Organic waste gas treatment device equipped with movable desorption and catalytic combustion vehicle

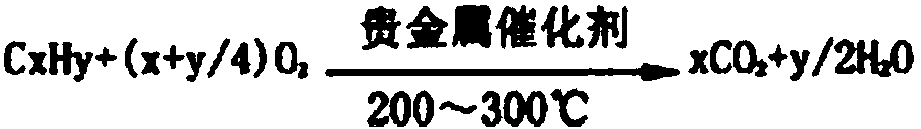

A catalytic combustion, organic waste gas technology, applied in the combustion method, combustion type, incinerator and other directions, can solve the problems of large area, hinder the development of enterprises, and be overwhelmed by enterprises, achieve quick connection and installation, reduce installation costs, reduce The effect of taking up space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0069] Experimental environment: The input air volume of organic waste gas into the main pipe is 45000m3 / h, and the concentration of VOCs waste gas is less than 60mg / m3. Exhaust gas components: methyl acrylate, ethyl ester, butyl ester, ethylene glycol, propylene glycol, vinyl acetate ethylene, amine and other volatile organic compounds.

[0070] Emission requirements: Ensure that under the premise of normal operation of the production line, volatile organic compound VOCs will meet the "Sichuan Provincial Stationary Pollution Source Atmospheric Volatile Organic Compound Emission Standard" (DB51 / 2377-2017) emission after being treated by environmental protection equipment.

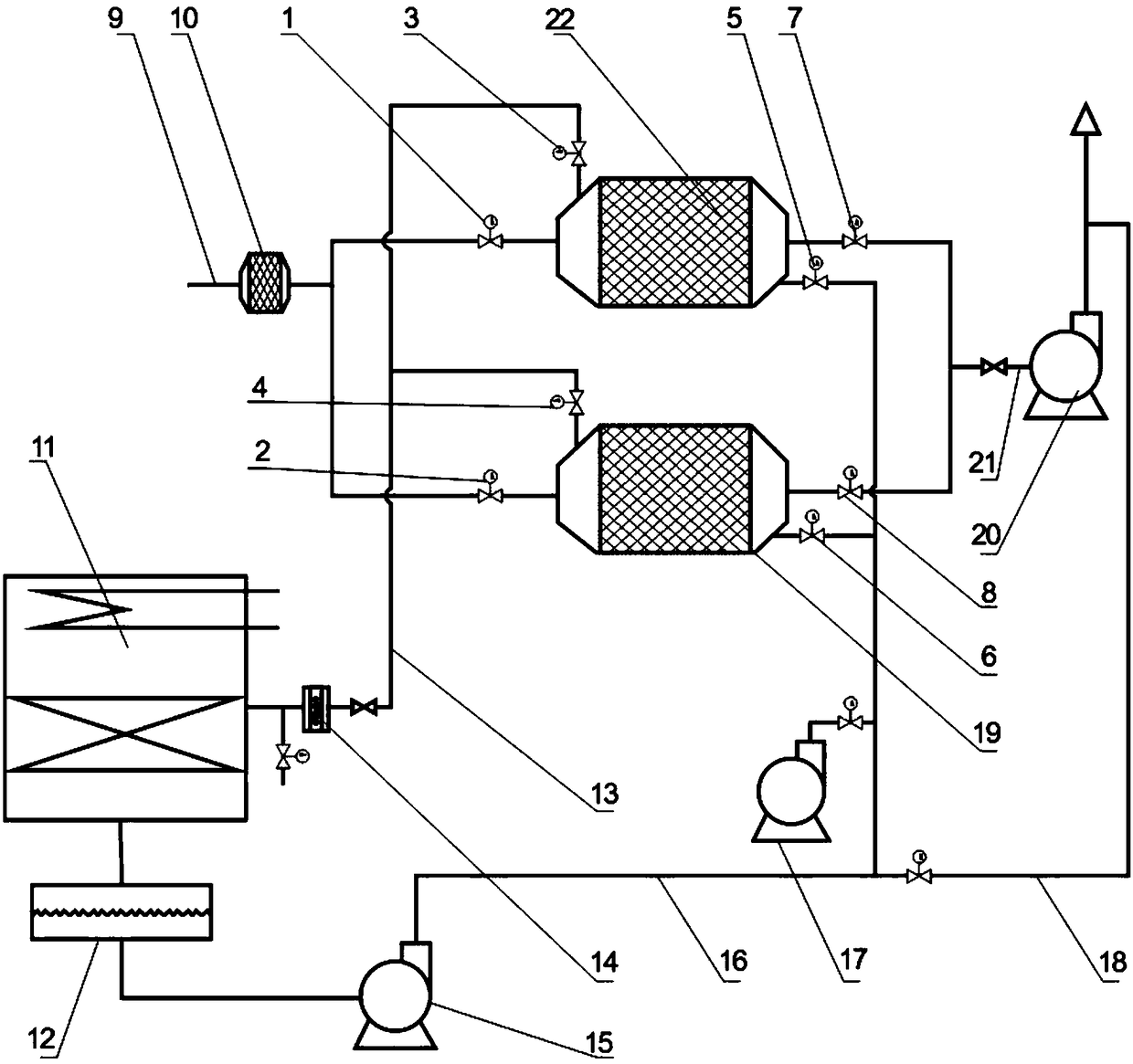

[0071] The equipment is equipped with a first group of adsorption beds 22 and a second group of adsorption beds 19, one for standby and one for use. Each group of adsorption beds is equipped with 3 standard activated carbon adsorption boxes with a processing capacity of 15000m3 / h air volume.

[0072] Proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com