Patents

Literature

62results about How to "No delay in production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production system for thistle board

ActiveCN102371621AQuality improvementSave energyCeramic shaping plantsProduct inspectionMicrowave tube

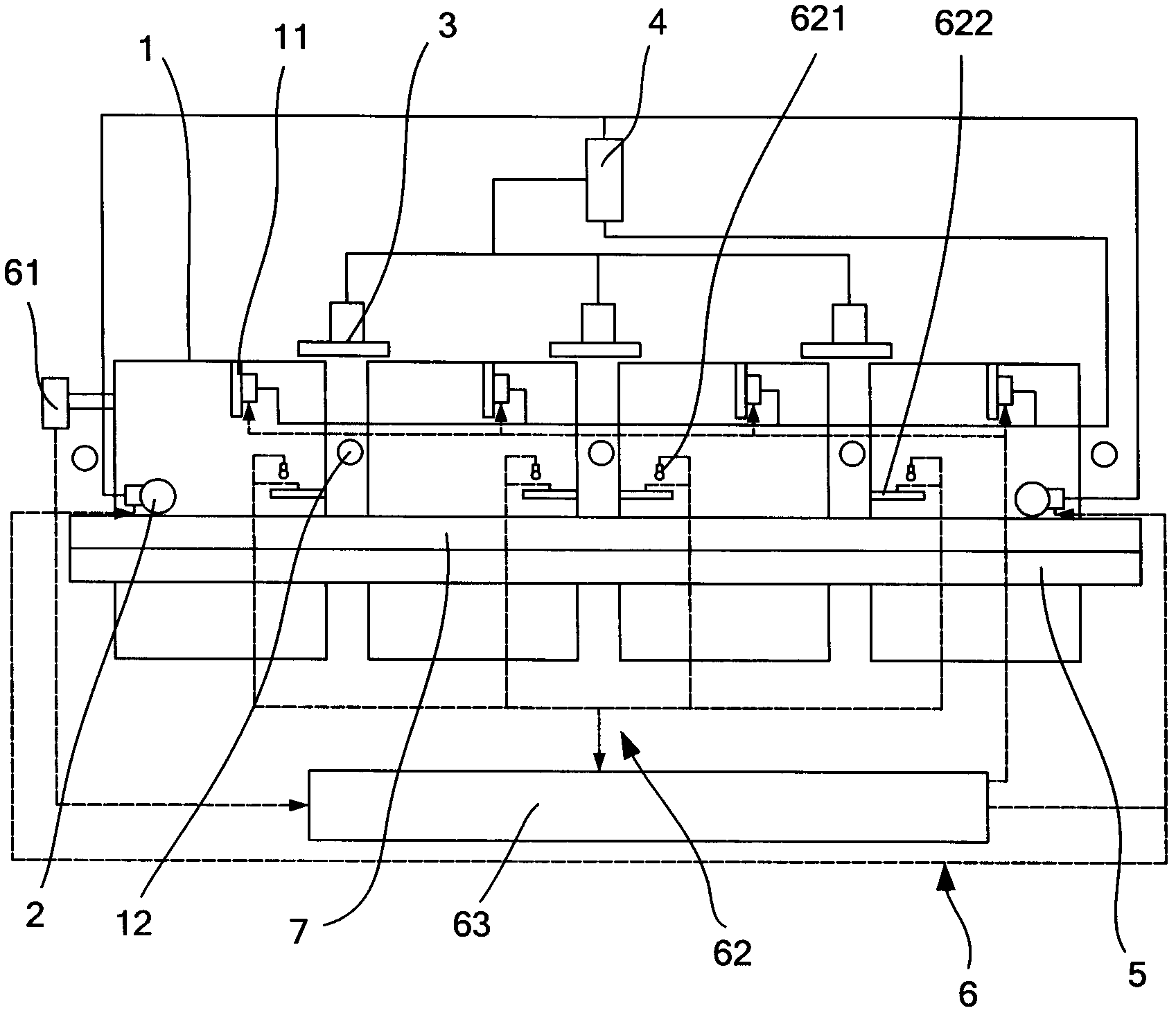

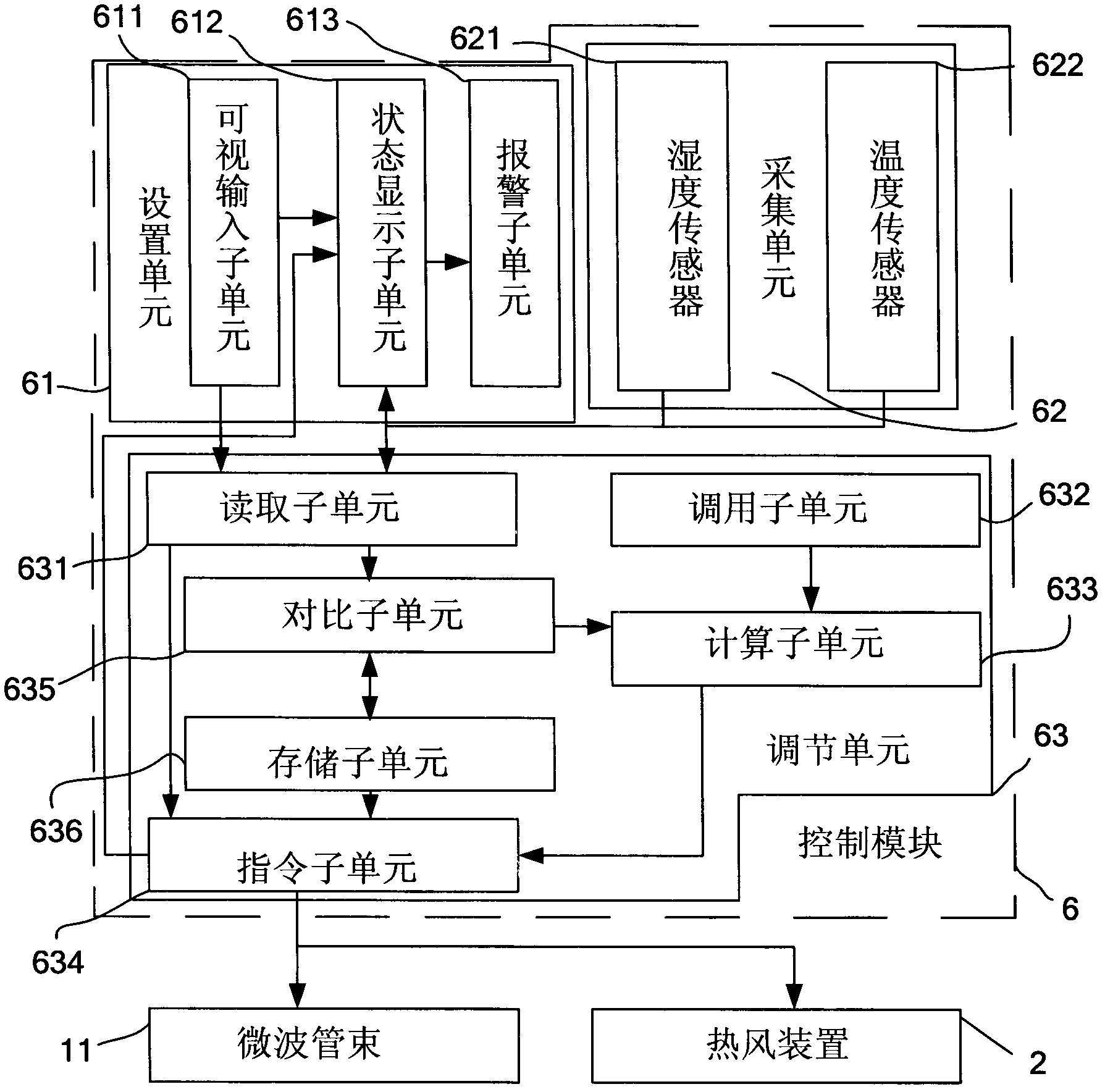

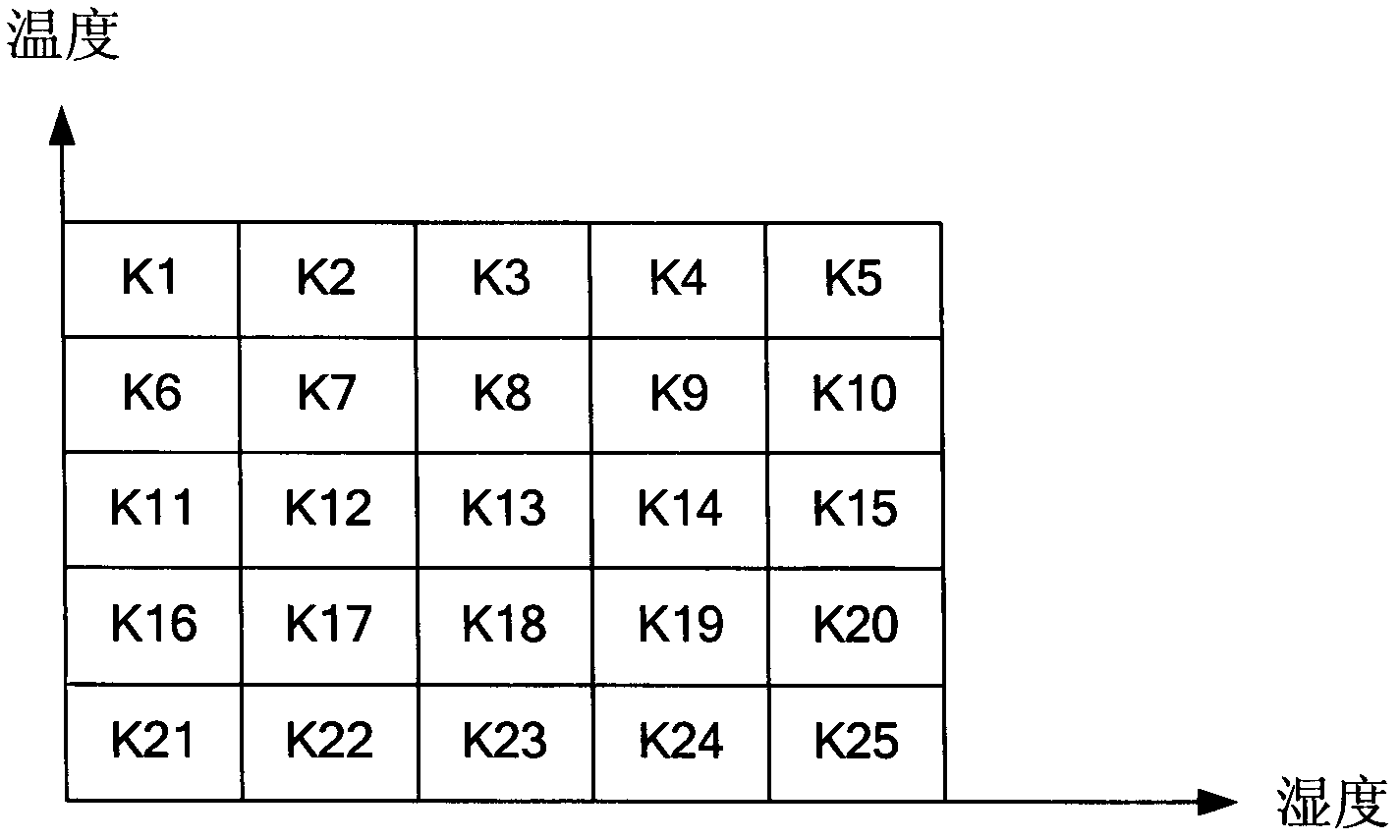

The invention discloses a production system for a thistle board. The production system comprises a raw material preparing section, an extruding forming section, a panel cutting section, a drying section and an end-product inspection storing section, which are arranged in turn. The drying section further comprises more than one box body, and the box bodies are sequentially arranged in parallel, wherein microwave tube bundles are arranged in the box bodies; microwave restrainers are arranged between the box bodies; hot air devices are arranged in the box bodies and are used for blowing hot air to the thistle board; dehumidification devices are arranged on top parts between the box bodies and are used for sucking wet hot air; a heat circulating device is connected to the hot air devices, the dehumidification devices and the microwave tube bundles and is used for circulating heat; conveying devices are connected to each other in the box bodies and are used for conveying the thistle board; and a control module comprises a setting unit, an acquiring unit and an adjusting unit. The production system can be used for detecting the humidity and temperature variation of the thistle board in real time and adjusting the power of the microwave tube bundles and the strength of the hot air devices according to detected data.

Owner:肇庆北新建材有限公司

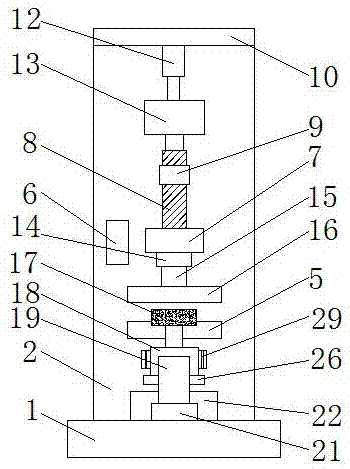

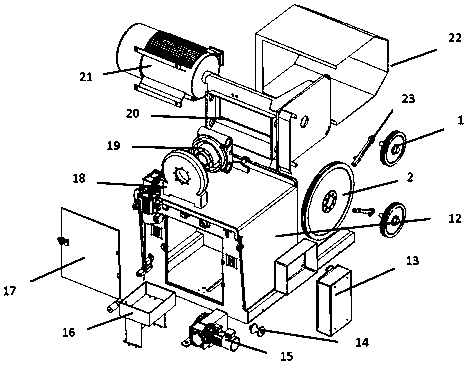

Automobile part grinding device for finished automobile manufacturing

InactiveCN107971882ANo delay in productionNo need to waste energyGrinding drivesGrinding machinesEngineeringMechanical engineering

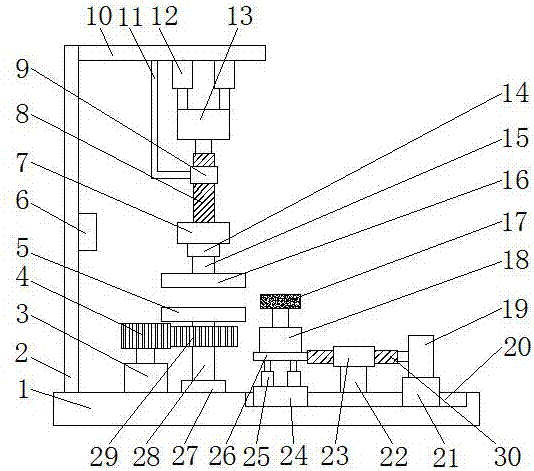

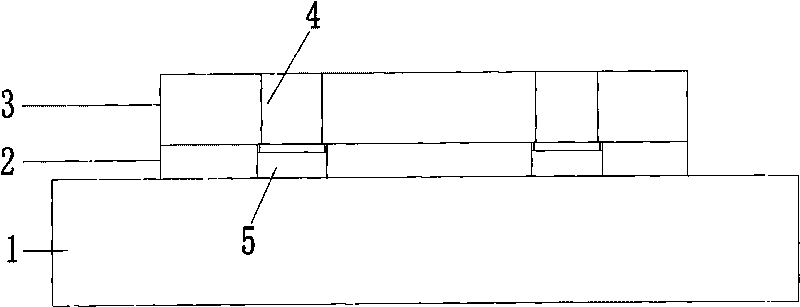

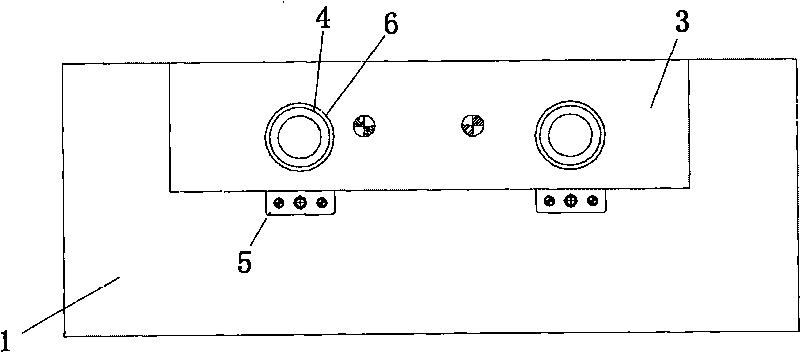

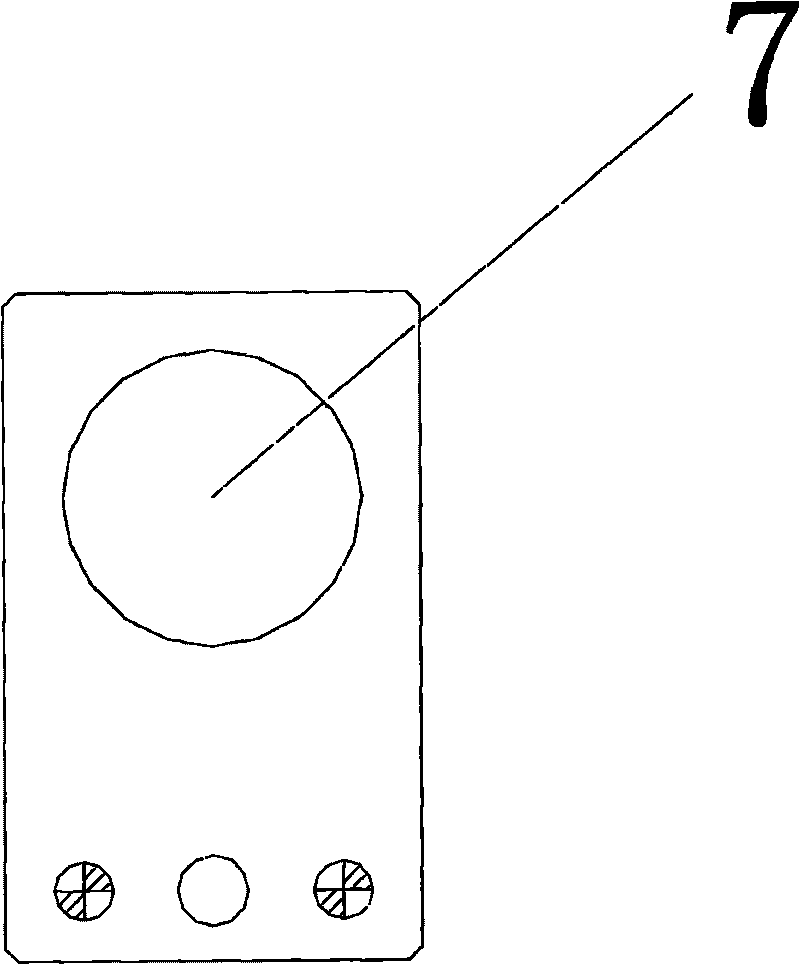

The invention discloses an automobile part grinding device for finished automobile manufacturing. The automobile part grinding device comprises a bottom plate. The upper surface of the bottom plate isfixedly connected with the lower surface of a side plate. The right side face of the side plate is fixedly connected with the left side face of a top plate. The lower surface of the top plate is fixedly connected with the top ends of telescopic rods. According to the automobile part grinding device for finished automobile manufacturing, through the arrangement of a first motor, a control panel, asecond motor, a first disc, a second disc, a third motor and electric push rods, the second motor is controlled through the control panel to work, an output shaft of the second motor achieves forwardrotation to drive a first threaded column to achieve forward rotation, and therefore the first threaded column drives the second motor to move downwards, an automobile part rotates along with the first disc, and the part can be omni-directionally ground; and the angle of the automobile part does not need to be manually adjusted by workers during grinding, and therefore the physical power of the workers does not need to be wasted, the grinding efficiency is improved, and automobile production cannot be delayed.

