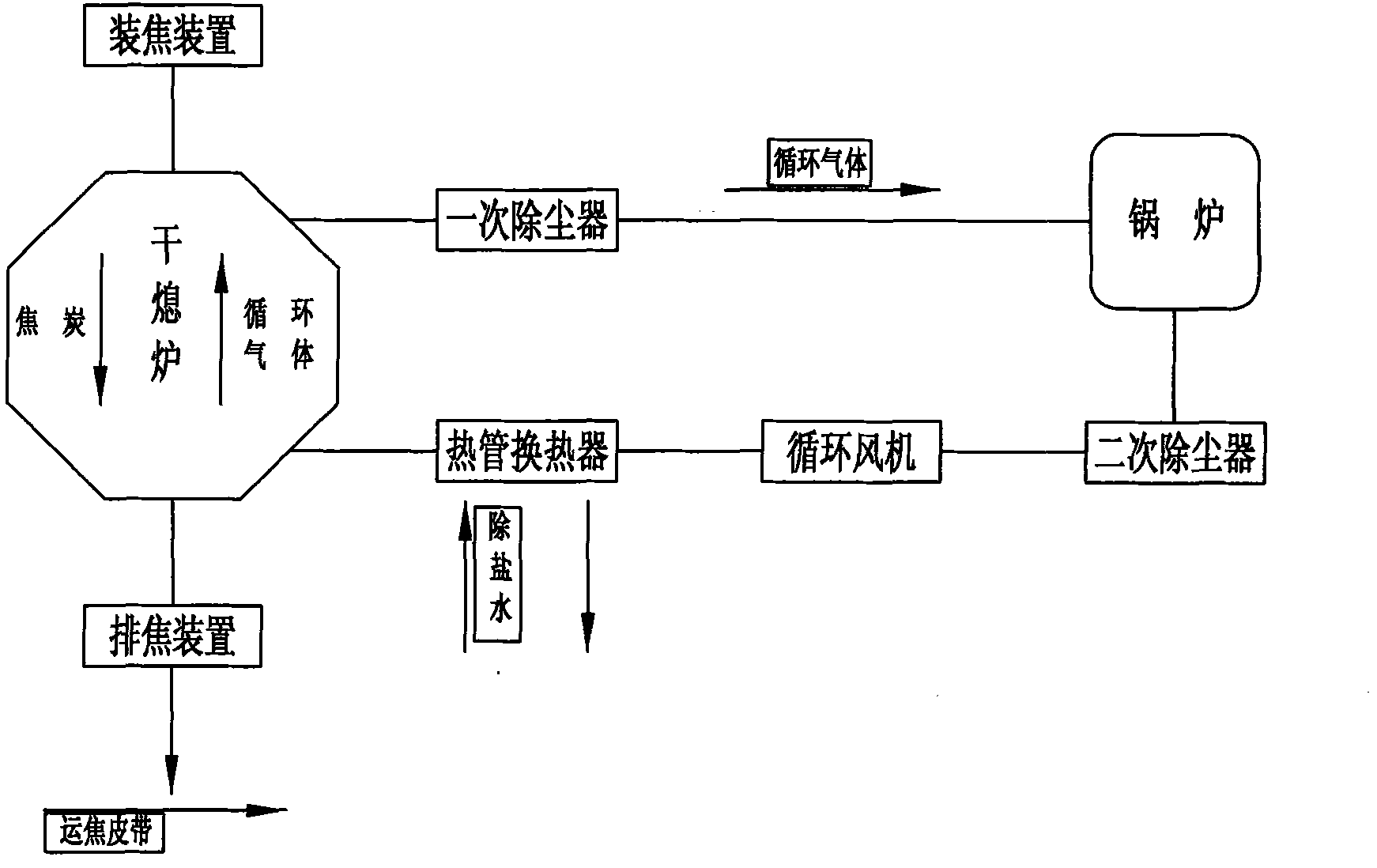

Method for keeping stable coke dry quenching gas circulation system after pipe explosion of heat pipe exchanger and device thereof

A technology of heat pipe heat exchanger and circulation system, which is applied in the field of coke dry quenching technology, can solve the problems of long order cycle and replacement time, failure of pipeline repair welding, rise of combustible gas, etc., to achieve convenient operation and ensure dry The effect of reducing the extinguishing rate and steam generation and reducing production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

