Diamond wire saw

The technology of a diamond wire saw machine and main motor is applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., which can solve the problems of difficult maintenance, large machine vibration, troublesome disassembly and assembly, etc., to improve the climbing ability and machine vibration. Small, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

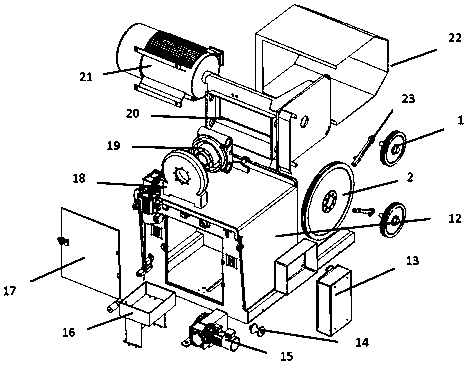

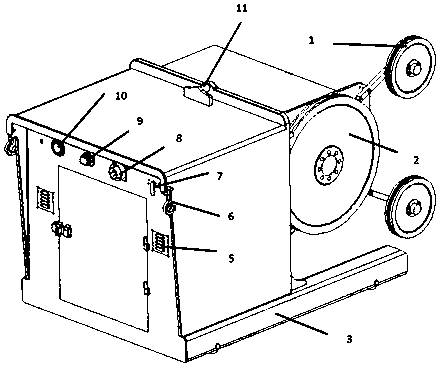

[0049] Such as image 3 , combined with figure 1 , figure 2 , Figure 4 with Figure 5 . This diamond wire saw machine includes the power head at the front end, the host frame at the rear end, the slewing mechanism and the walking mechanism arranged in the box body 12 of the host frame, the inverter of the host machine 13, and the control system (placed in a separate electric control box). A power wheel 2 and two guide wheels 1 are installed on the power head, and four traveling wheels 14 are distributed and installed under the machine pin 3 of the main engine frame. Ventilation fans 5 and hooks 6 are placed on both sides of the rear side of the cabinet 12. Switches 7, power ports 8, console communication ports 9 and lighting spotlights 10 are arranged on the upper part of the rear side of the cabinet 12, and lifting lugs 11 are connected to the top plate of the cabinet 12. The whole board is made.

[0050] Two guide wheels 1 are installed on one side of the power bra...

Embodiment 2

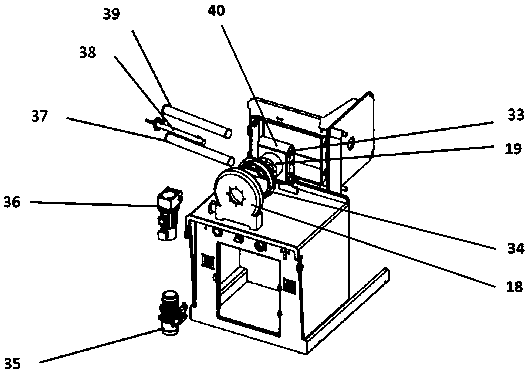

[0069] combined with Image 6 .

[0070] Another embodiment of the present invention is as follows. It differs from Embodiment 1 in that the piston rod 41 of the traversing oil cylinder 38 is connected to the traversing shaft instead of the power support 20 .

[0071] The piston rod 41 is connected with the fixed plate 43 , and the two ends of the fixed plate 43 are connected with the upper traverse shaft 39 and the lower traverse shaft 37 . Piston 42 of traversing oil cylinder 38 drives piston rod 41 to reciprocate, directly drives two traversing shafts, makes the two traversing shafts reciprocally slide in sliding bearing seat 33 and drives power bracket 20 and the whole power head to move linearly together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com