Owner:郭斌

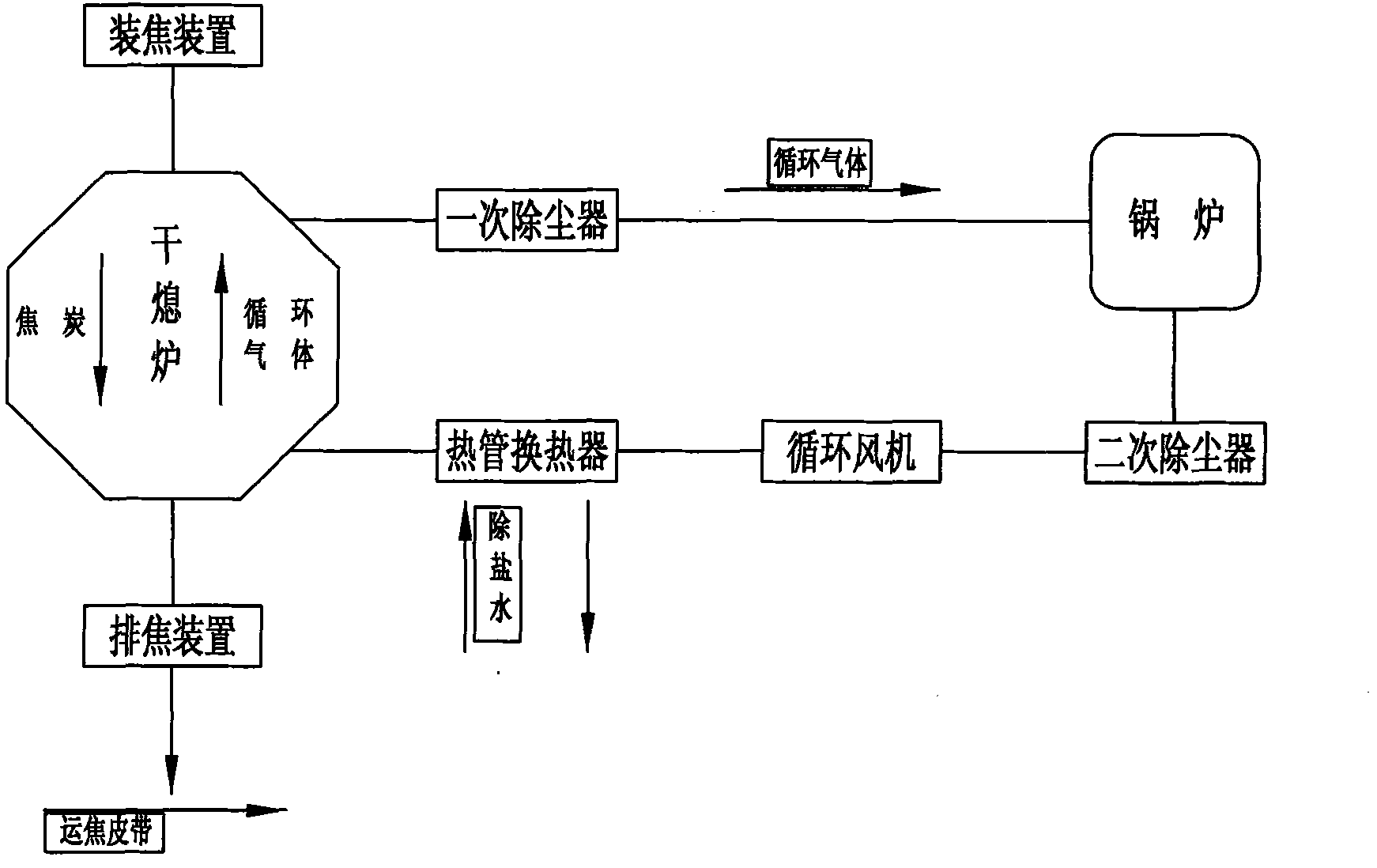

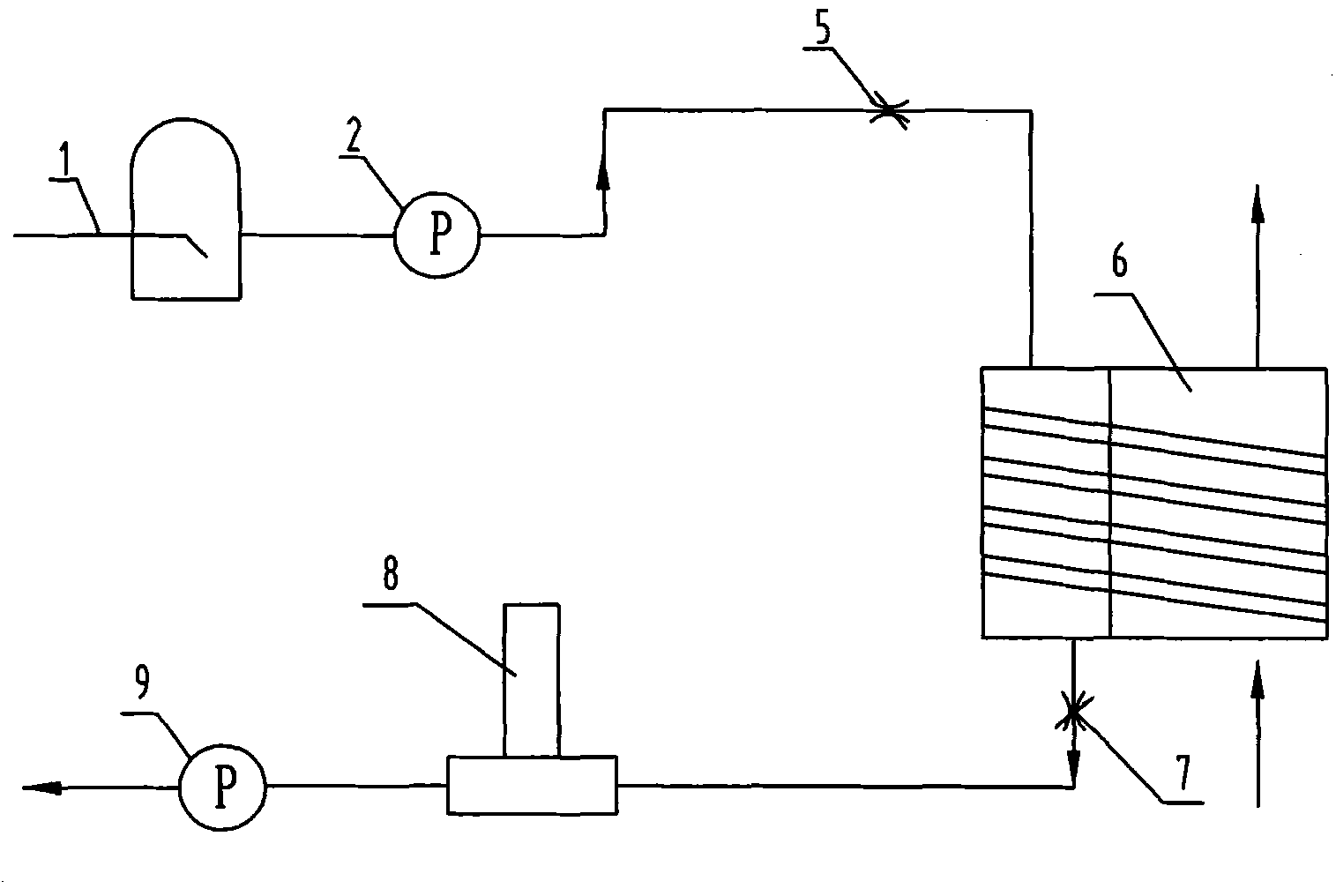

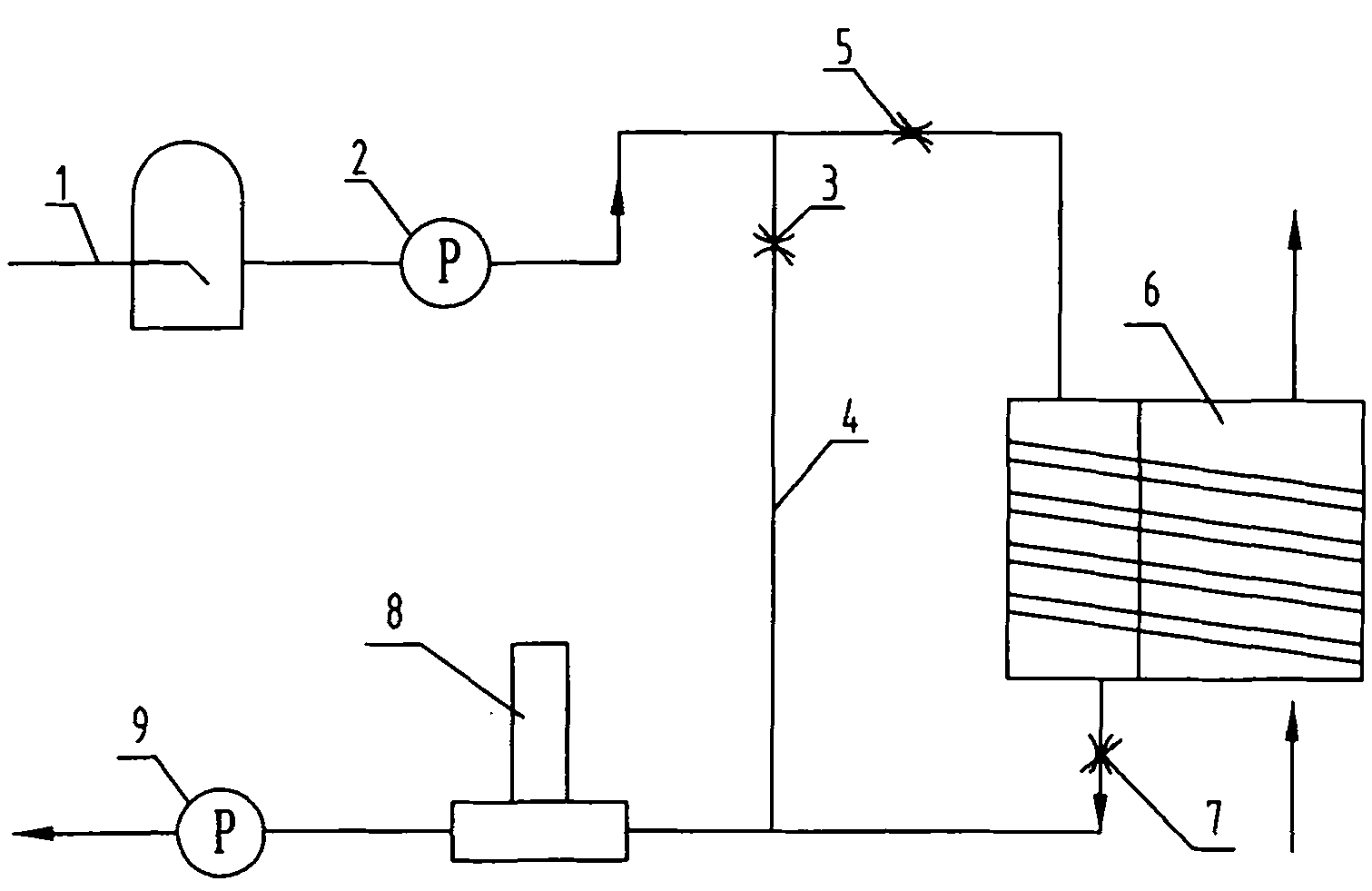

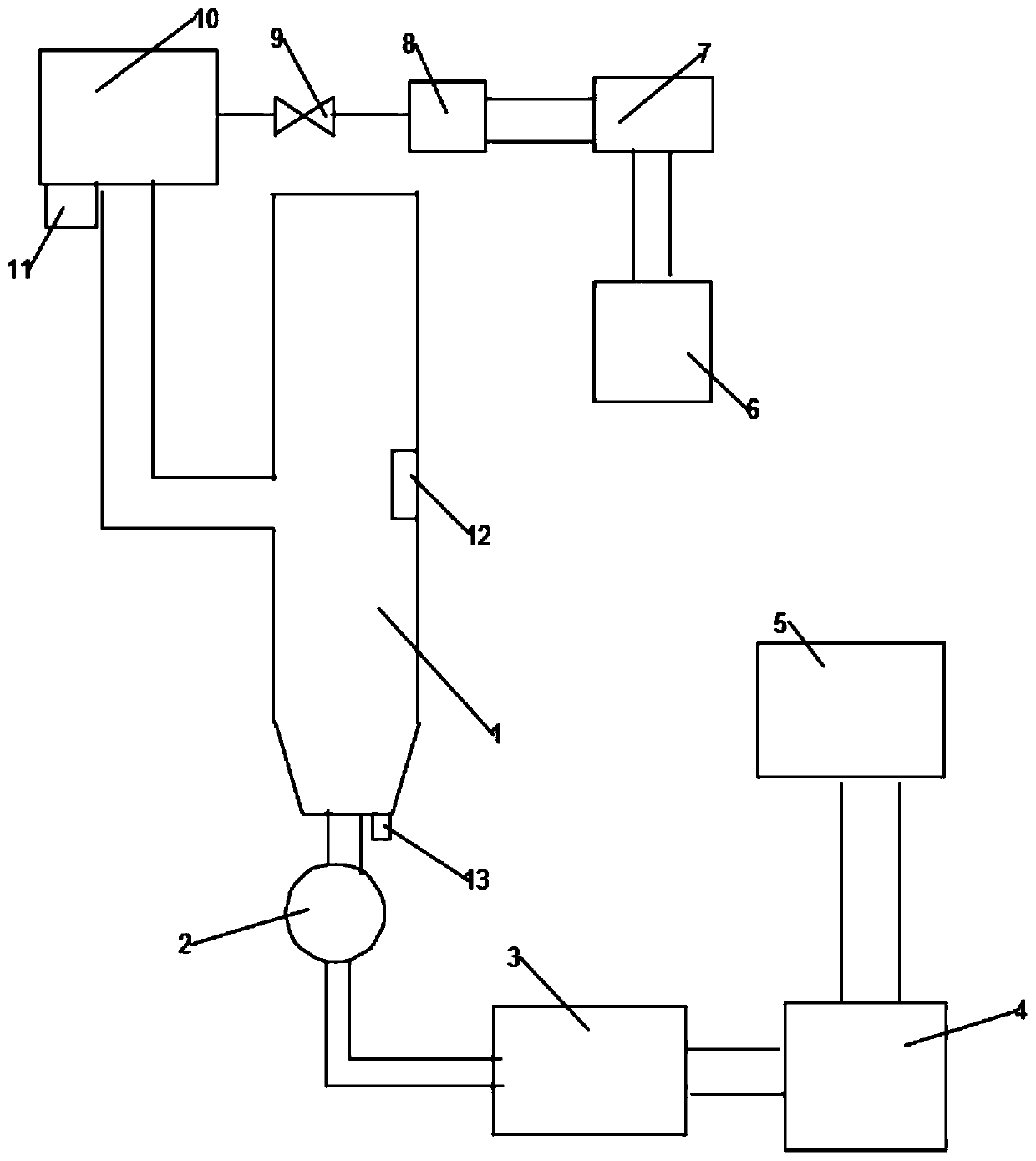

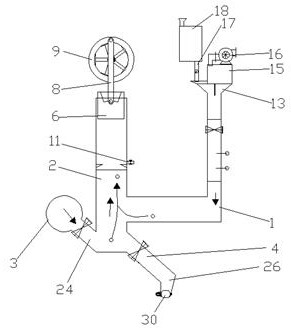

Method for keeping stable coke dry quenching gas circulation system after pipe explosion of heat pipe exchanger and device thereof

The invention relates to a relative technology of a coke dry quenching process and discloses a method for keeping a stable coke dry quenching gas circulation system after pipe explosion of a heat pipe exchanger and a device thereof. The device comprises the heat pipe exchanger. A water inlet pipe and a water outlet pipe are connected to the heat pipe exchanger, a water pipe is in short connection between the water inlet pipe of the heat pipe exchanger and the water outlet pipe of the heat pipe exchanger, and a valve is arranged on the short connected water pipe. After pipe explosion of the heat pipe exchanger occurs, the heat pipe exchanger is in short circuit through the short connected water pipe, and water of a pipeline in the heat pipe exchanger can be avoided entering the whole coke dry quenching gas circulation system, thereby recovering the coke dry quenching gas circulation system to be in a normal state, keeping the stable system, efficiently preventing an explosive accident from occuring and conveniently maintaining the heat pipe exchanger. The method has the advantages of convenient maintenance, convenient and suitable operation and ensures the dry quenching ratio and the steam productivity without delaying production.

Owner:NANJING IRON & STEEL CO LTD

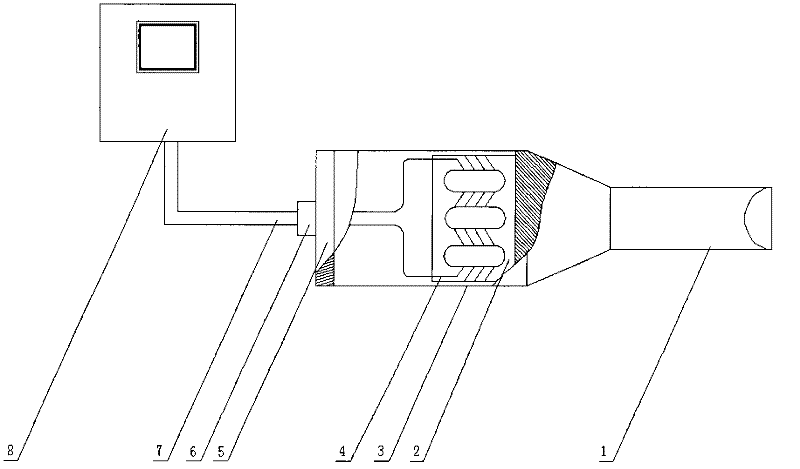

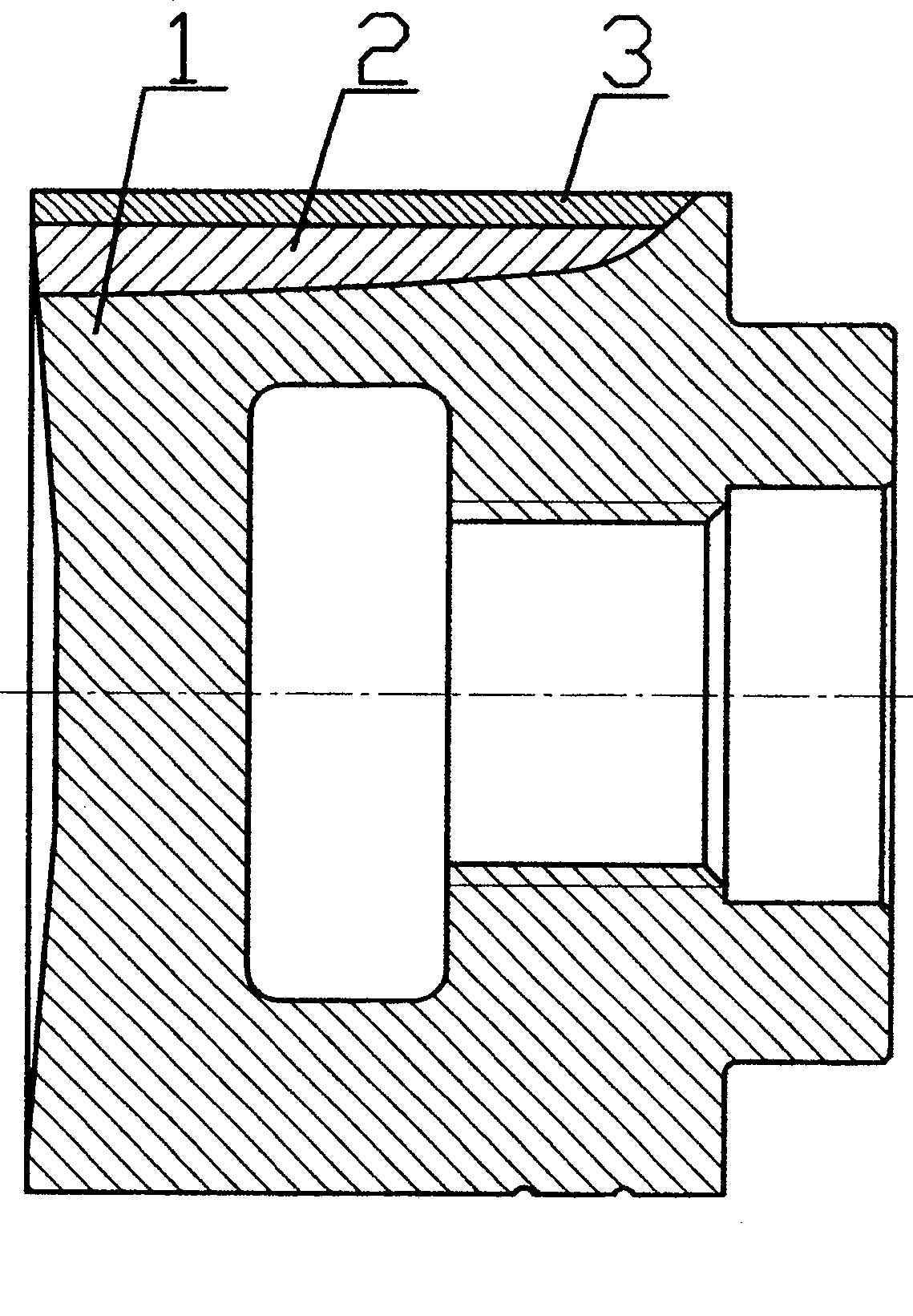

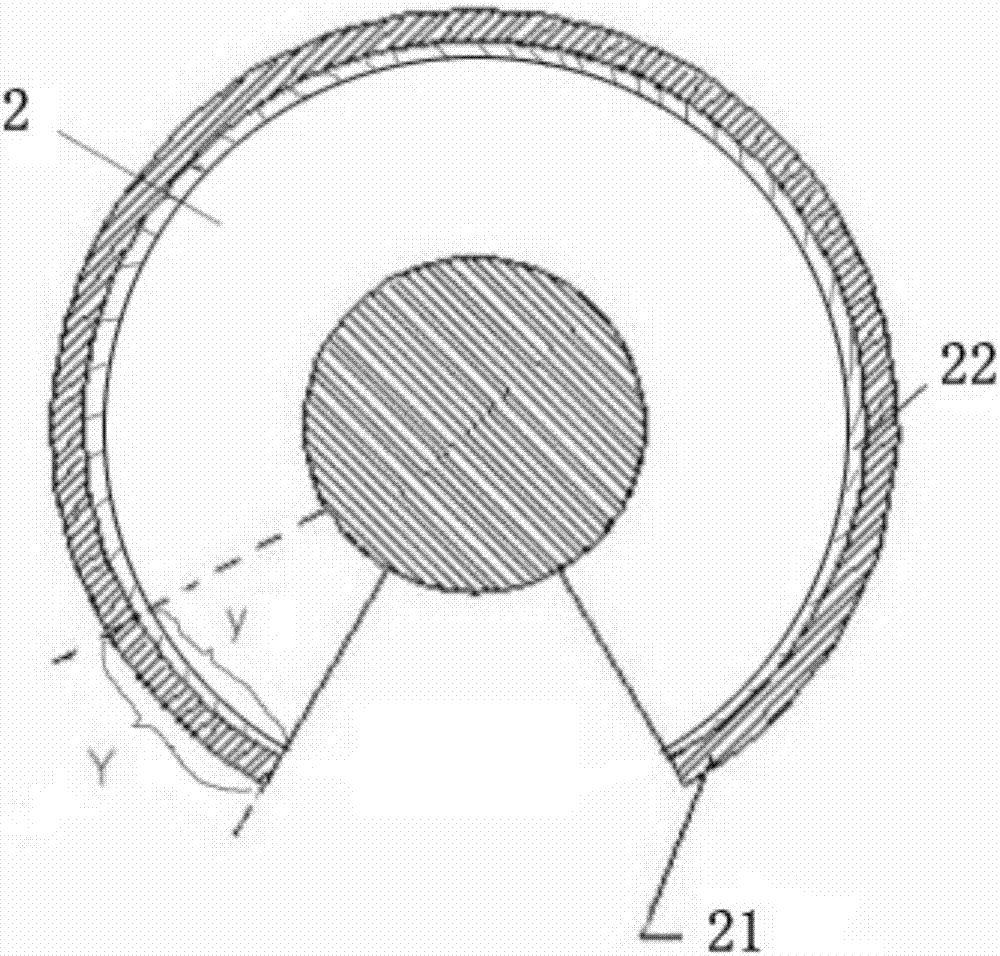

Large-power ultrasonic magnetostrictive transducer

InactiveCN102205312AImprove performanceLow costMechanical vibrations separationEngineeringChemical agent

The invention discloses a large-power ultrasonic magnetostrictive transducer which is characterized in that a plurality of layers of magnetostrictive material sheets are oxidized and laminated, the front ends of the magnetostrictive material sheets are welded with a metal vibration energy collector, coils are wound on the plurality of layers of magnetostrictive material sheets, the plurality of layers of magnetostrictive material sheets are installed in a protective shell, and the coils are led out of the shell to be installed on a binding post and connected with a controller through data lines. The large-power ultrasonic magnetostrictive transducer is simple and easy to use, works online in real time without delaying production and life, and has no secondary pollution due to no use of chemical agents so that corrosion to equipment and economic cost are reduced.

