Control device for hydrogen-oxygen generator

A control device and generator technology, applied in liquid level control, non-electric variable control, control/regulation system, etc., can solve the problems of hydrogen and oxygen generators not working, delaying production, etc., to reduce travel costs, reduce costs, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

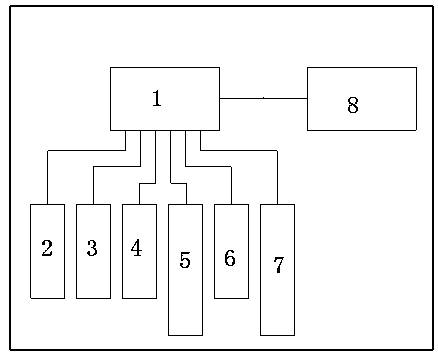

[0042] Such as figure 1 and figure 2 Shown, a kind of control device of oxyhydrogen generator, comprises:

[0043] PLC controller 1,

[0044] Electrolyzer liquid level monitoring system 3, the input end of described electrolyzer liquid level monitoring system 3 is used for being electrically connected with hydrogen-oxygen generator, and the output end of electrolyzer liquid level monitoring system 3 is electrically connected with PLC controller 1, is used for The liquid level information of the electrolytic cell of the hydrogen-oxygen generator is sent to the PLC controller 1;

[0045]The electrolyzer liquid level monitoring system 3 includes a differential pressure transmitter and a float level gauge installed in the electrolytic tank of the hydrogen-oxygen generator, the differential pressure transmitter is electrically connected to the PLC controller 1, and the PLC controller 1 is also It is electrically connected to the water pump of the hydrogen-oxygen generator, the ...

Embodiment 2

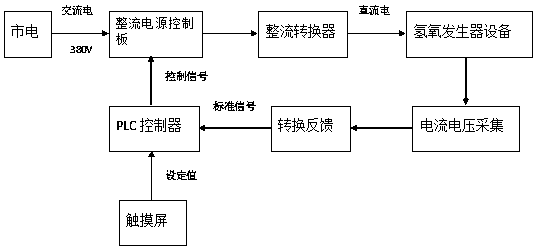

[0076] Such as Figure 1 to Figure 3 Shown, a kind of automatic regulation method of hydrogen-oxygen generator electric current, comprises the following steps:

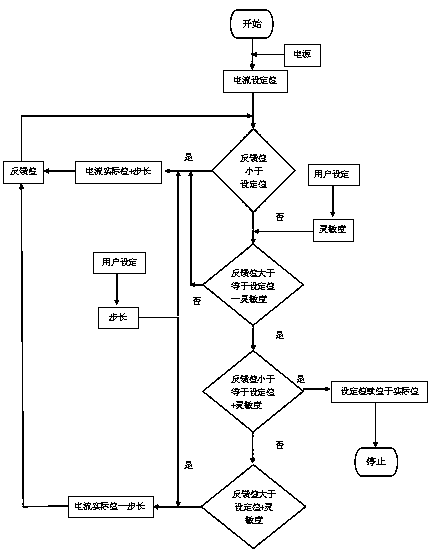

[0077] The first step is to set parameters, and set the current setting value, step size and sensitivity for the PLC controller 1 through the touch screen 8, the step size is a fixed current value, and the sensitivity is an acceptable error range.

[0078] The second step is the first judgment, read the actual current value in the hydrogen-oxygen generator as feedback, if the feedback value is less than the current setting value, add a step size on the basis of the actual current value, that is, increase the actual current value If the current value is one step larger, repeat the second step after adding one step until the feedback value is greater than or equal to the current setting value; if the feedback value is greater than or equal to the setting value, make a second judgment;

[0079] The third step is the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com