Semi-automatic groove cutting machine

A semi-automatic, cutting machine technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve problems affecting product quality and enterprise production efficiency, waste of human resources, waste of time, etc., to reduce labor costs, easy to Control and improve the effect of enterprise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

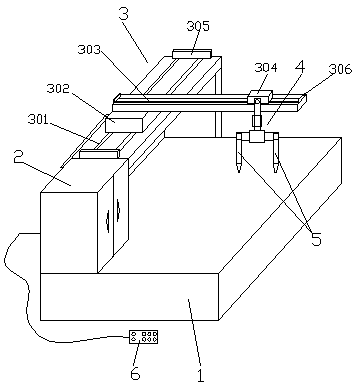

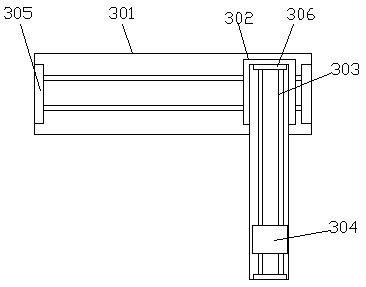

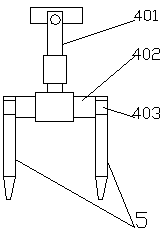

[0027] As shown in the figure, a semi-automatic bevel cutting machine includes a working platform 1, an electrical control cabinet 2, a moving mechanism 3, a lifting mechanism 4 and a double cutting torch 5, the moving mechanism 3 is located on one side of the working platform 1, and the electrical control cabinet 2 Located at the end of the moving mechanism 3, the lifting mechanism 4 is located on one side of the moving mechanism 3, and the double cutting torch 5 is fixedly arranged at the lower part of the lifting mechanism 4, and the movement of the moving mechanism 3 is controlled by the electric control cabinet 2 and drives the double cutting torch 5 on the working platform 1 For workpiece cutting, the motion mechanism 3 includes a longitudinal track 301, a longitudinal speed-regulating sports car 302, a transverse t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com