Owner:谭定忠

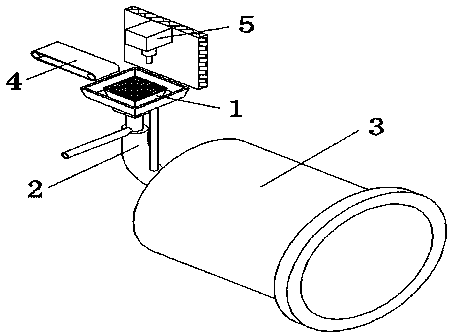

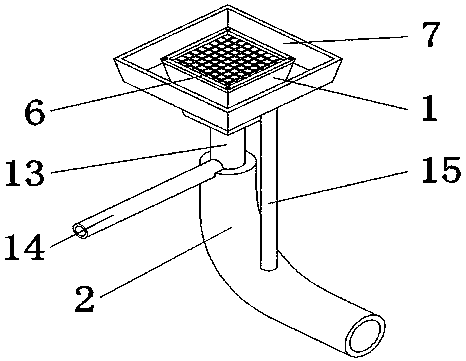

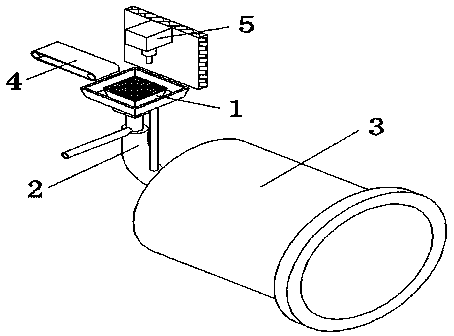

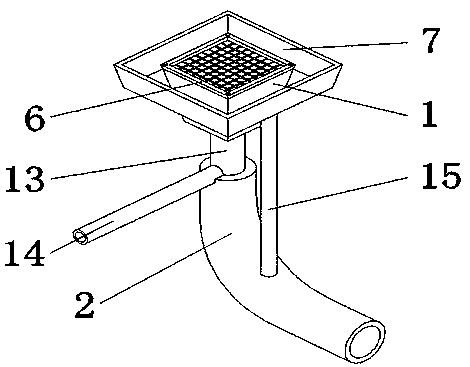

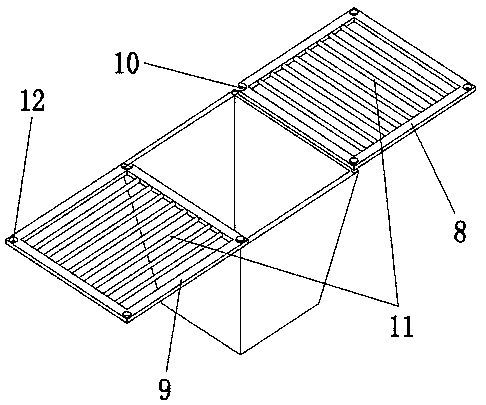

Anti-blocking dredging device for discharge port of ball mill

The invention discloses an anti-blocking dredging device for a discharge port of a ball mill. The anti-blocking dredging device comprises a hopper, a discharge pipe, the ball mill, a belt conveyor anda drilling machine; the hopper is provided with a sieve plate and a material blocking apron; the sieve plate is formed through combination of an upper sieve plate and a lower sieve plate; the upper sieve plate is connected to the right side of the rear end of the hopper through a rotating shaft; the lower sieve plate is connected on the left side of the rear end of the hopper through the rotatingshaft; each of the upper sieve plate and the lower sieve plate is provided with a round opening and a through hole; the material blocking apron is welded on the outer side of the hopper; the discharge pipe is in pipe connection at the bottom part of the hopper through an upper pipe section; an alkaline liquor pipe is in pipe connection between the discharge pipe and the upper pipe section; a material return pipe is welded at the rear end of the discharge pipe and is in pipe connection with the material blocking apron; the ball mill is installed at the rear end of the discharge pipe; the rearend of the discharge pipe is inserted into a feed port of the ball mill; the belt conveyor is installed above the hopper; and the drilling machine is installed right above the hopper. The anti-blocking dredging device can effectively prevent the phenomenon of blockage of the discharge pipe.

Owner:江苏新达石英有限公司

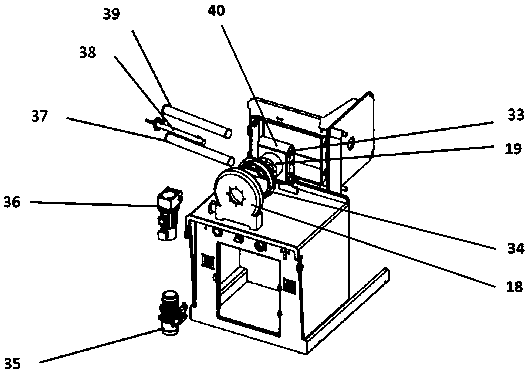

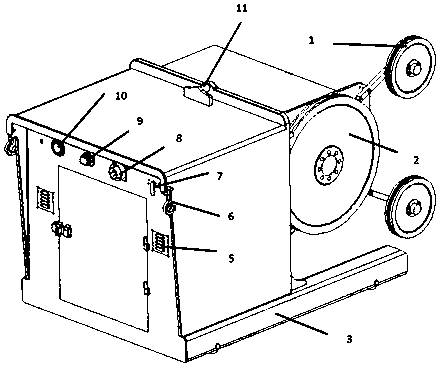

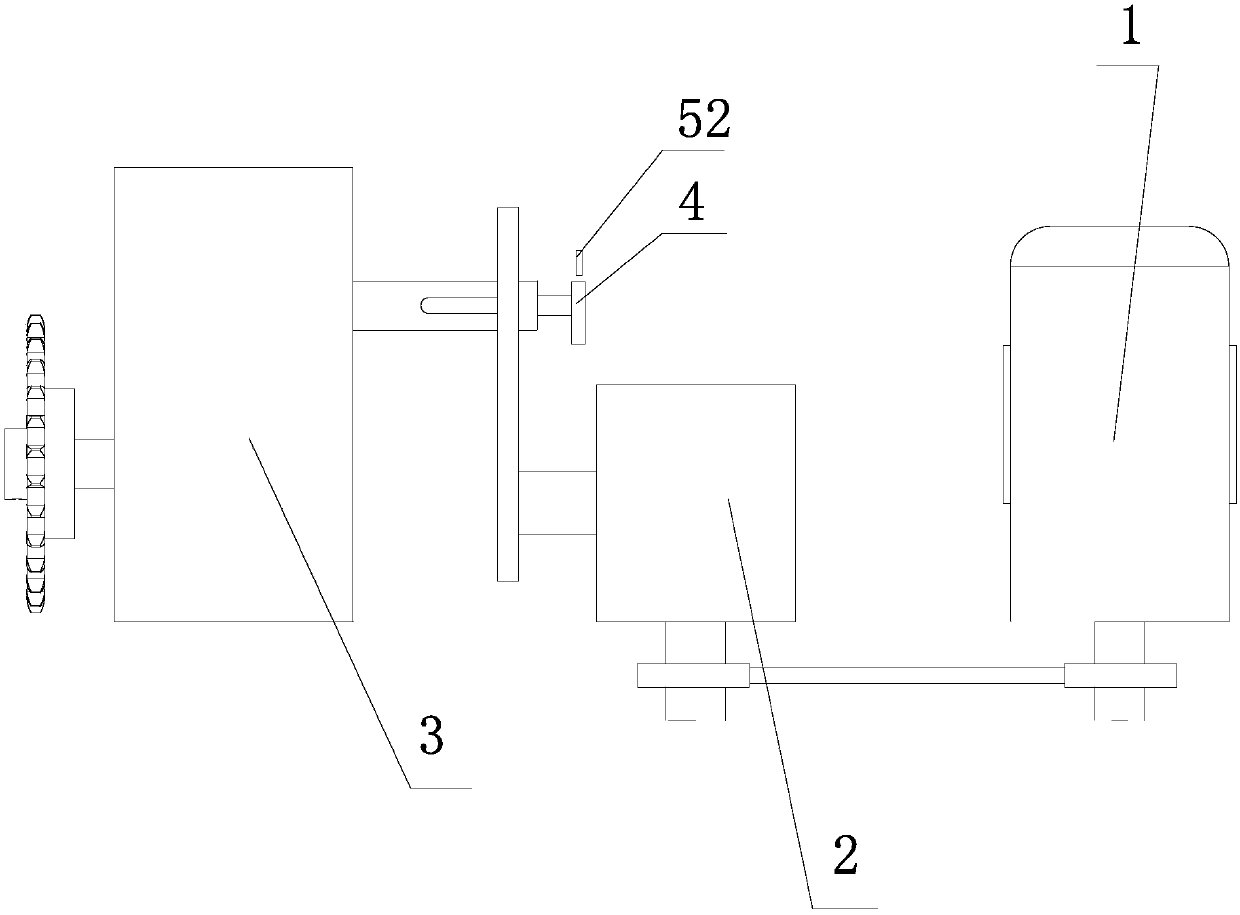

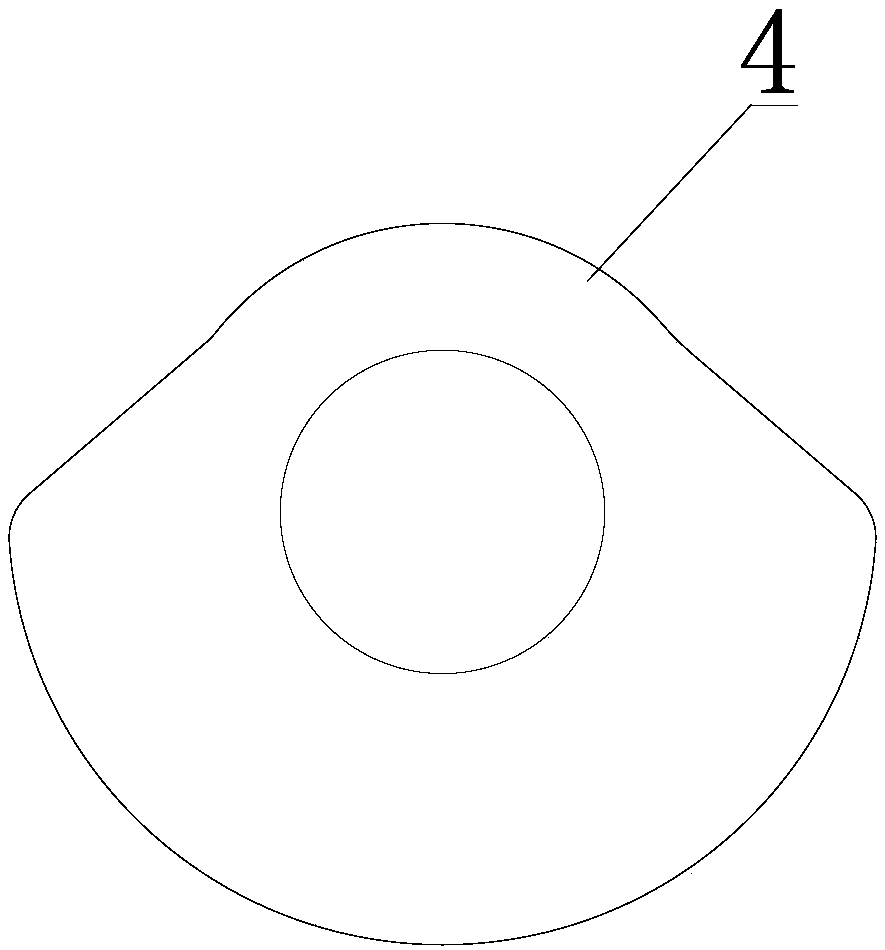

Diamond wire saw

InactiveCN107745451ALow failure rateGuaranteed uptimeWorking accessoriesStone-like material working toolsMachining vibrationsReduction drive

The invention relates to a diamond wire saw which comprises a power head, a rotation mechanism, a travelling mechanism, a box body and a control system. A transversely-moving shaft in the power head of the diamond wire saw is placed in a sliding bearing seat of a rotation spindle connecting piece in the rotation mechanism, and a transversely-moving oil cylinder is fixedly arranged in the rotationspindle connecting piece; a hydraulic station controls a piston rod of the transversely-moving oil cylinder to move, and the travelling mechanism comprises a vertical adjusting mechanism in an adjusting chain wheel and a chain track engaged mode; a traveling chain adopts a direct connection mode; a rotation spindle of the diamond wire saw is subjected to double supporting of a double-supporting rotation speed reducer and a rotation spindle bearing seat, and the power head supports force and stably rotates; the power head and a power wheel stably operate, drooping and shaking are avoided even if the power head is used for a long period, during cutting, shaking is small, and machine vibration is also small; transverse movement is achieved in a hydraulic mode, and the parallelism depth errorof movement in the up-down and left-right directions is small; and through the vertical adjusting mechanism, the diamond wire saw normally travels on various tracks, and the climbing ability of the diamond wire saw is improved.

Owner:毛光华

Method for preventing slipping of lower belt of blast furnace groove

ActiveCN103508178ALow failure rateNo delay in productionControl devices for conveyorsFailure rateEngineering

The invention relates to a method for preventing slipping of a lower belt of a blast furnace groove. The method for preventing slipping of the lower belt of the blast furnace groove is characterized in that the method comprises the steps that (1) the speed of the belt is detected; (2) the output of a device in the field is controlled and then the speed of the belt is detected, wherein probes, namely high-speed proximity switches, of a metal induction device fixed on a driven roller and of a detection device mainly serve as signal sources of a speed detection device. The method for preventing slipping of the lower belt of the blast furnace groove has the advantages that equipment is simple, the failure rate is low, and normal production can not be delayed.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Well-drilling micro overflow while-drilling monitoring method

The invention relates to the field of oil and gas field well-drilling pressure control, in particular to a well-drilling micro overflow while-drilling monitoring method. The well-drilling micro overflow while-drilling monitoring method comprises the following steps that (1) at the drilling stage before formation fluid enters a wellbore, the inlet flow Q<in>(i) is calculated, filter processing is conducted, and the average flow Q<inA> is calculated; (2) the outlet flow Q<out>(i) is measured in real time, filter processing is conducted, the average flow Q<outA> is calculated, the inlet flow is checked according to the outlet displacement, and the check coefficient f is calculated, wherein f=Q<outA> / Q<inA>; (3) when a new formation is drilled, the real-time inlet displacement Q<in>(i) and thechecked inlet flow Q<inc>(i) are calculated, wherein Q<inc>(i)=Q<in>(i)*f; and (4) the cumulative flow difference (Q<out>(i)-Q<inc>(i))*delta t in one time period delta t is calculated, if (Q<out>(i)-Q<inc>(i))*delta t is greater than cL, (c is greater than or equal to 0.01 L and less than or equal to 2000 L, delta t is greater than or equal to 1 s), and when c is greater than or equal to 1 L under the general condition, micro overflow is judged. The well-drilling micro overflow while-drilling monitoring method is small in monitoring error, fast in monitoring and low in cost.

Owner:SOUTHWEST PETROLEUM UNIV

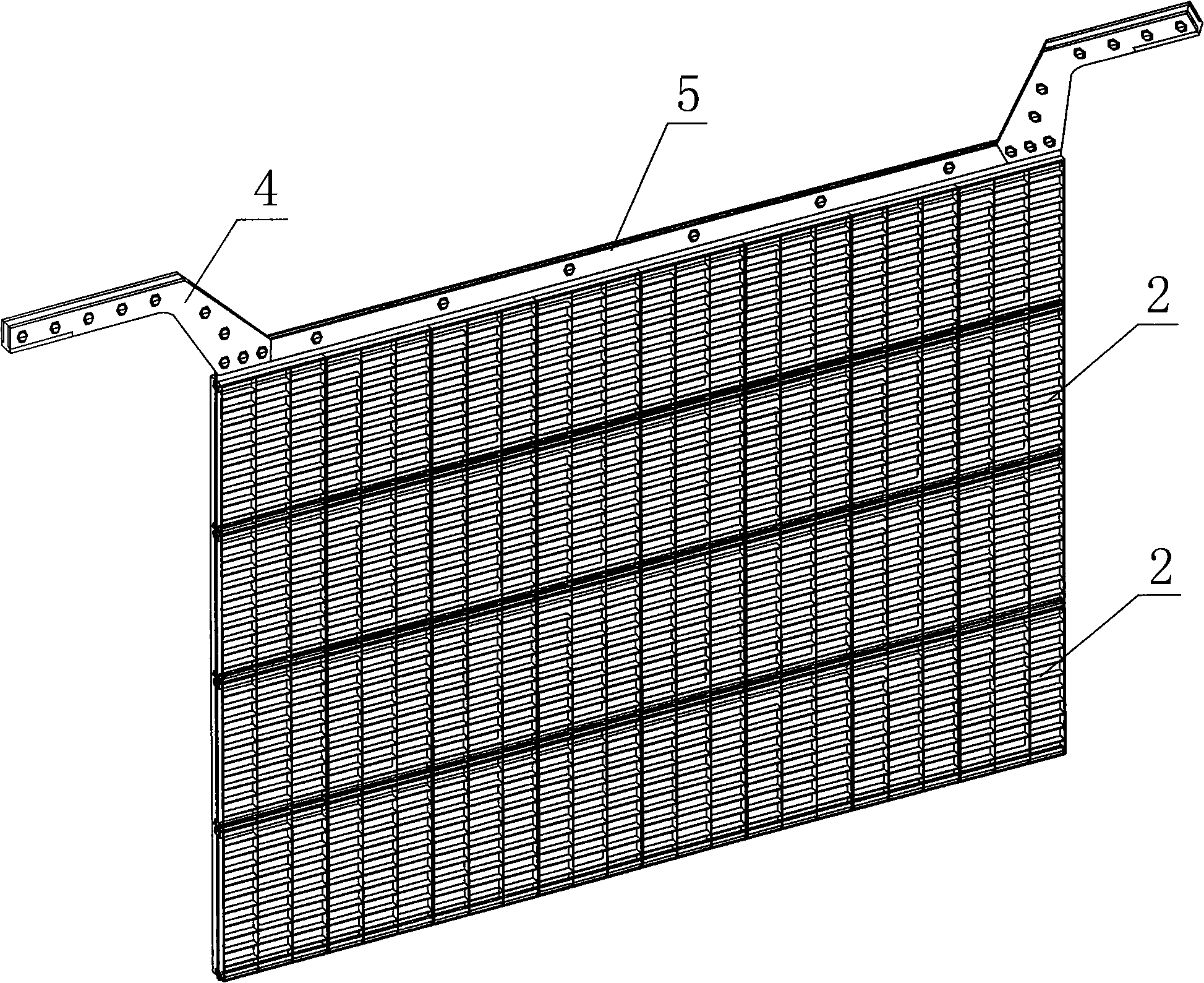

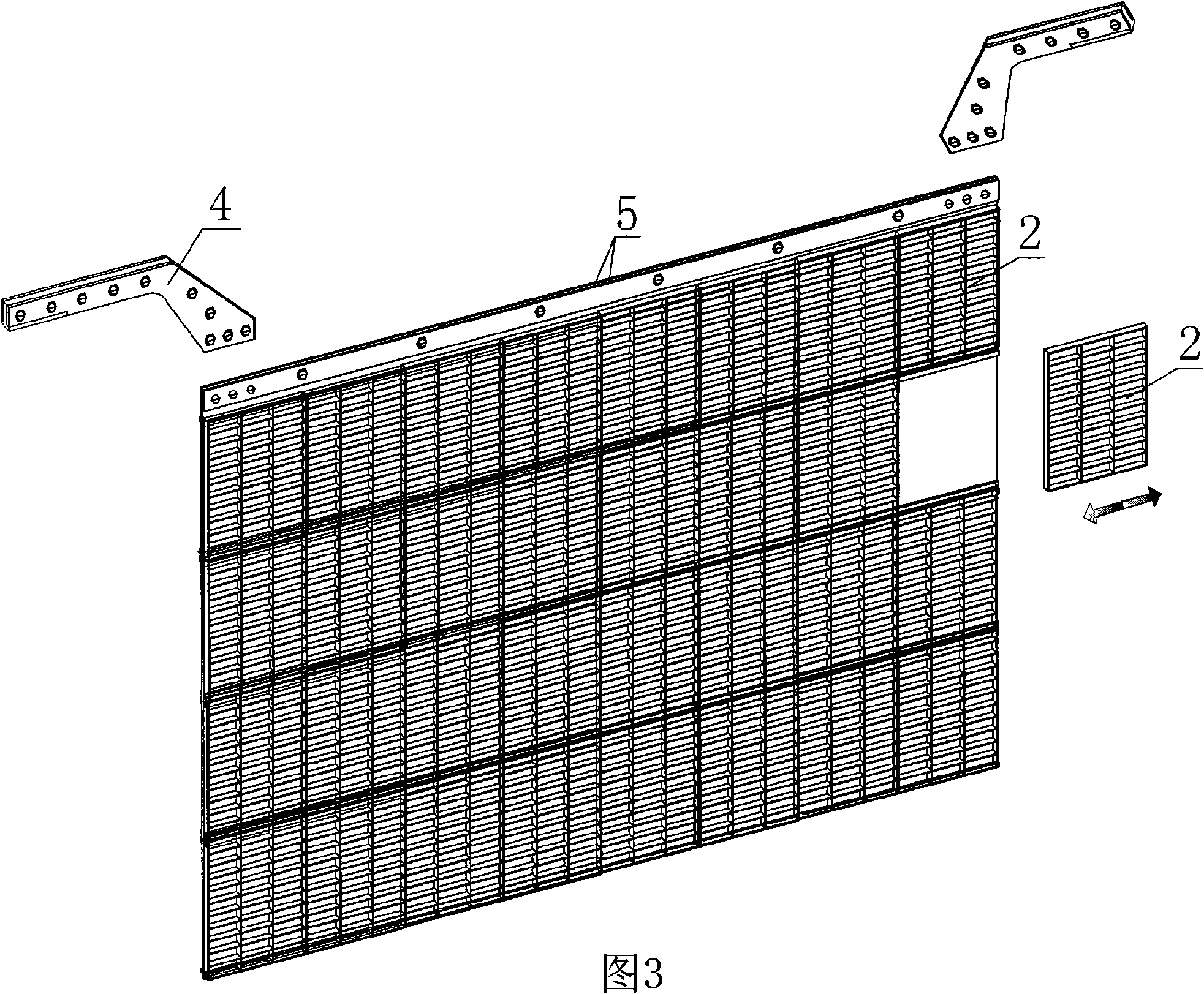

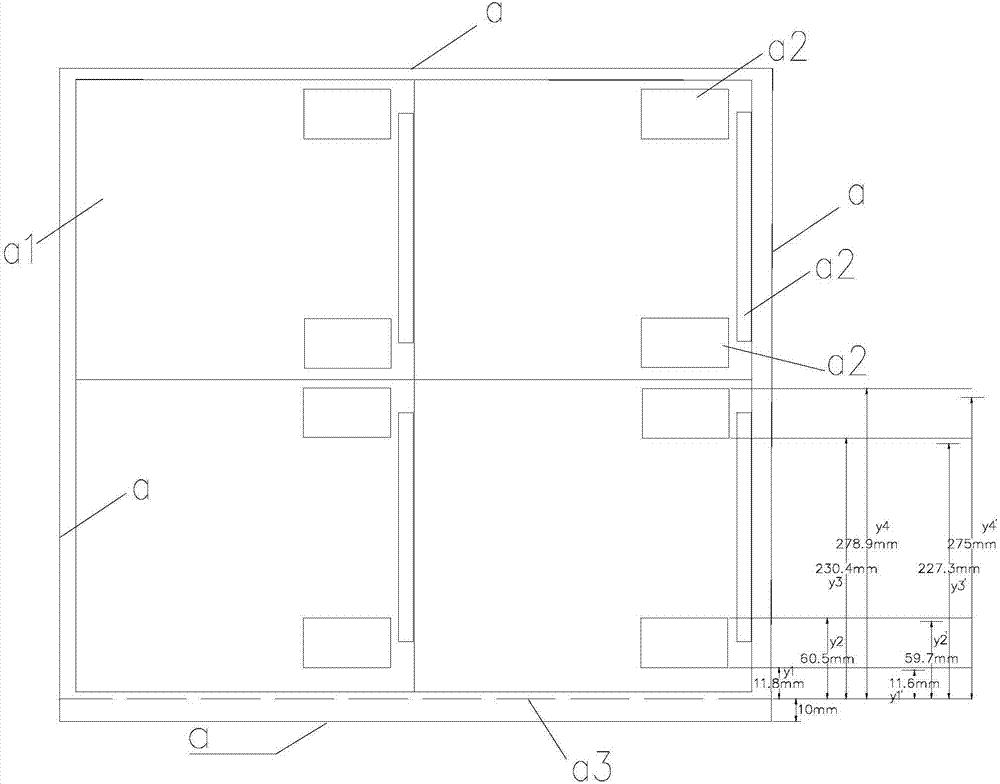

Combined electrolytic cathode plate

InactiveCN101358360AImprove the effective area of electrolysisImprove loading and unloading efficiencyPhotography auxillary processesElectrodesElectrolysisEngineering

