Three-way distributor with baffle replaced rapidly

A three-way distributor and baffle technology, which is applied to conveyor objects, transportation and packaging, slideways, etc., can solve the problems of waste of manpower, material and financial resources, large impact force of lining plates, and hidden safety hazards, and save time. , The effect of swinging flexibly and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

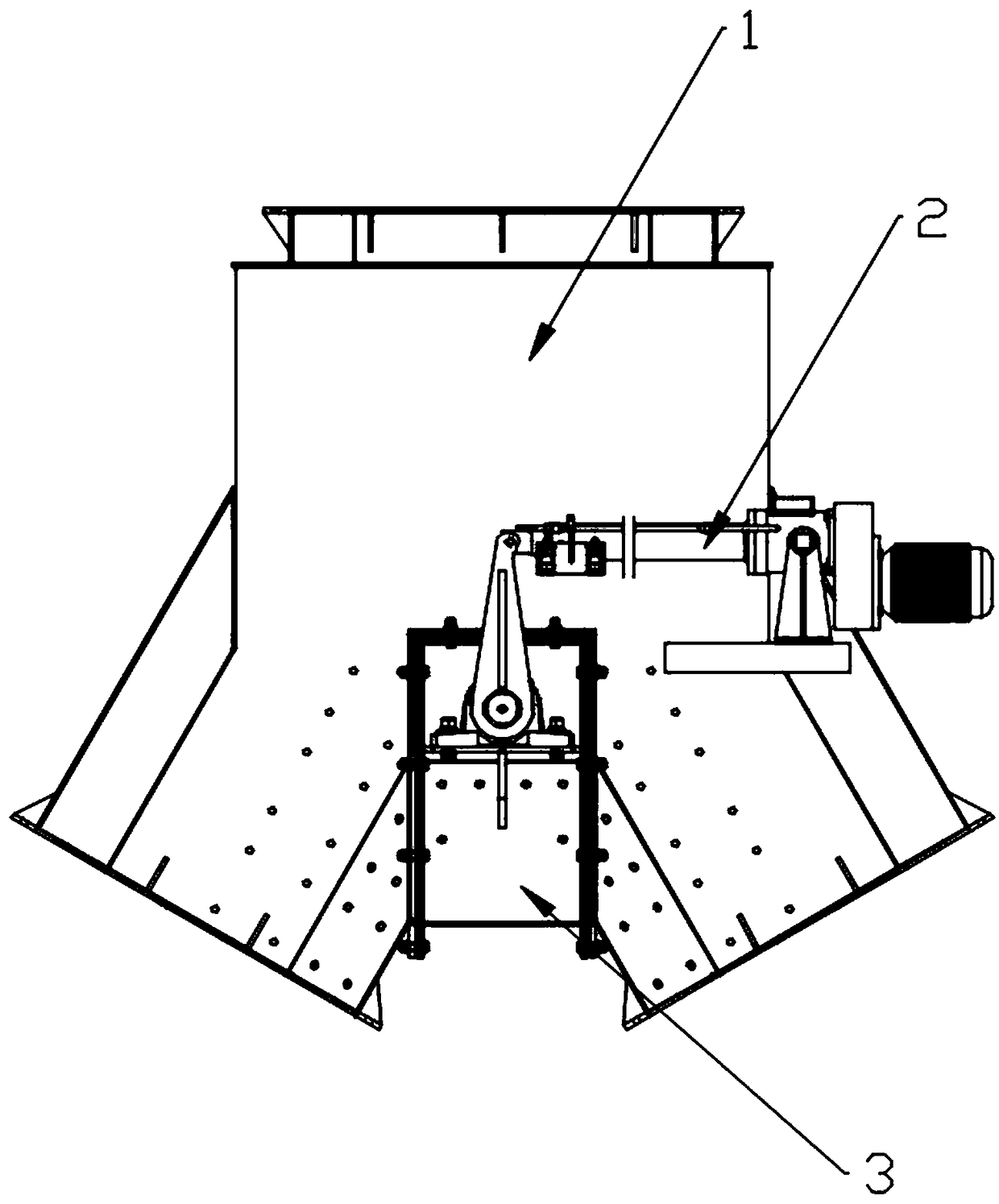

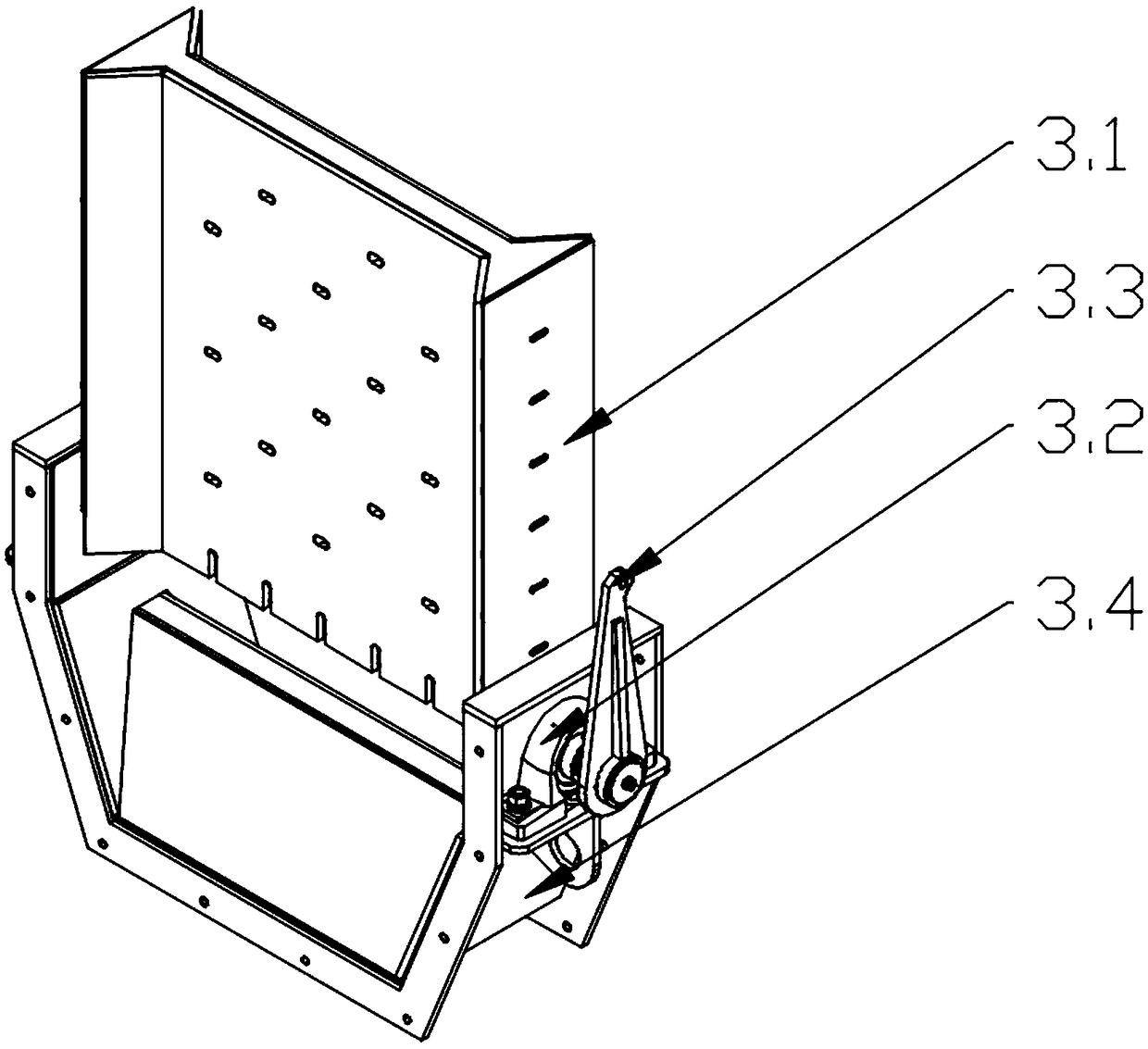

[0026] Such as figure 1 As shown, the embodiment of the present invention discloses a three-way distributor for quickly replacing the baffle, which adopts a pull-out structure, and can quickly replace the worn baffle without removing the three-way pipe, and is easy to operate and fast. The three-way distributor for quickly changing the baffle includes a three-way pipe 1, a push rod 2 and a baffle assembly 3, and the three-way pipe 1 includes a feed pipe and two discharge pipes, and the two discharge pipes An installation opening is provided at the pipe connection, and the baffle assembly 3 is arranged in the installation opening and is disassembled and connected with the tee pipe 1, so as to communicate with the feed pipe and one of the discharge pipes; The opening end of the installation opening is flange-connected to the baffle assembly 3; a sealing plate is also provided at the flange connection between the opening end of the installation opening and the baffle assembly 3....