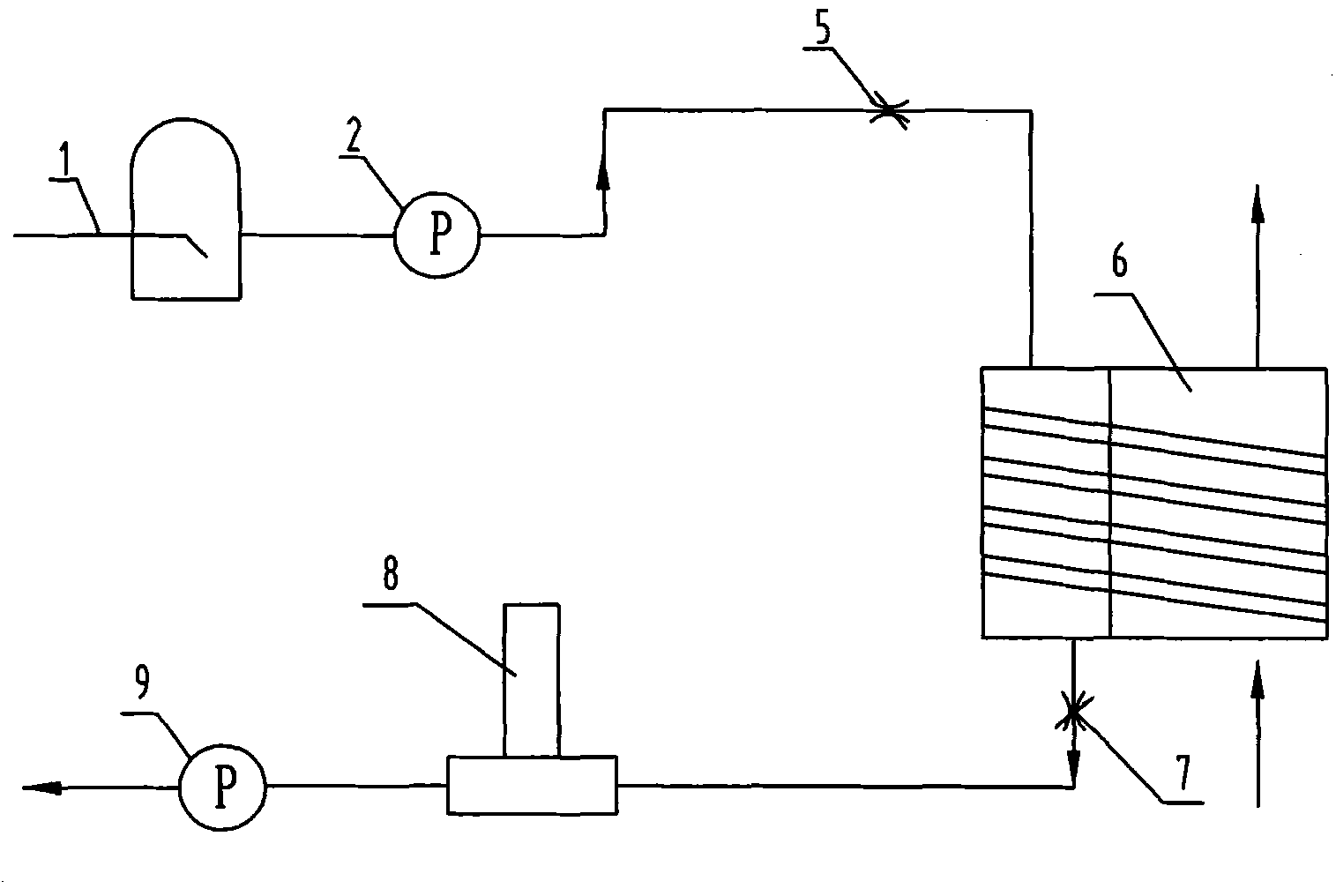

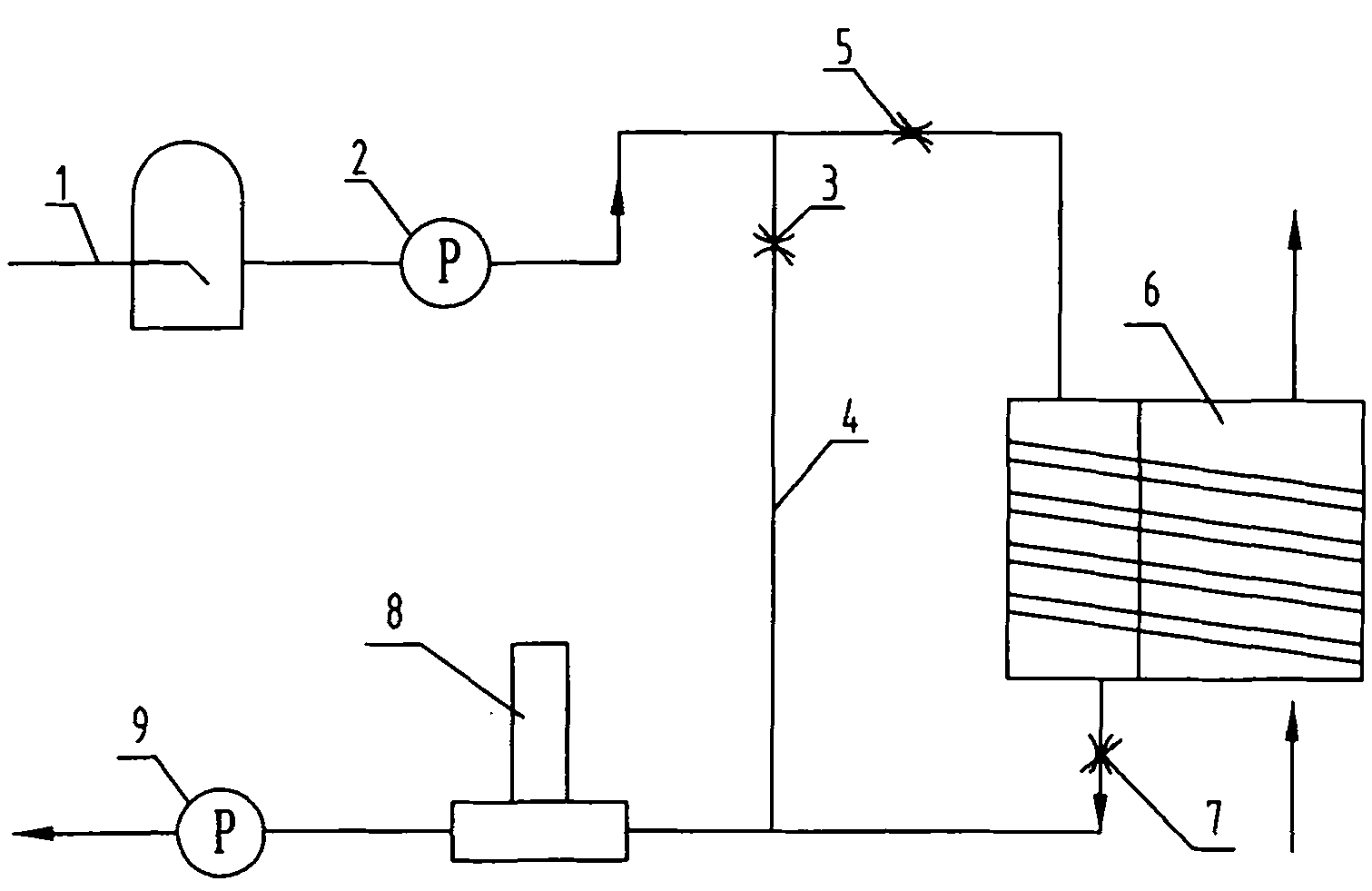

[0018] This embodiment is a method for maintaining the stability of the CDQ gas circulation system after the heat pipe heat exchanger bursts, and it is carried out according to the following steps:

[0019] (1) Make a short connection between the water inlet pipe and the water outlet pipe of the heat pipe heat exchanger, connect a short connection water pipe, and set a valve on the short connection water pipe;

[0020] (2) After the heat pipe heat exchanger bursts, immediately open the valve on the short-circuit pipe, close the water inlet valve and the water outlet valve on the heat pipe heat exchanger inlet and outlet pipes, and cut off the heat pipe heat exchanger;

[0021] (3) Adjust the air volume of the circulating fan so that the pressure of the pre-stored section in the entire CDQ gas circulation system is stable at 30 Pa, and the circulating gas composition is reduced to the acceptable range of 2% hydrogen and 5% carbon monoxide. Only the circulating gas entering the C...

Embodiment 2

[0026] This embodiment is a method for maintaining the stability of the CDQ gas circulation system after the heat pipe heat exchanger bursts, and it is carried out according to the following steps:

[0027] (1) Make a short connection between the water inlet pipe and the water outlet pipe of the heat pipe heat exchanger, connect a short connection water pipe, and set a valve on the short connection water pipe;

