Support-isolation combined type paste filling system and filling method

A paste filling and combined technology, applied in the directions of backfill, earthwork drilling, pillars/supports, etc., can solve the problems of paste filling, leakage of slurry, difficulty in recovering single pillars, etc., so as to maintain integrity and shorten filling time. , the effect of reasonable filling and recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

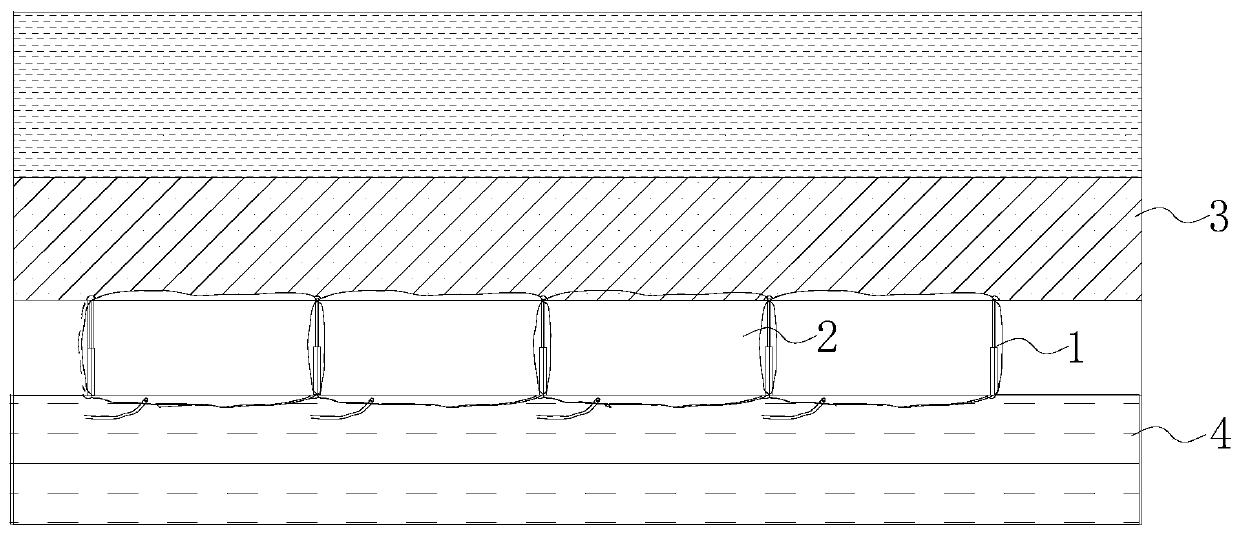

[0035] A support-isolation combined paste filling system, the structure of which includes pressure-releasing single pillars 1 and isolation and leakage-proof slurry devices 2, such as figure 1 As shown, the yielding single pillar realizes the yielding deformation of the goaf, and the airbag of the isolation and leakage prevention slurry device is in close contact with the top and bottom plates, thus ensuring the isolation and prevention of leakage during the filling process.