The invention discloses a combined electrolysis cathode plate which comprises an electrolysis cathode plate and a conductive connecting piece, and is characterized in that the electrolysis cathode plate comprises an electrolysis mother plate, a plurality of electrolysis unit plates and connecting mechanisms thereof, wherein, the electrolysis mother plate is in a plane structure, and the upper end of the mother plate is connected with a conductive connecting structure; the connecting mechanism is arranged on the surface of the electrolysis mother plate; the electrolysis unit plates are frame plates which are applicable to paste application and removing devices with surface area smaller than that of the electrolysis mother plate; the electrolysis unit plates are movably arranged on the electrolysis mother plate by the connecting mechanisms, to form a large removable combined electrolysis cathode plate. The combined electrolysis cathode plate of the invention can not only meet the requirements for the mechanical operation during paste application and removing processes, but also realize wet electrolysis mass industrialized production, improve production efficiency, improve current efficiency and reduce power consumption.

Owner:DONGGUAN SONGSHAN TECH GROUP

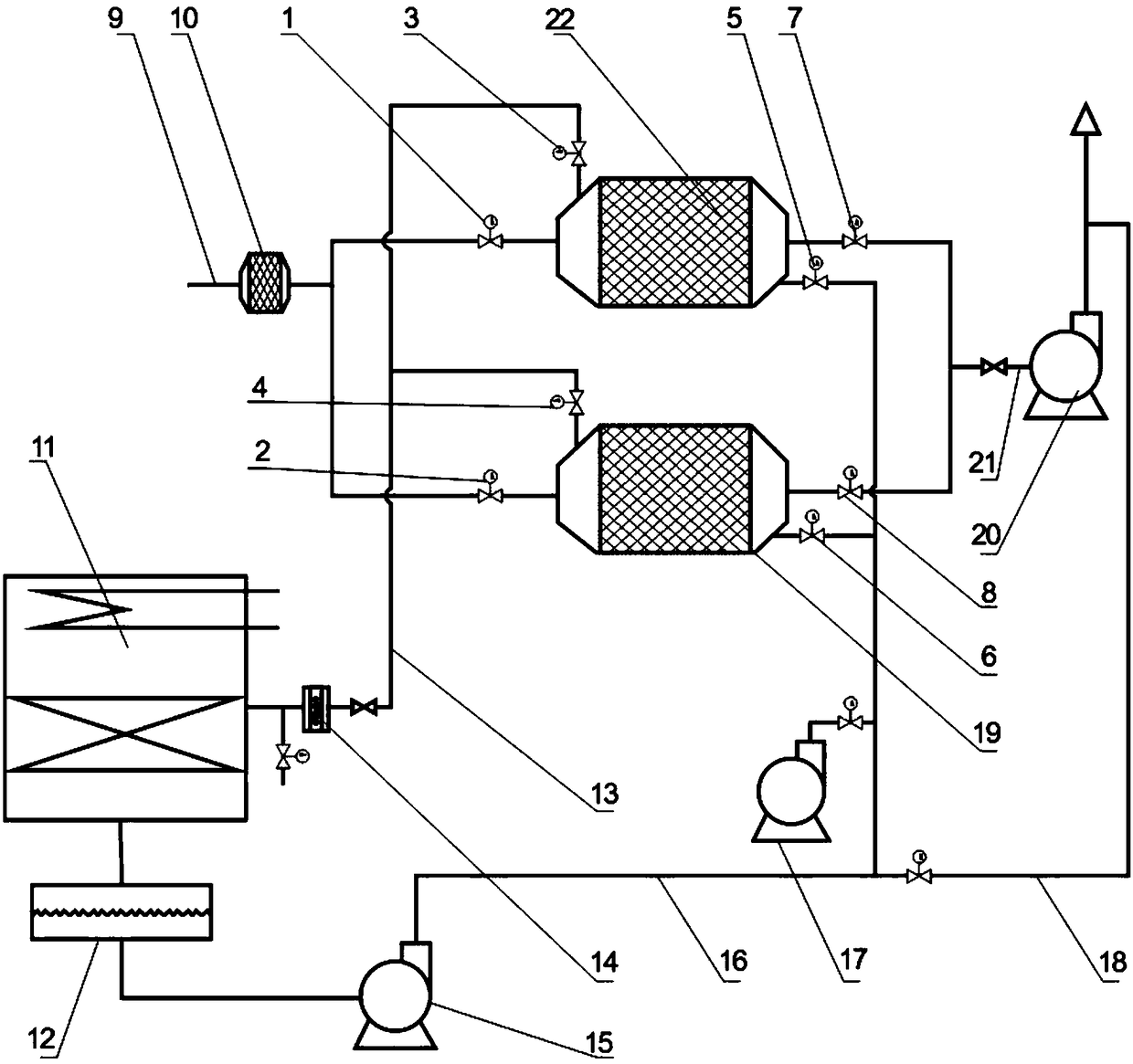

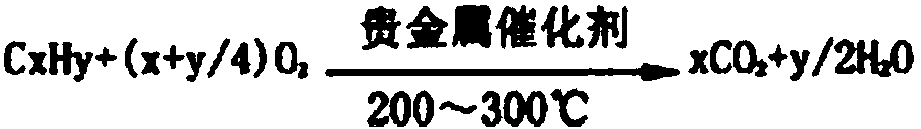

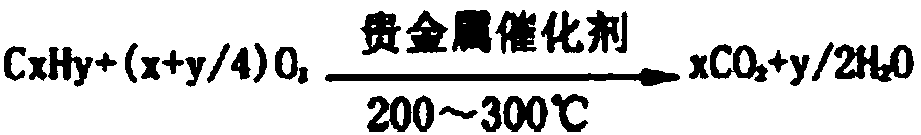

Organic waste gas treatment device equipped with movable desorption and catalytic combustion vehicle

InactiveCN108421369ASmall footprintNo delay in productionDispersed particle separationIncinerator apparatusPositive pressureDesorption

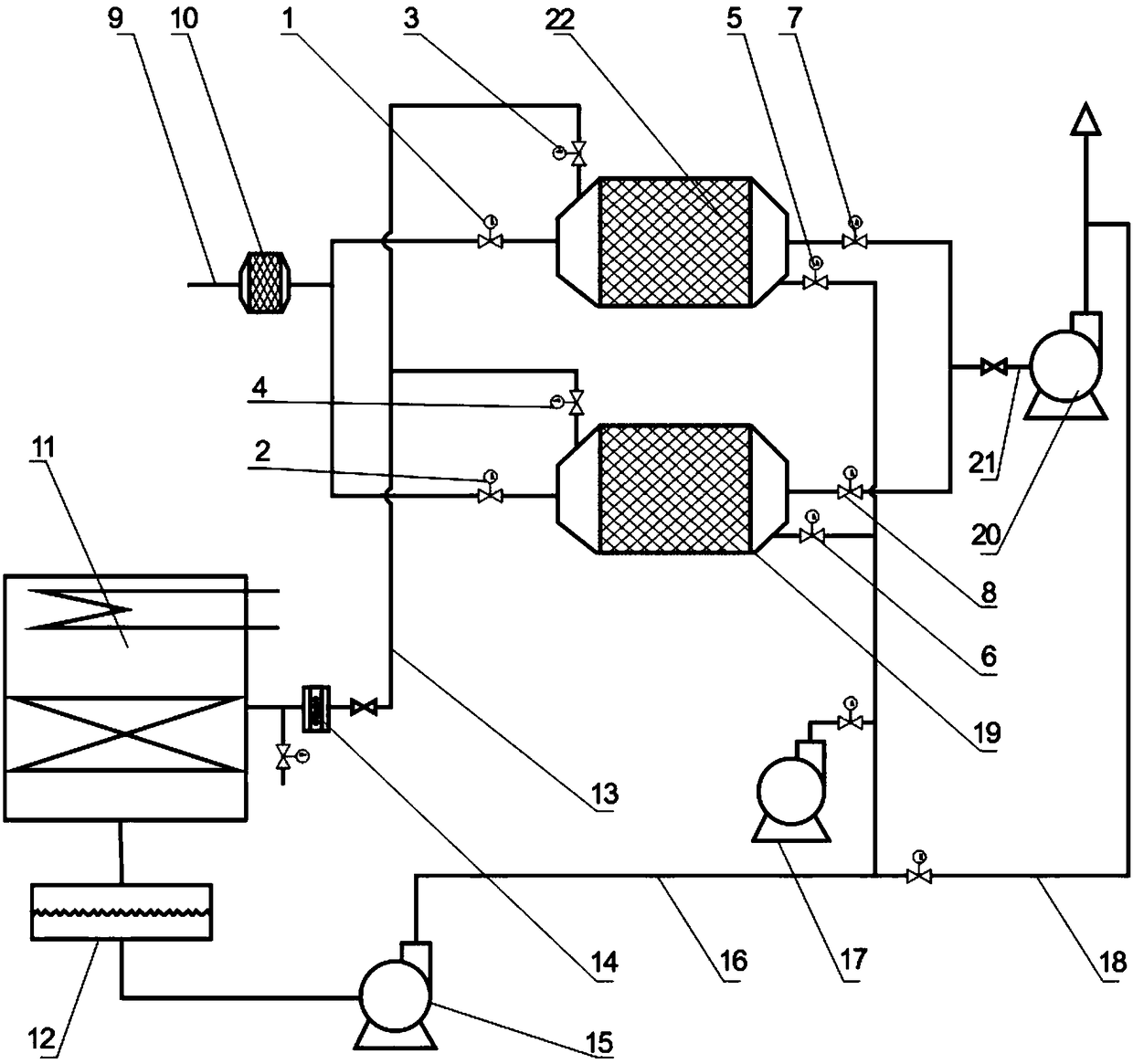

The invention discloses an organic waste gas treatment device equipped with a movable desorption and catalytic combustion vehicle. The organic waste gas treatment device structurally comprises a fixedpart consisting of an absorption part, a discharge part and a desorption fan and a catalytic combustion part as a movable part, wherein the absorption part is formed by arranging at least two adsorption beds in parallel; the front ends of the adsorption beds are connected with the inlet ends of an organic waste gas inlet main pipe and the catalytic combustion part; the output ends of the adsorption beds are connected with the positive pressure ends of the discharge part and the desorption fan; the catalytic combustion part is connected with the absorption part through a detachable fast interface; the catalytic combustion part is arranged on the movable vehicle body. When an enterprise invests environmental protection equipment, the enterprise only needs to purchase and mount the relatively low-cost absorption part and the relatively low-cost discharge part, while the high-cost and low-utilization rate catalytic combustion part only needs to purchase catalytic combustion service so asto greatly reduce the initial mounting cost of organic waste gas treatment equipment and reduce the space occupied by the catalytic combustion part; the absorption part is equipped with the two adsorption beds for alternating adsorption and desorption.

Owner:成都鑫金臣节能环保科技有限公司

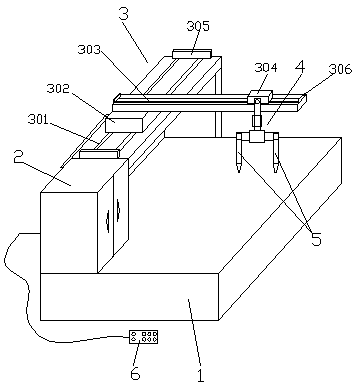

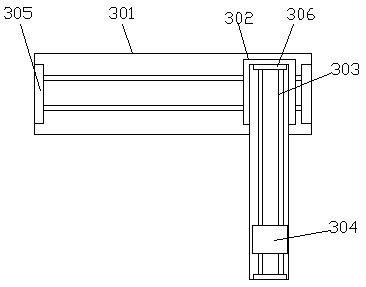

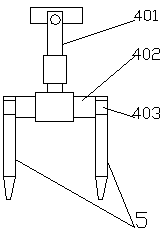

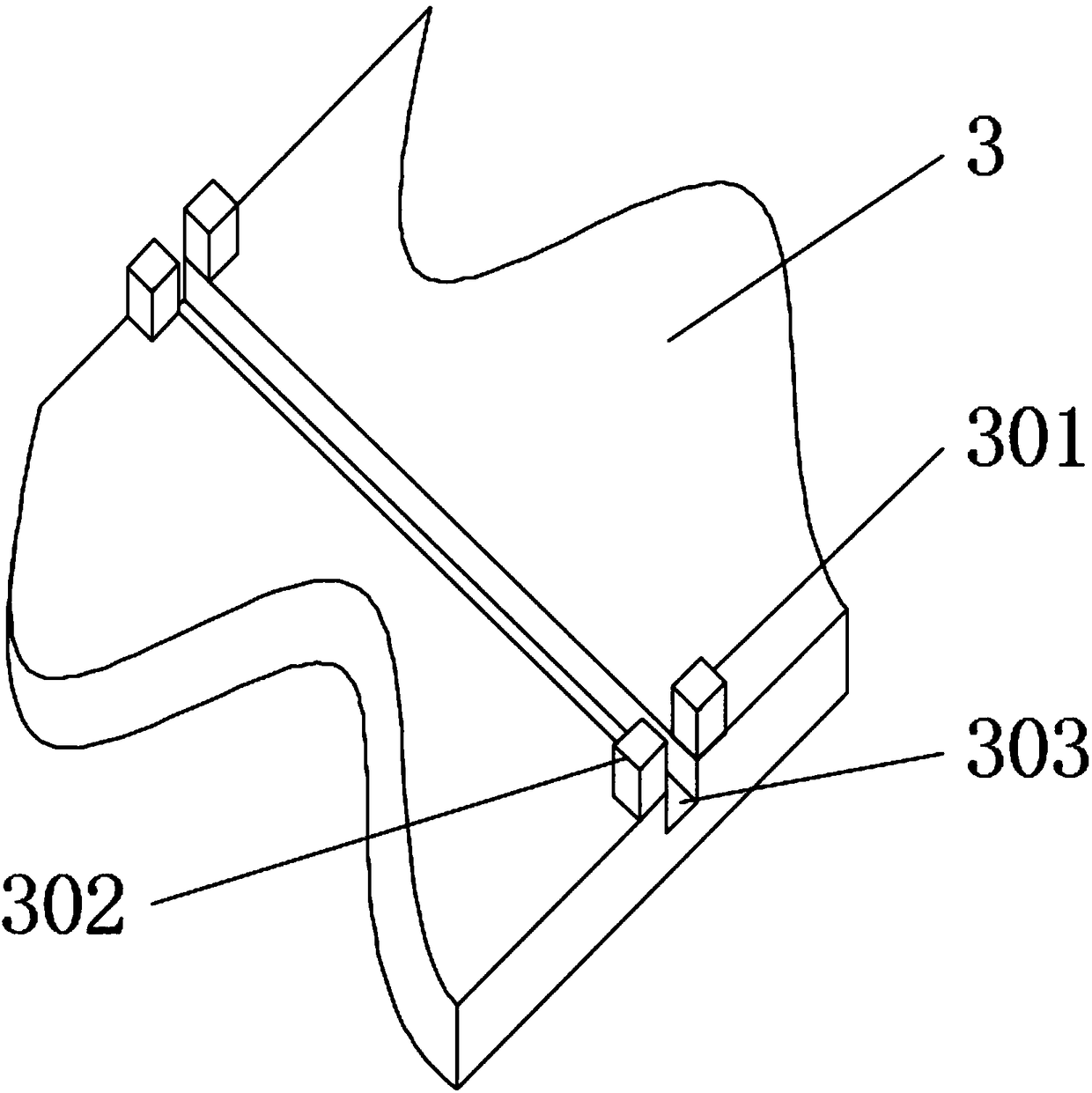

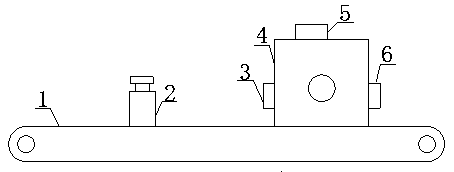

Semi-automatic groove cutting machine

PendingCN108746932AImprove efficiencyReduce labor costsGas flame welding apparatusElectrical controlSemi automatic

The invention relates to a semi-automatic groove cutting machine. The semi-automatic groove cutting machine comprises a working platform, an electrical control cabinet, a movement mechanism, a liftingmechanism and two cutting torches; the electric control cabinet is used for controlling the movement mechanism to move to drive the two cutting torches to cut a workpiece on the working platform, themovement mechanism comprises a longitudinal track, a longitudinal speed regulation running trolley, a transverse track and a transverse speed regulation running trolley, and the lifting mechanism comprises a telescopic rod, a horizontal connecting rod and two rotating arms. According to the semi-automatic groove cutting machine, the structure is reasonable, the use is safe and convenient, repeated and uninterrupted working can be achieved, the positions of the running trolleys and the position of the workpiece can be prevented from being repeatedly adjusted, the fuel gas consumption is saved,the working efficiency is improved, the technical problems that for an existing groove cutting machine, a small running trolley is in a one-way circulation mode, and then the track angle needs to beadjusted back and forth, so that the time is wasted, the error during machining is increased, the working efficiency is reduced, the product quality is influenced and the like are solved, and for theprior art, the semi-automatic groove cutting machine has the good market prospect and development space.

