Multistage swing type oil-gas-sand separating device

A separation device and swing-type technology, applied in filtration separation, separation method, liquid degassing and other directions, can solve the problems of increasing equipment, pipeline sand cleaning and maintenance workload, low oil yield, and high maintenance cost. The effect of super oil and gas sand separation ability, reduction of production and use costs, and simple internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

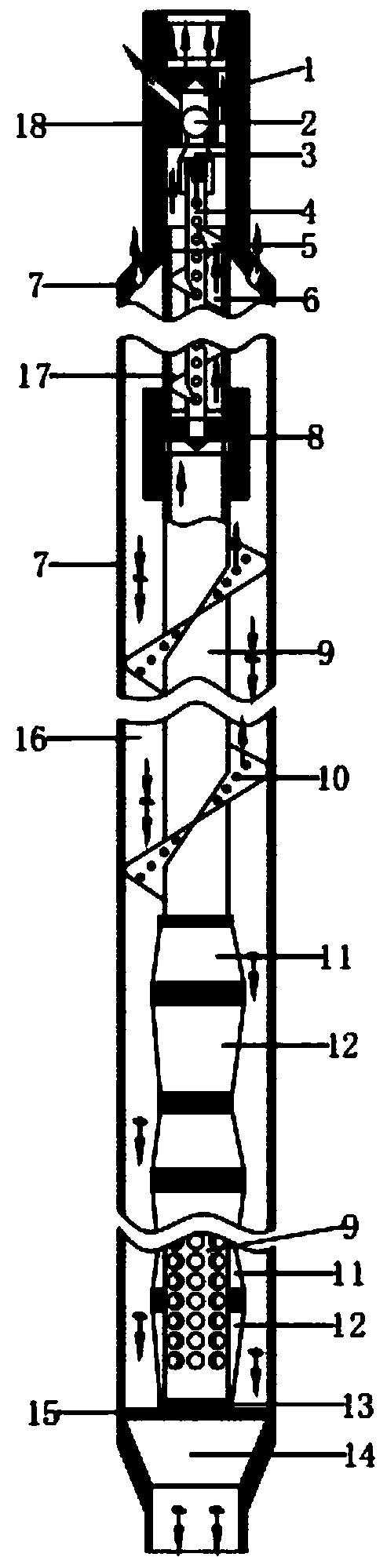

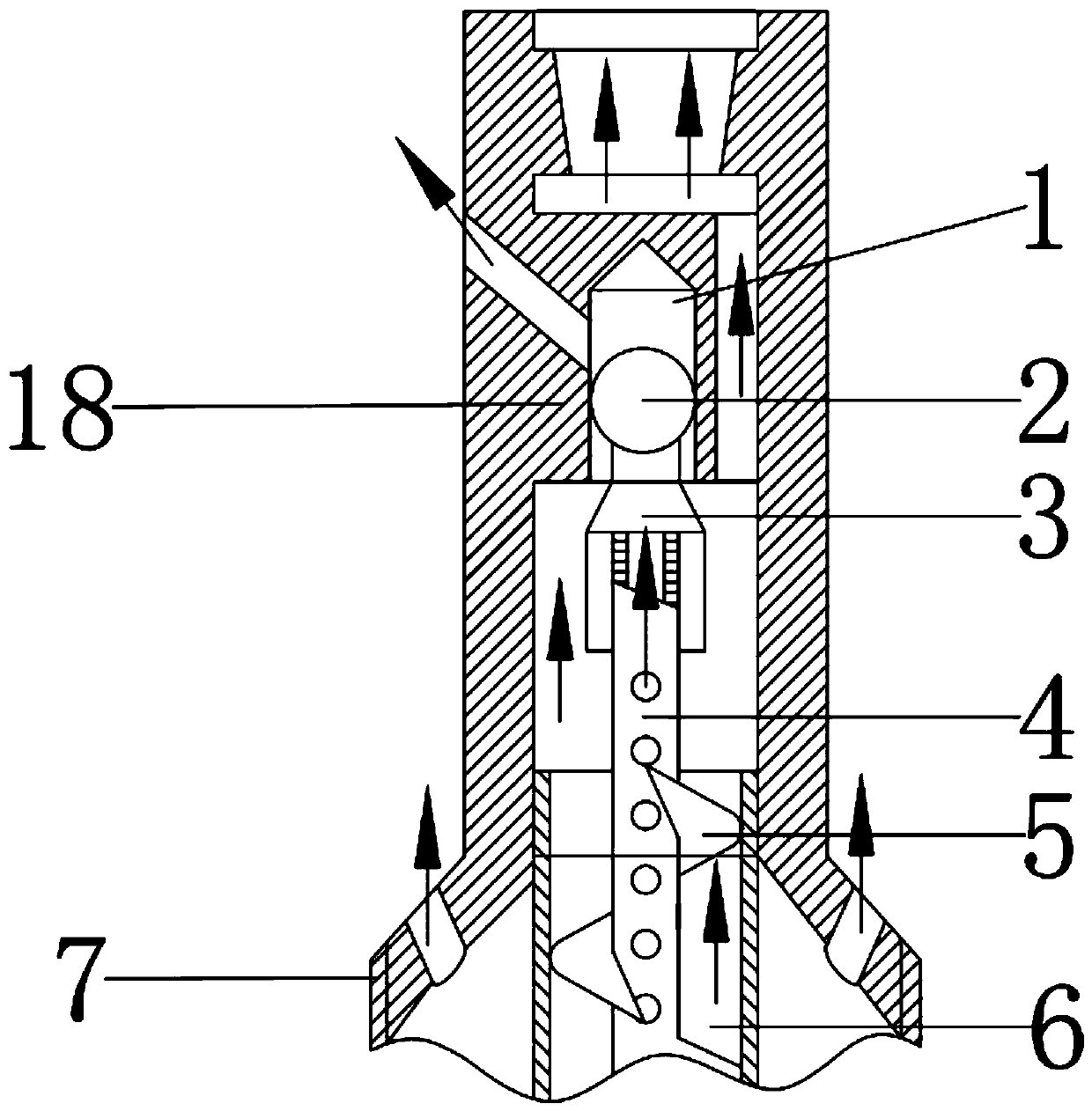

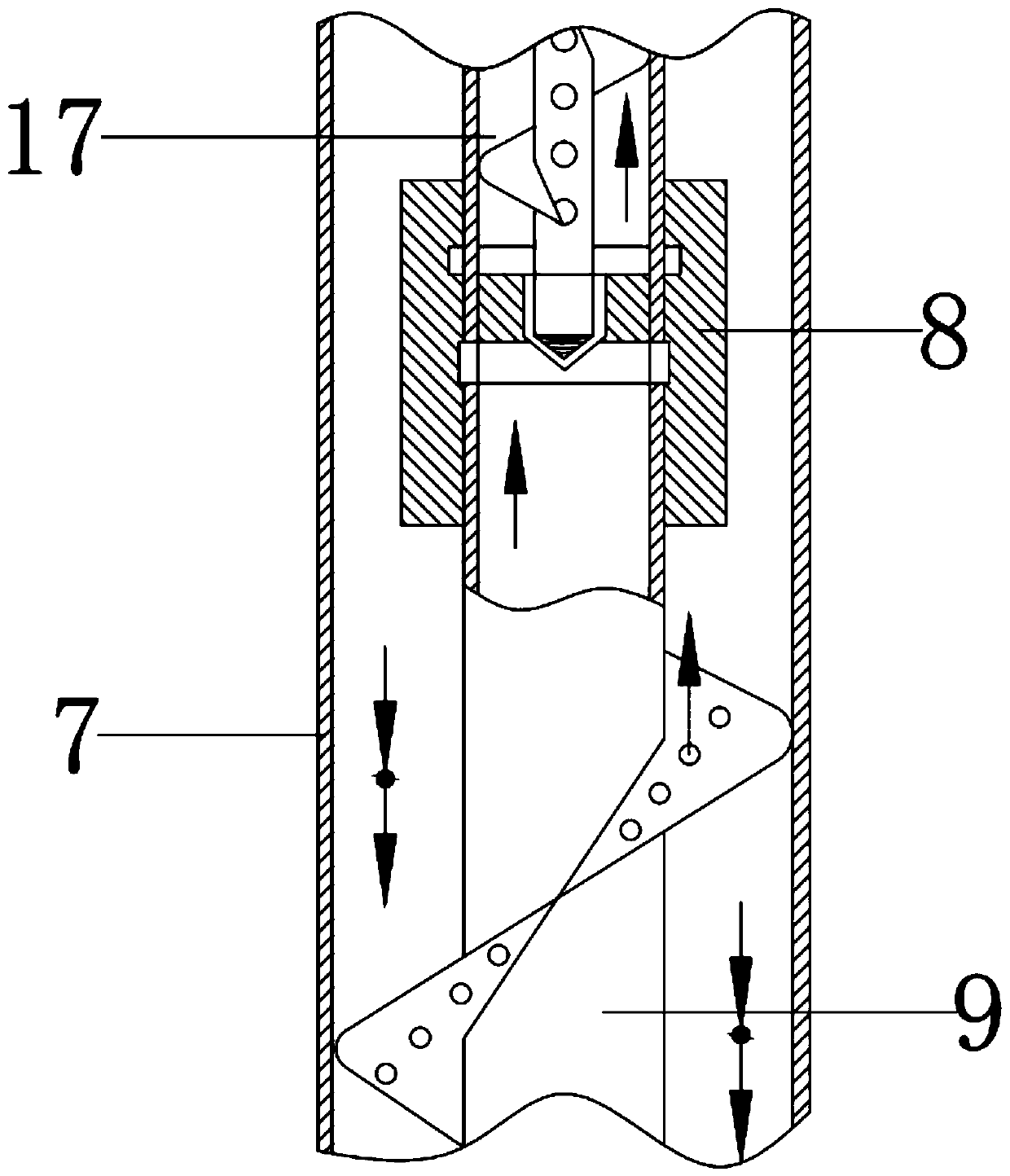

[0025] see Figure 1-5 , the present invention provides the following technical solutions:

[0026] In a specific embodiment of the present invention, including the casing 7, the upper and middle walls of the casing 7 are provided with densely distributed oil, gas, and sand inlet and outlet holes, which are convenient for a large amount of oil, gas, and sand to enter. An oil-gas separation mechanism is provided, and the oil-gas separation mechanism is a one-way exhaust valve 18 composed of a valve body 1, a ball core 2, and a valve seat 3, and an internal spiral valve composed of an exhaust pipe 4, a small spiral guide plate 5, and an oil pipe 6. The passage 17, a joint 8, and an outer spiral passage 16 formed by the upper half of the perforated oil pipe 9 and the large spiral guide plate 10 are connected from top to bottom. The one-way exhaust valve 18 is composed of the valve body 1, The ball core 2 and the valve seat 3 are composed. The outline of the valve body 1 is cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com