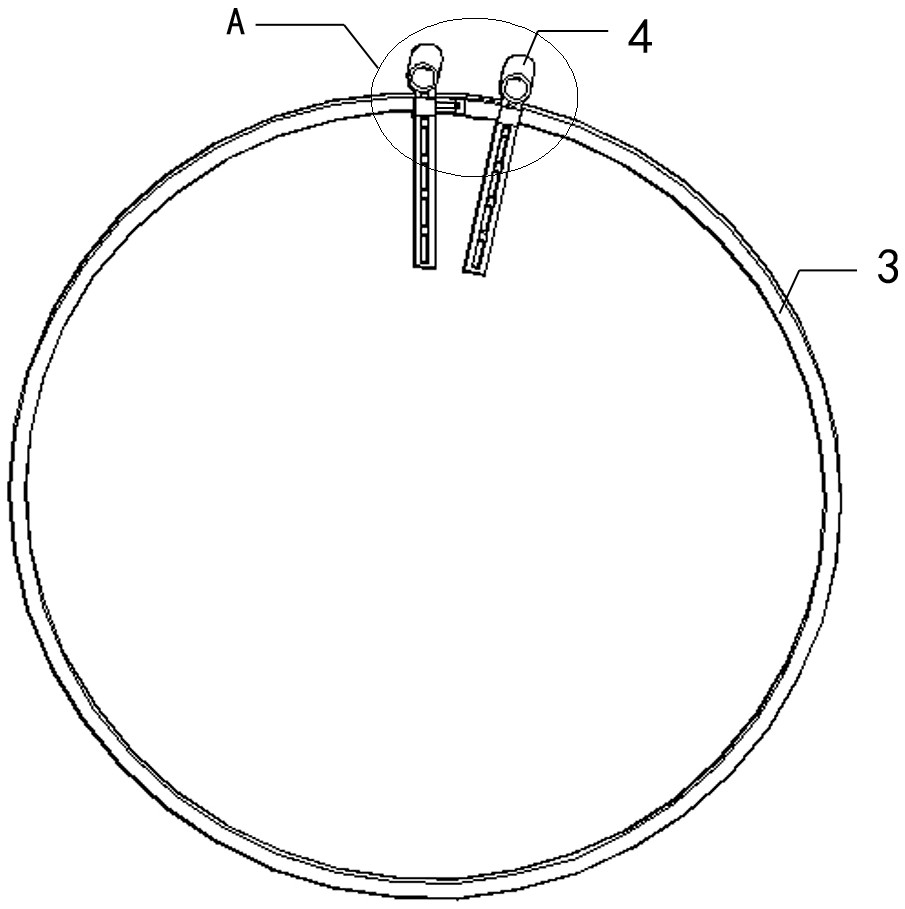

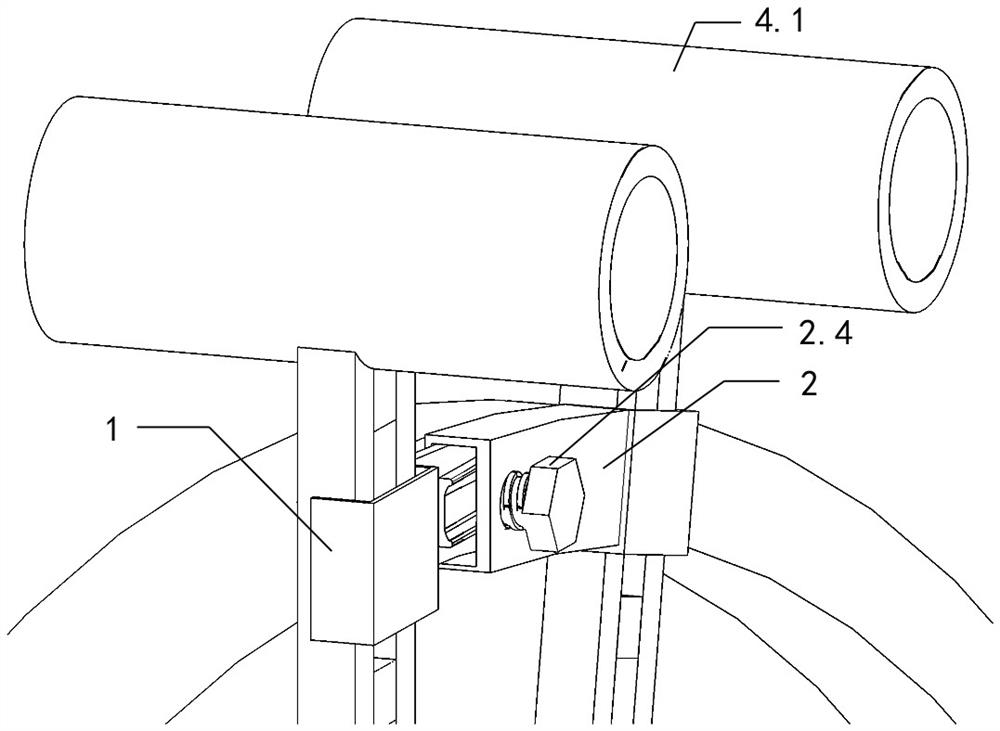

[0068] Examples see figure 1 As shown, the positioning device, positioning structure and construction method of the steel bar fixture of the steel cage roll welding machine of the present invention, the positioning device of the steel bar roll welding machine steel bar clamp is in the shape of an arc as a whole, including two U-shaped slots 1 arranged side by side And the chute 2 connected between the two U-shaped slots 1; wherein the U-shaped slot 1 is a channel steel; the chute 2 includes an outer sleeve 2.1 with a rectangular arc shape in cross section and an adaptive movable plug in The cross-section of the outer sleeve 2.1 is a rectangular arc-shaped inner block 2.2, the inner side of the inner block 2.2 is closely attached to the inner inner wall of the outer sleeve 2.1; the middle part of the outer side of the inner block 2.2 is arranged through the long axis A C-shaped block 2.3 is fixedly connected, and the opening of the C-shaped block 2.3 is set outward; the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com