Owner:HENAN JINJIYE HEAVY IND CO LTD

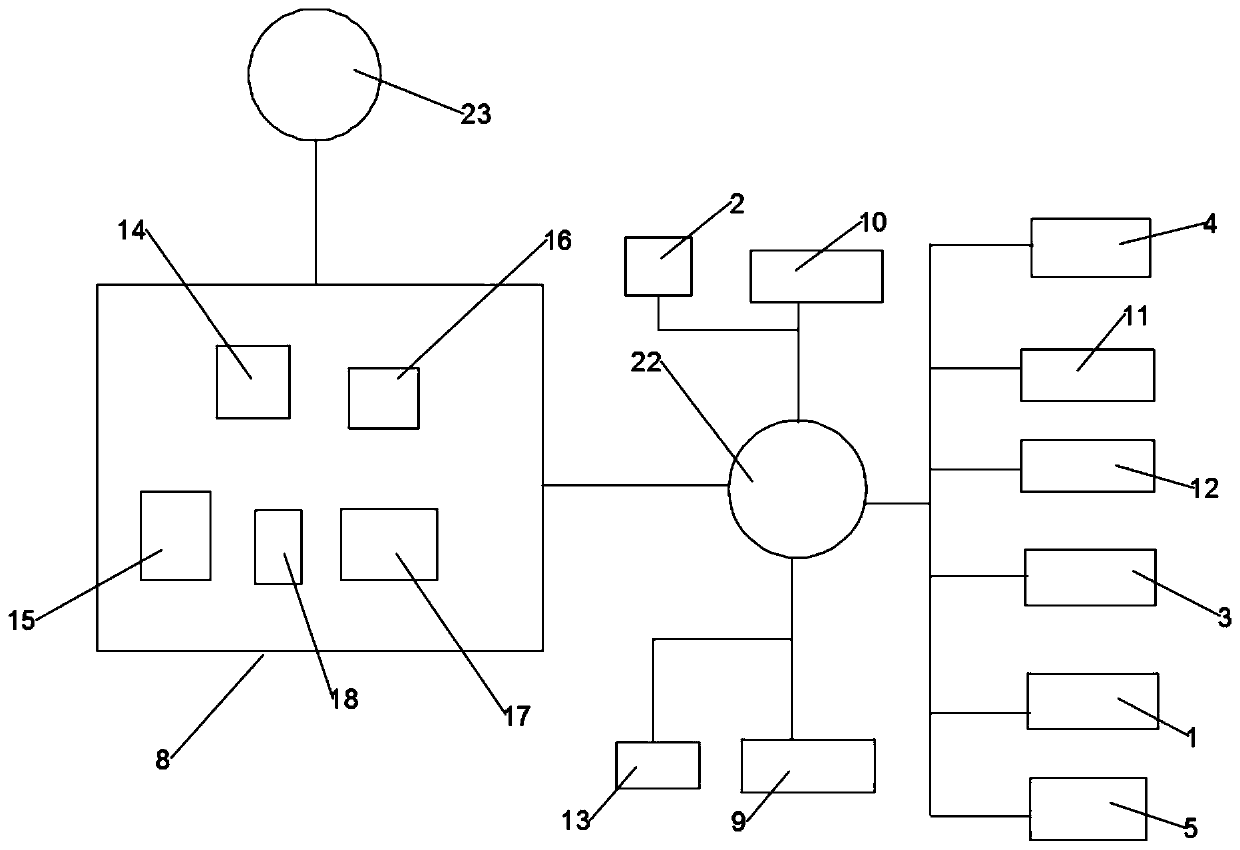

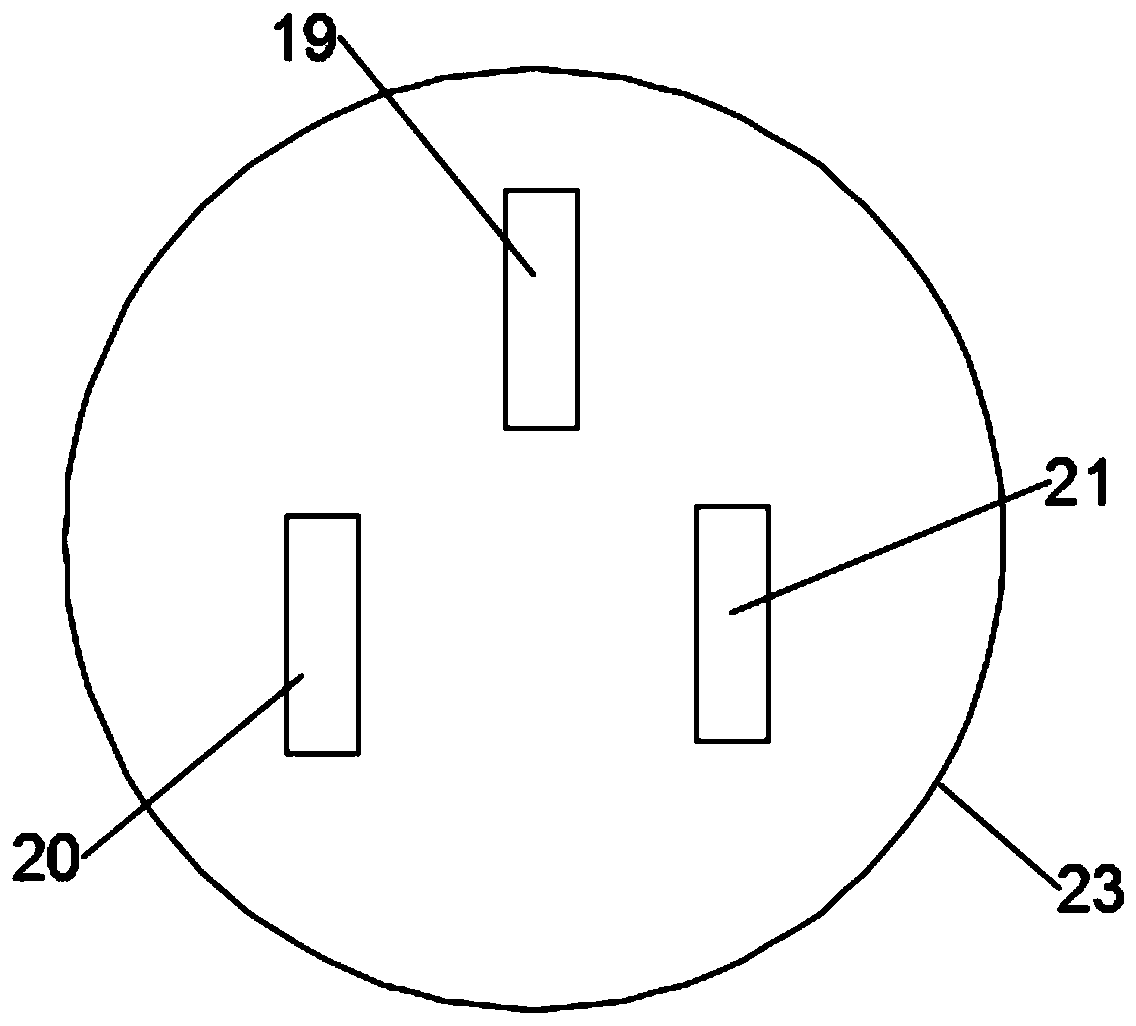

Denitrification SCR ammonia injection control system and workflow thereof

InactiveCN109908754AReduce labor intensitySimple working processDispersed particle separationControl systemFlue gas

The invention discloses a denitrification SCR ammonia injection control system which comprises a control terminal, a mixed flow meter, a thermometer, a flue gas flow meter and a solenoid valve, wherein the mixed flow meter is mounted at an outlet of a mixer, the thermometer is mounted inside an SCR reaction tower, the solenoid valve is located between the mixer and an evaporator, the flue gas flowmeter is located at the outlet of the SCR reaction tower, and the control terminal is respectively connected with the mixed flow meter, the thermometer, the flue gas flow meter and the solenoid valvethrough a communication module. The invention further discloses a workflow of the denitrification SCR ammonia injection control system. The denitrification SCR ammonia injection control system disclosed by the invention has the benefits of being capable of instantly and quickly responding to automatically follow the adjustment of the denitrification ammonia injection amount and not requiring personnel to be monitored at all times, thereby reducing the labor intensity of the monitoring personnel.

Owner:DATANG ENVIRONMENT IND GRP

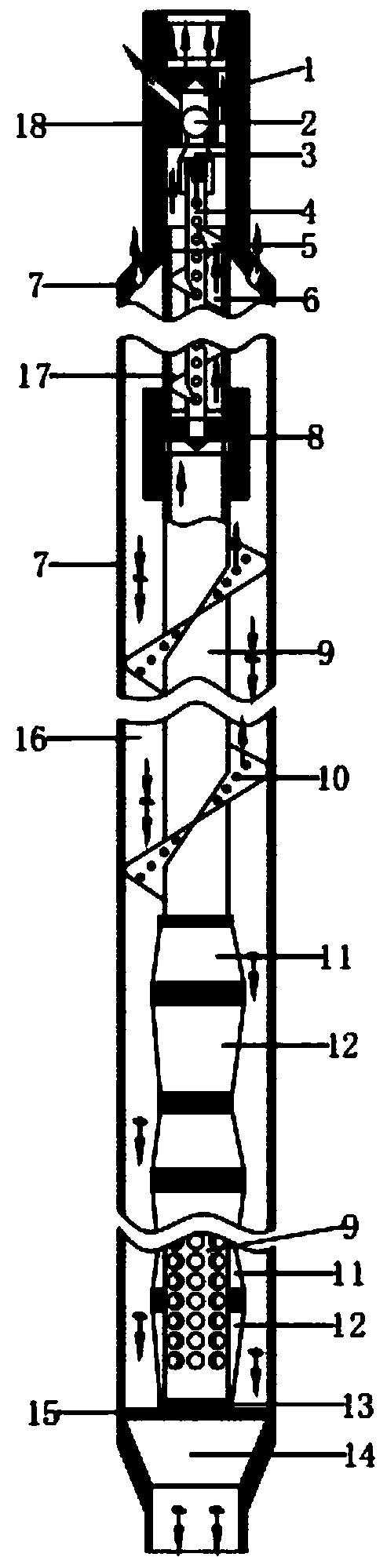

Multistage swing type oil-gas-sand separating device

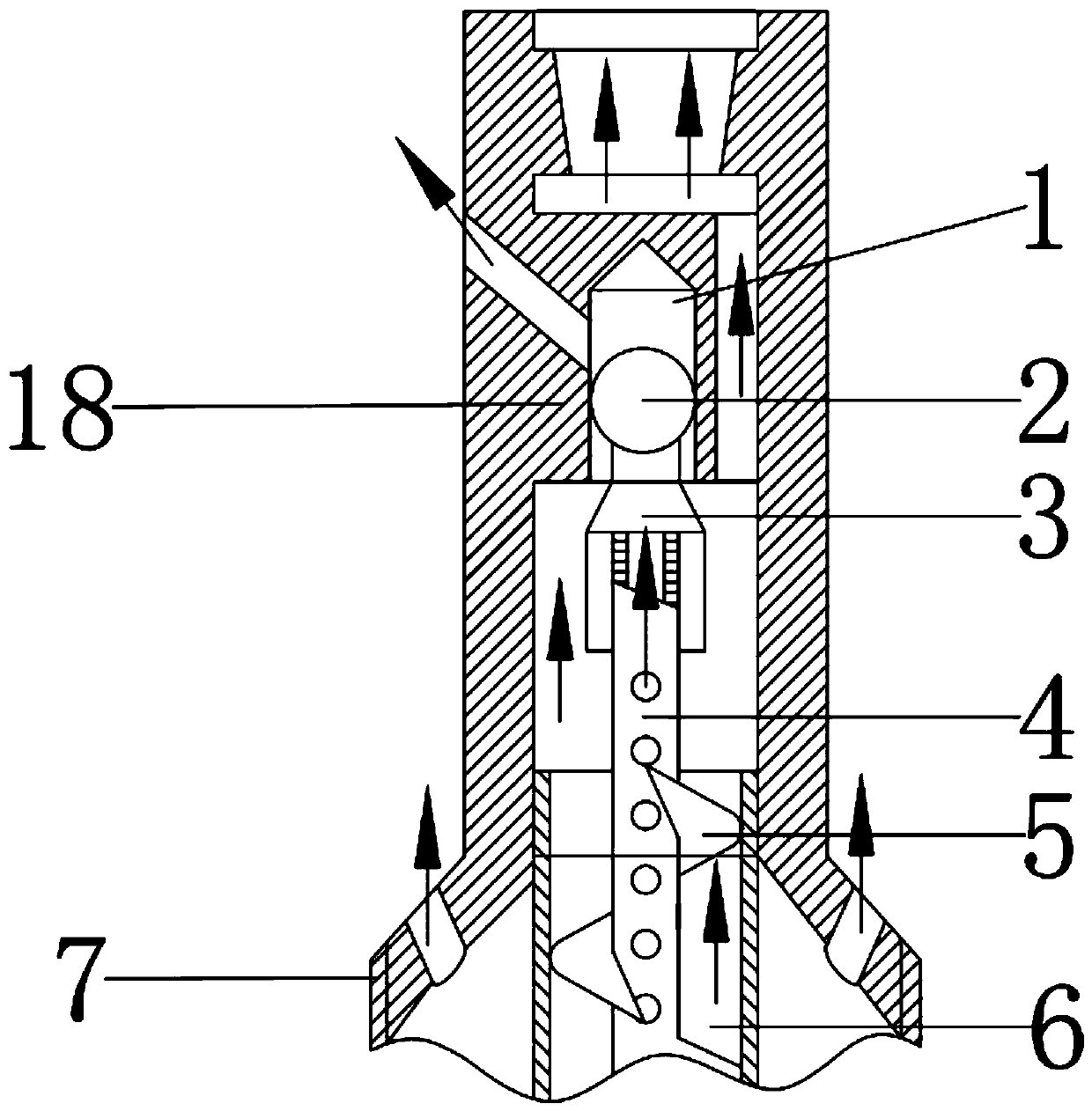

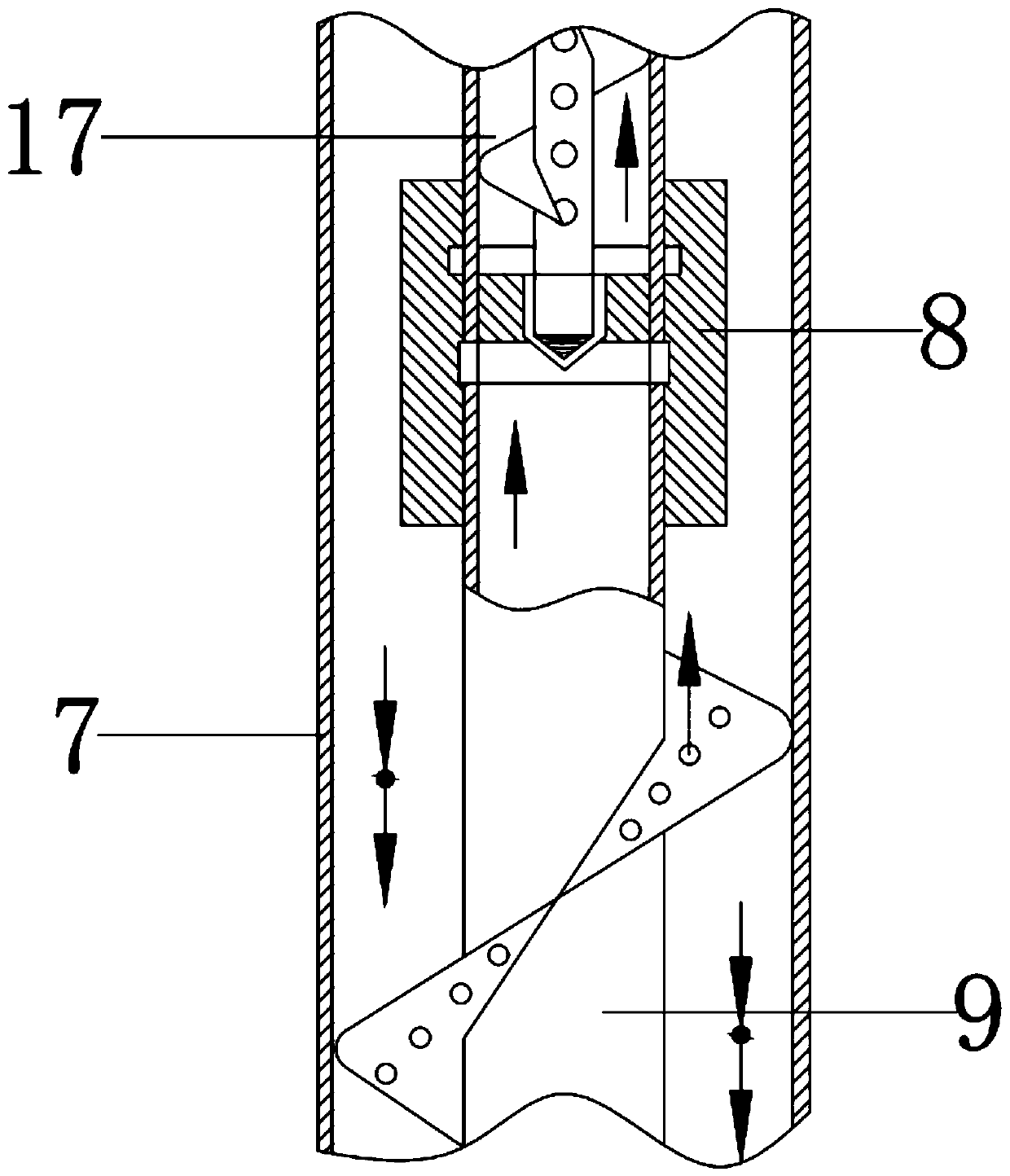

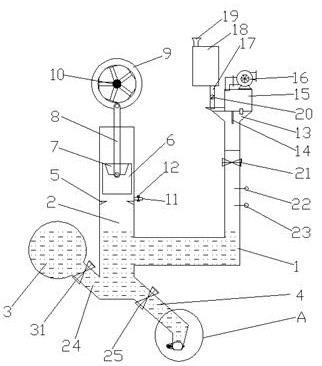

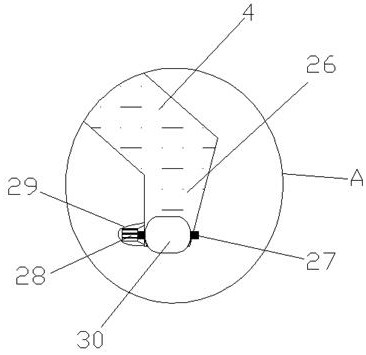

PendingCN110778303AEasy to separateIncrease productionFluid removalFlash degasificationExhaust valveSand filter

The invention provides a multistage swing type oil-gas-sand separating device and belongs to the field of downhole oil recovery auxiliary tool equipment. The multistage swing type oil-gas-sand separating device comprises a sleeve, and dense and even oil, gas and sand inlet and outlet holes are formed in the upper middle wall of the sleeve. An oil-gas separating mechanism is arranged on the upper portion in the sleeve. An oil-sand separating mechanism is arranged on the lower portion in the sleeve. The lower end of the sleeve is fixedly connected with a sand discharge opening. The oil-gas separating mechanism is formed by connecting a one-way exhaust valve formed by a valve body, a ball element and a valve seat, an inner spiral channel formed by an exhaust pipe, a small spiral guide plate and an oil pipe, a connector and an outer spiral channel formed by an upper half section of an oil pipe with a hole and a large spiral guide plate from top to bottom. The oil-sand separating mechanismis formed by a lower half section of the oil pipe with the hole, multiple flow guide covers and multiple sand filtering screens. The multistage swing type oil-gas-sand separating device provides an ultrastrong separating effect, is convenient to repair, not high in replacing and maintaining cost and not likely to cause long-term halt production of a gas well.

Owner:FUNING COUNTY PETROL MECHANICAL LIMITED

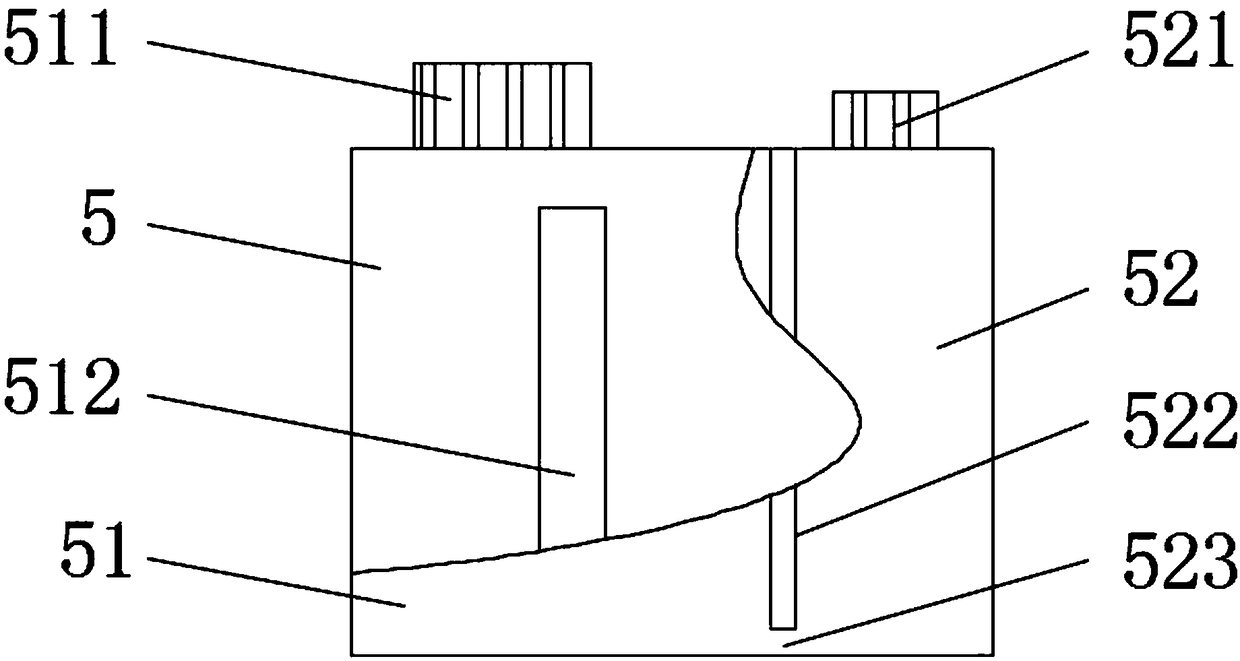

Filter stick center line glue applying device

InactiveCN111687000APromotes thorough mixingControl mixing timeLiquid surface applicatorsTobacco smoke filtersHydraulic cylinderDrive wheel

The invention discloses a filter stick center line glue applying device. The filter stick center line glue applying device comprises a communicating tubular structure composed of an L-shaped feeding cylinder, a hydraulic cylinder, a mixing balloon, an inclined pipe and a glue spraying pipe, wherein a piston section of the hydraulic cylinder is sleeved with a piston column, the piston column is connected to a driving wheel through a precession rod, a pressure stabilizing pipe and a pressure stabilizing valve are arranged at the bottom of the piston section, a sealed hopper bin is arranged at the top end of the L-shaped feeding cylinder, an air inlet chamber of the sealed hopper bin communicates with a pressure relief tank and a pressurizing air pump, a liquid inlet chamber communicates witha glue solution tank through a liquid inlet pipe, the inclined pipe is provided with a mixing valve, the glue spraying pipe is provided with a glue spraying valve, the lower portion of the glue spraying pipe is provided with a crane-type nozzle, and an opening of the crane-type nozzle is provided with a rolling motor shaft and a glue applying roller. According to the filter stick center line glueapplying device, the mixing balloon is adopted as a glue spraying pressure stabilizing component, and a non-contact mixing method is achieved through piston reciprocating motion, so that the mixing efficiency is high, cleaning is convenient, operation is easy and convenient, the problems that glue inside an existing glue applying device is difficult to clear, stirring is uneven, the glue supply amount is unstable, and glue liquid is wasted are solved, the glue breaking phenomenon is avoided, applying is uniform, and the filter stick finished product quality is improved.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

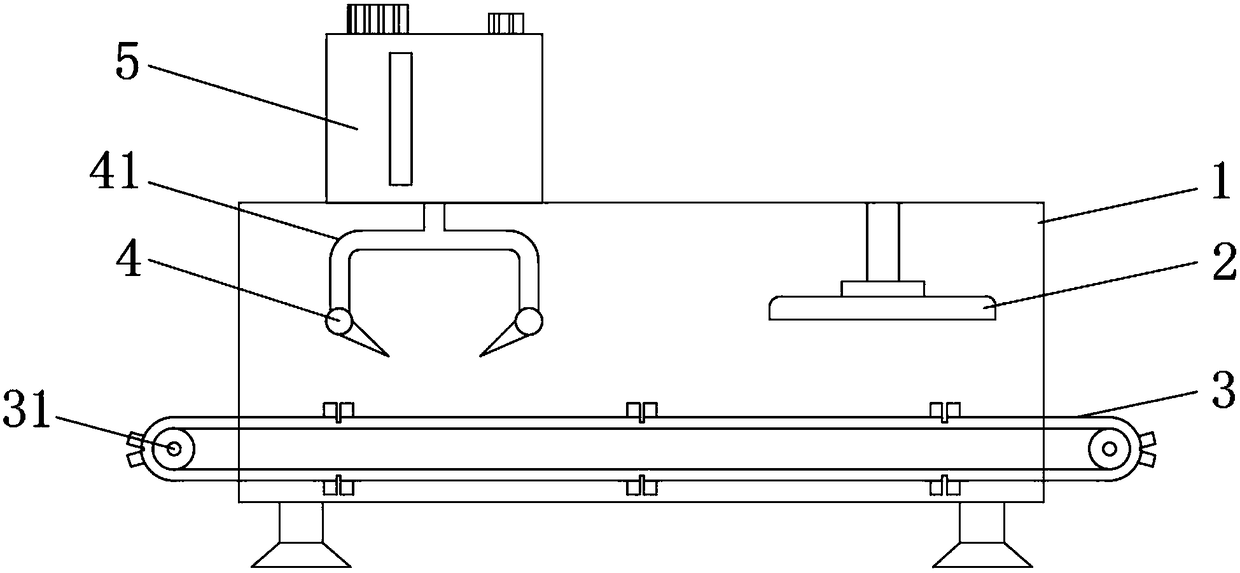

Device for spraying coating on wood

InactiveCN108499793AReduce the amount of manual laborImprove work efficiencyLiquid spraying apparatusSpray boothsSpray nozzleBlock structure

The invention discloses a device for spraying coating on wood. The device comprises a main machine shell, a conveying belt and a coating tank. According to the device for spraying the coating on the wood, grooves are formed in the conveying belt, clamping block structures are arranged at the two ends of the grooves correspondingly, and the wood is inserted into the grooves and fixed through clamping blocks; after the spraying and drying processes are completed, the wood reaches the positions of rollers, the positions, at the roller ends, of the conveying belt are each in an arc shape so that the clamping blocks and the grooves can be largened, accordingly, the wood inside the grooves falls off, and the manual labor amount is decreased; the two sides of the wood can be painted simultaneously through nozzles at the two ends, and thus the working efficiency is improved; and an accessory tank is arranged inside the coating tank, according to the principle of atmospheric pressure, when thecoating inside a main coating tank is used up, the coating inside the accessory tank enters the main coating tank through a penetrating groove, accordingly, the wood can continue being sprayed, the time for adding the coating is provided for people, shutdown is not needed, thus production is not delayed, and the production efficiency is improved.