[0028] (2) After the heat pipe heat exchanger bursts, immediately open the valve on the short-circuit pipe, close the water inlet valve and the water outlet valve on the heat pipe heat exchanger inlet and outlet pipes, and cut off the heat pipe heat exchanger;

[0029] (3) Adjust the air volume of the circulating fan so that the pressure of the pre-stored section in the entire CDQ gas circulation system is stable at 60 Pa, and the components of the circulating gas are reduced to the acceptable range of 1% hydrogen and 3% carbon monoxide, and only the circulating gas ent...

Embodiment 3

[0034] This embodiment is a method for maintaining the stability of the CDQ gas circulation system after the heat pipe heat exchanger bursts, and it is carried out according to the following steps:

[0035] (1) Make a short connection between the water inlet pipe and the water outlet pipe of the heat pipe heat exchanger, connect a short connection water pipe, and set a valve on the short connection water pipe;

[0036] (2) After the heat pipe heat exchanger bursts, immediately open the valve on the short-circuit pipe, close the water inlet valve and the water outlet valve on the heat pipe heat exchanger inlet and outlet pipes, and cut off the heat pipe heat exchanger;

[0037] (3) Adjust the air volume of the circulating fan to stabilize the pressure of the pre-stored section in the entire CDQ gas circulation system at 100 Pa, and reduce the circulating gas composition to the qualified range of 1% hydrogen and 2% carbon monoxide, and only the circulating gas entering the CDQ fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com