Embodiment 2

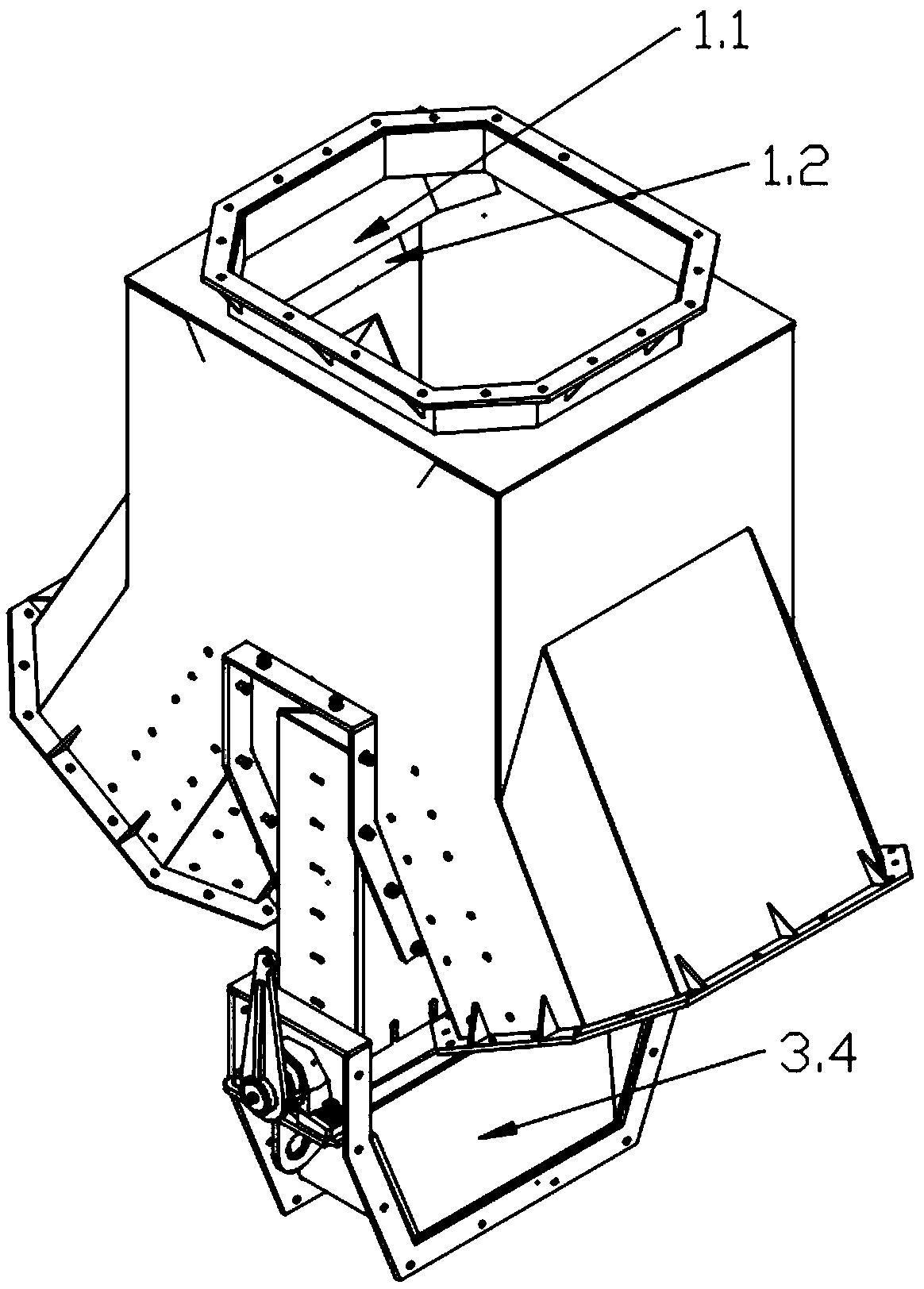

[0032] The difference between this embodiment and Implementation 1 is that four gathering plates 1.1 are arranged symmetrically at the opening of the feed pipe of the three-way pipe 1, and the four gathering plates 1.1 are inclined toward the inside of the three-way pipe 1 to form a gathering hopper .

[0033] The present invention provides a three-way distributor for quickly replacing the baffle. When the baffle in the three-way distributor is worn out, it can be replaced by replacing the baffle assembly 3 without removing the three-way distributor. The baffle 3.1 avoids dismantling the entire tee pipe 1, saving time, and more importantly, not delaying production. The baffle 3.1 adopts a U-shaped section arc shape, and the material flows at the bottom of the U-shape, which can well control or guide the material flow direction. The phenomenon of material accumulation and material jam is avoided, the structure is simple, the manufacture is convenient, and the swing is flexible....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com