Owner:FOSHAN SUIYUAN HENGKE BUILDING MATERIAL CO LTD

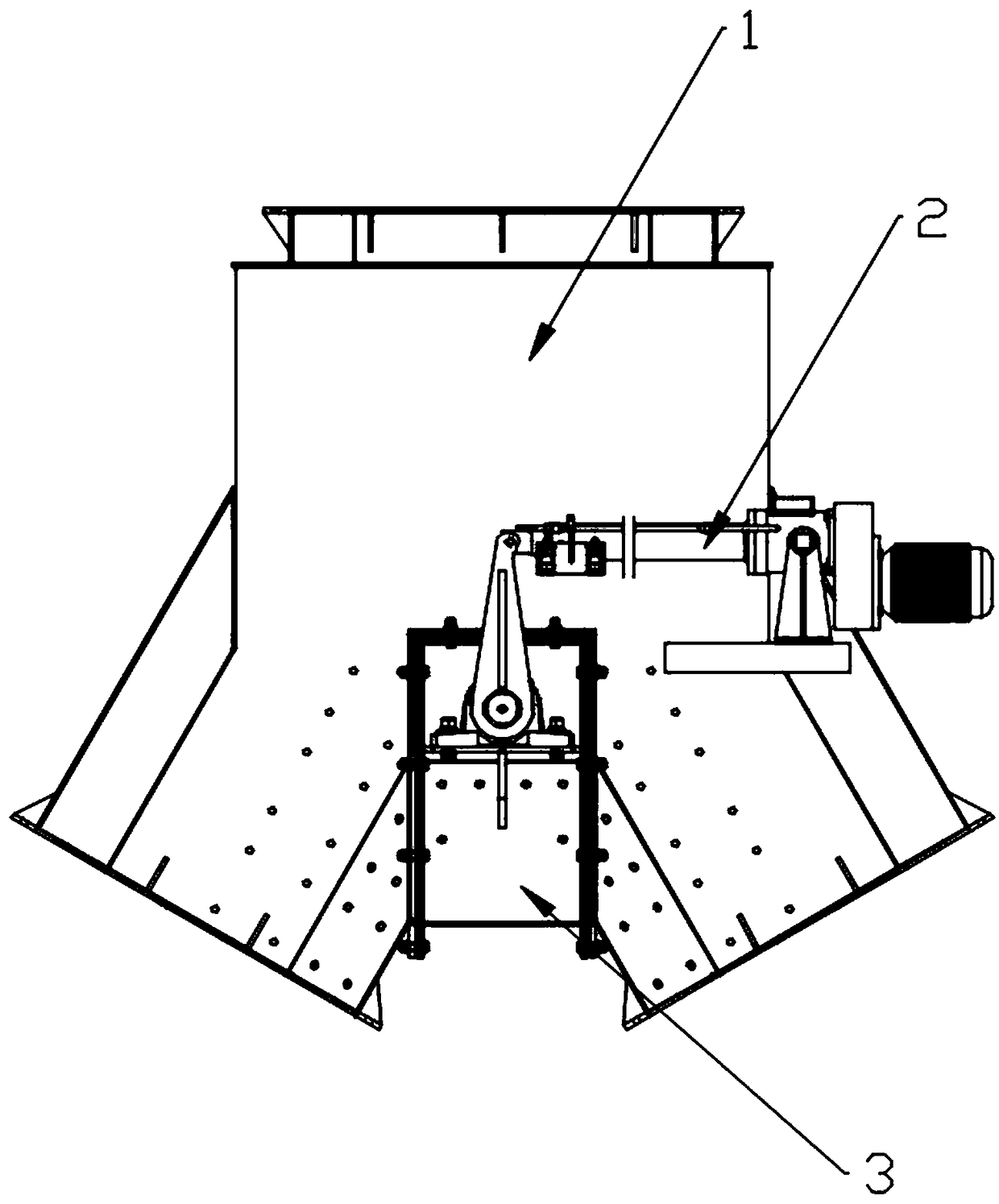

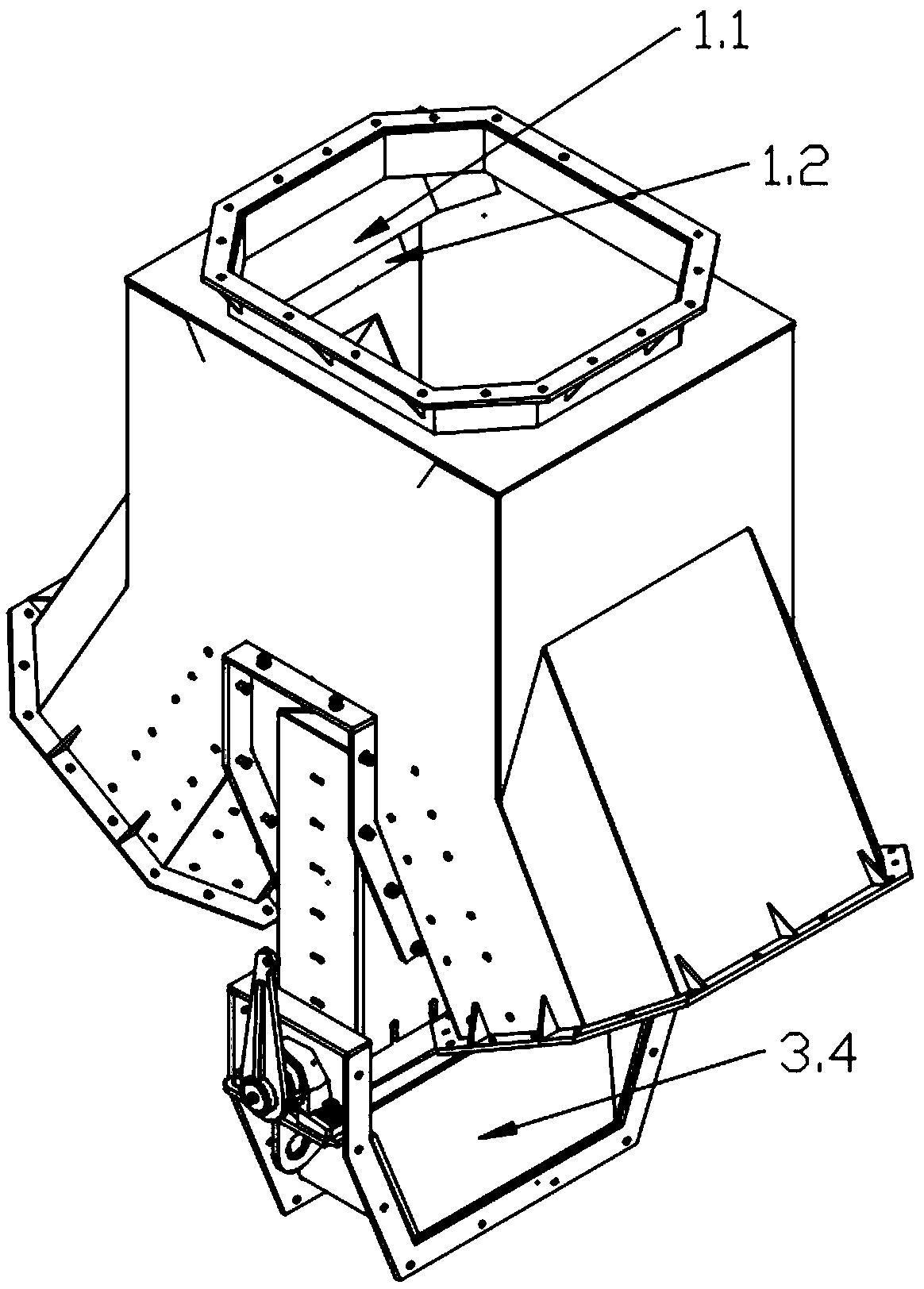

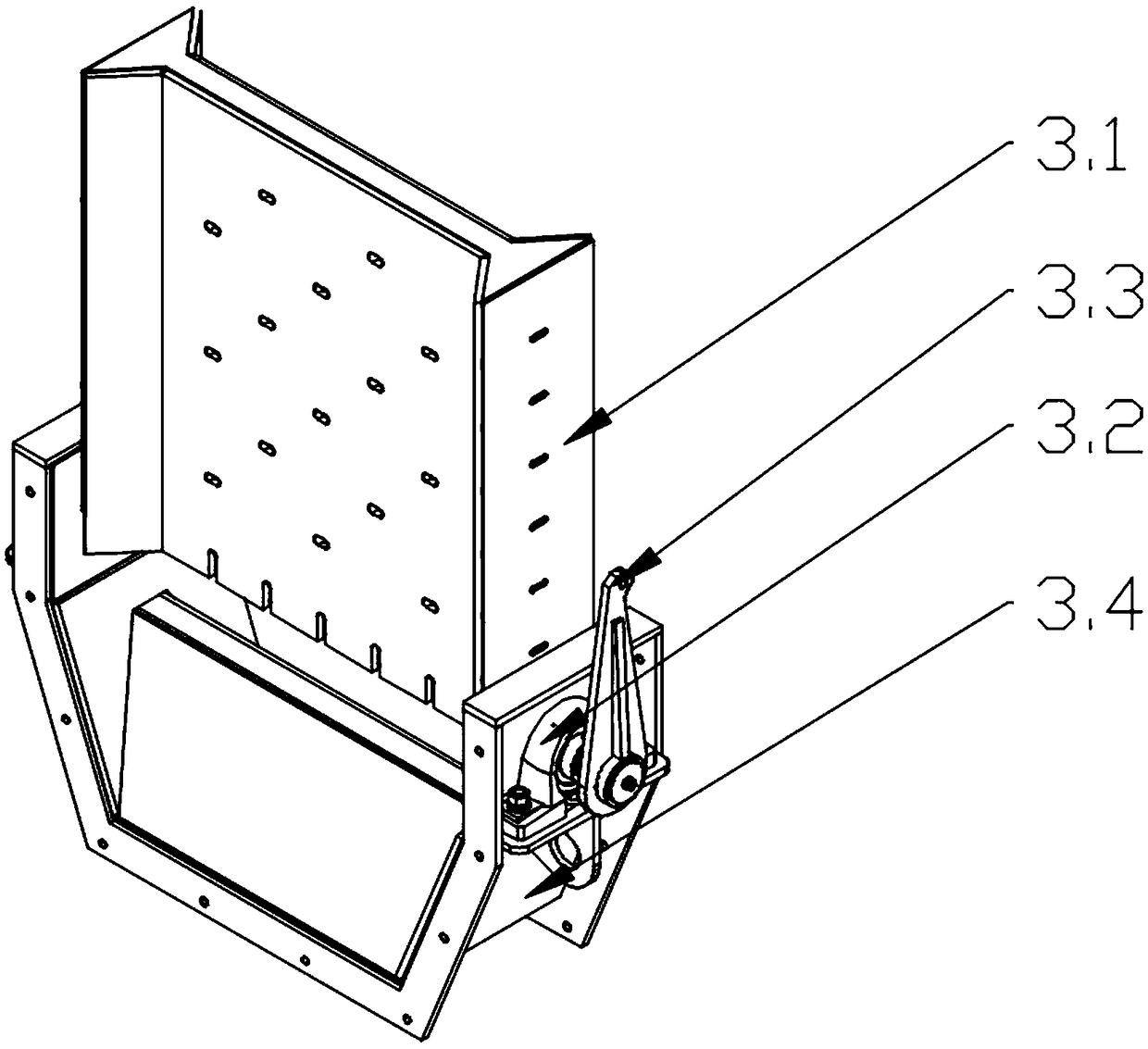

Three-way distributor with baffle replaced rapidly

The invention provides a three-way distributor with a baffle replaced rapidly. The three-way distributor comprises a three-way pipe, a pushing rod and a baffle assembly. The three-way pipe comprises afeeding pipe and two discharging pipes. An installing opening is formed in the connecting portion of the two discharging pipes. The baffle assembly is arranged in the installing opening, detachably connected with the three-way pipe and used for communicating with the feeding pipe and one of the discharging pipes. According to the three-way distributor, under the circumstance of not disassemblingthe three-way distributor, the baffle is replaced only by disassembling the baffle assembly, or the baffle assembly is directly replaced, potential safety hazards caused by three-way disassembling areavoided, time is saved, and more importantly, production is not delayed. The surface with the U-shaped section is adopted in the baffle, materials flow in the U-shaped bottom, the flowing direction of the materials can be well controlled or guided, and phenomena of material accumulating and blocking are avoided. Replaceable lining plates are arranged on the surfaces of the two sides of the baffle, after the lining plates are worn, only the surface lining plates are replaced, maintaining is facilitated, and the production cost is reduced. The three-way distributor is simple in structure, convenient to manufacture and flexible to swing.

Owner:湖北展高机械装备有限公司

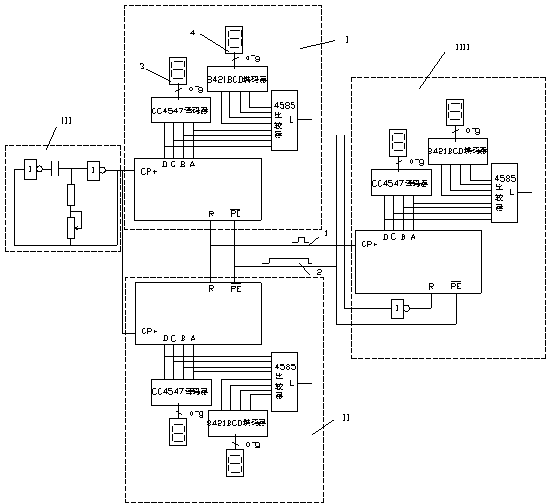

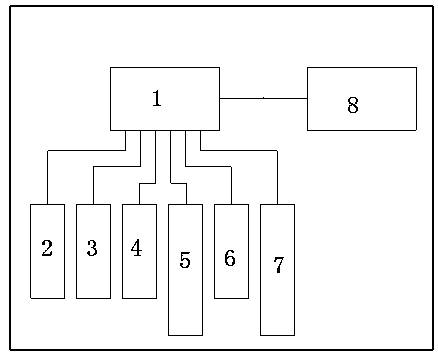

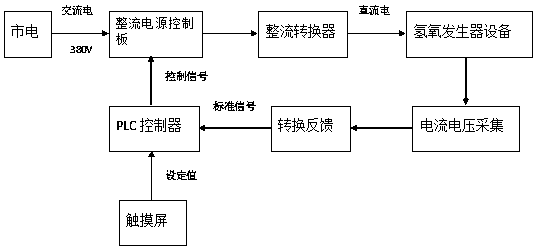

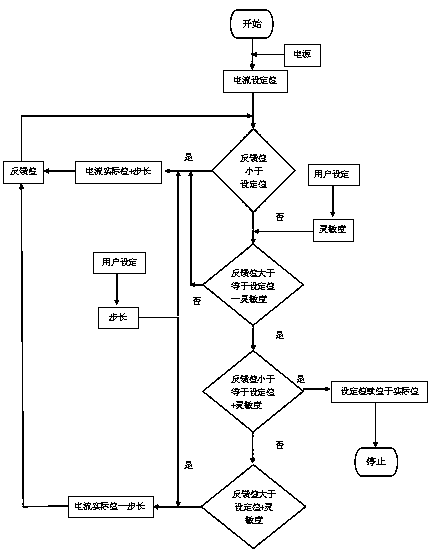

Control device for hydrogen-oxygen generator

The invention discloses a control device for a hydrogen-oxygen generator. The control device for the hydrogen-oxygen generator comprises a PLC, an electrolytic tank liquid level monitoring system, a gas accommodating chamber pressure monitoring system, a current regulating system, an alarm system, a remote monitoring system, a touch screen, a rectifying power controller and a rectifying inverter unit. A current value can be automatically set, a double monitoring is provided through a liquid level and air pressure, the hydrogen-oxygen generator cannot work normally or an accident is brought dueto the fault of the PLC is avoided, safety is high, and high efficiency is achieved.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

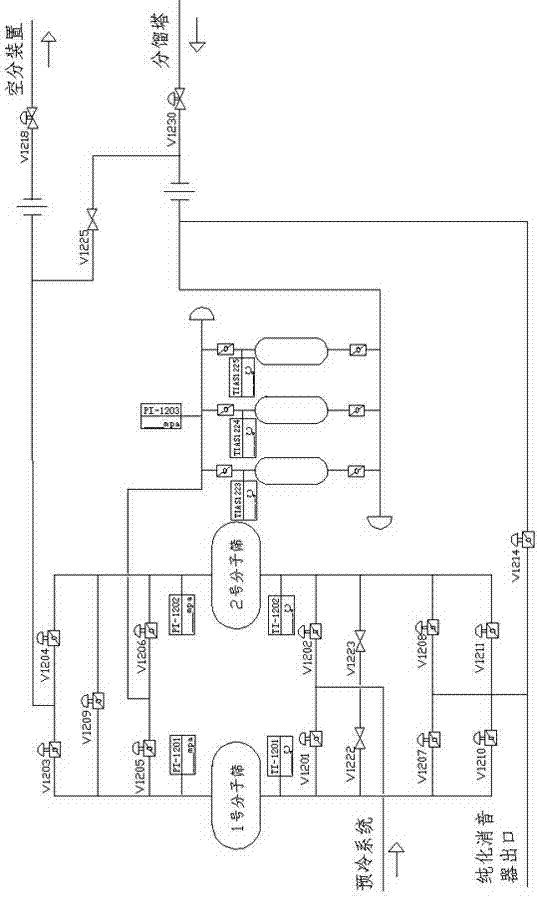

Pressure maintaining and leakage testing method of purification changeover valves for oxygen generation

ActiveCN104502040AAvoidance of detection deficienciesImprove efficiencyMachine part testingMeasurement of fluid loss/gain rateStopped workMeasuring instrument

The invention discloses a pressure maintaining and leakage testing method of purification changeover valves for oxygen generation. After an air separation unit is stopped, a whole system stops working; follow-up pressure maintaining and leakage testing are performed under the condition that valve switches are controlled manually; the pressure of an air compressor is 0.45mpa; pressure measuring instruments PI-1201 and PI-1202 are observed to judge whether the valves leak or not ; the pressure of the air compressor still exists; according to opening and closing conditions of the valves, whether the valves leak or not is detected through pressure changes caused by flowing of air in pipelines. The pressure maintaining and leakage testing method has the advantages that maintenance is achieved without valve demounting, the defects that shutdown is needed for demounting of the valves and equipment is needed for detection in the prior art are avoided, normal operation of an oxygenator can be guaranteed effectively, shutdown time is reduced, production of steel mills is not affected, and hoisting for valve demounting is reduced.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

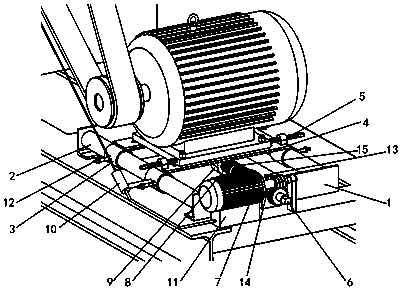

Oil pumping unit motor belt tightness automatic adjustment device

PendingCN107947441AEasy to adjustRealize regulationSupports/enclosures/casingsWireless transmissionElectrical control

The invention provides an oil pumping unit motor belt tightness automatic adjustment device, which can move automatically to adjust tightness between a motor of each type of oil pumping unit and a belt, and can also be used for automatic movement and adjustment of each large-scale motor belt in other use occasions. The oil pumping unit motor belt tightness automatic adjustment device comprises a support, a guide rail, a guide rail sliding sleeve, a motor fixation base and an adjusting screw rod. The guide rail sliding sleeve is sleeved outside the a guide rail; the support is fixedly arrangedat the two ends of the guide rail; the motor fixation base is fixedly arranged on the guide rail sliding sleeve; and a nut is fixedly arranged on the lower end surface of the motor fixation base and is in threaded connection with the external thread of the adjusting screw rod mounted in the support. An adjustment motor and an infrared proximity switch are connected with a data transmission controlcabinet through cables, and an output shaft of the adjustment motor is engaged with the adjusting screw rod; a cable of the data transmission control cabinet is connected with a ground electrical control cabinet, and a data cable or a wireless transmission device of the data transmission control cabinet is connected with a regional network center. The automatic adjustment device has a good use effect and application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