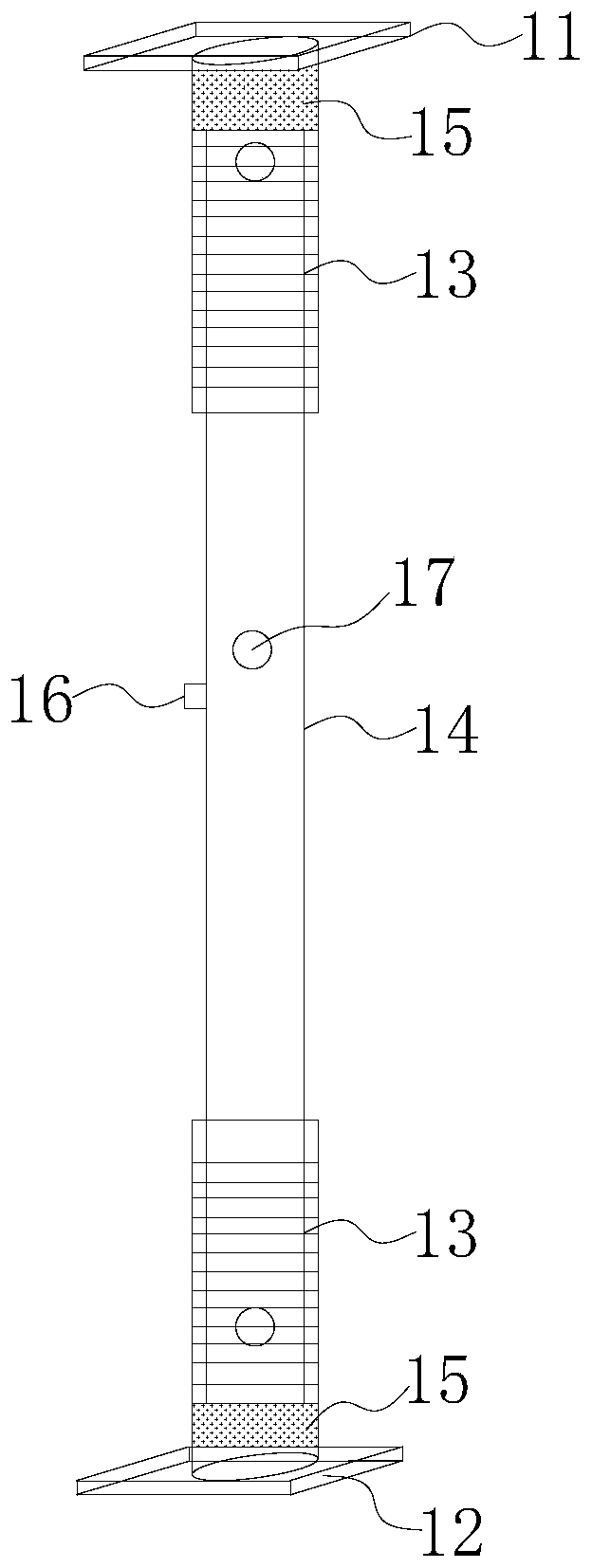

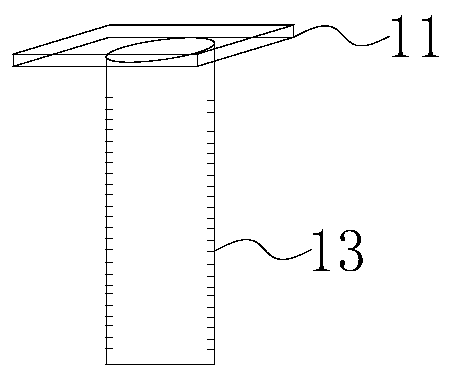

[0036] like Figure 2 to Figure 4 As shown, the pressure relief single prop 1 includes a top tray 11, a base tray 12, a threaded sleeve 13, a threaded hydraulic prop 14 and a shock absorber 15, and the two ends of the threaded hydraulic prop 14 are respectively provided with a threaded sleeve 13, and the threaded sleeve The other end of the cylinder 13 is connected to the top tray 11 or the base tray 12, wherein the top tray 11 or the base tray 12 can be rectangular, circular or oval, and the area can be...

Embodiment 2

[0048] On the basis of Example 1, in order to further illustrate the structure of the support-isolation combined paste filling system provided by the present invention, and the filling method using the system, take the 3301 working face of a certain mine as an example to explain the technical solution of the present invention Describe in detail.

[0049] The main coal seam of the 3301 working face of a certain mine is the 3rd coal seam of the Shanxi Formation. The strike length of the working face is 500m, the inclination length is 200m, the average thickness of the coal seam is 3.2m, and the average inclination angle is 5°. Using this method for filling mining, the specific construction steps are as follows.

[0050] Step A. After the working face is cut, when the filling step is reached, arrange a row of yielding single pillars behind the fully mechanized mining hydraulic supports, and arrange the yielding single pillars close to the side of the fully mechanized mining hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com