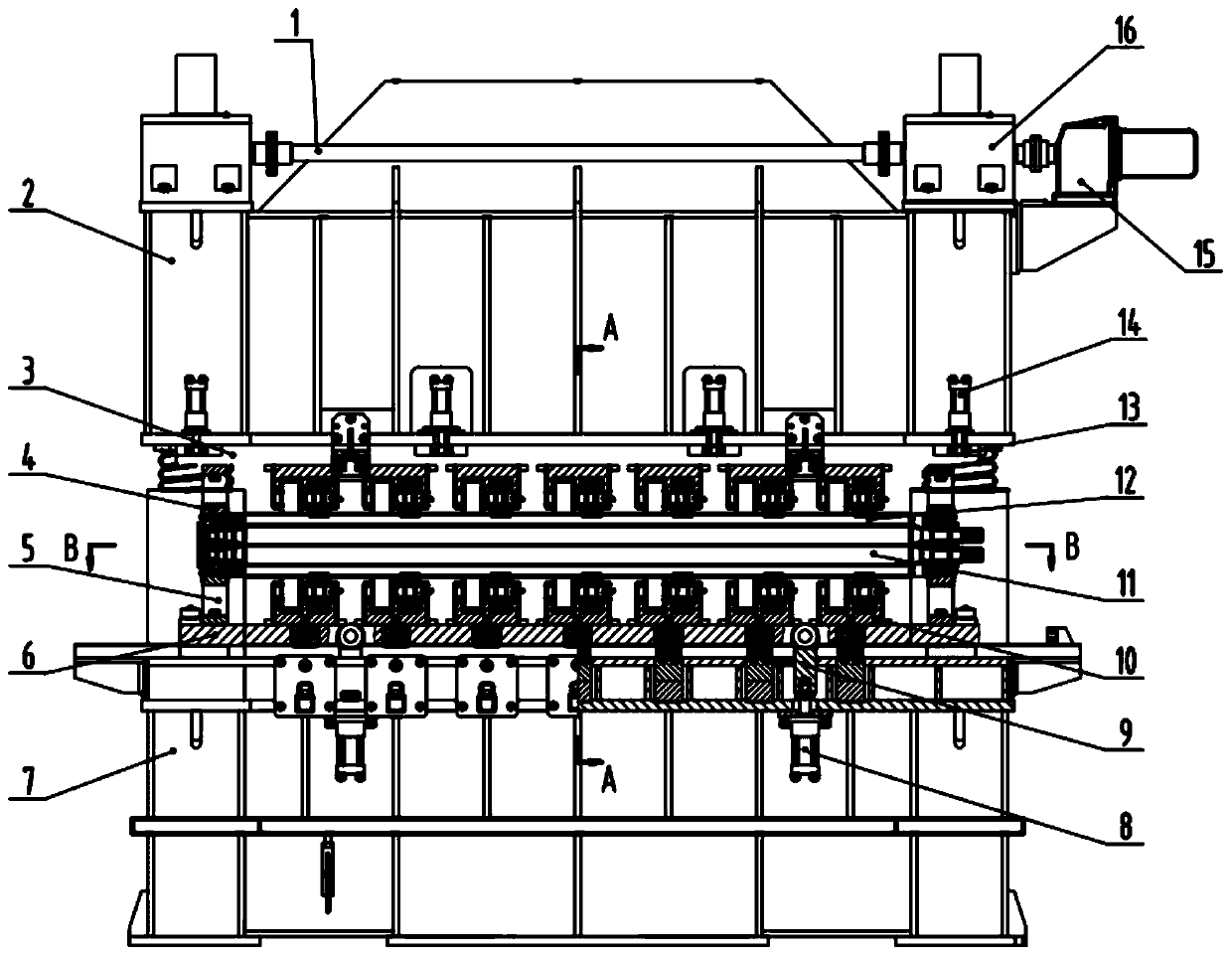

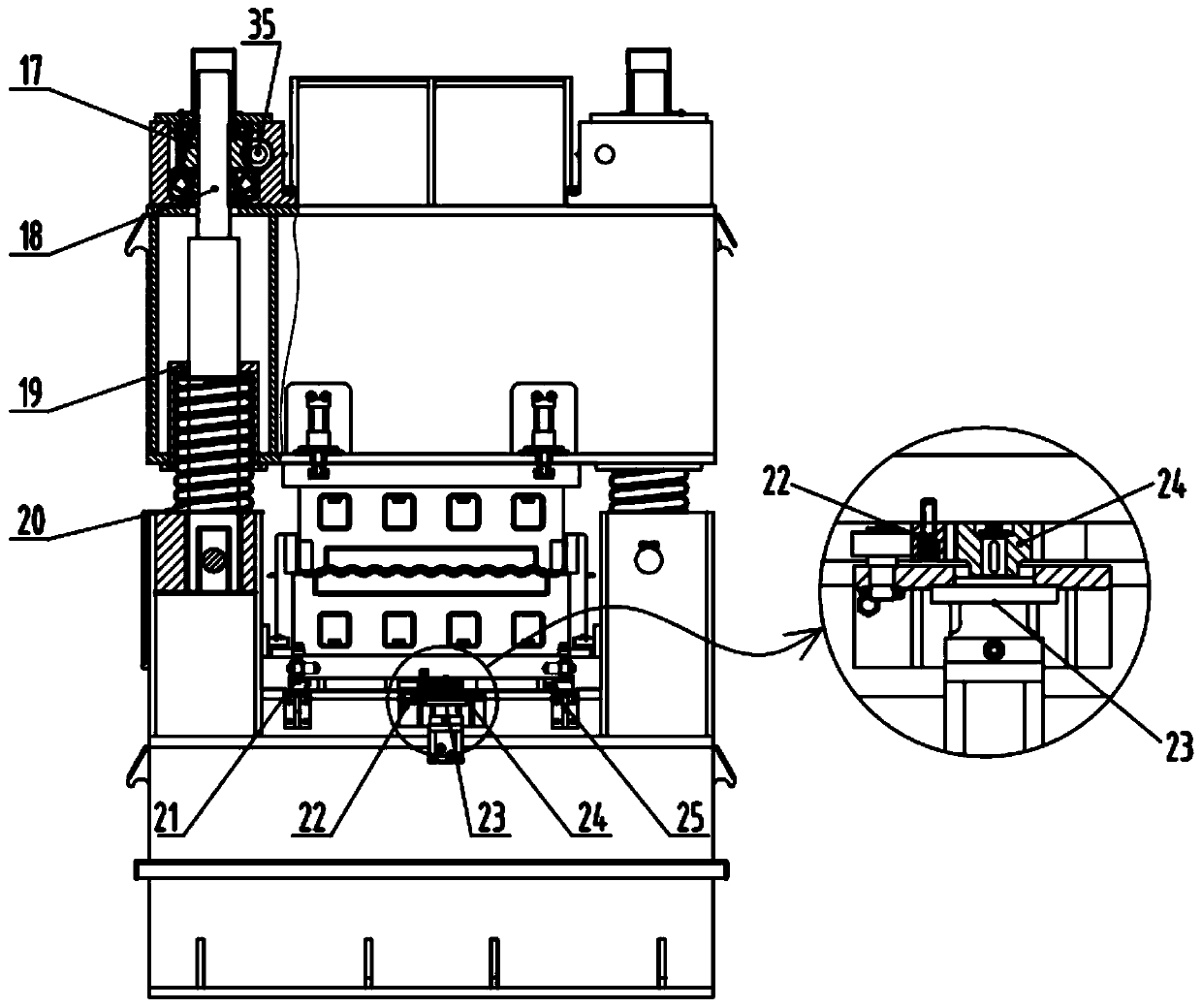

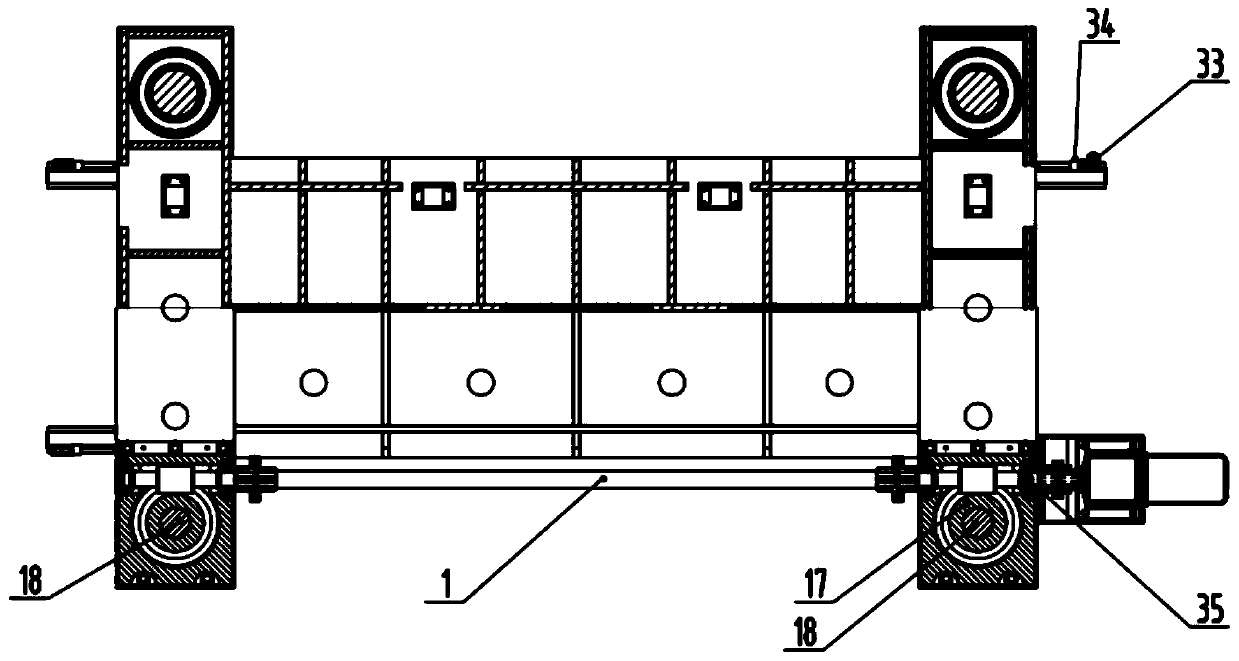

Quick roll changing leveling machine

The invention discloses a quick roll changing leveling machine. The quick roll changing leveling machine structurally comprises an upper cross beam, an upper roll system downward pressing mechanism, agap eliminating mechanism, a 1 # roll system capable of changing with a 2 # roll system, an upper roller system positioning and locking mechanism, a lower roller system positioning and locking mechanism, a lower base, a supporting roller adjusting mechanism, a roller system moving-out mechanism, a transmission part, a gear box part and the like. One leveling main machine corresponds to two rollersystems with different leveling roller diameters, and the two sets of roller systems can be quickly interchanged; the roller systems are installed on chopping boards, are positioned and locked by oilcylinders, and rapidness and reliability are achieved; and ball-tooth coupling is adopted to realize automatic centering of two sets of roller systems, and a hydraulic motor drives a gear rack to drive the roller systems to quickly and stably move out.

Owner:JINAN EAGLE CNC MASCH CO LTD

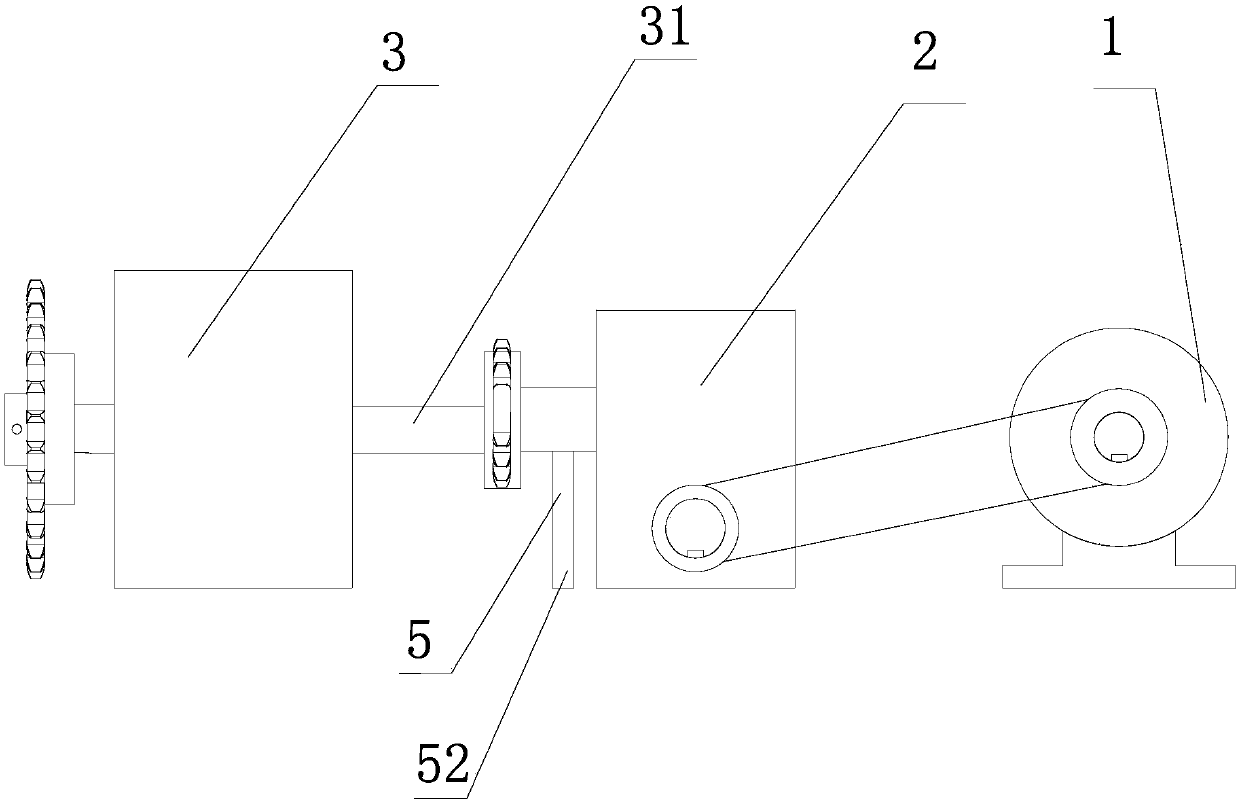

Intermittent motion mechanism

The invention relates to an intermittent motion mechanism. The intermittent motion mechanism comprises an alternating current motor, a reducer and a splitter, wherein a cam is fixed at the shaft extension end of the splitter, and a detection device not in contact with the cam is mounted on one side of the cam, and comprises a photoelectric sensor. According to the intermittent motion mechanism disclosed by the invention, the motion sensing of multiple filling stations can be controlled through one photoelectric sensor to realize sensing, and a reliable information parameter is provided for thesubsequent control to reduce the use of other sensors so as to lower cost, furthermore, for only one photoelectric sensor, the deviation produced in the use process is adjusted only by adjusting onephotoelectric sensor, without adjusting the other sensors to save trouble and effort and not to delay production. In addition, the intermittent motion mechanism is simple in structure, stable and easyto adjust.

Owner:江苏首达机械有限公司

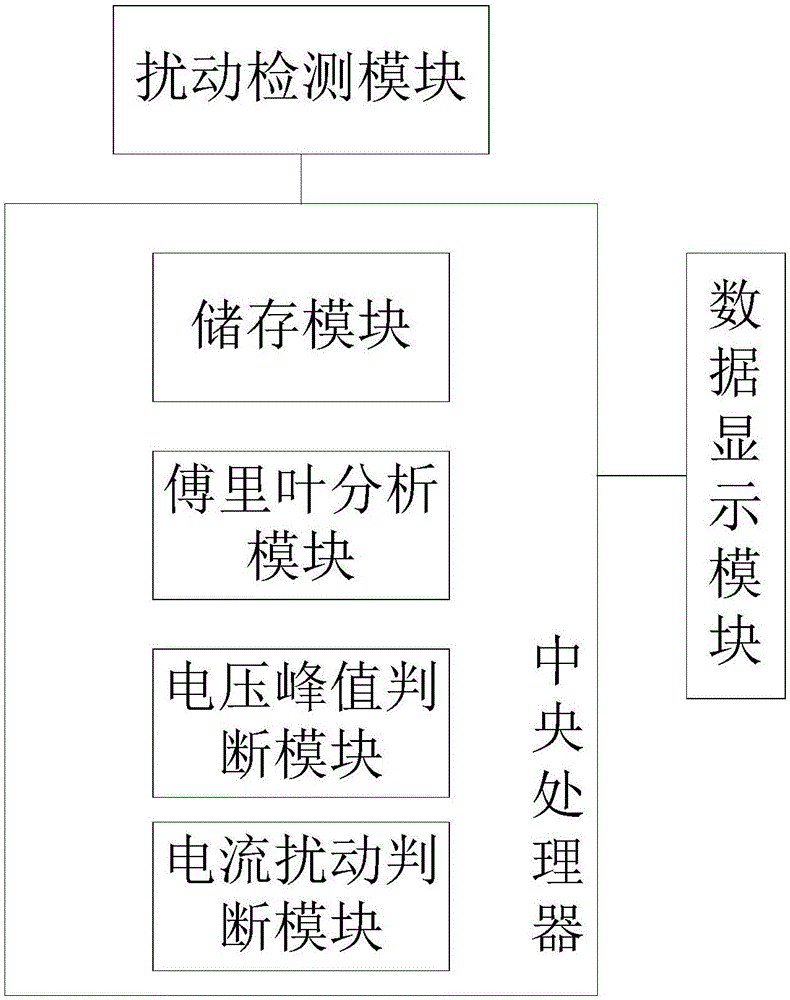

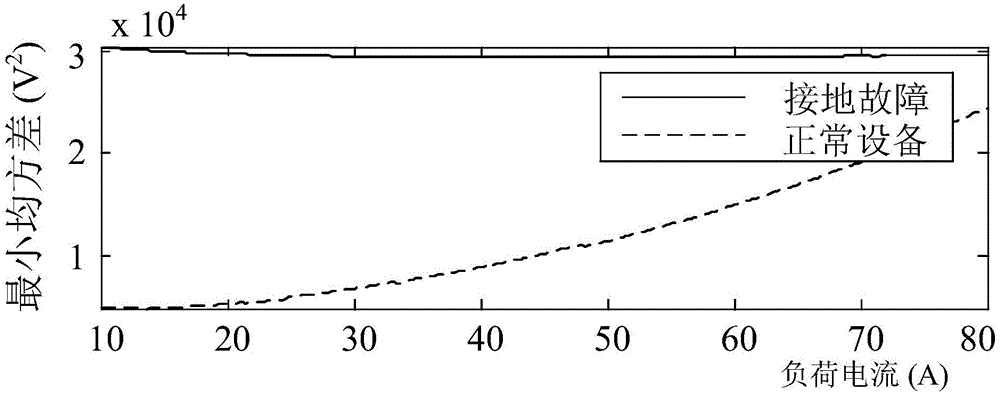

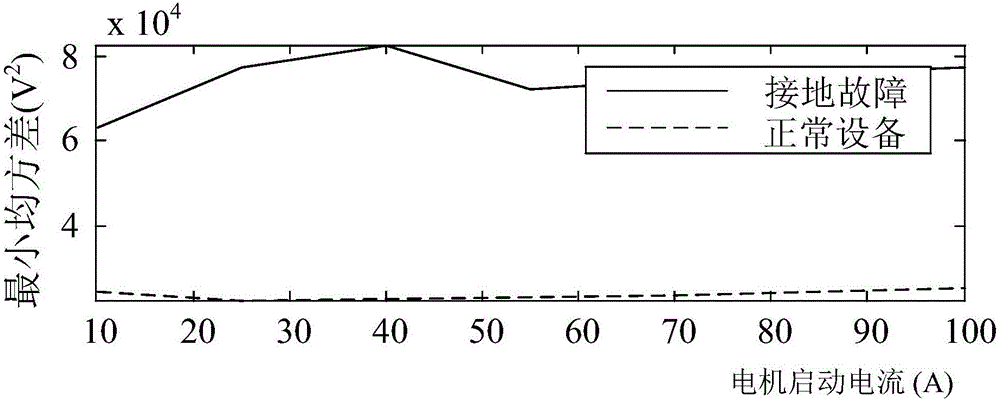

Method and system for detecting cable single-phase earth fault

ActiveCN107436392AImprove detection accuracyAvoid power outagesFault location by conductor typesSingle phasePeak value

The invention discloses a method for detecting cable single-phase earth fault. The method includes the steps of S1, detecting current disturbance of cables; S2, recording time of occurrence of current disturbance when the current disturbance of the cables is detected; S3, subjecting data of previous two cycles before the time of occurrence of the current disturbance of the cables to Fourier transform analysis to obtain initial phase angle of the current disturbance, and judging whether the disturbance occurs at the voltage peak or not according to the initial phase angle; S4, if the disturbance occurs at the voltage peak, then judging whether the current disturbance of the cables is caused by earth fault or is normal equipment disturbance. The invention further discloses a system for detecting cable single-phase earth fault by the method. By the method and the system, online detection of disturbance caused by single-phase earth fault is realized, shutdown due to off-line detection is avoided, and production delay is omitted; further, since the cables are subjected to online detection and equipment on line is in normal service state, the detection accuracy is high.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

An anti-blocking and dredging device for the discharge port of a ball mill

The invention discloses an anti-blocking dredging device for a discharge port of a ball mill. The anti-blocking dredging device comprises a hopper, a discharge pipe, the ball mill, a belt conveyor anda drilling machine; the hopper is provided with a sieve plate and a material blocking apron; the sieve plate is formed through combination of an upper sieve plate and a lower sieve plate; the upper sieve plate is connected to the right side of the rear end of the hopper through a rotating shaft; the lower sieve plate is connected on the left side of the rear end of the hopper through the rotatingshaft; each of the upper sieve plate and the lower sieve plate is provided with a round opening and a through hole; the material blocking apron is welded on the outer side of the hopper; the discharge pipe is in pipe connection at the bottom part of the hopper through an upper pipe section; an alkaline liquor pipe is in pipe connection between the discharge pipe and the upper pipe section; a material return pipe is welded at the rear end of the discharge pipe and is in pipe connection with the material blocking apron; the ball mill is installed at the rear end of the discharge pipe; the rearend of the discharge pipe is inserted into a feed port of the ball mill; the belt conveyor is installed above the hopper; and the drilling machine is installed right above the hopper. The anti-blocking dredging device can effectively prevent the phenomenon of blockage of the discharge pipe.

Owner:江苏新达石英有限公司

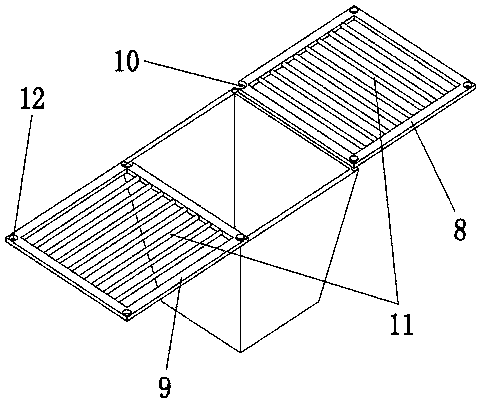

Support-isolation combined type paste filling system and filling method

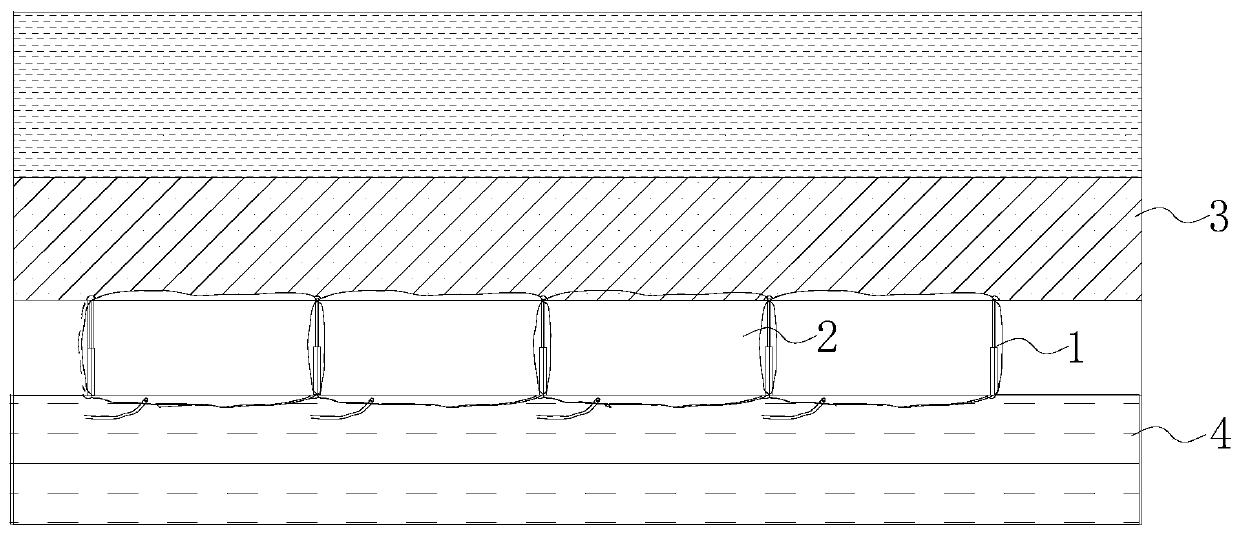

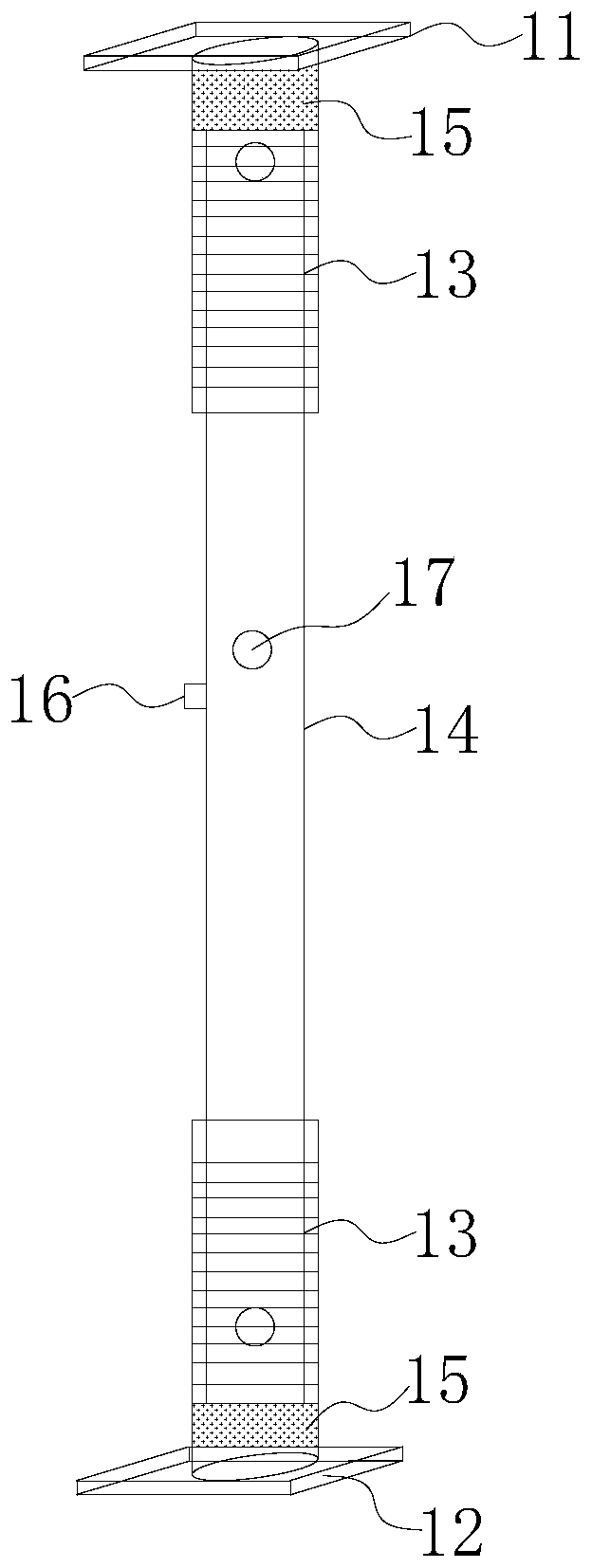

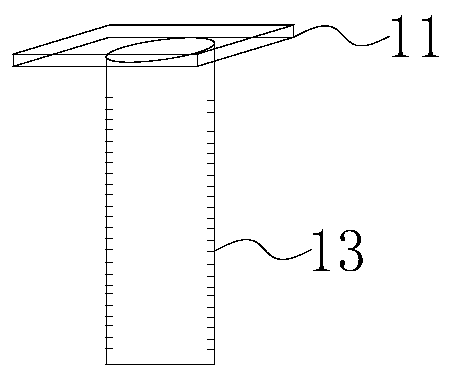

ActiveCN109779681AGuaranteed solidification forming timeGuarantee the effect of isolation and leak-proof slurryMaterial fill-upProps/chocksSlurryEngineering

The invention discloses a support-isolation combined type paste filling system and a filling method, and relates to the technical field of underground mining methods. The system comprises a yielding single prop and an isolation slurry leakage prevention device, wherein the yielding single prop comprises a top seat tray, a base tray, threaded sleeves, a threaded hydraulic prop and damping blocks, the threaded sleeves are arranged at the two ends of the threaded hydraulic prop respectively, the other ends of the threaded sleeves are connected with the top seat tray or the base tray, and the damping blocks are arranged in the threaded sleeves; the isolation slurry leakage prevention device comprises air bags, folding plates, air taps, elastic ropes and annular hooks, the folding plates are arranged in the air bags, the folding plates are hinged to be used for supporting the air bags, the elastic ropes are further arranged between the folding plates, the two ends of the elastic ropes are fixed to the air bags, and the annular hooks are arranged on the outer sides of the air bags. The problems that a single prop is difficult to recover and paste filling and slurry leakage occur are solved, synchronous filling and stoping are achieved, and the system has the advantages that construction is easy and convenient, and materials are saved.

Owner:SHANDONG UNIV OF SCI & TECH

Welding repairing restoration method for beryllium bronze metal accessory

InactiveCN100491042CEasy to useTimely repairArc welding apparatusWelding/cutting media/materialsRestoration methodAlternating current

The invention relates to a welding repair method of expensive metal element. Wherein, it comprises (1), using general method to clean the surface of element; (2) increasing the temperature of element in furnace to 300Deg. C, keeping for 2-3h; (3), the basic layer of element is welded via direct current and using common steel welding solder; (4), when at 2-3mm from the shaping surface of repaired groove, using alternative current welding, to weld surface with color metal welding solder. The invention has low cost and wide application.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Paint spraying device used for glass bottle

The invention discloses a paint spraying device used for a glass bottle. The paint spraying device used for the glass bottle comprises a conveying belt, the glass bottle, a sensor I, a paint sprayer,a switch and a sensor II. The glass bottle is placed on the surface of the conveying belt. The paint sprayer is mounted on one side of the conveying belt. The sensor I and the sensor II are fixedly mounted on the two sides of the paint sprayer. The switch is fixedly mounted on the paint sprayer. The sensor I and the sensor II are fixedly mounted on the two sides of the paint sprayer, so that production is prevented from being delayed, the situation that the glass bottle is not completely sprayed with paint is prevented, the glass bottle does not need to be moved away by workers, the paint sprayer does not need to be stopped, and thus, the work time is saved.

Owner:徐州恒发玻璃制品有限公司

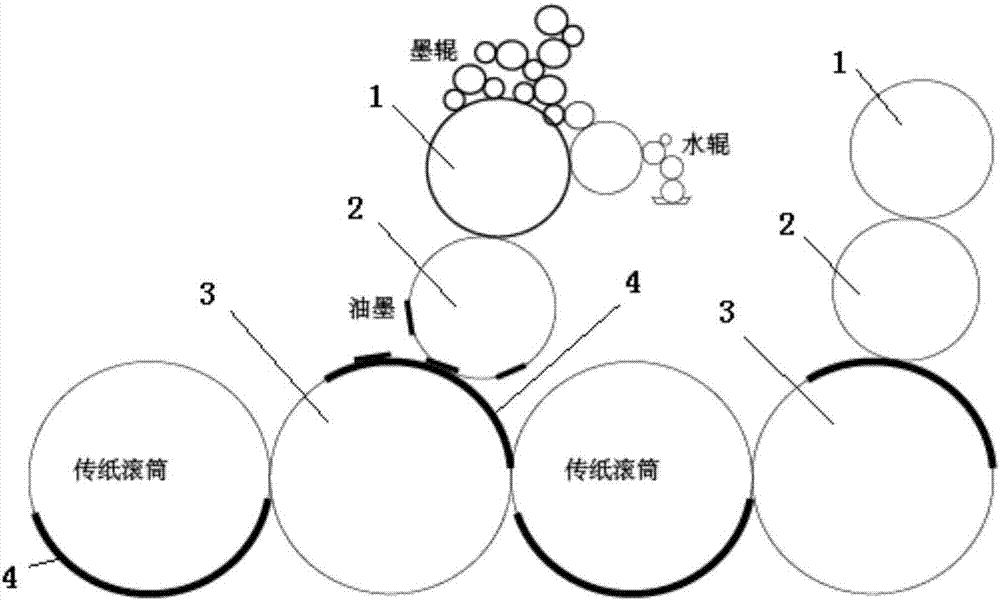

Method for partial oiling by using hollowed-out lining paper

ActiveCN107443946ALow costEasy to operatePrinting after-treatmentPrinting press partsPulp and paper industryWhite area

The invention discloses a method for partial oiling by using hollowed-outlining paper. The method comprises the following steps that according to a reserved white area, lining paper of the inner side of rubber blanket rolled around a rubber roller is hollowed out, and then by using squeezing action between the rubber roller and an impression cylinder, gloss oil on the rubber blanket is transferred to a printing stock between the rubber roller and the impression cylinder. A traditional partial oiling method is difficult to overcome the problem of high cost, according to the method for partial oiling by using the hollowed-out lining paper, by hollowing-out the lining paper on the inner side of the rubber blanket, in the reserved white area, because pressure is reduced when the rubber blanket and the impression cylinder are in contact, the gloss oil cannot be transferred, so that partial oiling is realized, the cost of the lining paper is only about 1 yuan, therefore, the method for partial oiling by using the hollowed-out lining paper greatly reduces the cost of partial oiling, is simple and convenient to operate, and cannot delay production.

Owner:广州市恒远彩印有限公司

Quick-change type guide sleeve fixing structure

InactiveCN101704056AShorten the timeNo delay in productionShaping toolsBiochemical engineeringChange Type

The invention discloses a quick-change type guide sleeve fixing structure comprising a guide sleeve, a cushion block, a die holder, a lower cushion block and a lower template, the lower cushion block is arranged on the die holder, the lower template is arranged on the lower cushion block, and the lower template is internally provided with through holes for installing the guide sleeve; the invention is characterized in that the guide sleeve is provided with a T-shaped hanging boss which hangs outside the bottom of the lower template, the lower template is internally provided with a groove for the T-shaped hanging boss to penetrate through, the lower cushion block is provided with a notch, the cushion block is inserted into the notch to clamp the guide sleeve, and the die holder is internally provided with open holes with diameter larger than that of the guide sleeve. The invention solves the problems in the prior art that replacement time of glue pouring type guide sleeve after abrasion to influence normal production of enterprises and that the die with glue pouring type guide sleeve fixing structure has poor preciseness. The invention is convenient in operation, a new guide sleeve only needs about one hour to replace without needing to reassemble the die, and the structure is stable, thus being of greatly help to quality and production efficiency.

Owner:皇裕精密技术(苏州)有限公司

Split type activated carbon adsorption-desorption catalytic combustion device

The invention discloses a split type activated carbon adsorption-desorption catalytic combustion device. The device comprises an adsorption part which forms a fixed part, a catalytic combustion part,an exhausting part and a desorption fan, wherein the catalytic combustion part is a movable part; the adsorption part is formed by connecting two adsorption beds in parallel; the front ends of the adsorption beds are correspondingly connected to an organic waste gas input head pipe and the input end of the catalytic combustion part; the output ends of the adsorption beds are correspondingly connected to the exhausting part and the positive pressure end of the desorption fan; the catalytic combustion part is connected to the adsorption through a separable rapid joint; the catalytic combustion part is arranged on a movable trolley body. According to the device, an enterprise needs to buy and mount the adsorption part and the exhausting part which are low in cost during investing environmentally-friendly equipment, and the catalytic combustion service is outsourced for the catalytic combustion part which is high in cost and low in use rate, so that the primary mounting cost of organic waste gas treatment equipment can be greatly decreased, and the space occupied by the catalytic combustion part is reduced; and the adsorption part is provided with the two adsorption beds for alternatively performing adsorption and desorption.

Owner:成都鑫金臣节能环保科技有限公司

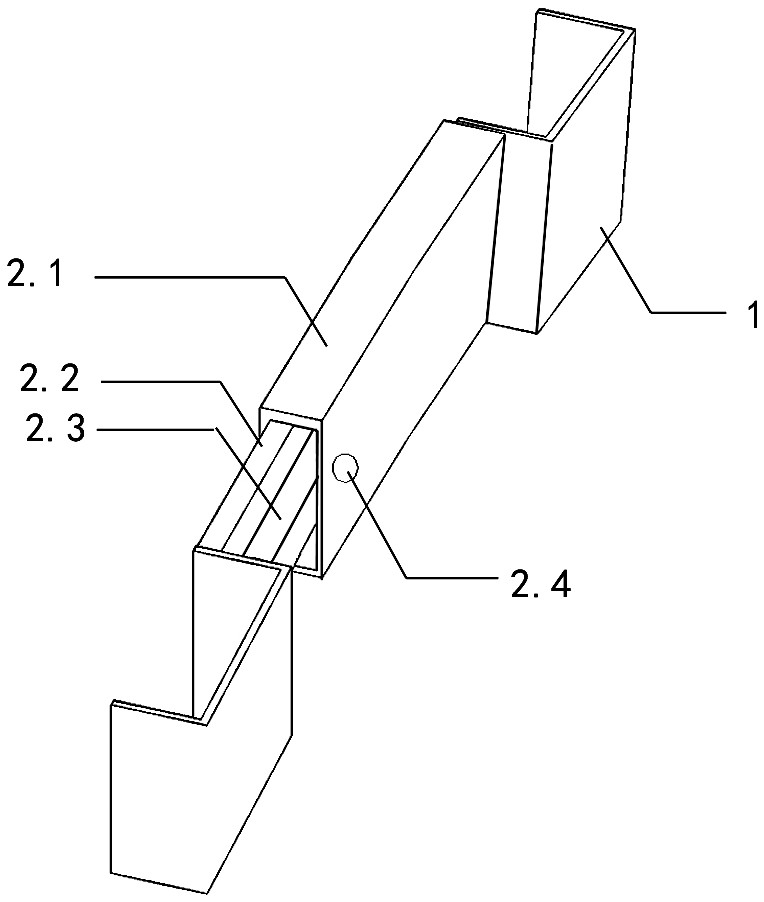

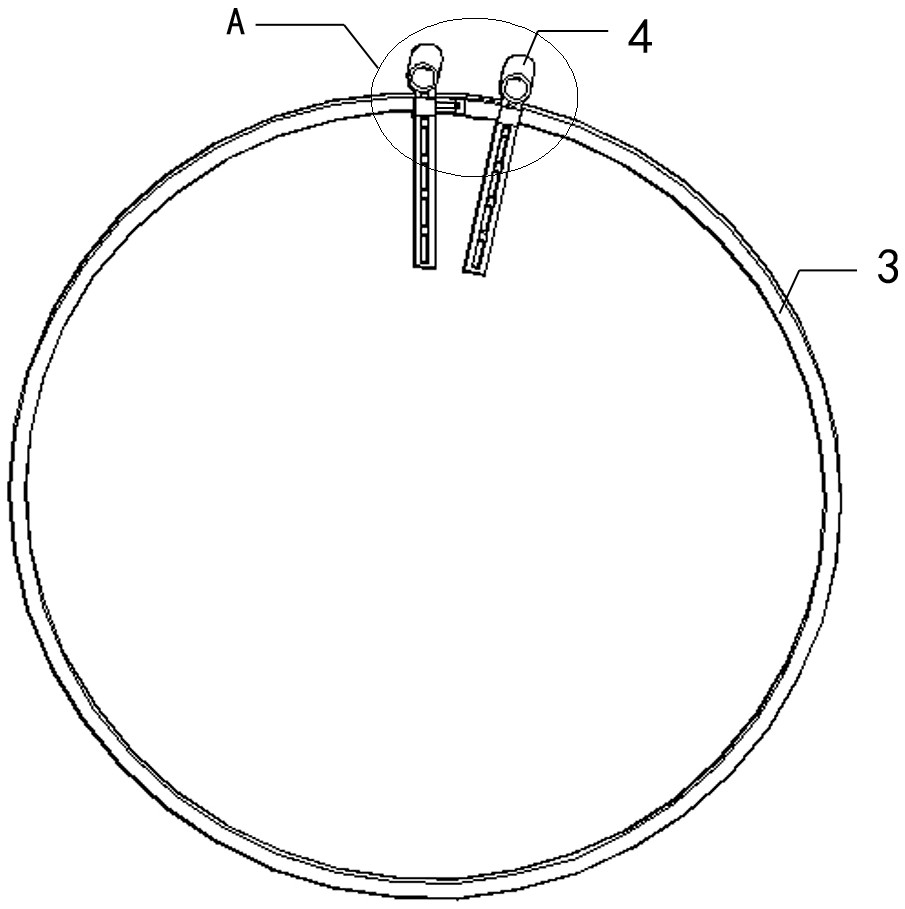

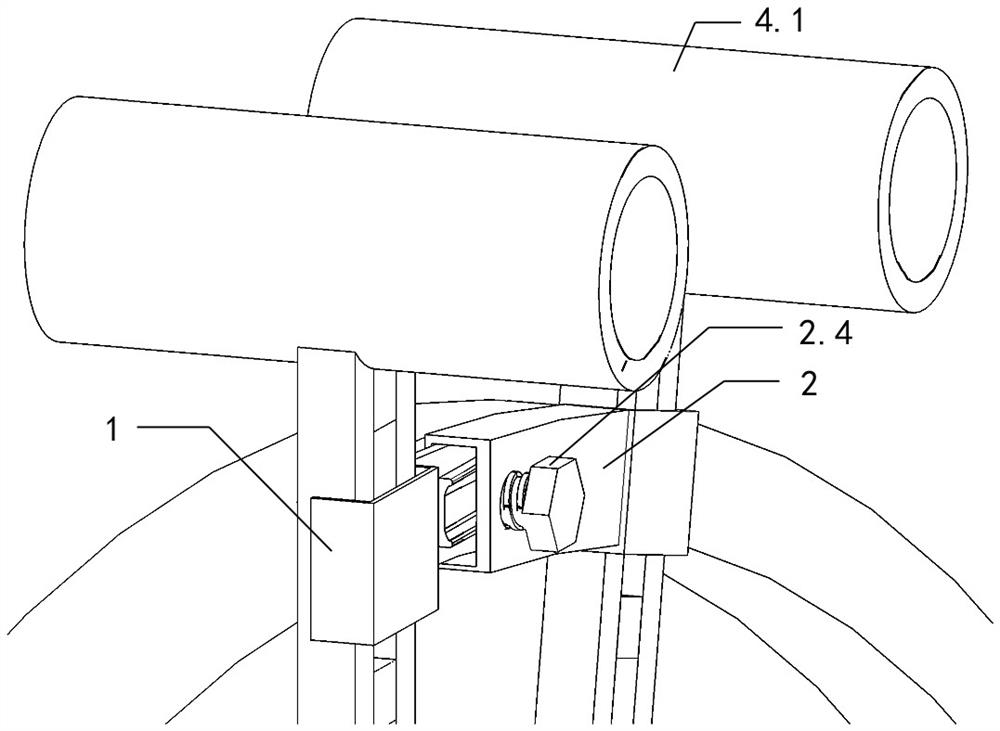

Positioning device, positioning structure and construction method of steel bar fixture for steel cage roll welding machine

ActiveCN112171156BSpeed up productionEasy to manufactureWelding/cutting auxillary devicesWire networkEngineeringSeam welding

The positioning device, positioning structure and construction method of the steel bar fixture of the steel cage roll welding machine relate to the field of pile foundation steel bar processing. The chute between the card slots. The chute includes an outer sleeve with a rectangular arc shape in cross section and an inner block with a rectangular arc shape in cross section that is adapted to be movably inserted into the outer sleeve. Adjacent; the middle part of the outer surface of the inner inserting block is fixedly connected with a C-shaped clamping block along the long axis. Go through the bolt holes and tighten on the C-shaped clamping block. The invention solves the problems in the prior art that when a steel cage roll welder processes steel cages with different diameters and different numbers of main bars, it needs to be stopped to replace the clamps in place, and workers hold a ruler to adjust the distance between the clamps. The process is time-consuming and has low precision.

Owner:中国建筑土木建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com